Condenser with liquid separation type spiral tube structure

A helical tube and condenser technology, applied in the field of heat exchange and heat transfer, can solve the problem of unreported research on the strengthening of condensation phase change heat transfer in the helical tube, and achieve the goal of enhancing heat transfer performance, improving heat transfer efficiency, and improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

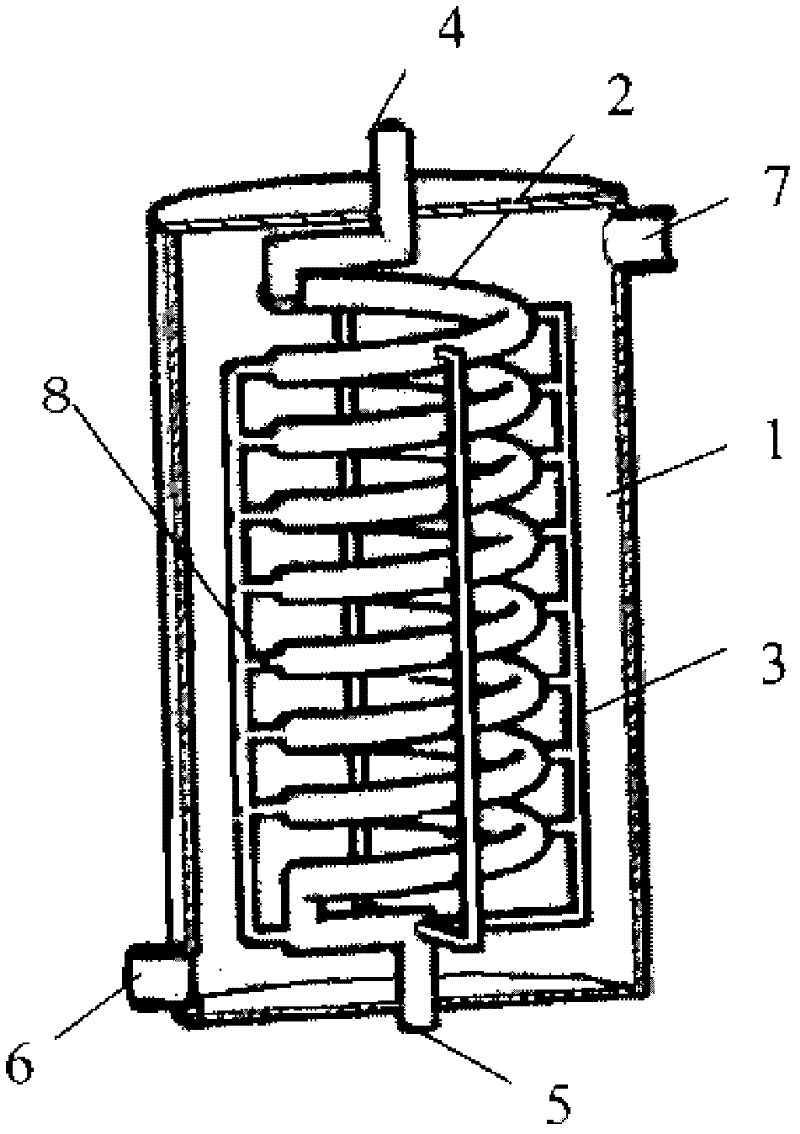

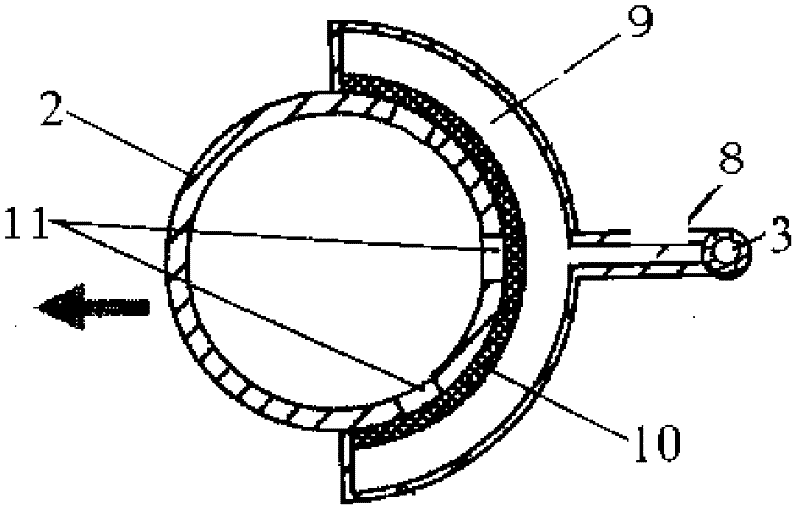

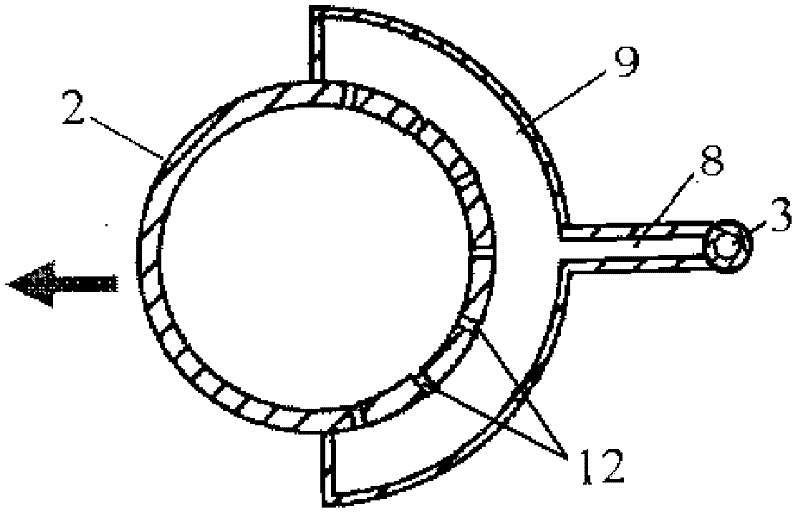

[0029] For the heat exchange process of condensed water, a 2600mm long φ10mm×1mm ordinary smooth copper tube is selected to be wound into a spiral ascending tube with a diameter of 80mm and a pitch of 15mm; a 220mm long φ180mm×5mm stainless steel tube is used as the shell; The first and last ends of the tube are welded to the condensate inlet and outlet tubes with the same diameter as the spiral copper tube, and the inlet and outlet tubes are parallel to the axis of the shell. On the outer circumference side of the spiral tube, micro-holes with a diameter of 1mm are processed on each circle of the spiral tube from four directions, and a smooth copper tube of φ3mm×1mm is welded to it perpendicular to the axis of the shell, and the outer circumference of the spiral tube is The microtubes welded in each direction of the wall are communicated with a copper tube parallel to the axis of the shell φ4mm×1mm, and extend to the end of the spiral tube to connect with the condensate outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com