Adhesive agent composition for optical films, adhesive agent layer for optical films, optical film having adhesive agent layer attached thereto, and image display device

A technology of adhesive layer and optical film, which is applied in the direction of film/sheet adhesive, non-polymer adhesive additive, polyether adhesive, etc., which can solve defects, influence of liquid crystal orientation, uneven display, etc. problems, achieve the effect of achieving durability, suppressing peeling, and stabilizing durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

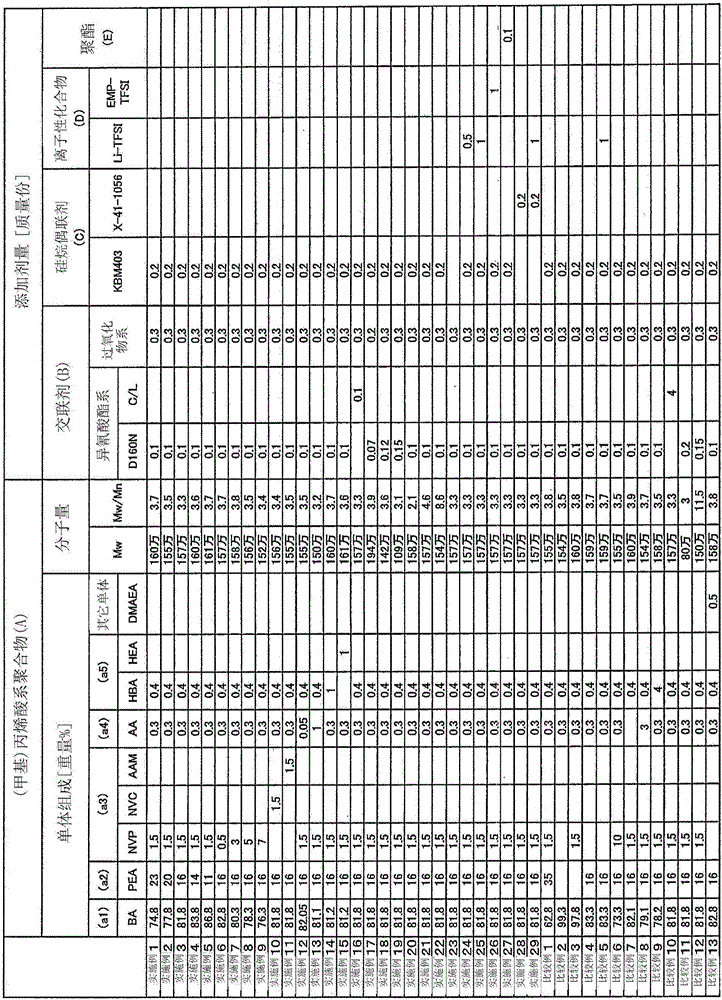

[0183] (Preparation of Acrylic Polymer (A1))

[0184] 74.8 parts of butyl acrylate, 23 parts of phenoxyethyl acrylate, 1.5 parts of N-vinyl-2-pyrrolidone, 0.3 parts of acrylic acid, A monomer mixture of 0.4 parts of 4-hydroxybutyl acrylate. In addition, 0.1 part of 2,2'-azobisisobutyronitrile as a polymerization initiator was added to 100 parts of the above-mentioned monomer mixture (solid content) together with 100 parts of ethyl acetate, and nitrogen gas was introduced while slowly stirring. After nitrogen substitution, the liquid temperature in the flask was kept at around 55° C. and polymerization was performed for 8 hours to prepare a solution of an acrylic polymer (A1) with a weight average molecular weight (Mw) of 1.6 million and Mw / Mn=3.7.

[0185] (Preparation of Adhesive Composition)

[0186] With respect to 100 parts of solid content of the solution of the acrylic polymer (A1) obtained in Production Example 1, an isocyanate crosslinking agent (TAKENATE D160N, trim...

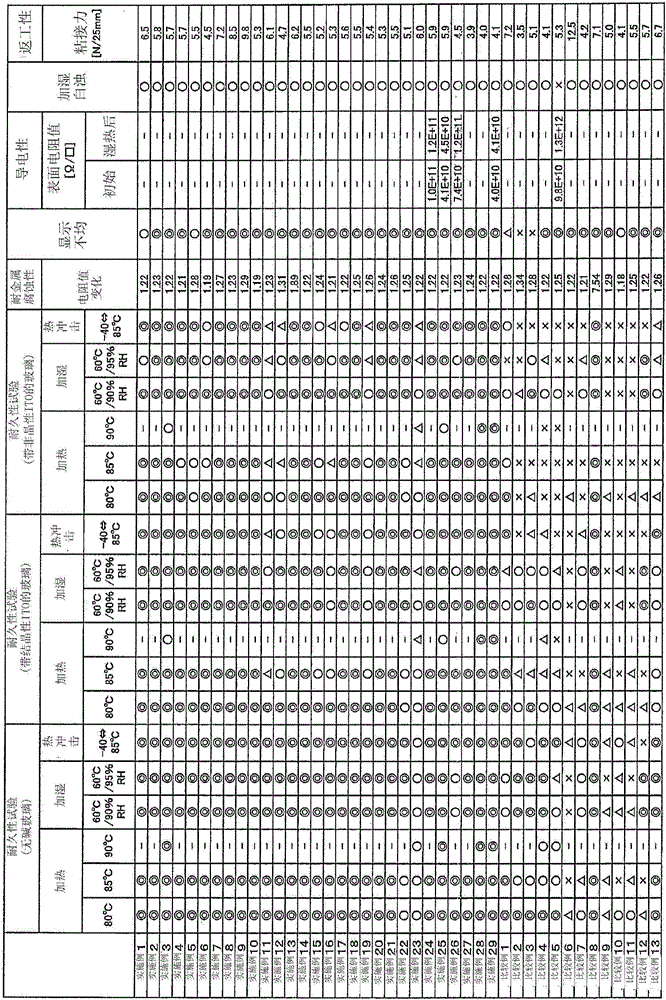

Embodiment 2~29、 comparative example 1~13

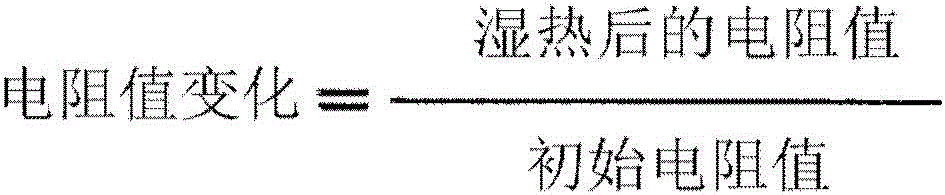

[0190] In embodiment 1, as shown in table 1, change the kind of monomer used in the preparation of acrylic polymer (A), its use ratio, control manufacturing conditions in addition, prepared the polymkeric substance character described in table 1 ( Weight average molecular weight, Mw / Mn) of acrylic polymer solution.

[0191]In addition, for each obtained solution of the acrylic polymer, in addition to changing the type or amount of the crosslinking agent (B) as shown in Table 1, the type or amount of the silane coupling agent (C) or the amount used (or not Except using ), it carried out similarly to Example 1, and prepared the solution of the acrylic adhesive composition. Moreover, the polarizing plate with an adhesive layer was produced similarly to Example 1 using the solution of this acrylic adhesive composition. It should be noted that, in Examples 24 to 26, 28 and Comparative Example 5, a solution of an acrylic polymer containing an ionic compound (D) in the ratio shown i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com