Energy-saving compact type vacuum extrusion machine

A vacuum extruder, compact technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of large volume and high energy consumption, and achieve the effects of easy promotion, lower production costs, and a wide market.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

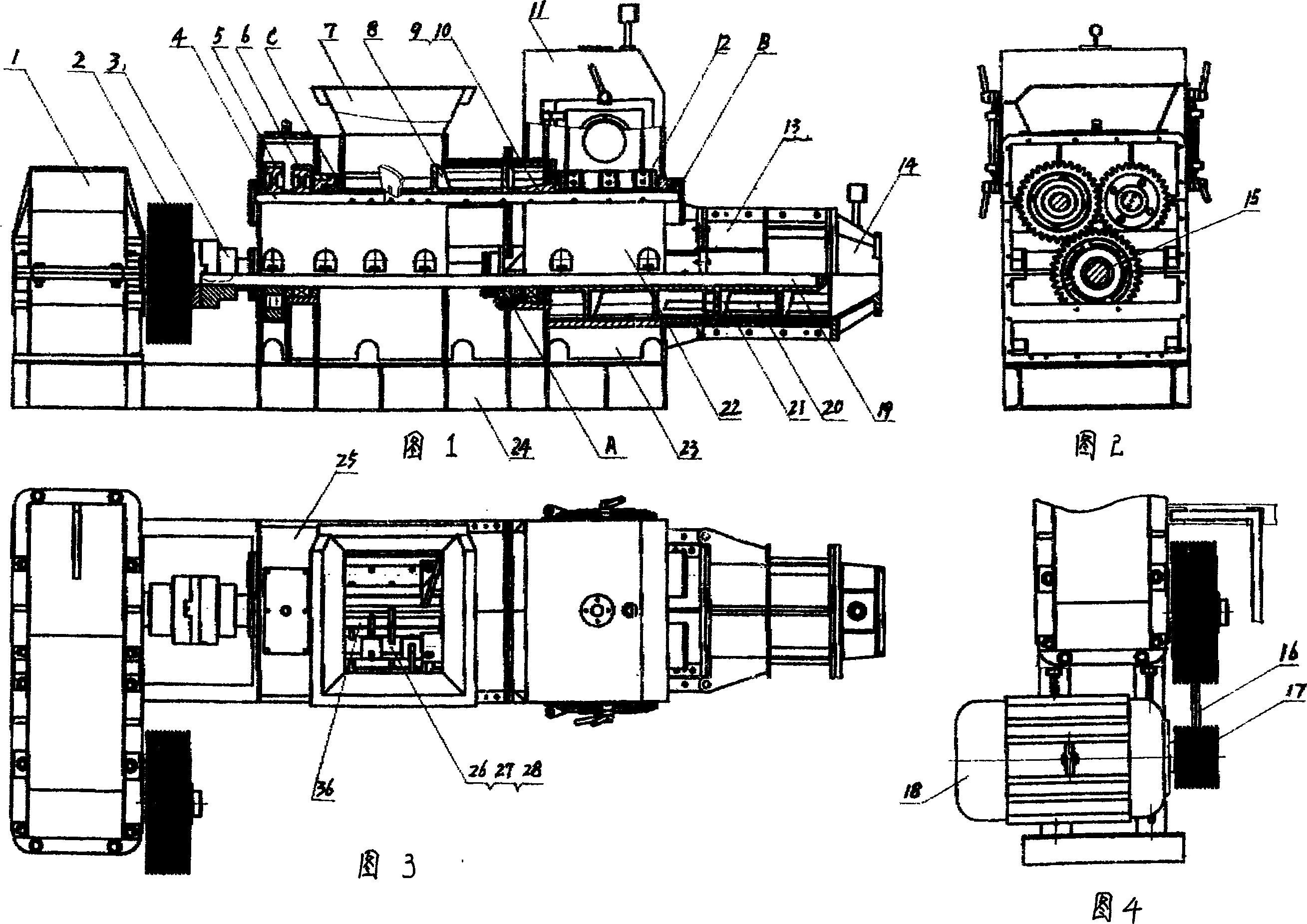

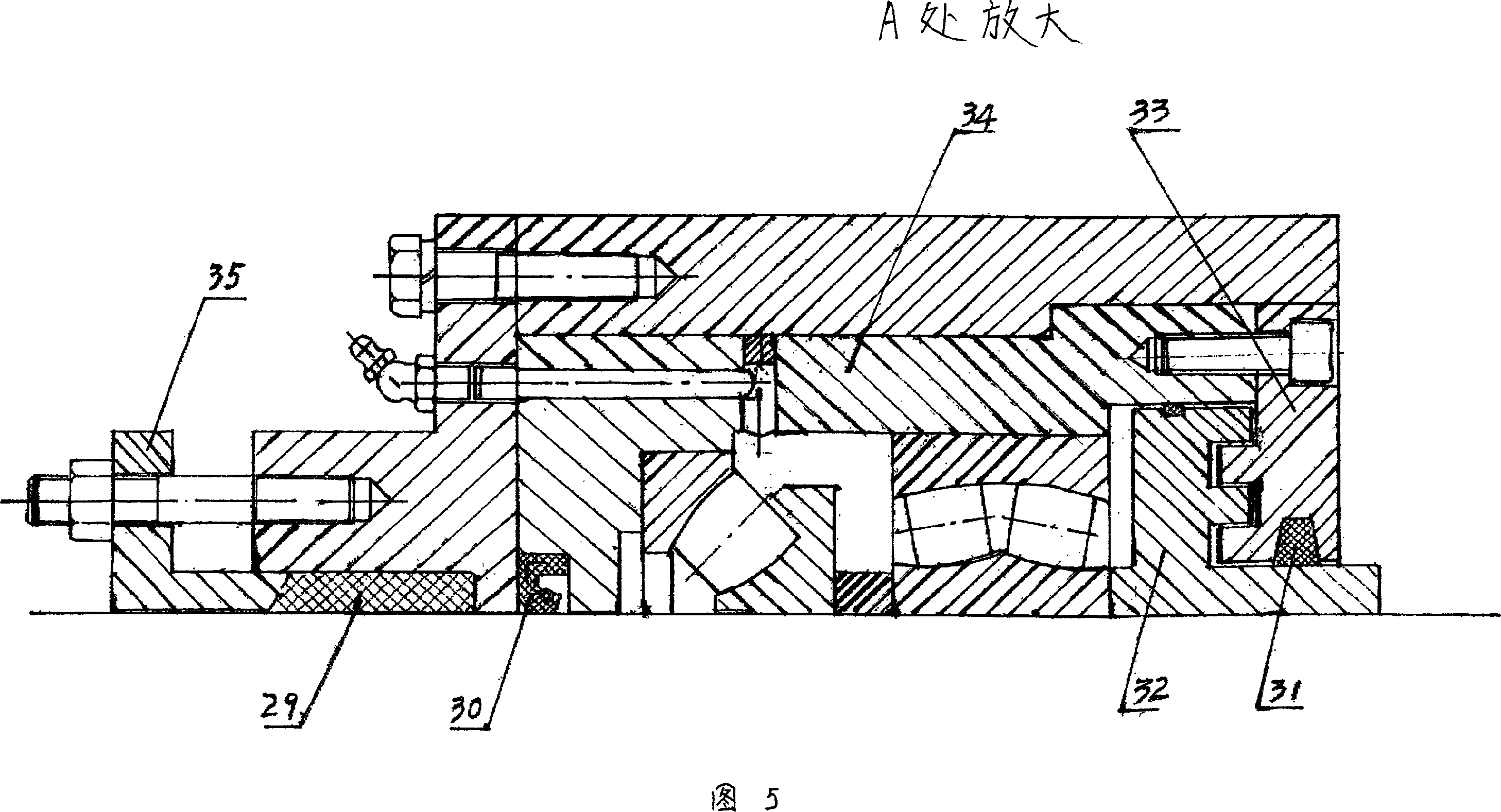

[0023] Accompanying drawing 1-5 has provided the specific embodiment of the present invention.

[0024] An energy-saving and compact vacuum extruder, which includes a reducer (1), a pneumatic clutch (2), a slider coupling (3), an extrusion shaft (19), transmission gears (5, 6, 15), Stirring shaft (4, 26), Huff mixing knife (8), vacuum chamber (11), mud pressing plate (12), extrusion cylinder (13), machine head (14), extrusion auger (21), Upper, middle and lower casings (22), (23), (25), machine base (24) and hopper (7); , 26) installed in the mixing box (36), the vacuum chamber (11) is located at the top of the extrusion auger (21) and communicated with it, the side of the vacuum chamber (11) communicates with the mixing box (36), and the mud pressing plate (12 ) is located in the vacuum chamber and on the top of the upper box; the extrusion cylinder (13) is connected with one end of the upper box (22) and the middle box (23), and the machine head (14) is installed on the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com