Method using electrolytic manganese slag to manufacture active mixed material

An active mixed material, electrolytic manganese slag technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the pollution of the environment, increase the land acquisition and site disposal costs of waste slag, and increase the production cost. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

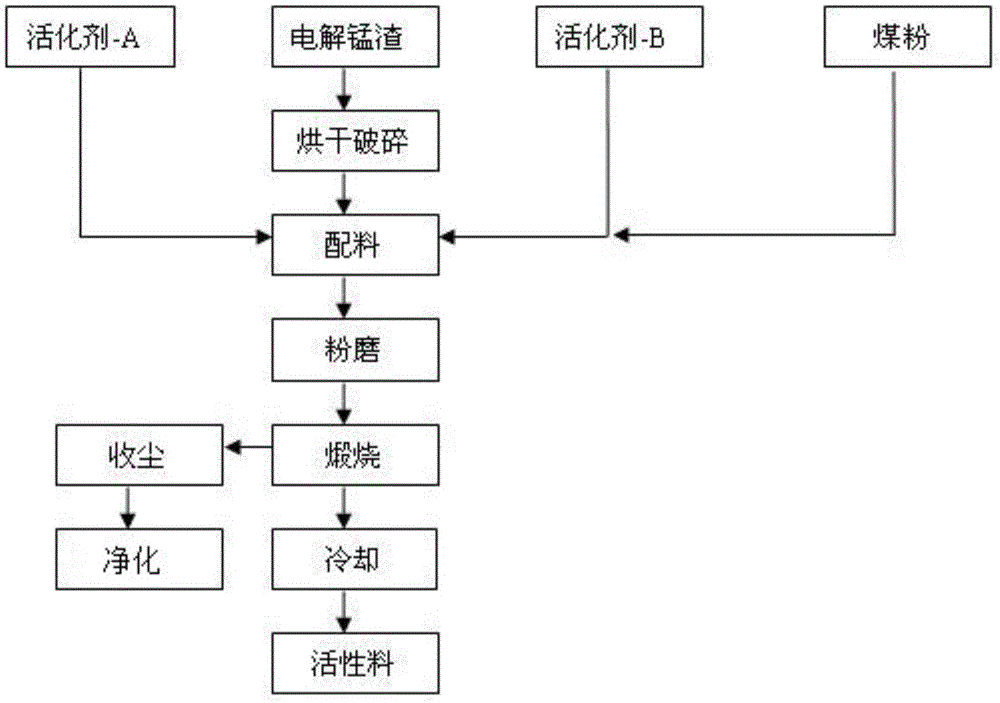

Method used

Image

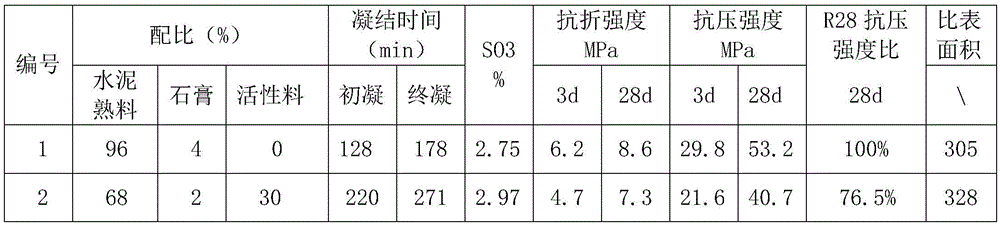

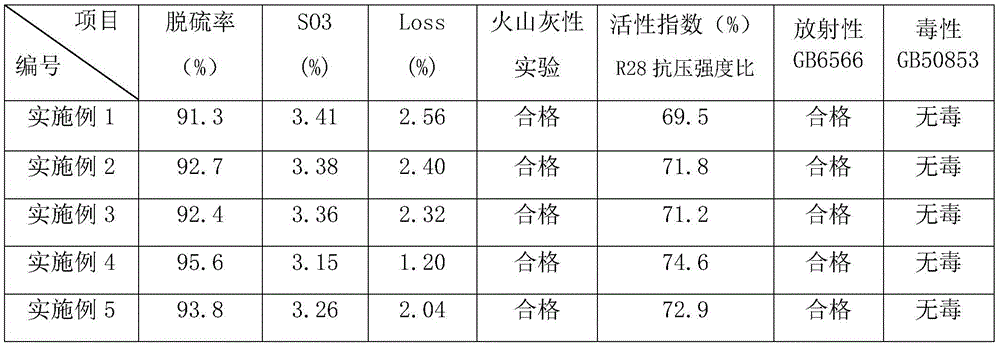

Examples

Embodiment 1

[0048] (1) Dry 90.0 parts of electrolytic manganese slag at 350°C, add 5.0 parts of activator A and 5.0 parts of activator B, grind and stir to make it uniform;

[0049] (2) Feed the product obtained in step (1) into a rotary kiln, heat up to 700°C-1350°C for calcination, and control the residence time of the material in the kiln to 75-120min;

[0050] (3) The product calcined at high temperature is cooled to below 180°C to obtain the active mixed material.

Embodiment 2

[0052] (1) Dry 90.0 parts of electrolytic manganese slag at 350°C, add 10.0 parts of activator A, grind and stir to make it uniform;

[0053] (2) Feed the product obtained in step (1) into a rotary kiln, heat up to 700°C-1350°C for calcination, and control the residence time of the material in the kiln to 75-120min;

[0054] (3) The product calcined at high temperature is cooled to below 180°C to obtain the active mixed material.

Embodiment 3

[0056] (1) Dry 90.0 parts of electrolytic manganese slag at 350°C, add 10.0 parts of activator B, grind and stir to make it uniform;

[0057] (2) Feed the product obtained in step (1) into a rotary kiln, heat up to 700°C-1350°C for calcination, and control the residence time of the material in the kiln to 75-120min;

[0058] (3) The product calcined at high temperature is cooled to below 180°C to obtain the active mixed material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com