Boundary coal shortwall continuously-mining tunnel arrangement and coal pillar preserving methods

A technology for roadway layout and edge coal, which is applied in ground mining, earthwork drilling, underground mining, etc., can solve problems such as increasing the risk of spontaneous ignition of roof coal seams, wasting resources, and complex roadway layout systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

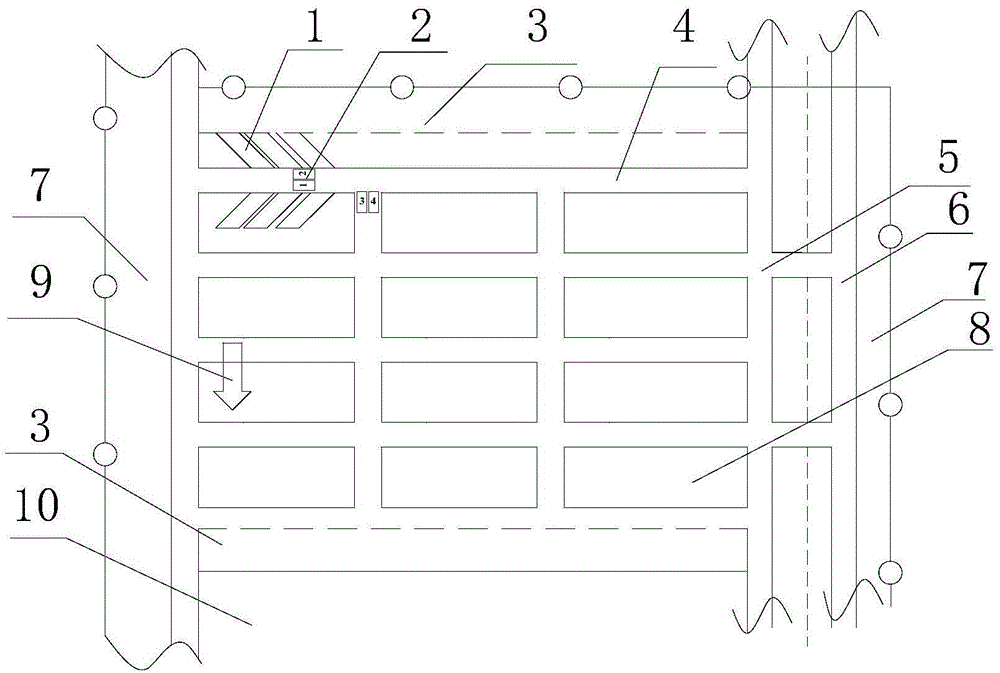

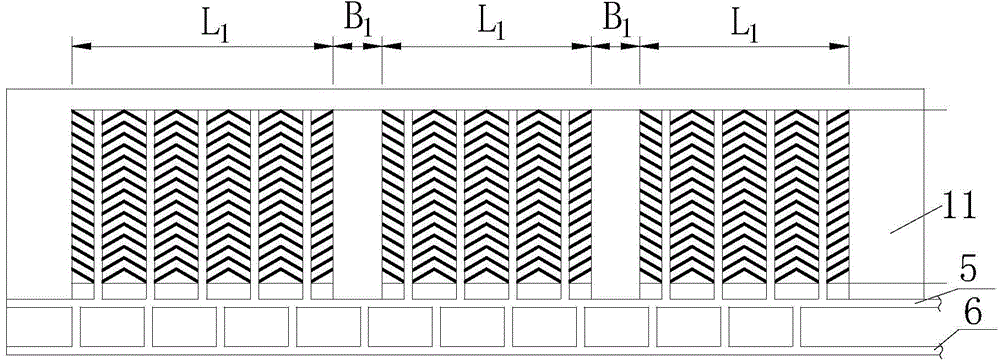

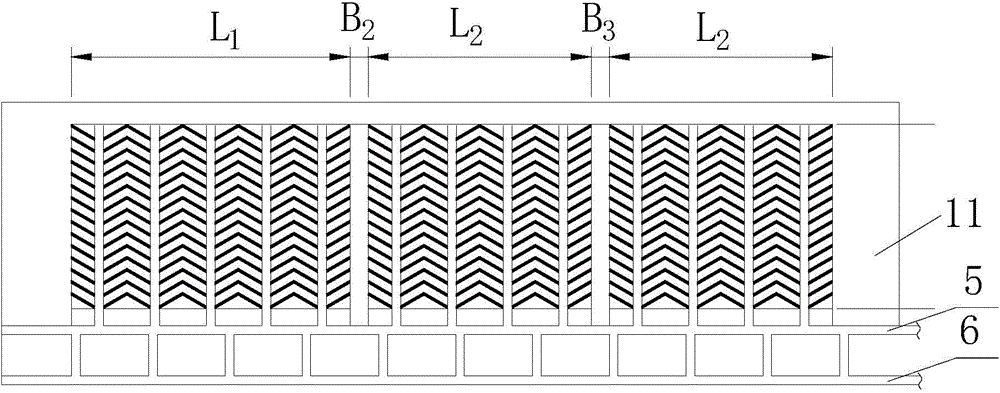

[0048] combine figure 1 and figure 2 , the roadway layout and coal pillar setting method of short-wall continuous mining of edge coal, in the coal seam with a short spontaneous combustion period, the goaf needs to be closed in time, and the coal seam occurrence conditions are thick bedrock and thin loose layer or thick bedrock and thick loose layer, adopt The block wide coal pillar arrangement method, the steps of the method are as follows:

[0049] Step 1: Leave a wide isolated coal pillar between each block, and the width of the coal pillar is B 1 The range is 10 ~ 15m, where B 1 The specific value of is calculated by the formula (1), the coal pillar can support the overlying strata, and keep stable for a long time, and can effectively isolate the goaf of the previous block;

[0050] Step 2: Determine the length L of the first block according to the initial caving step of the key layer 1 and the number of branch lanes, where L 1 The specific value is calculated by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com