Patents

Literature

44results about How to "Not prone to spontaneous combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

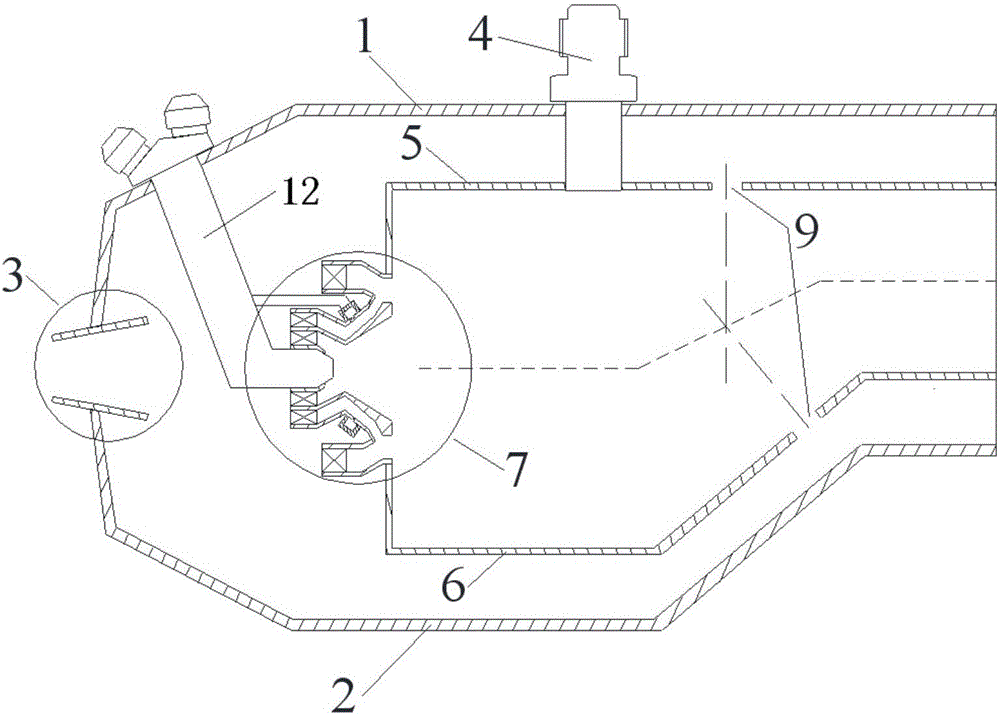

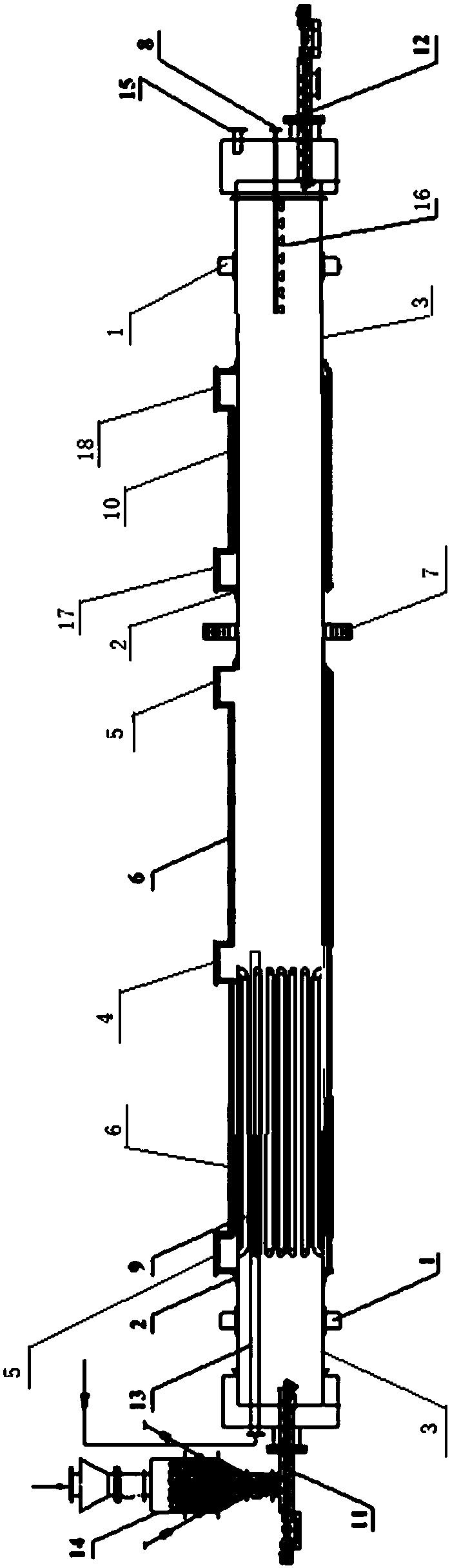

Layered part premixing low-pollution combustor of main combustion level lean oil premixing

ActiveCN104456628AImprove uniformityExtended service lifeContinuous combustion chamberCombustion chamberCoupling

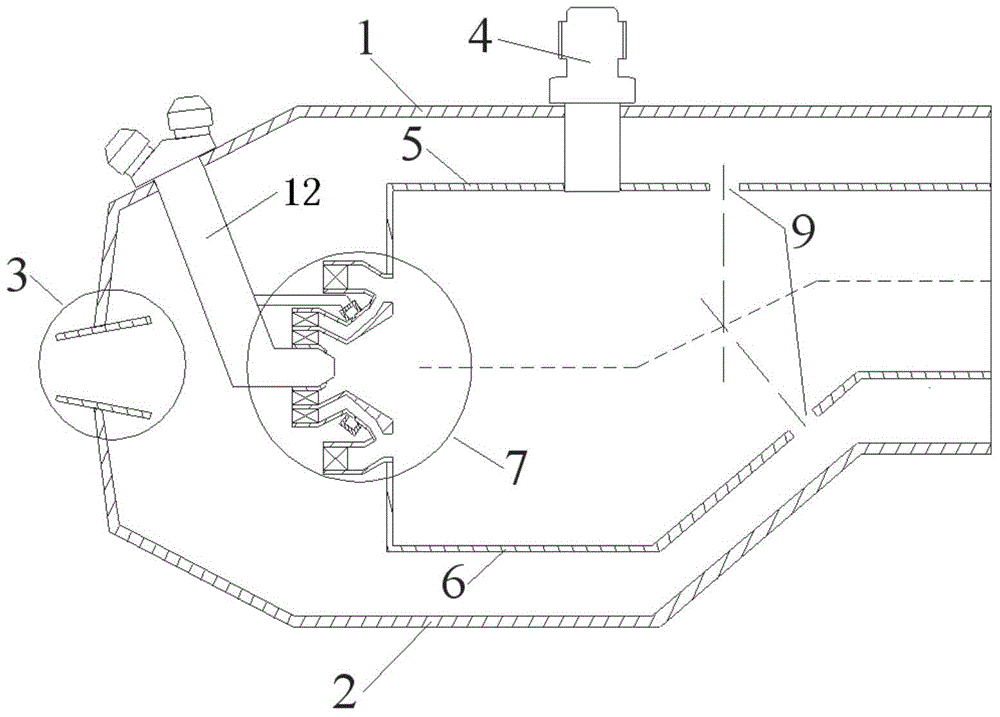

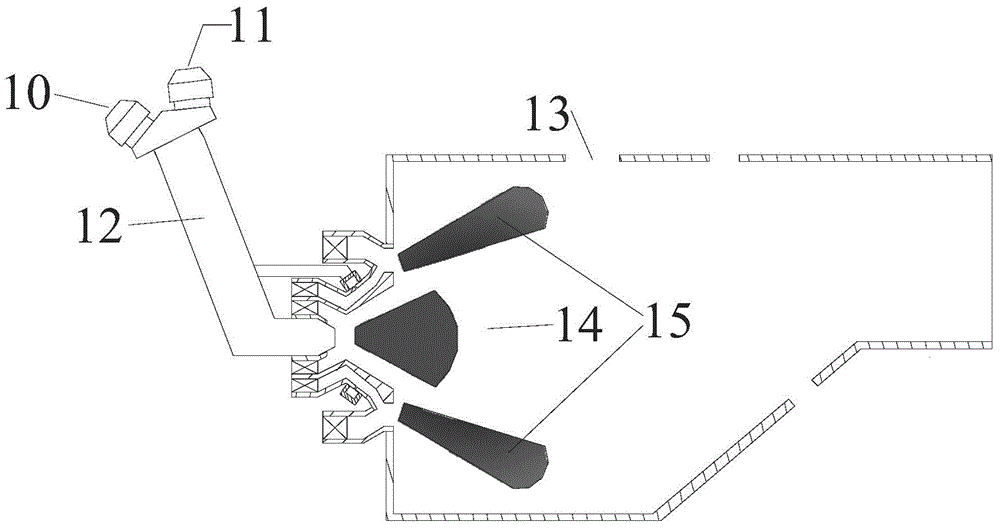

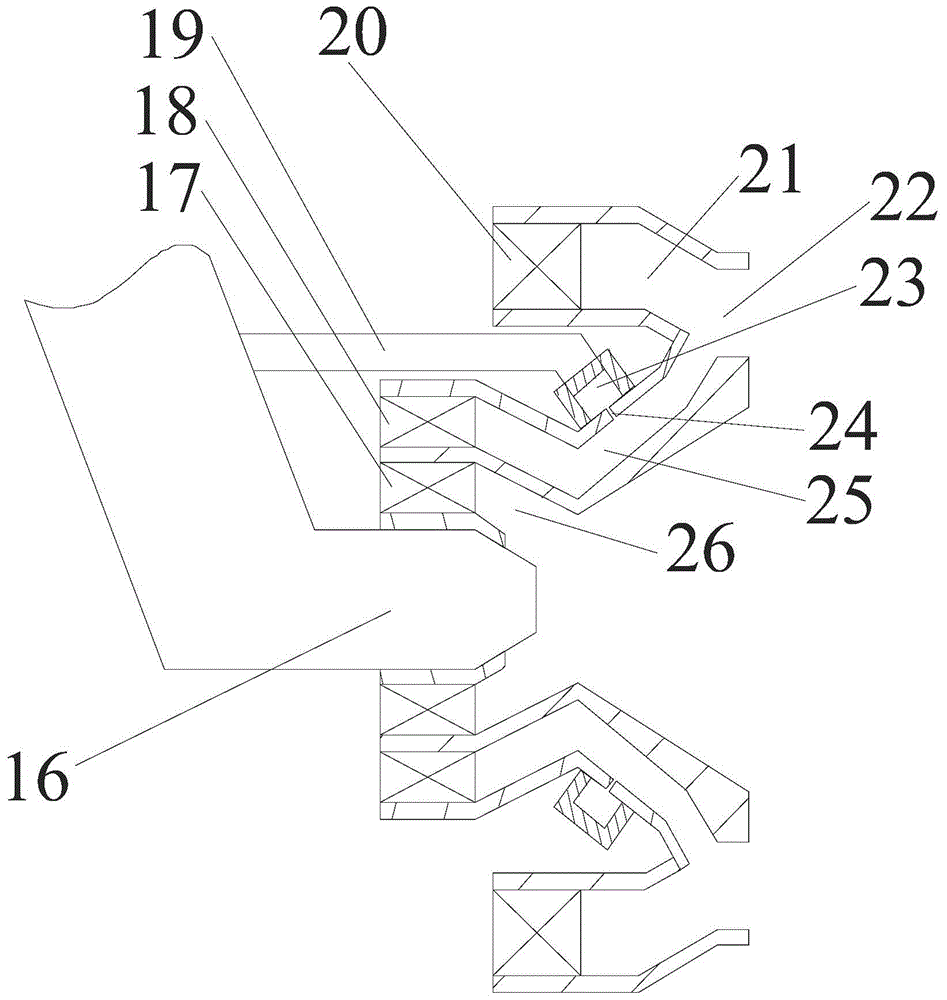

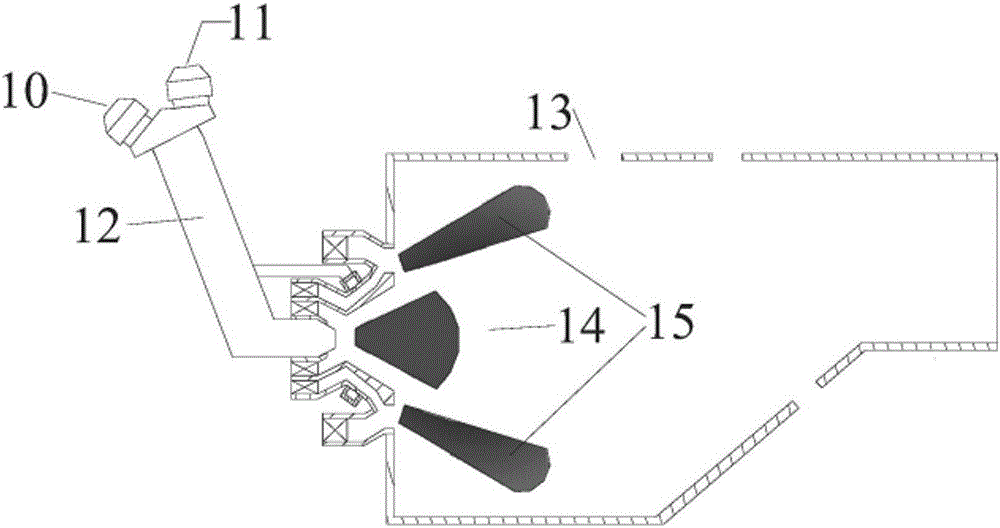

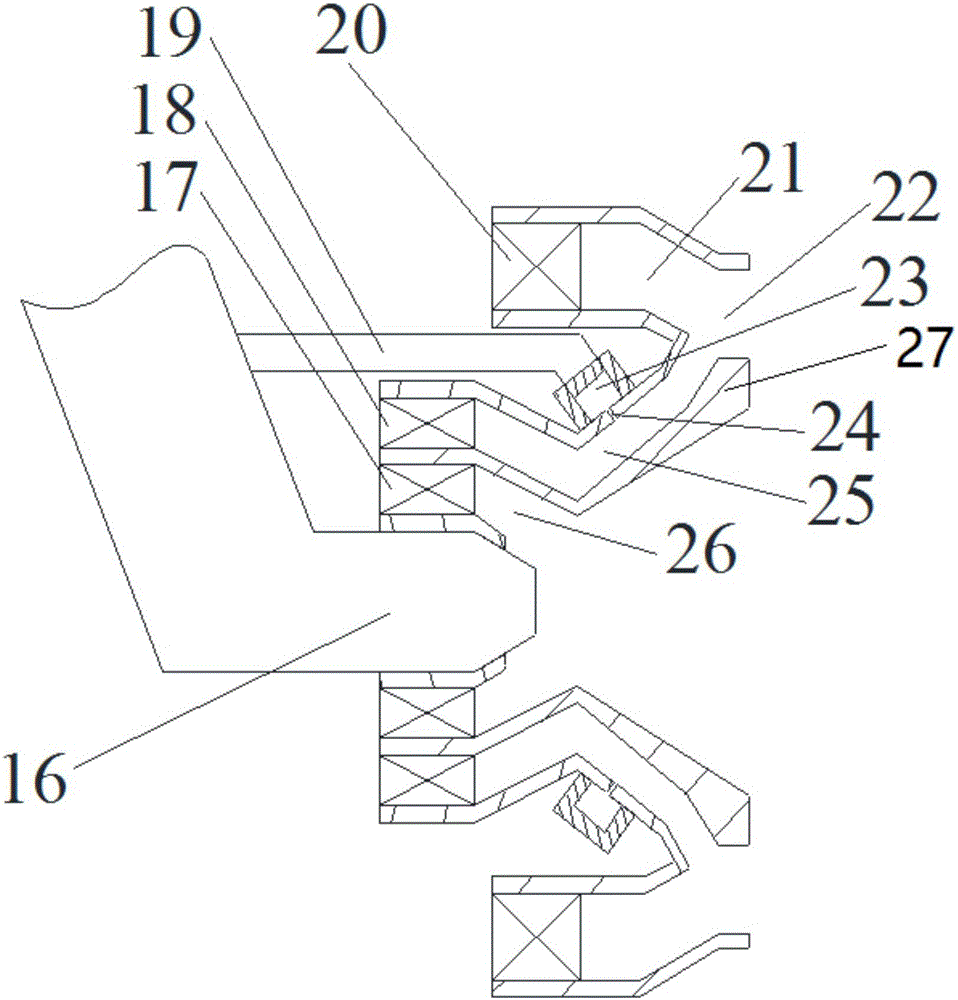

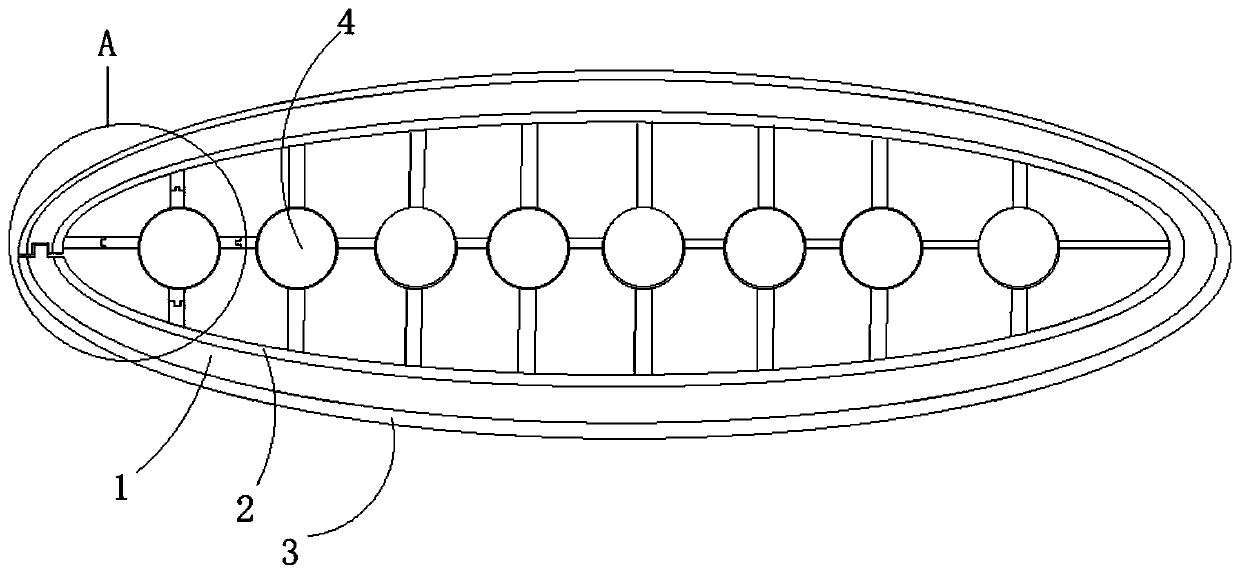

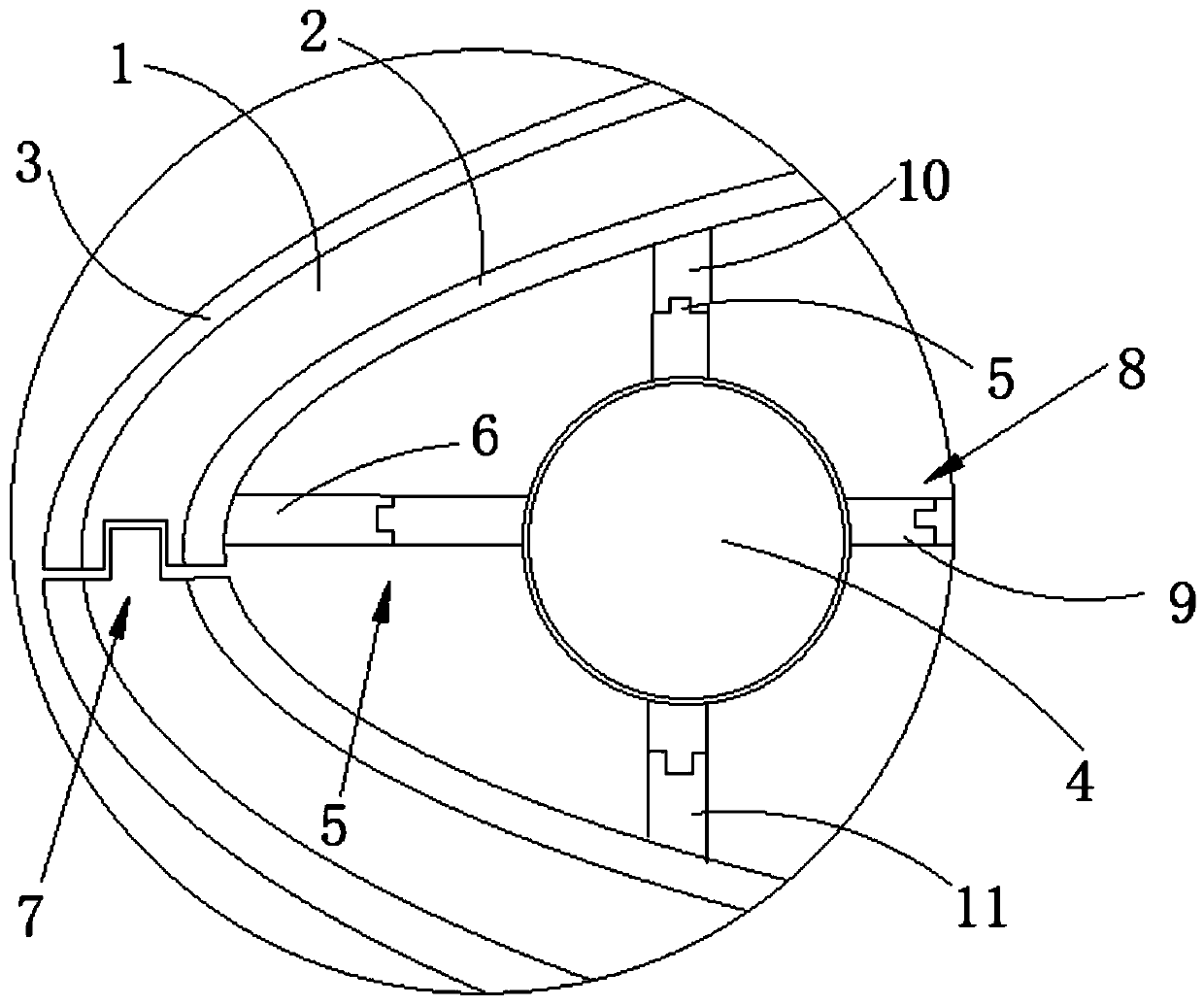

The invention discloses a layered part premixing low-pollution combustor of main combustion level premixing and pre-evaporation. The layered part premixing low-pollution combustor has a pre-heating function. Fuel oil is divided into a main combustion level and an on-duty level. Diffusive combustion is adopted by the on-duty level, lean oil premixed combustion is adopted by the main combustion level, and the premixed combustion of a layered part is achieved through coupling of the diffusive combustion and the lean oil premixed combustion. The on-duty level is composed of a centrifugal atomizing nozzle and first level rotational flow air. The fuel oil of the main combustion level is supplied through multi-point direct-injection type nozzles, and oil and air mixing is enhanced through preheating of second level rotational flow air by combination of transverse jet air and on-duty level flame. The on-duty level is used in part-load conditions such as starting and slow operation, a stable combustion range can be broadened, combustion efficiency can be improved, and emission of CO and UHC is lowered; the on-duty level and the main combustion level work at the same time in the heavy load working condition, the on-duty level provides stable ignition sources for the main combustion level, a main combustion area is in a lean oil state, the temperature is far lower than the adiabatic flame temperature, and emission of NOx of high-load conditions can be reduced remarkably.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

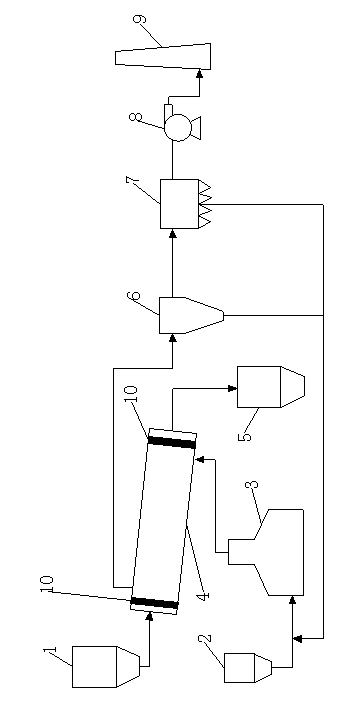

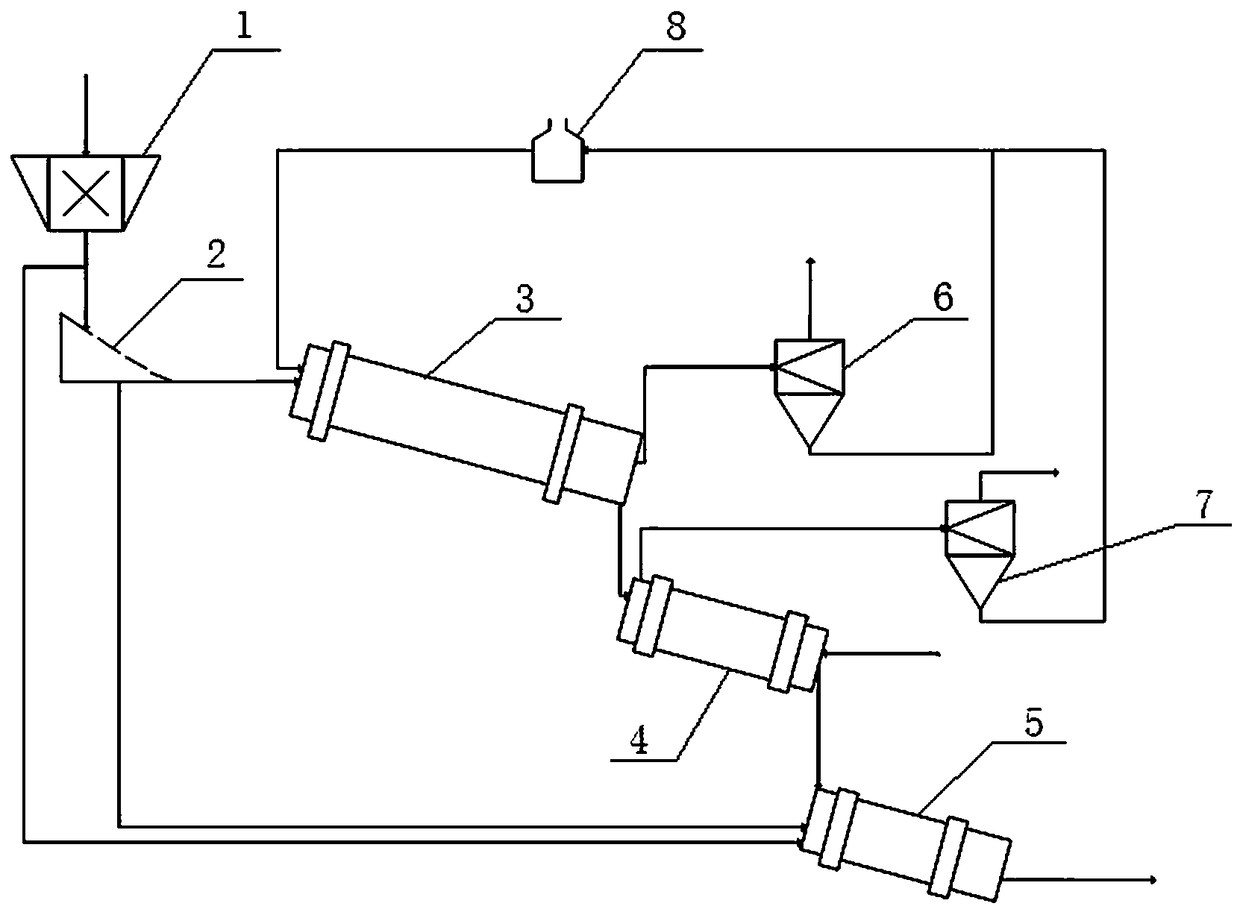

Efficient drying and quality-improving device and method for brown coal

The invention relates to an efficient drying and quality-improving device and method for brown coal. In the prior art, no efficient drying and quality-improving device or method for brown coal, which is used for improving the utilization value of the brown coal, exists. The efficient drying and quality-improving device is characterized by comprising a coal storage bin, a fuel bin, a hot blast stove, a cylinder-type dryer, a product bin, a cyclone dust collector, an electrical dust collector and a plurality of pipelines, wherein both the product bin and the coal storage bin are connected with the cylinder-type dryer; the cylinder-type dryer is connected with the cyclone dust collector; and the cyclone dust collector, the electrical dust collector, the fuel bin are all connected with the hot blast stove. The method is characterized in that the raw material of the brown coal is conveyed into the cylinder-type dryer from the coal storage bin; the hot blast stove generates high-temperature flue gas at the temperature of 700-900 DEG C, and the flue gas is conveyed into the cylinder-type dryer; the raw material of the brown coal is dried by the high-temperature flue gas and conveyed into the product bin from the cylinder-type dryer for sealing and cooling, so that the finished product of the brown coal is obtained after cooling. According to the device and the method, the moisture in the brown coal can be reduced substantially, and a part of ash content in the brown coal can also be reduced, so that the utilization value of the brown coal can be improved.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Preparation method for flame-retardant powdered rubber

Directed at the phenomenon that improper disposal in storage and transportation of powdered rubber easily causes spontaneous combustion, the invention provides a preparation method for flame-retardant powdered rubber. According to the method, carbon tetrachloride and the like are used as halogen donors, unsaturated fatty acid anhydride and the like are used as halogen acceptors, and the halogen donors and the halogen acceptors are subjected to an addition reaction and to saponification by an aqueous sodium hydroxide solution so as to prepare an isolating agent with a flame retardation function; then, the isolating agent is used for preparation of powdered rubber to produce a powdered rubber product with flame resistance; safety of the product in the processes of storage and transportation can be guaranteed.

Owner:PETROCHINA CO LTD

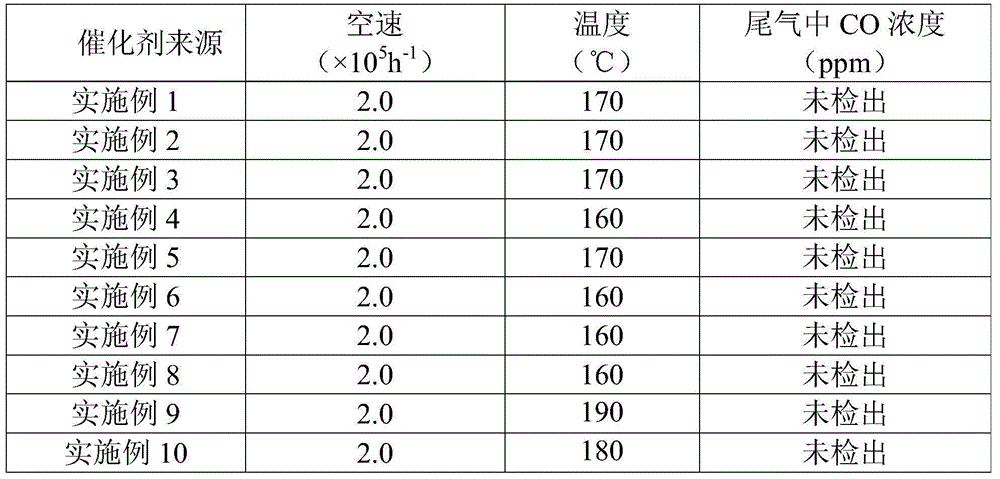

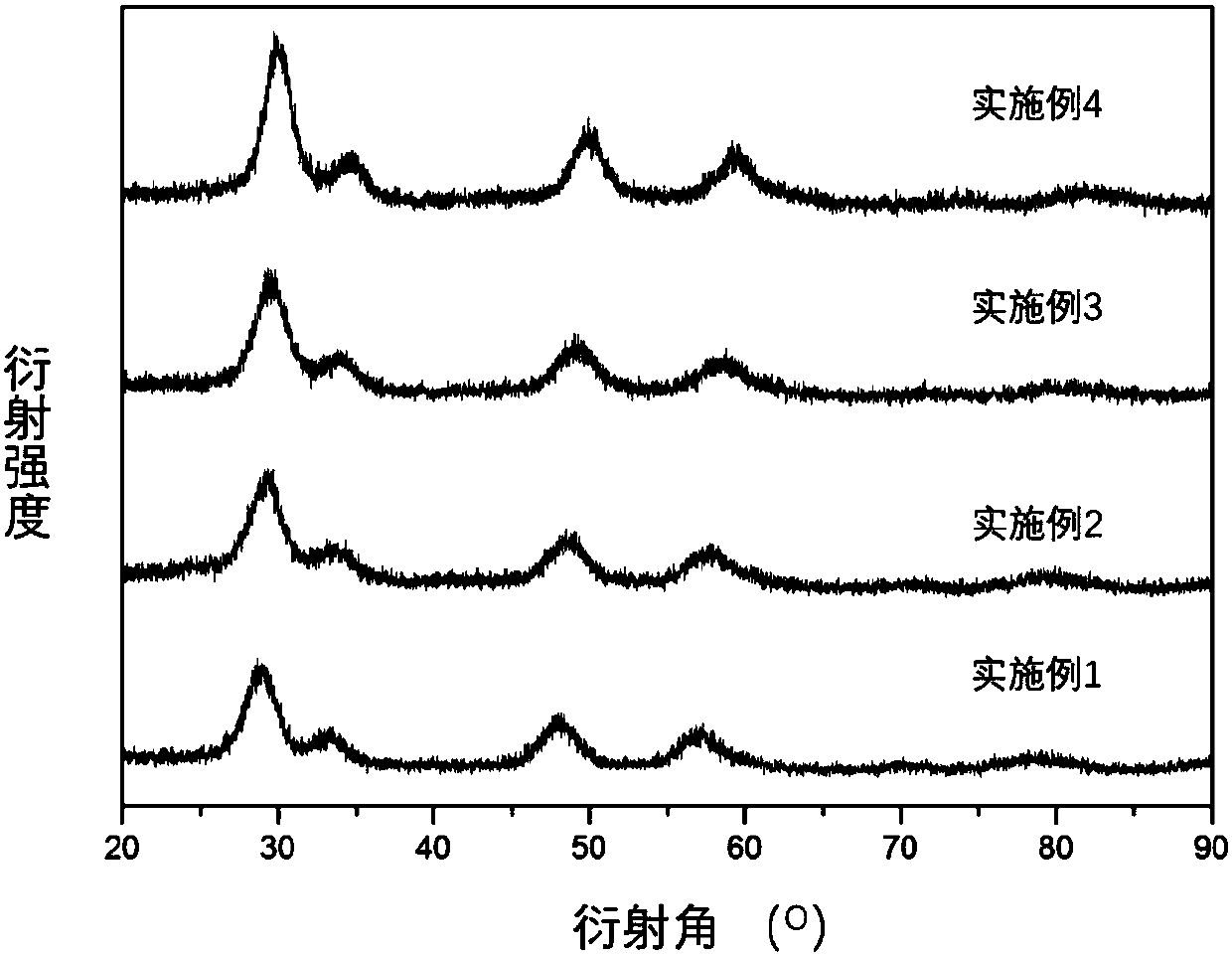

Methanation catalyst, preparation method and application thereof

InactiveCN104888783AReduce alkali consumptionHigh mechanical strengthHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsChemistryCarbon dioxide

The invention provides a methanation catalyst, a preparation method and application thereof. Specifically, the method includes: contacting nickel aluminum alloy and alkali in water. The method for preparation of the methanation catalyst consumes low alkali, and the catalyst prepared by the preparation method provided by the invention has the characteristics of difficult spontaneous combustion, high mechanical strength, and good low-temperature methanation performance, is suitable for removal of trace carbon oxides from hydrogen under low temperature, and especially has high activity and high selectivity to carbon dioxide methanation reaction in carbon oxides.

Owner:CHINA PETROLEUM & CHEM CORP +1

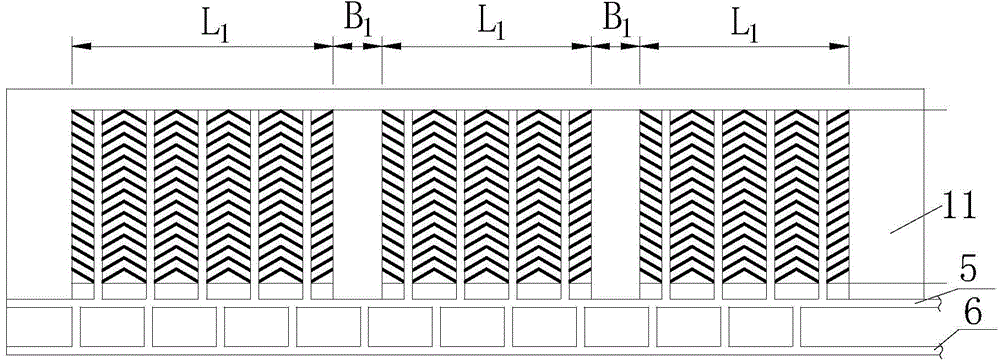

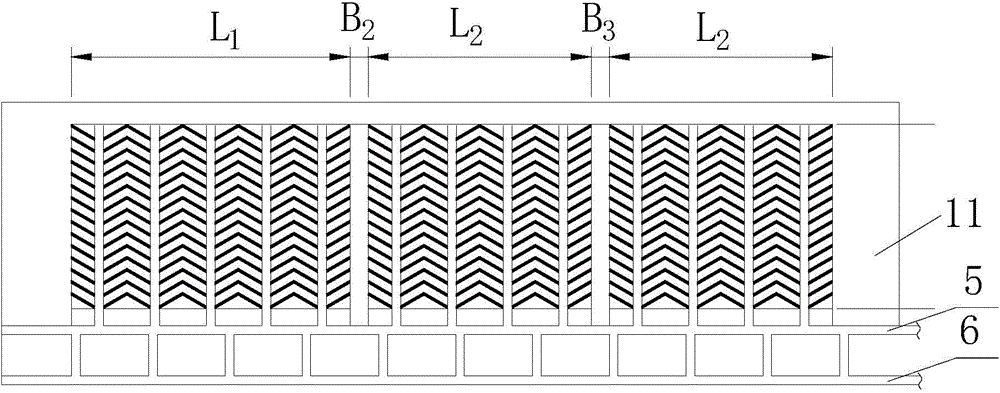

Boundary coal shortwall continuously-mining tunnel arrangement and coal pillar preserving methods

InactiveCN104790953APrevent spontaneous combustionLow recovery rateUnderground miningSurface miningCoal spontaneous combustionStructure of the Earth

The invention discloses a boundary coal shortwall continuously-mining tunnel arrangement and coal pillar preserving methods, according to three typical overlying rock structures, three coal pillar arrangement methods are proposed, and the three coal pillar arrangement methods are respectively a block section wide coal pillar arrangement method, a block section narrow coal pillar arrangement method and a block section non coal pillar arrangement method. Compared with the traditional shortwall continuously-mining tunnel technique tunnel arrangement and coal pillar preserving methods, by the boundary coal shortwall continuously-mining tunnel arrangement and coal pillar preserving methods, the coal pillar size is reduced, the recovery rate of resources can be improved, the roof essential security can be realized, roof safety can be effectively controlled, tunnel excavation and maintenance amount can be reduced, and the risk of coal spontaneous combustion can be reduced.

Owner:SHANDONG UNIV OF SCI & TECH

Modified aluminum hypophosphate flame retardant and preparation method thereof

The invention relates to the field of flame retardants, in particular to a modified aluminum hypophosphate flame retardant. A preparation method of the modified aluminum hypophosphate flame retardantcomprises the following steps: 1) adding aluminum hypophosphate and a dispersing agent in a reaction kettle and fully stirring, so that a solution is uniformly dispersed; 2) adding an adhesive and a modifying agent, raising the temperature, stirring and fully reacting to obtain a crude product; and 3) washing, filtering and drying the crude product to obtain the modified aluminum hypophosphate flame retardant. The modified aluminum hypophosphate flame retardant prepared by the preparation method provided by the invention can effectively solve the problems of low aluminum hypophosphate heat resistance, low compatibility, low dispersing performance and the like.

Owner:广东顺德同程新材料科技有限公司

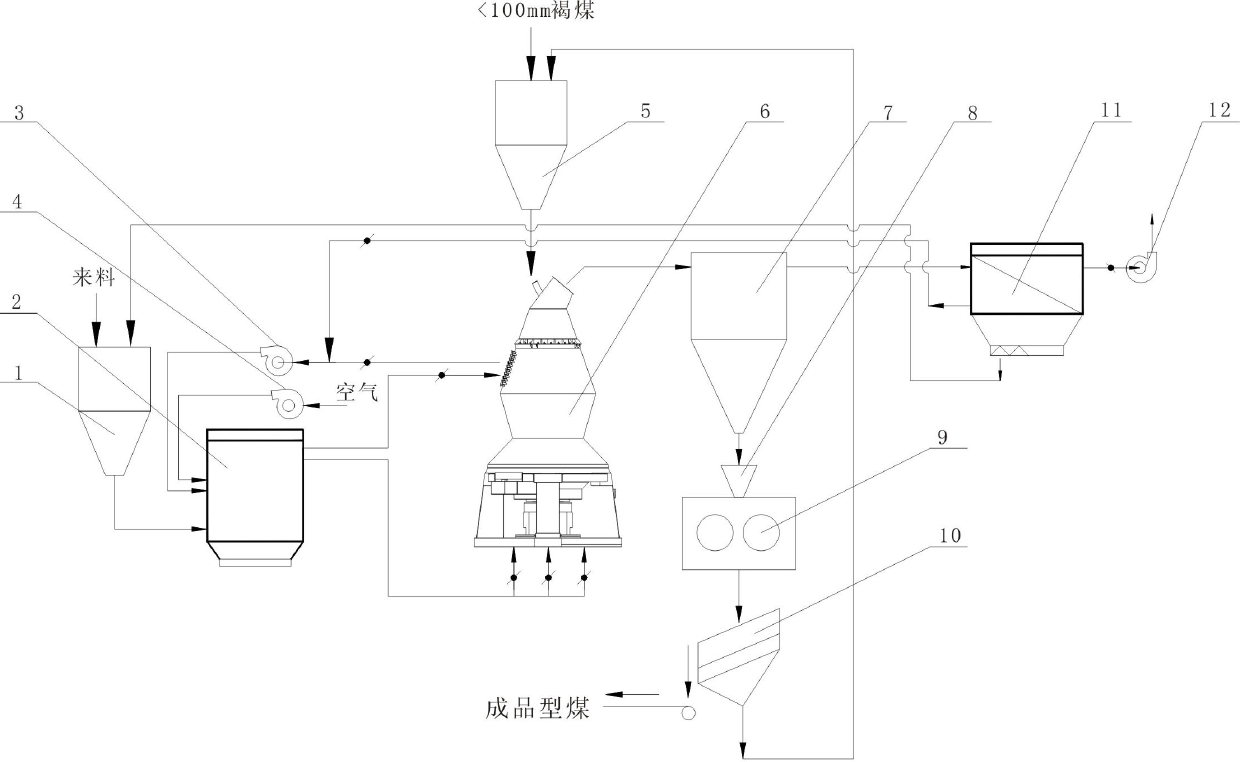

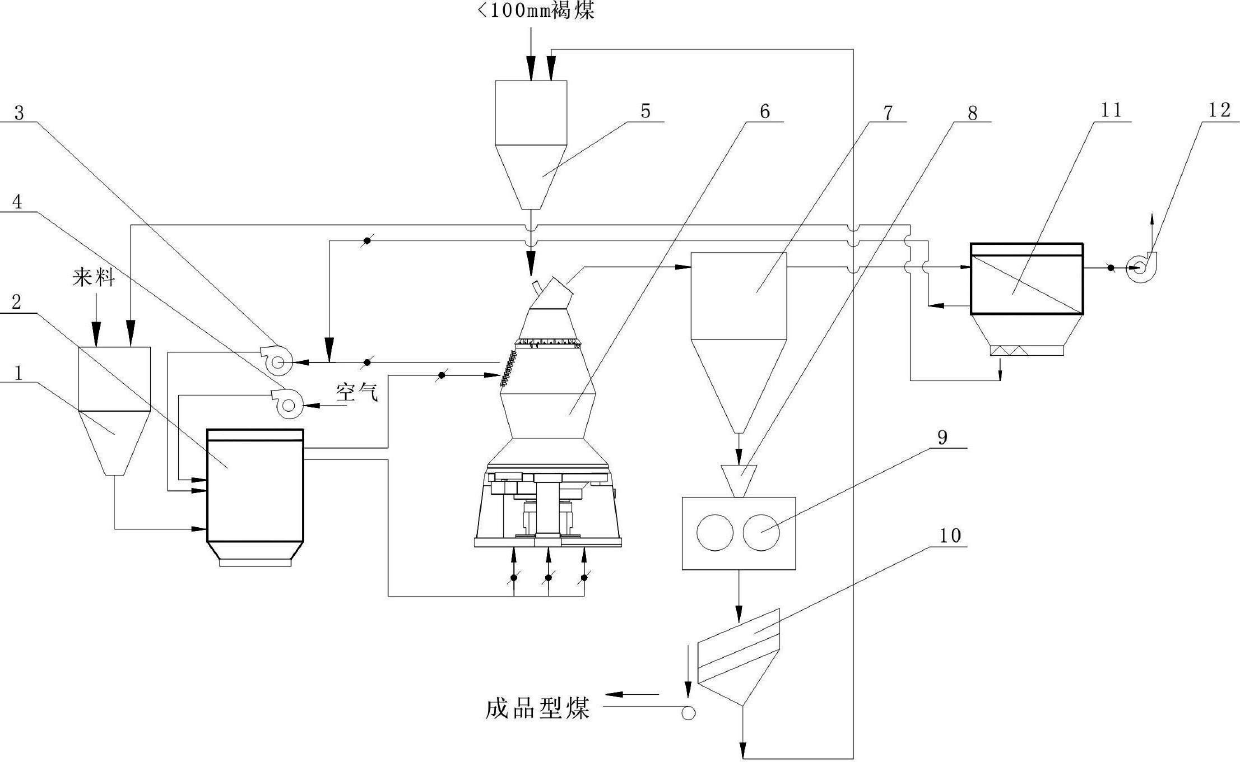

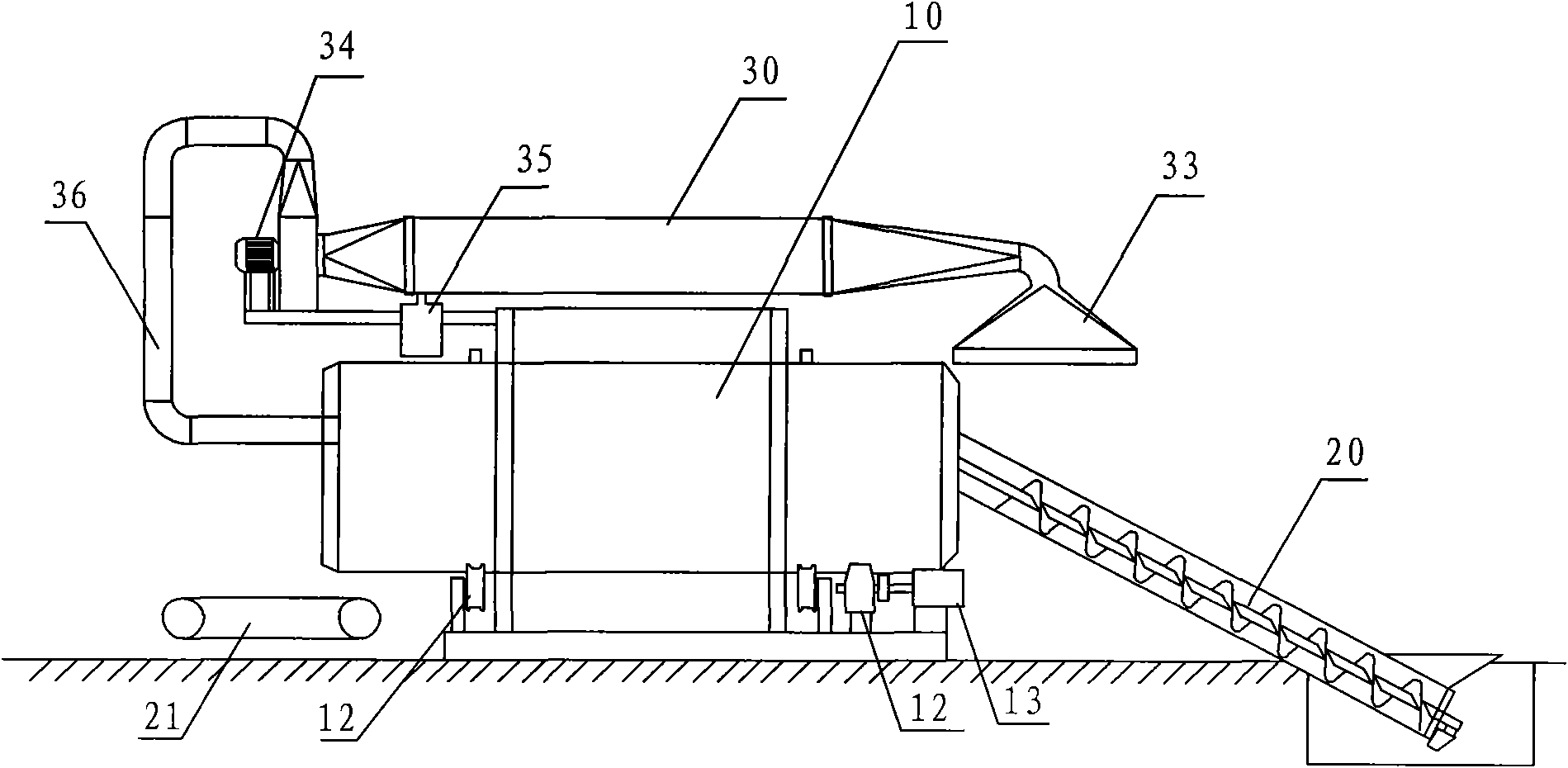

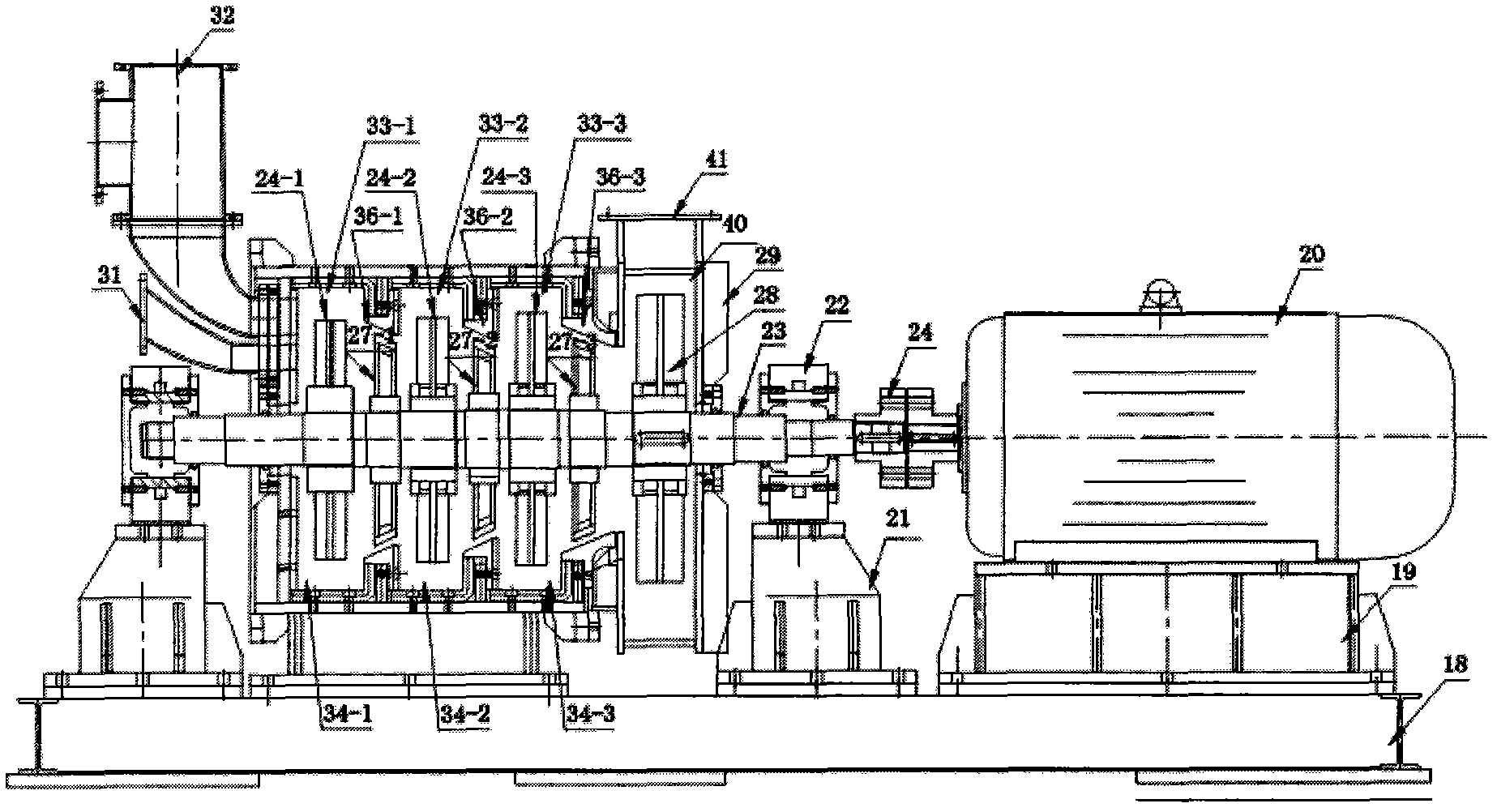

Integral process and device for crushing, drying, forming and upgrading lignite containing moisture

The invention discloses an integral process and a device for crushing, drying, forming and upgrading lignite containing moisture. The lignite with 20-50% of moisture and less than 100mm of granularity is sent into an integral crushing-drying device. The integral crushing-drying device crushes the lignite to have the granularity of less than 3mm, and high-temperature smoke produced by a smoke system is sent into the integral crushing-drying device at high speed to enable the crushed fine lignite particles and lignite power to be dried from bottom to top. Dried fine lignite particles and dried lignite power are driven by the high-speed high-temperature smoke to enter a cyclone separator to be separated. Separated fine lignite particles and separated lignite power enter a prepressing helical device from the position under the cyclone separator, and the lignite materials are prepressed and then enter a high pressure forming machine to be pressed and formed into finished lignite products. The device mainly comprises the smoke system, the integral crushing-drying device, the cyclone separator, the prepressing helical device and the high pressure forming machine. The integral process and the device for crushing, drying, forming and upgrading the lignite containing moisture is low in investment operating cost, high in upgrading efficiency and good in upgrading quality.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

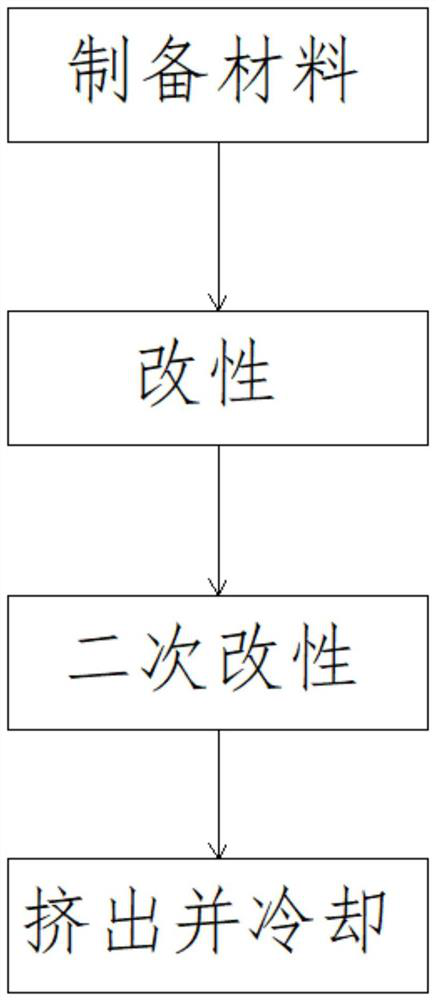

Halogen-free flame-retardant temperature-resistant polyolefin pyrocondensation material and preparation method thereof

InactiveCN105400057AImprove flame retardant performanceNot prone to spontaneous combustionSpontaneous combustionLinear low-density polyethylene

The invention discloses a halogen-free flame-retardant temperature-resistant polyolefin pyrocondensation material and a preparation scheme thereof. The material is prepared from, by weight, 20-100 parts of linear low-density polyethylene, 10-80 parts of vinyl copolymer, 0.5-5 parts of sensitizer, 5-20 parts of silicone flame retardant, 5-50 parts of inorganic flame retardant, 5-40 parts of phosphorus-nitrogen containing flame retardant, 1-5 parts of antioxidant, 1-5 parts of light stabilizer and 1-20 parts of smoke restraining agent. The halogen-free flame-retardant temperature-resistant polyolefin pyrocondensation material obtained through the preparation method can reach the high temperature resistant level of 150 DEG C or higher, is good in combustion resistant effect, can not release harmful gas, is not prone to spontaneous combustion, reduces potential safety hazards, is low in cost and high in cost performance, and can be widely applied to the fields of locomotives, aviation, electrons, ships, nuclear power, the war industry and the like.

Owner:苏州沃尔兴电子科技有限公司

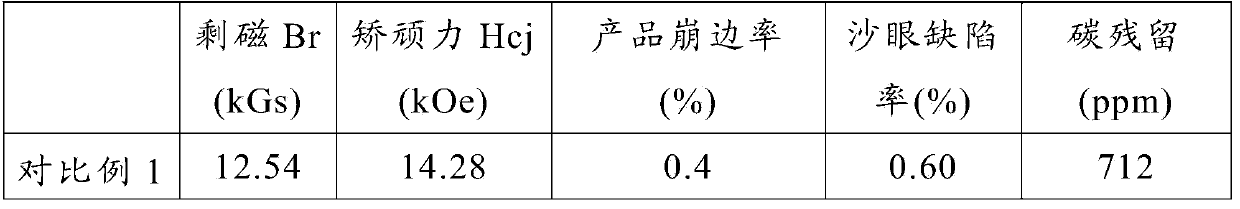

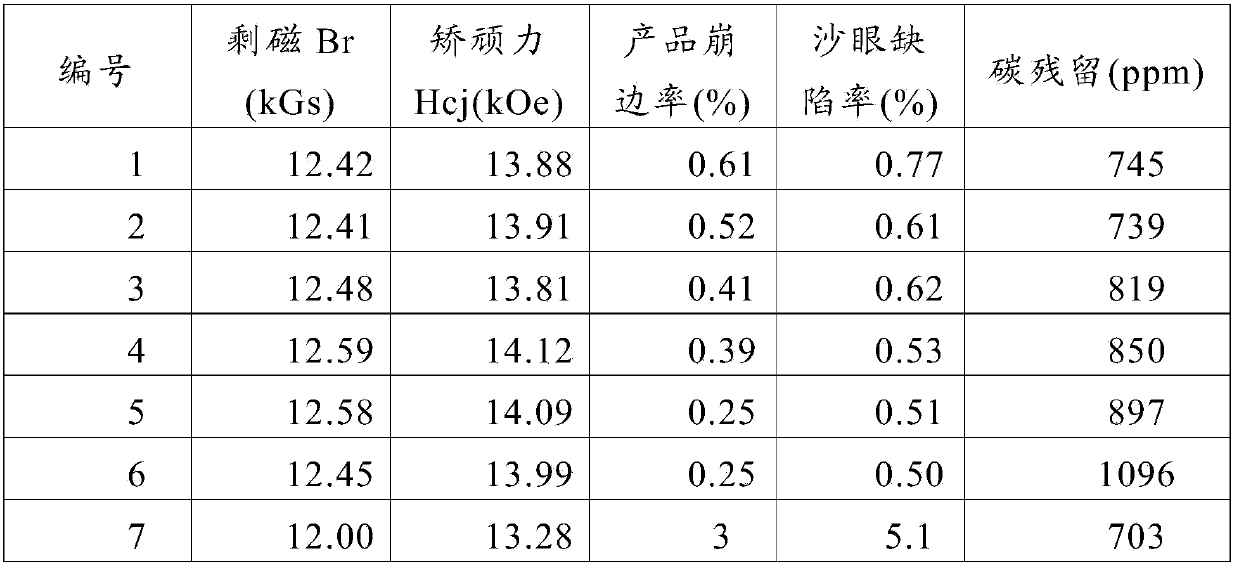

Method for manufacturing neodymium iron boron magnet

ActiveCN103996478AEfficient use ofNot prone to spontaneous combustionInorganic material magnetismInductances/transformers/magnets manufactureSpontaneous combustionPowder mixture

The invention provides an organic additive for neodymium iron boron magnet manufacturing. The additive is characterized by comprising, by mass percentage, 0.1-50% of ester matter, 0.1-25% of liquid paraffin, 0.05-10% of polybutylene, 0.01-5% of coupling agents and the balance varsol. The invention provides a method for manufacturing a neodymium iron boron magnet. The method includes the following steps that neodymium iron boron ultra-fine powder is mixed with the organic additive to obtain a neodymium iron boron ultra-fine powder mixture, and then the obtained neodymium iron boron ultra-fine powder mixture and neodymium iron boron powder are sintered to obtain the neodymium iron boron magnet. According to the method for manufacturing the neodymium iron boron magnet, the prepared organic additive and the neodymium iron boron ultra-fine powder are added into the sintering process of the magnet so that the ultra-fine powder can be effectively used; besides, the ultra-fine powder is not prone to spontaneous combustion and agglomeration in the production process, and safety hidden hazards are reduced, and production cost is lowered.

Owner:廊坊京磁精密材料有限公司

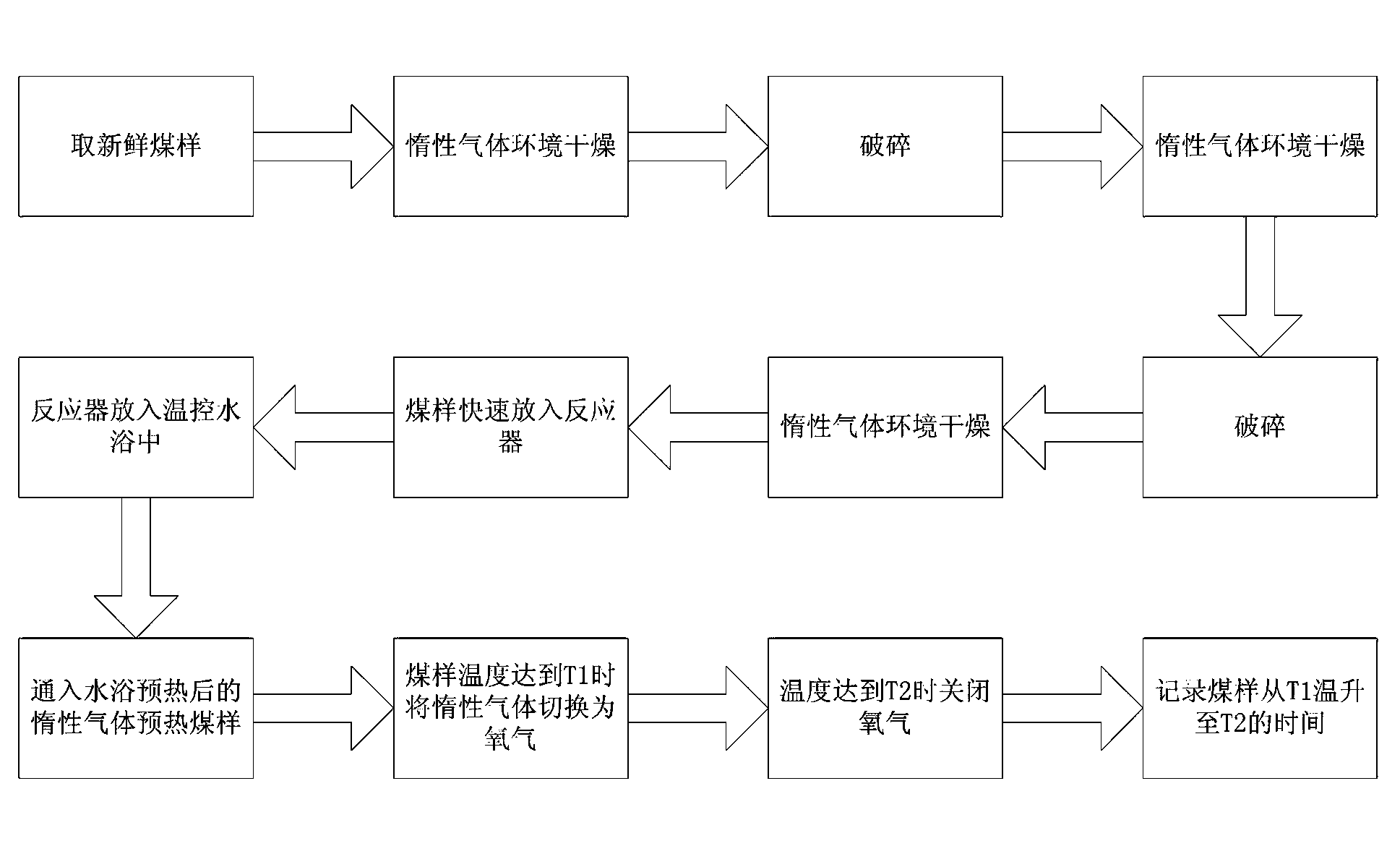

Method of testing coal spontaneous combustion tendentiousness by water bath heat insulation

InactiveCN103217455ANot prone to spontaneous combustionSpontaneous combustion is not easy to happenMaterial heat developmentWater bathsCoal spontaneous combustion

The invention discloses a method of testing coal spontaneous combustion tendentiousness by water bath heat insulation. The method comprises the following steps of: preheating a coal sample to be detected to be at first designed temperature T1 and placing the heated coal sample to be detected in a reactor in water bath or directly heating the coal sample to be detected in the reactor, introducing oxygen in the reactor, rising the temperature of the coal sample to be detected under the oxygen action, and rising the temperature of the water bath along with the rising of the temperature of the coal sample so as to enable the spontaneous combustion of the coal sample to be positioned in a heat insulation environment; and when the temperature of the coal sample to be detected achieves second designed temperature T2, stopping filling the oxygen, recording the time from the first designed temperature T1 to the second designed temperature T2 and temperature so as to form a coal sample result of the coal sample to be detected with the temperatures. The method provided by the invention has the advantages of simple principle, easiness of operation, high test precision, good test reliability and the like.

Owner:HUNAN SUNDY SCI & TECH DEV

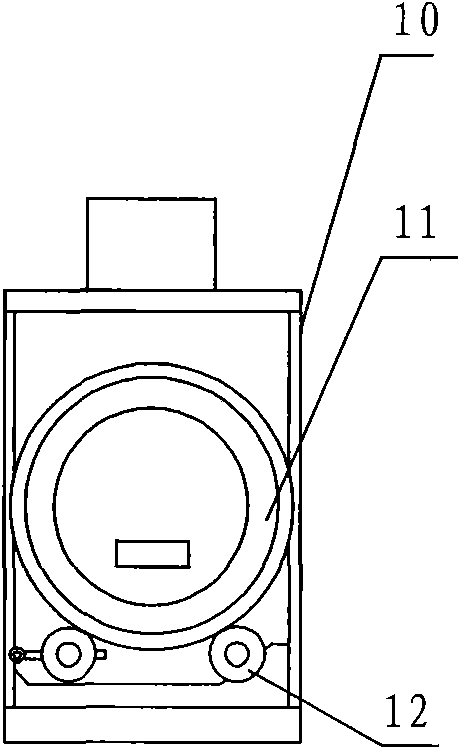

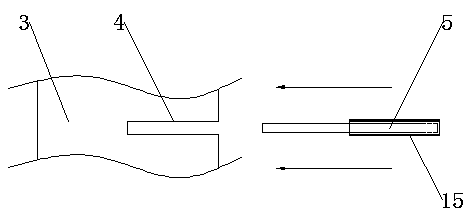

Continuous type rubber powder cooling and drying device

InactiveCN101659092ANot easy to thermal oxidation reactionNot prone to spontaneous combustionPlastic recyclingAirflowFlue gas

The invention relates to the field of waste rubber regeneration technology, in particular to a mechanical device for cooling and drying desulfurated rubber powder. The mechanical device comprises a rotary drum and a driving mechanism for driving the rotary drum to rotate, wherein the rotary drum is internally provided with a spiral guide plate; furthermore, the device also comprises a conveying mechanism which is connected with a cooling rotary drum and used for conveying the rubber powder to the feeding end of the cooling rotary drum, and a flue gas collection and air supply mechanism that isprovided with a cooler on a pipeline provided with a blast blower, wherein two ends of the pipeline are respectively provided with a smoke absorbing hole arranged at the feeding end of the rotary drum and an air blowing hole positioned at the discharge end of the rotary drum, and the air flow of the smoke absorbing hole and the air blowing hole can be communicated in a circulating air flow channel by the pipeline and the rotary drum. The device solves the problem in the prior art, so that after being output from a tank, the high temperature rubber powder can be rapidly cooled through a cooling air supply system, thus being difficult to generate thermal oxidation reaction and more difficult to combust spontaneously. Therefore, the device saves the work place for cooling the rubber powder and reduces the pollution for the atmosphere.

Owner:黄子盛

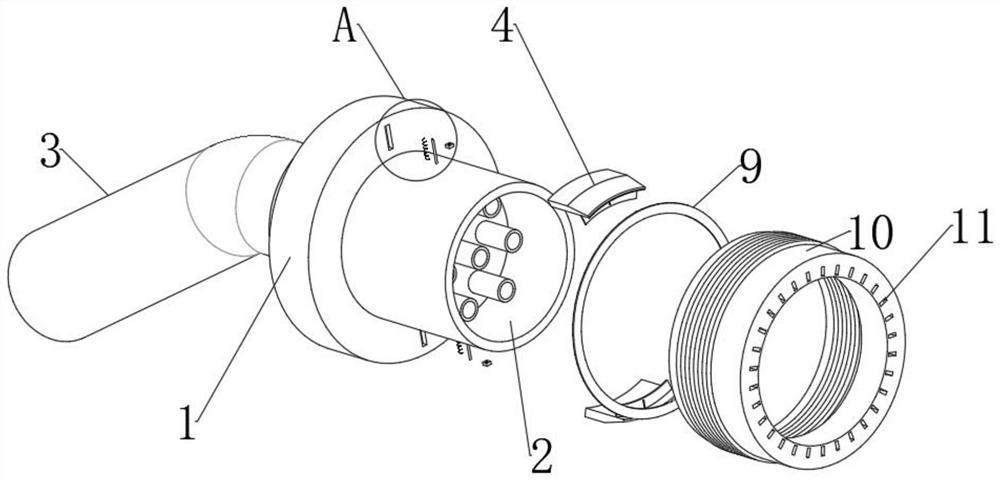

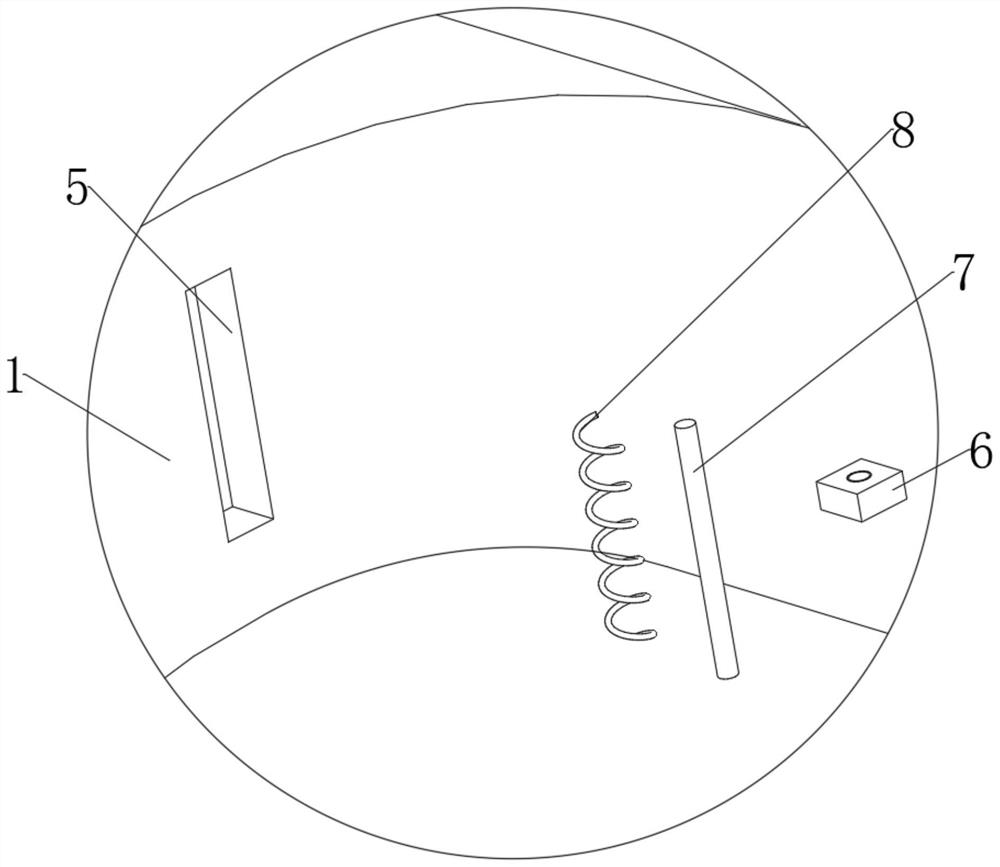

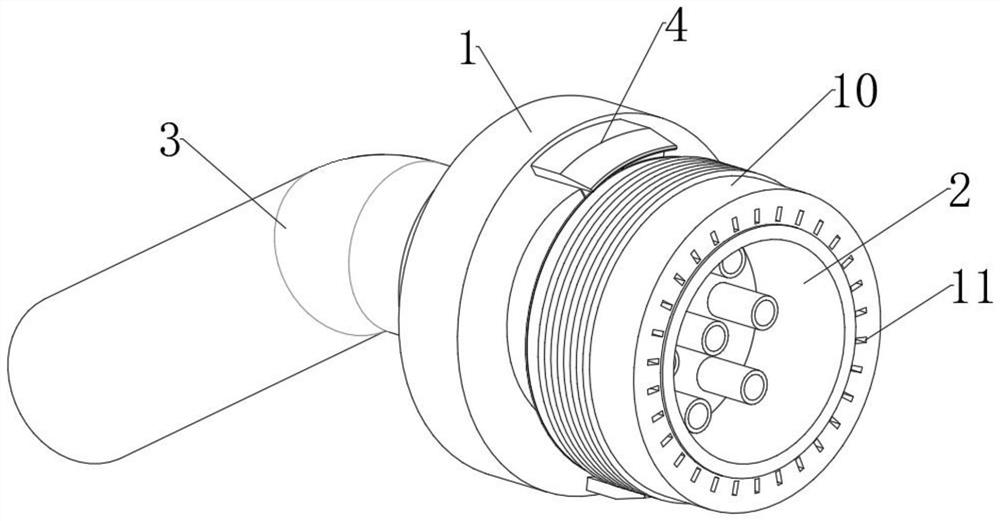

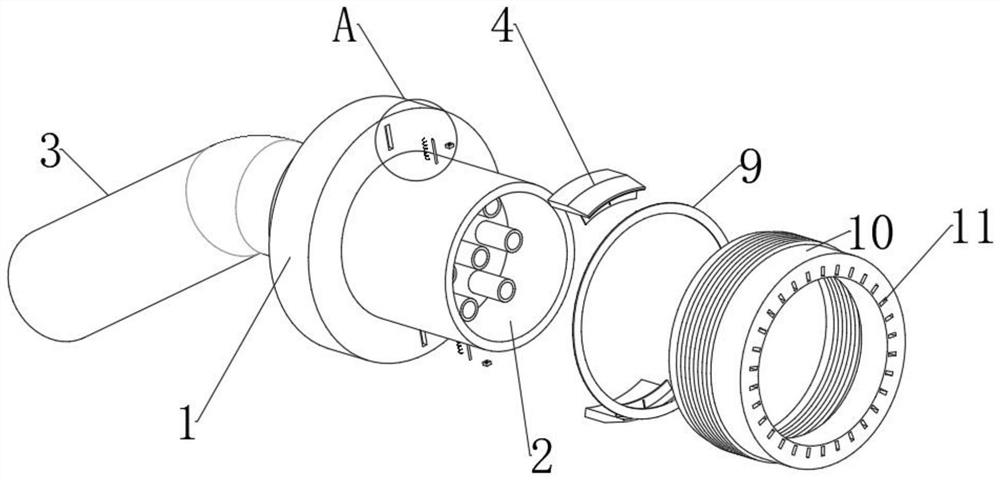

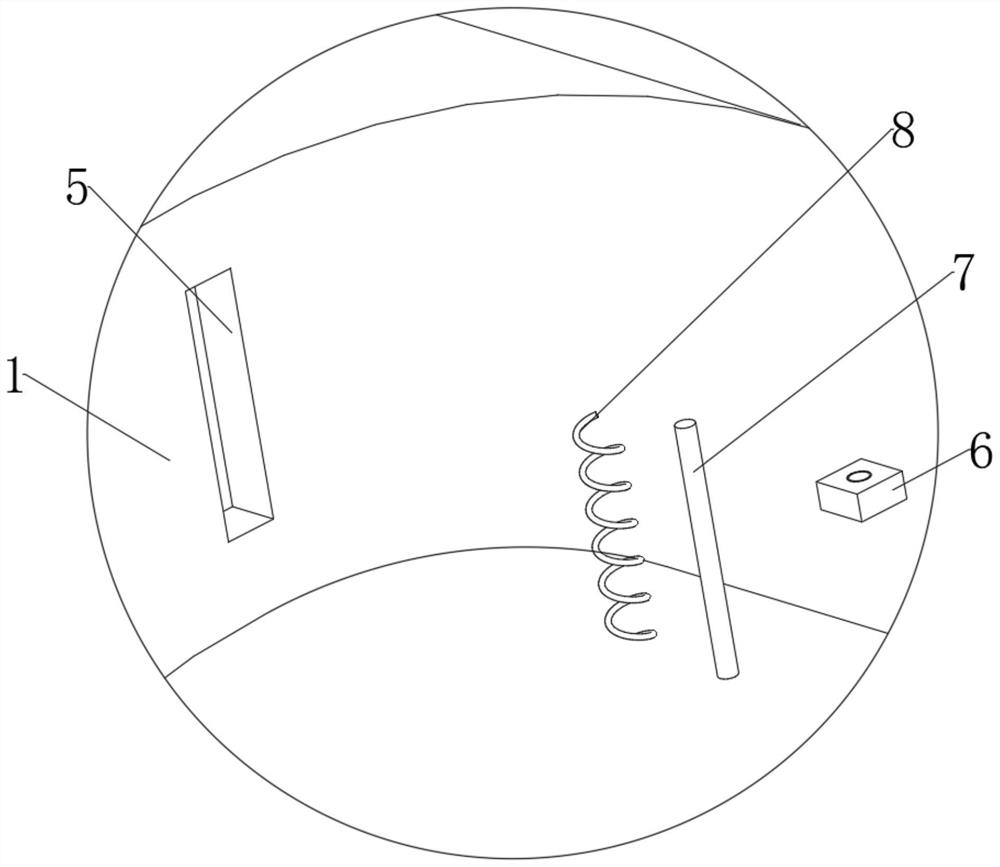

New energy charging pile with anti-spontaneous-combustion interface

ActiveCN112140934AImprove cooling effectNot prone to spontaneous combustionCharging stationsElectric vehicle charging technologyAutomotive engineeringInternet of Things

The invention discloses a new energy charging pile with an anti-spontaneous-combustion interface, and belongs to the field of new energy charging piles. The new energy charging pile with the anti-spontaneous-combustion interface can realize the effects that when a new energy automobile is charged by using a charging pile, excessive heat accumulation of a storage battery due to long-time charging of the storage battery is not liable to occur, the storage battery of the new energy automobile is not prone to spontaneous combustion, serious threats to life and property safety of a new energy automobile owner are not prone to being caused, meanwhile, through the Internet of Things technology, charging records of the new energy automobile are synchronized to processing terminals of different charging fields, charging services for different automobile owners are perfected through shared charging data, meanwhile, related information of automobile charging can be sent to a user mobile terminalthrough an Internet of Things module, a health report of an automobile charging port is sent to the automobile owner in time, the automobile owner is reminded to check the automobile in time when thecharging pile interface is frequently disconnected due to overheating, and potential safety hazards are eliminated.

Owner:东莞市牛牛新能源技术有限公司

a fuel composition

InactiveCN102277210ALow costEmission reductionLiquid carbonaceous fuelsSpontaneous combustionPotassium

The invention relates to a fuel oil composition, which is mainly prepared from the following raw materials in weight ratio: methanol 50-100; ethanol 5-10; potassium oxide 0.3-1.5 and sodium oxide 0.5-5; ethyl fat 6-15; Iron 0.7-2; rapeseed oil 2-8; stabilizer 5-7 and water 10-20, the production method is: fully dissolve potassium oxide and sodium oxide with water to form a solution, add ethyl fat and ethanol to mix, and set aside ; Ferrocene dissolved in methanol, ready to use; rapeseed oil, stabilizer and water fully mixed, that is, the finished product. The product of the invention is used as boiler fuel, has high calorific value, sufficient combustion, is stable at room temperature, is not easy to spontaneously combust, and the waste gas emission after combustion is more than 80% lower than that of petroleum liquefied gas, has obvious environmental protection effect, and is easy to store and transport. Ordinary plastic barrels Ready to store. The raw materials are simple and extensive, easy to purchase, low in cost, simple in manufacturing process and convenient for market promotion.

Owner:任城锋

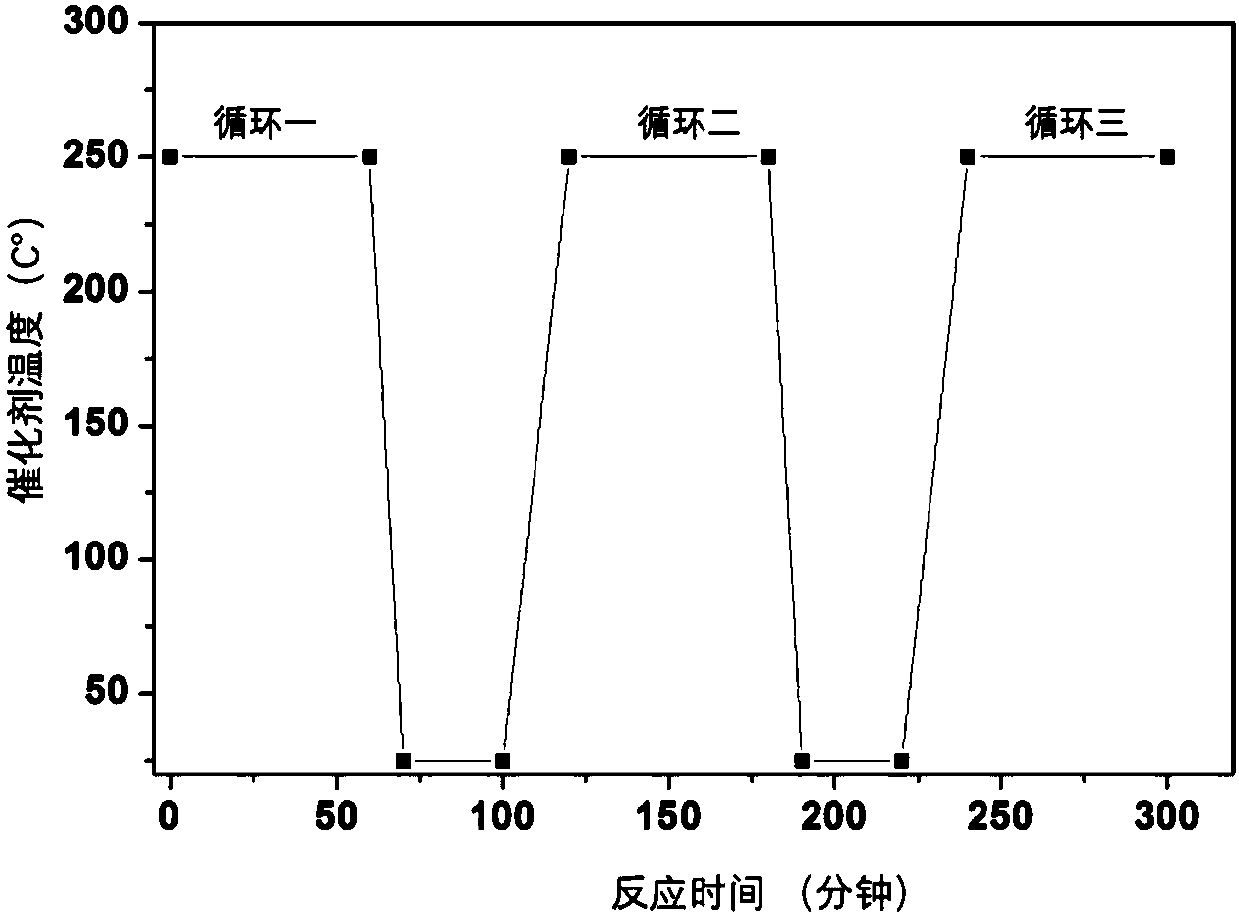

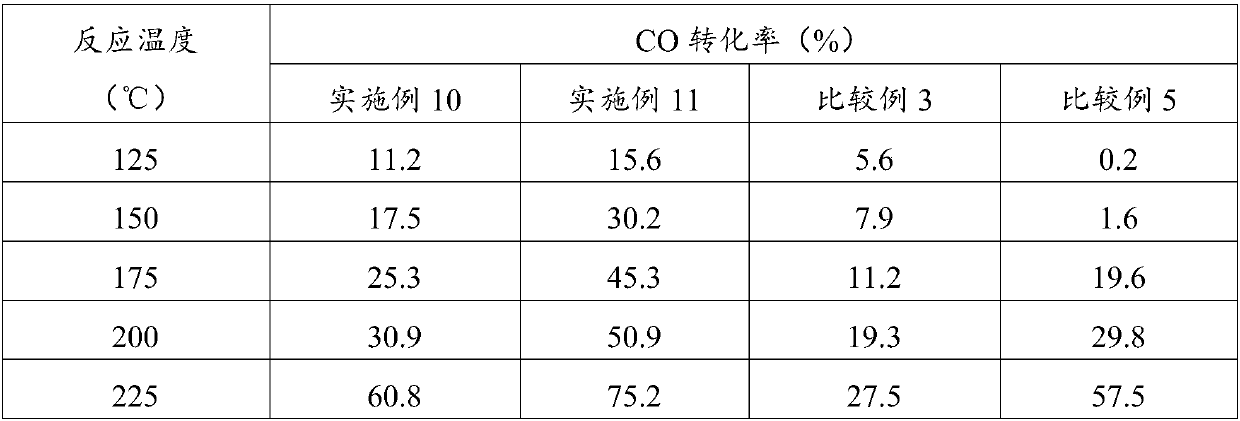

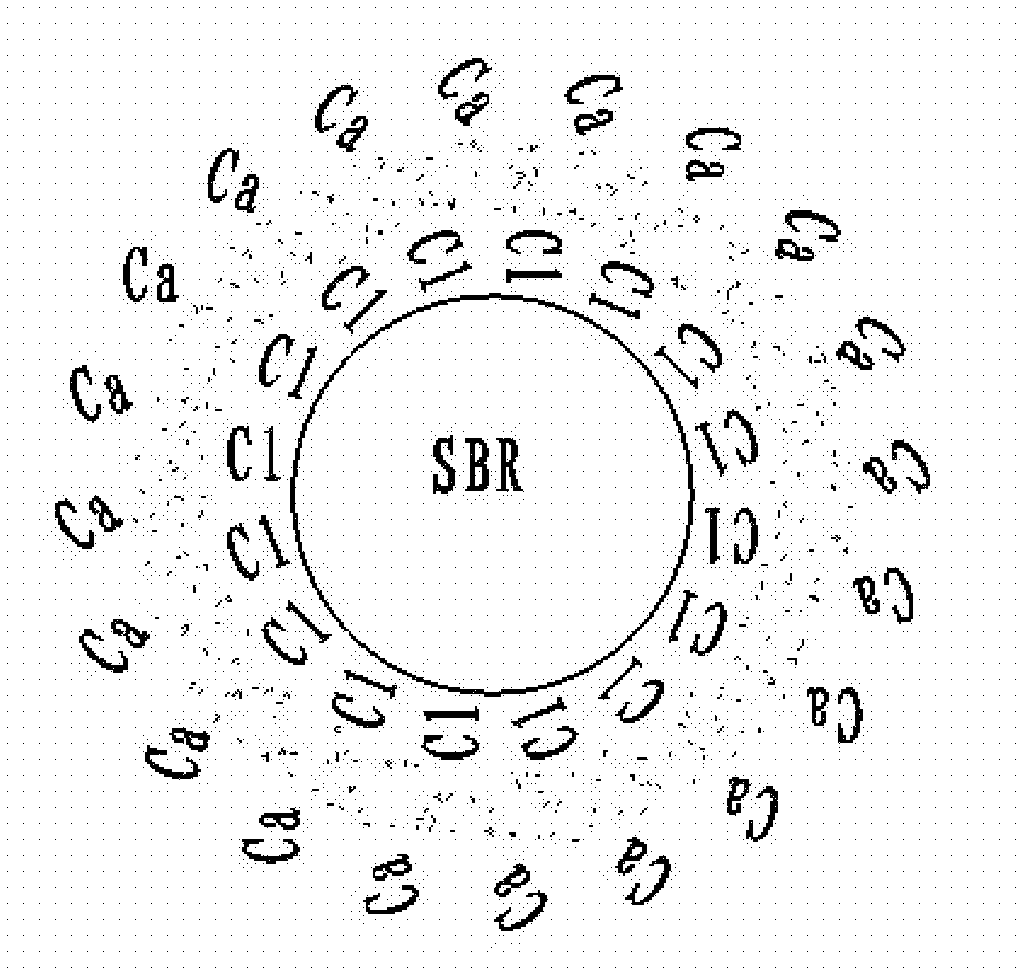

Water-gas shift reaction method

ActiveCN107915205AHigh and low temperature conversion rateGood start-stop stabilityCatalyst carriersHydrogenStart stopActive component

The invention relates to a water-gas shift reaction method which is mainly used for solving problems that reaction temperature is higher, start-stop stability is poor and a catalyst is spontaneously combustible in the prior art. The problem is better solved by means of the technical scheme as follows: the method comprises the step that water gas is contacted with the catalyst in a fixed bed reactor and CO2 and H2 are produced, wherein the catalyst is prepared from a) 0.1wt%-5wt% of at least one active component selected from Pt, Pd and Au and b) 95wt%-99.9wt% of a carrier, the carrier is nano-zirconia, and the specific surface area of nano-zirconia is larger than 100 cm<2> / g. The water-gas shift reaction method can be applied to industrial production of removal of CO in gas or regulation of CO-H2 ratio of synthesis gas by the aid of water-gas shift reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

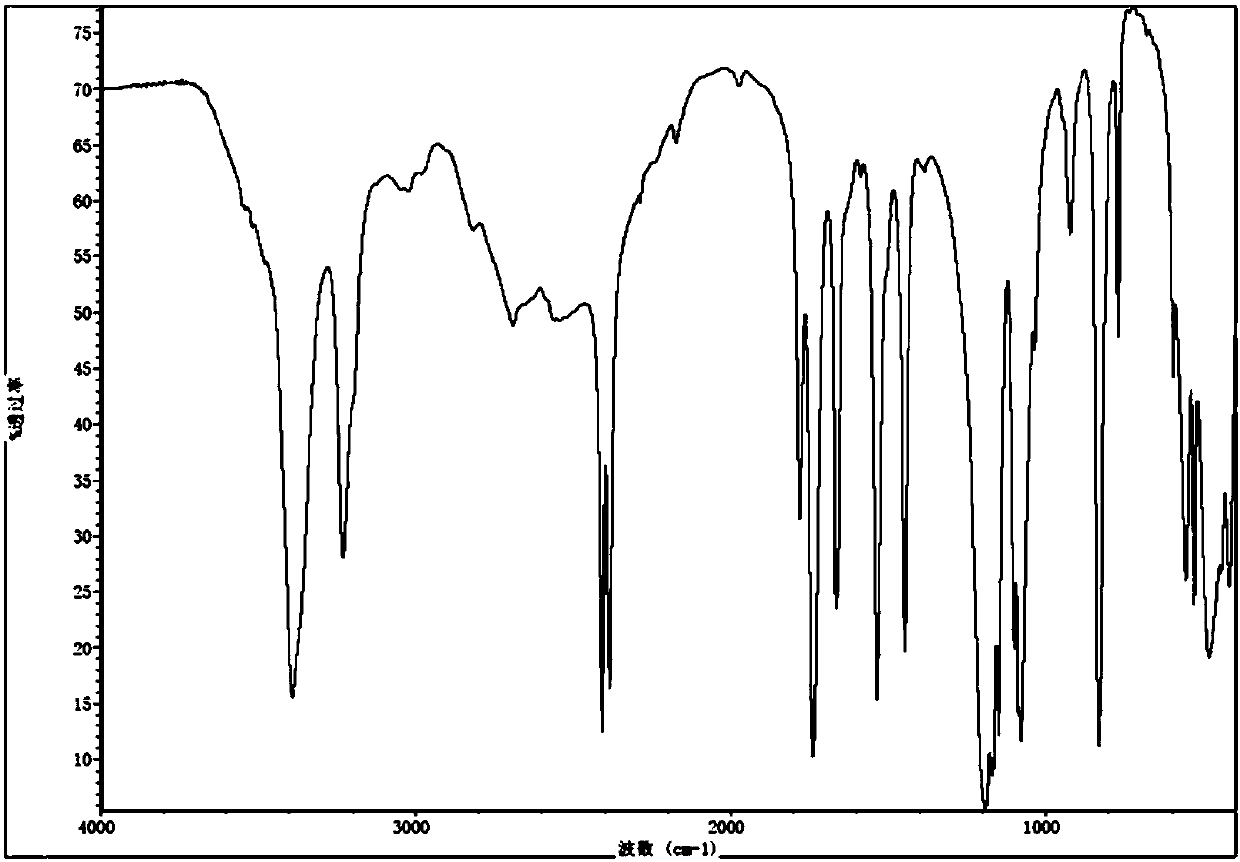

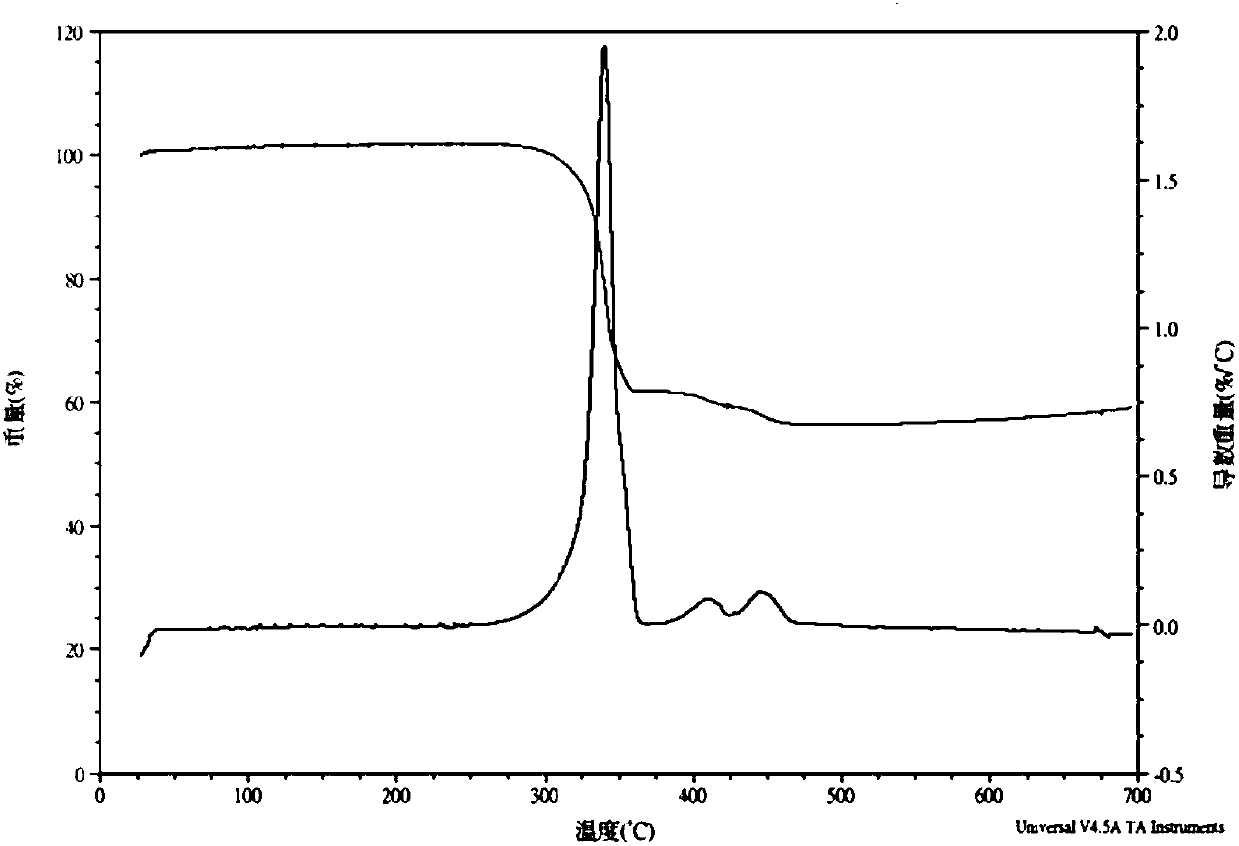

Preparation method of flame retardant type separant

ActiveCN103159611AIts oxygen index increasedNot prone to spontaneous combustionCarboxylic acid salt preparationCondensation processSpontaneous combustion

Aiming at spontaneous combustion caused by improper dispose in storage and transportation of powder rubber, the invention provides a preparation method of a flame retardant type separant. The method is as below: conducting an addition reaction on a halogen donor of carbon tetrachloride and a halogen acceptor of unsaturated fatty acid, and saponifying by a sodium hydroxide aqueous solution, so as to prepare the separant with flame retardant function. The flame retardant type separant can be used in condensation process of rubber latex and preparation of powder rubber product with flame retardance, and can guarantee safety of product storage and transportation process.

Owner:PETROCHINA CO LTD

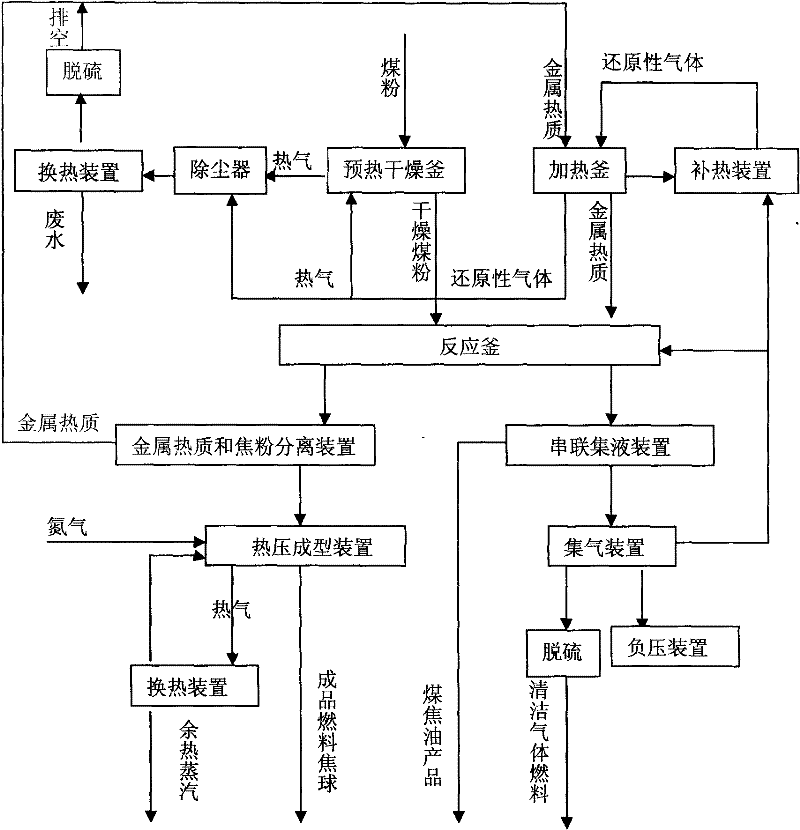

Metal caloric low-temperature dry distillation process for long flame coal or lignite

InactiveCN102391884AIncrease profitImprove use valueDirect heating destructive distillationEnergy inputThermal energyReaction temperature

The invention discloses a metal caloric low-temperature dry distillation process for long flame coal or lignite. The process comprises the steps of washing, dressing and milling of raw coal, drying of coal powder, dry distillation, collection of dry distillation gas and tar and treatment of coke powder. A metal carrier medium serving as a caloric carrier is heated to a predetermined temperature and then mixed with the coal powder in a ratio in a closed container, the mixture is distilled, the tar and the dry distillation gas are collected by using negative pressure, the caloric carrier is separated from the rest solid mixture, the rest solid mixture is reheated and recycled, the thermal energy generated when the coke powder is cooled is recycled, the raw coal is preheated and dried by using tail gas waste heat, and the preheated and dried coal is directly extracted in a reaction kettle; the quality of the obtained tar and the obtained dry distillation gas is good, the utilization rate and the utilization value of the coal are improved, the extraction process is easily controlled under normal pressure and at medium temperature, and the reaction temperature is below 750 DEG C; the process does not consume water resources; and the product is stable, has high additional value, is not easily self-ignited, does not absorb moisture, and can be transported for long distance.

Owner:河北邦农电子商务有限公司

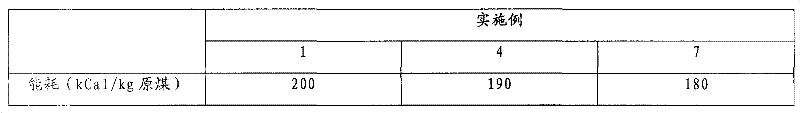

Microencapsulated inorganic hypophosphite flame retardant and preparation method thereof

ActiveCN103992512BImprove performanceEasy to processMicroballoon preparationMicrocapsule preparationSpontaneous combustionPolymer science

this invention It relates to a microencapsulated inorganic hypophosphite flame retardant and a preparation method thereof, wherein the capsule material is a cross-linked polymer containing a triazine ring. The present invention overcomes the problem that inorganic hypophosphite flame retardants are prone to spontaneous combustion in the prior art, Through microencapsulation technology, the triazine ring-containing cross-linked polymer is used as a capsule material to wrap the surface of inorganic hypophosphite, and a microencapsulated inorganic hypophosphite flame retardant is obtained, which has higher thermal stability and is not easy to spontaneously ignite. Higher flame retardant efficiency, better compatibility with polymer matrix and other advantages. In addition, the preparation method of the present invention has simple process, easy operation and is suitable for industrial production.

Owner:苏州安鸿泰新材料有限公司

A stratified partially premixed low-pollution combustor with lean premixed main combustion stage

ActiveCN104456628BImprove uniformityExtended service lifeContinuous combustion chamberCombustion chamberCoupling

The invention discloses a layered part premixing low-pollution combustor of main combustion level premixing and pre-evaporation. The layered part premixing low-pollution combustor has a pre-heating function. Fuel oil is divided into a main combustion level and an on-duty level. Diffusive combustion is adopted by the on-duty level, lean oil premixed combustion is adopted by the main combustion level, and the premixed combustion of a layered part is achieved through coupling of the diffusive combustion and the lean oil premixed combustion. The on-duty level is composed of a centrifugal atomizing nozzle and first level rotational flow air. The fuel oil of the main combustion level is supplied through multi-point direct-injection type nozzles, and oil and air mixing is enhanced through preheating of second level rotational flow air by combination of transverse jet air and on-duty level flame. The on-duty level is used in part-load conditions such as starting and slow operation, a stable combustion range can be broadened, combustion efficiency can be improved, and emission of CO and UHC is lowered; the on-duty level and the main combustion level work at the same time in the heavy load working condition, the on-duty level provides stable ignition sources for the main combustion level, a main combustion area is in a lean oil state, the temperature is far lower than the adiabatic flame temperature, and emission of NOx of high-load conditions can be reduced remarkably.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

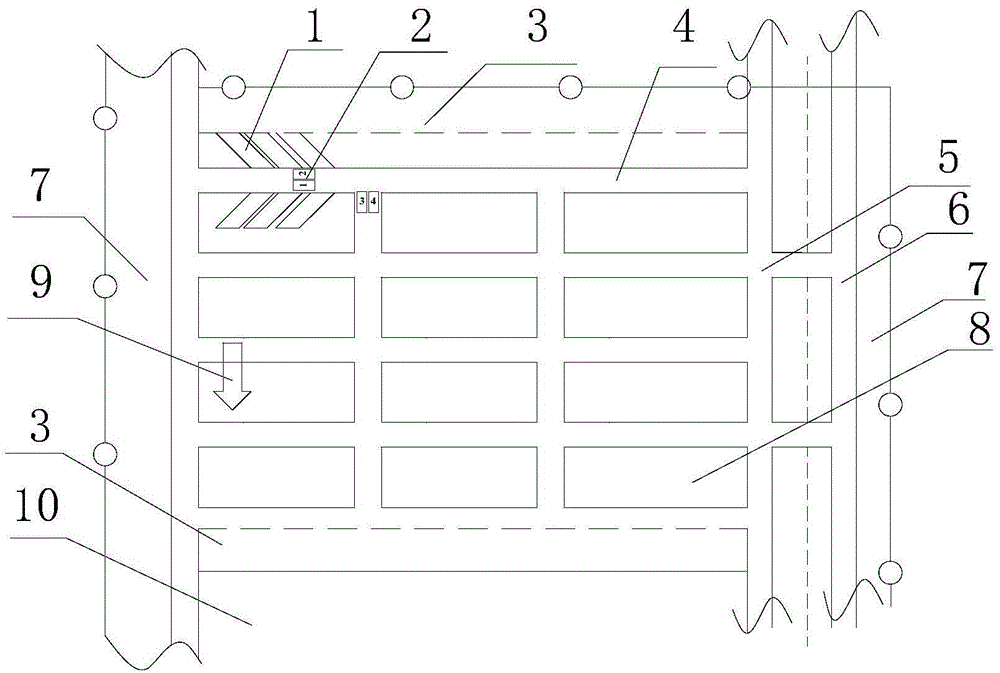

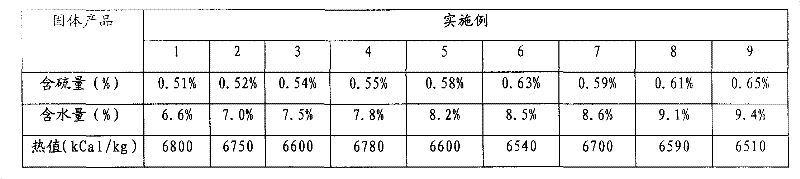

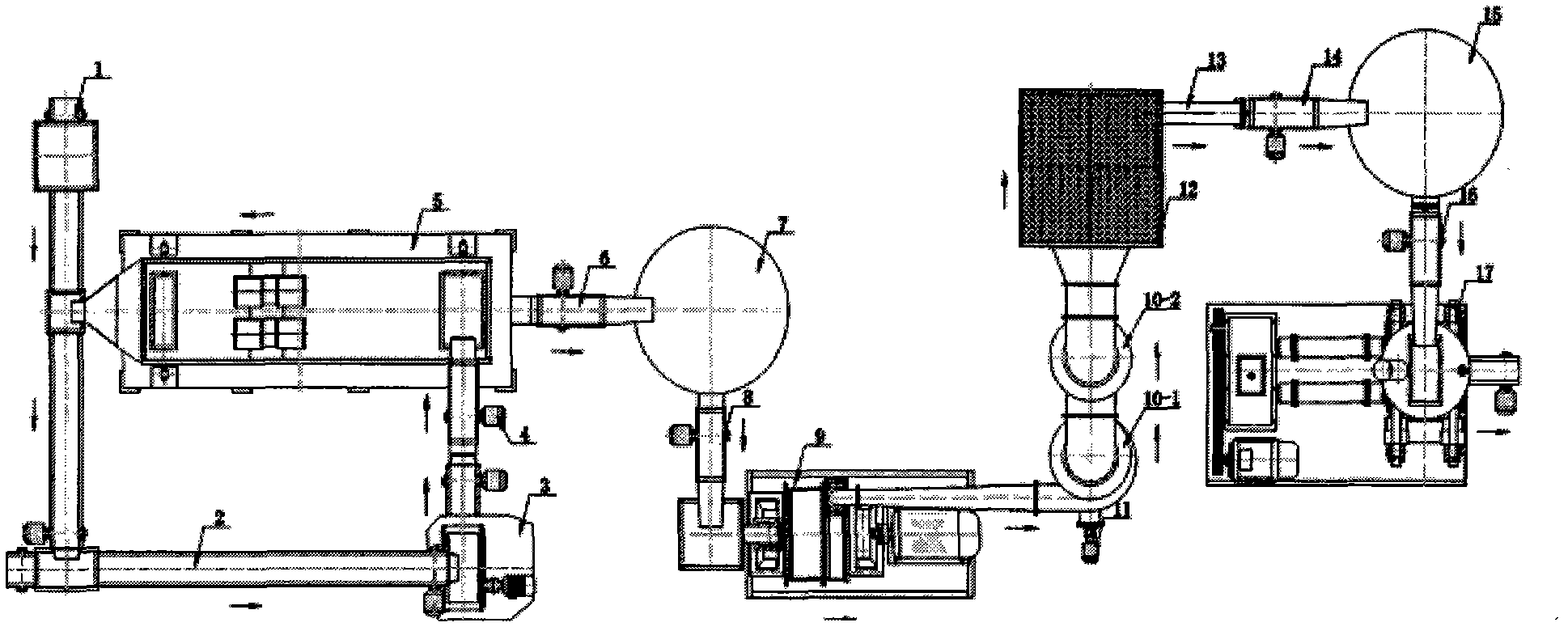

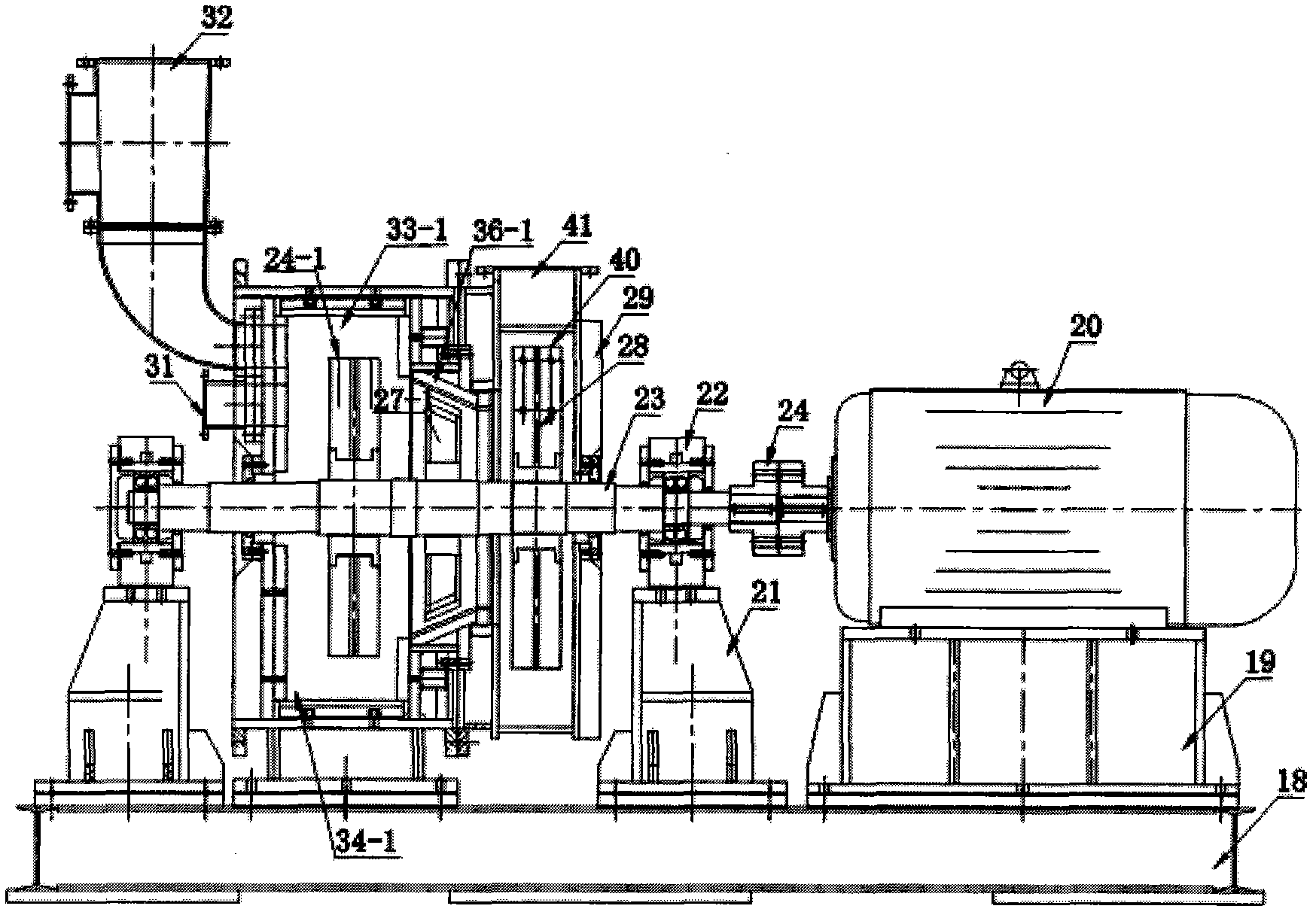

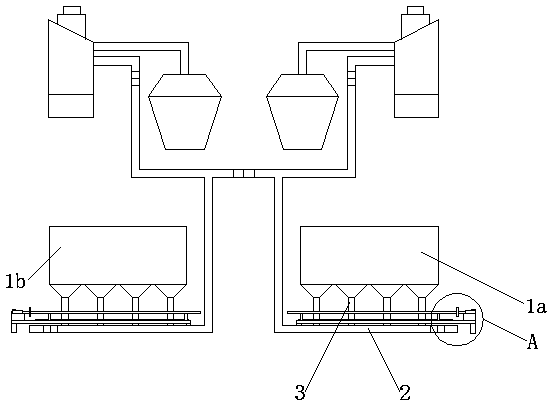

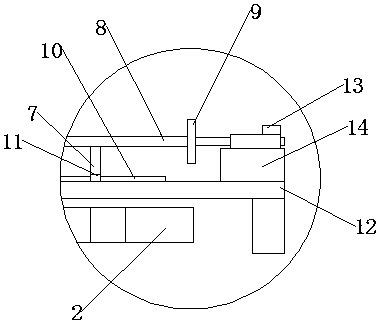

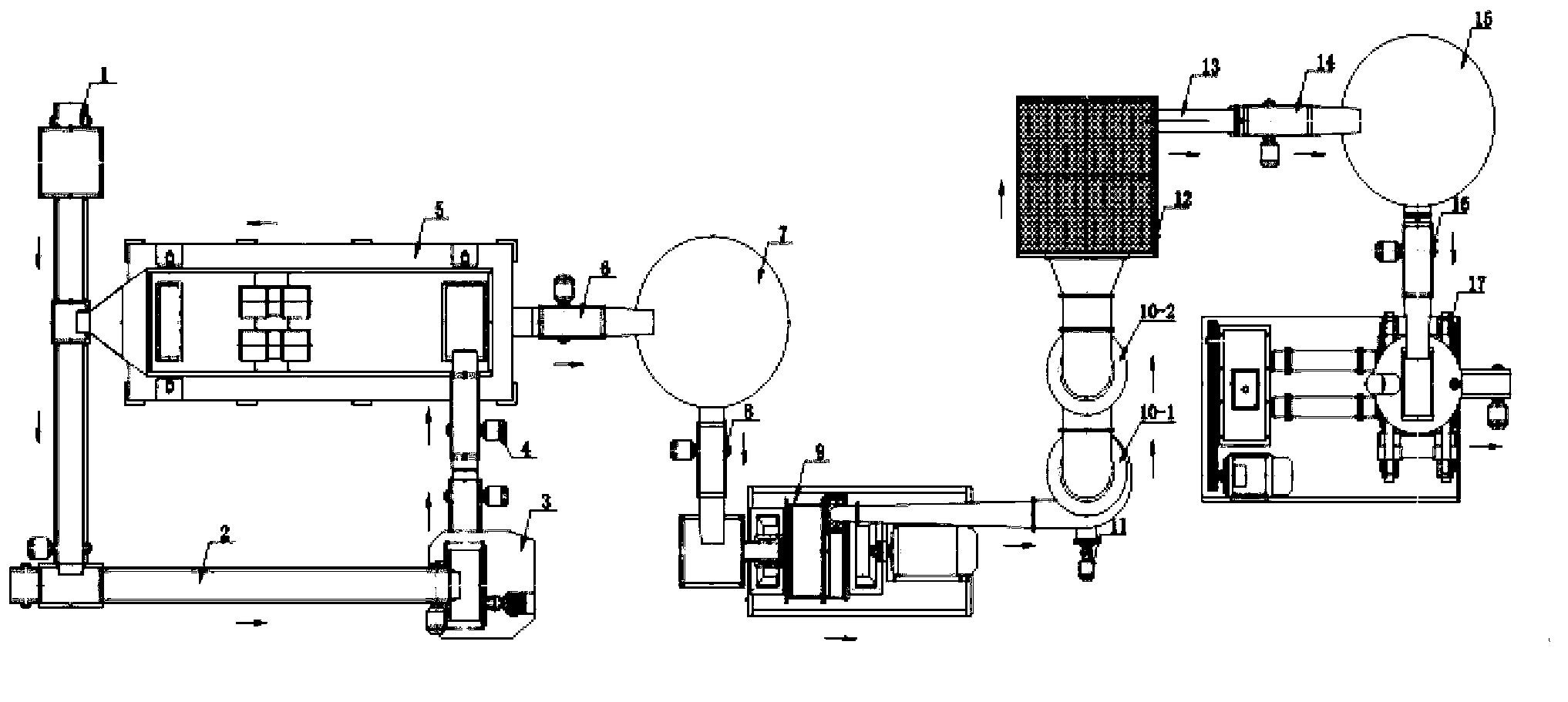

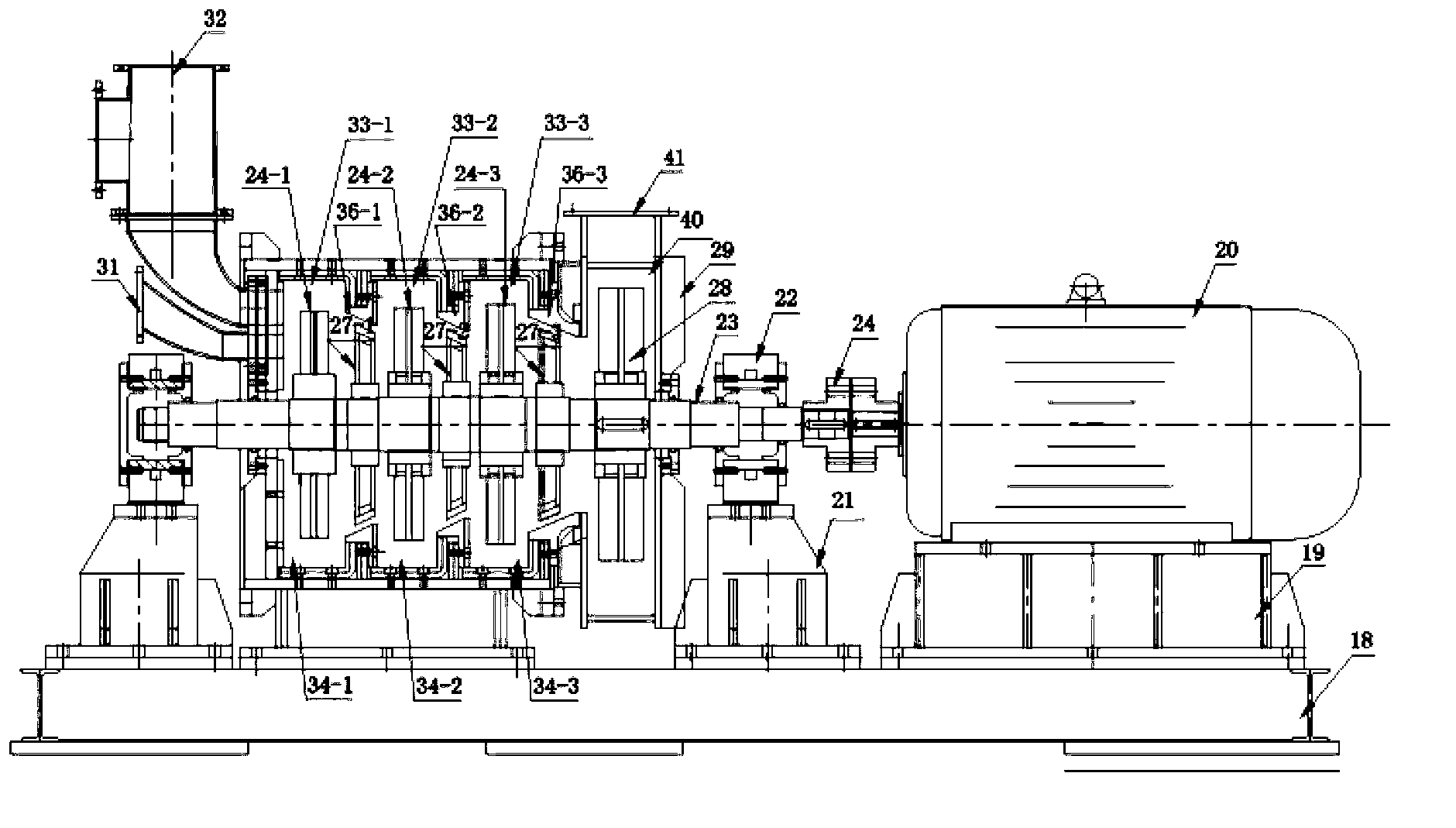

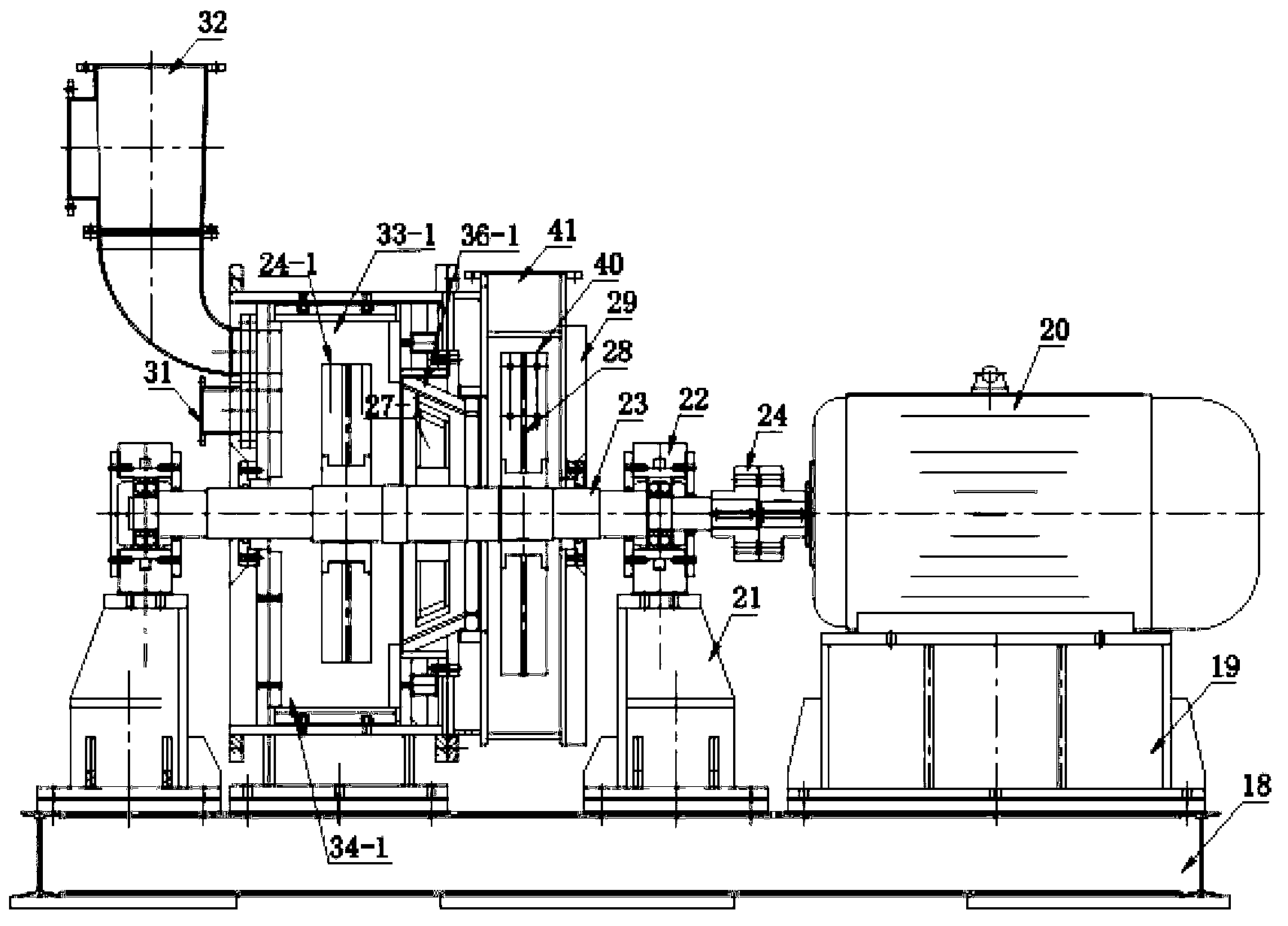

Industrial automation production equipment and production method used for lignite fine-drying and quality-improving moulding

InactiveCN102585954AReduce moisture contentHigh calorific valueSolid fuelsSpontaneous combustionBriquette

The invention relates to industrial automation production equipment and a production method which are used for lignite-drying and quality-improving moulding. The industrial automation production equipment mainly comprises a belt deironing conveyor, a belt conveyor, a coarse grinding machine, a classifying screen, a hoisting machine, main equipment 1-3-stage fine drying machine, a wet-type separating and aggregating device and a dust-removing purifying chamber, wherein a fine lignite dry powder storage silo and a moulding machine are successively arranged and connected in a technological process; and the lignite is converted into briquette, wherein the original all water of lignite is reduced to less than 10wt% from less than 65wt% by virtue of the 1-3-stage fine drying machine, hydrophilicity which is smooth outside and coarse inside and is compact outside and loose inside is changed into hydrophobicity, and surface property is converted into the property similar to excellent bituminite. The equipment provided by the invention has unique and novel structure, high drying efficiency and low cost; a product is difficult to absorb water, spontaneous combustion and heat value are greatly improved, and the problems of weathering, spontaneous combustion, transportation, storage, great investment and high cost are comprehensively solved. The equipment and method provided by the invention can be widely applied to lignite dehydration moulding in power plants at home and aboard and other boilers, and the equipment provided by the invention is dehydration drying and quality improving technical equipment of a new generation.

Owner:何永峰

Method and device for passivating, cooling, destructively distilling and pyrolyzing anthracite coal

ActiveCN107841360APrevent spontaneous combustionFor long-term storageSolid fuelsSpontaneous combustionCombustible gas

The invention provides a method and a device for passivating, cooling, destructively distilling and pyrolyzing anthracite coal. According to the method provided by the invention, medium-temperature passivated anthracite coal is initiatively subjected to temperature-raising passivation and the content of combustible gas and volatile matters in micro-pores of the anthracite coal can be reduced to the greatest extent; spontaneous combustion of the anthracite coal is avoided and the anthracite coal can be stored for a long period; moreover, the moisture content of the anthracite coal prepared by the method is maintained in a range of 4 weight percent to 5.5 weight percent and is less than 6 weight percent to 12 weight percent in the prior art, so that weathering, cracking and spontaneous combustion of the anthracite coal are avoided; an effective heating mount of the anthracite coal is kept and the transportation amount of the anthracite coal is alleviated; meanwhile, the temperature of the passivated and cooled anthracite coal can be kept in a range of 25 DEG C to 45 DEG C after the method provided by the invention is used, so that the extreme temperature 60 DEG C of a coal pile of the anthracite coal is avoided and the spontaneous combustion of the anthracite coal can be further avoided.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND +1

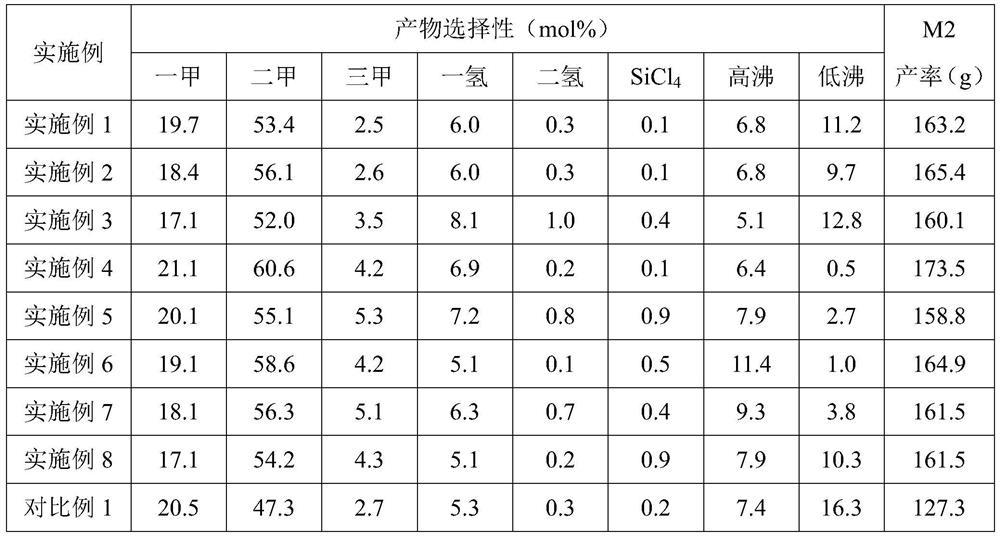

Preparation method and application of black phosphorus treated copper-based catalyst

ActiveCN112892564AEnhanced interactionImprove stabilityGroup 4/14 element organic compoundsPhysical/chemical process catalystsSpontaneous combustionPtru catalyst

The invention discloses a preparation method of a black phosphorus treated copper-based catalyst and application of the black phosphorus treated copper-based catalyst in a reaction for synthesizing methyl chlorosilane by a direct method. According to the invention, a black phosphorus precursor is added into a copper-based catalyst, and a new species phosphide is introduced through the phosphating effect of black phosphorus on the surface of a copper species. The activity test result shows that the formation of the species can effectively improve the selectivity and yield of the target product dimethyl dichlorosilane. The treatment mode is simple to operate, wastewater difficult to treat is not generated in the preparation process, the method is very suitable for large-scale preparation of industrial catalysts, and good economic benefits can be generated. In addition, the black phosphorus crystal is stable, is not prone to spontaneous combustion, is suitable for large-scale industrial application, and can greatly improve the safety of enterprise production.

Owner:深圳市中科墨磷科技有限公司 +1

ABS material for packaging and preparation method thereof

The invention discloses an ABS material for packaging and a preparation method thereof, and relates to the technical field of ABS materials. The material comprises the following components in parts byweight: 45-55 parts of an acrylonitrile-butadiene-styrene copolymer, 20-24 parts of vinyl acetate, 10-12 parts of ethylene, 3-5 parts of 1,2-bis(pentabromophenyl) ethane, 4-6 parts of glass fiber, 7-9 parts of magnesium hydroxide, 12-18 parts of tackifying resin, 6-10 parts of mullite powder, 5-7 parts of white carbon black, and 3-8 parts of a mixed solution. The ABS material of the scheme has excellent flame retardant properties and high-temperature resistance.

Owner:南京德荣包装制品有限公司

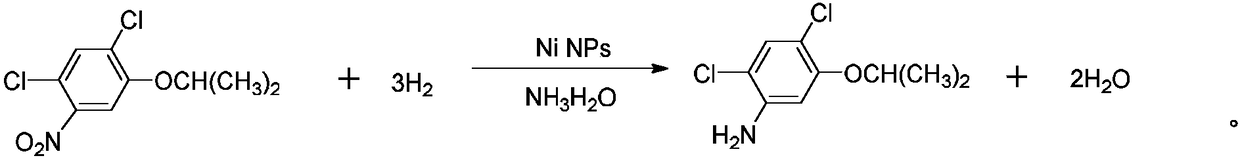

Synthesis method for 2, 4-dichloro-5-isopropoxyaniline

InactiveCN109336775ALow costNot easy to be poisonedOrganic compound preparationChemical recyclingNano catalystHydrogen

The invention discloses a synthesis method for 2, 4-dichloro-5-isopropoxyaniline. The method comprises the following steps: feeding an auxiliary agent and a catalyst into a reaction kettle, so as to obtain first mixed liquor; feeding an organic solvent and an original compound into the first mixed liquor, and feeding hydrogen into the reaction kettle, so as to ensure that the original compound performs reduction reaction in the condition of the existence of the organic solvent, the auxiliary agent and the catalyst and obtain a reaction product; removing the catalyst and solvent of the reactionproduct, so as to obtain the 2, 4-dichloro-5-isopropoxyaniline. The catalyst adopts a nano-catalyst. The method simplifies synthesis steps of the 2, 4-dichloro-5-isopropoxyaniline, reduces the cost and the recycling difficulty of the catalyst, and meanwhile avoids ricks in traditional technical processes.

Owner:ANHUI RES INST OF CHEM IND

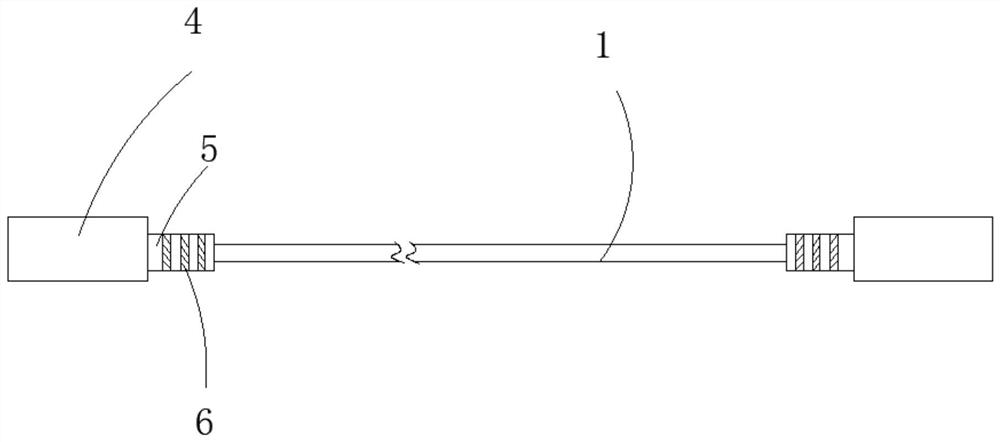

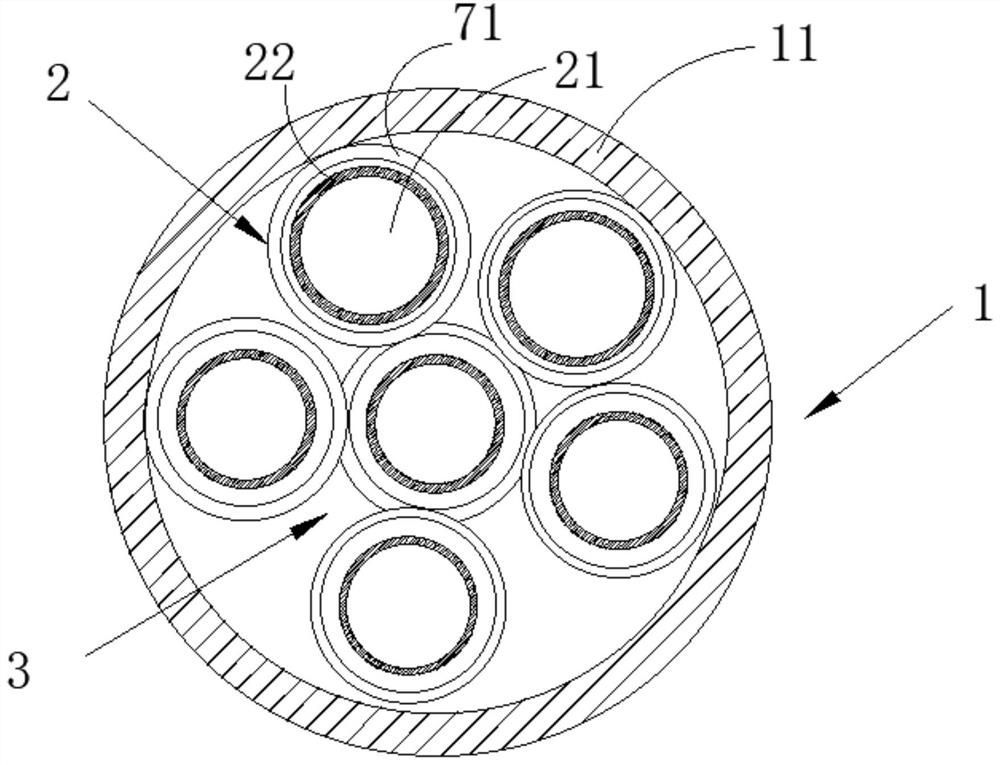

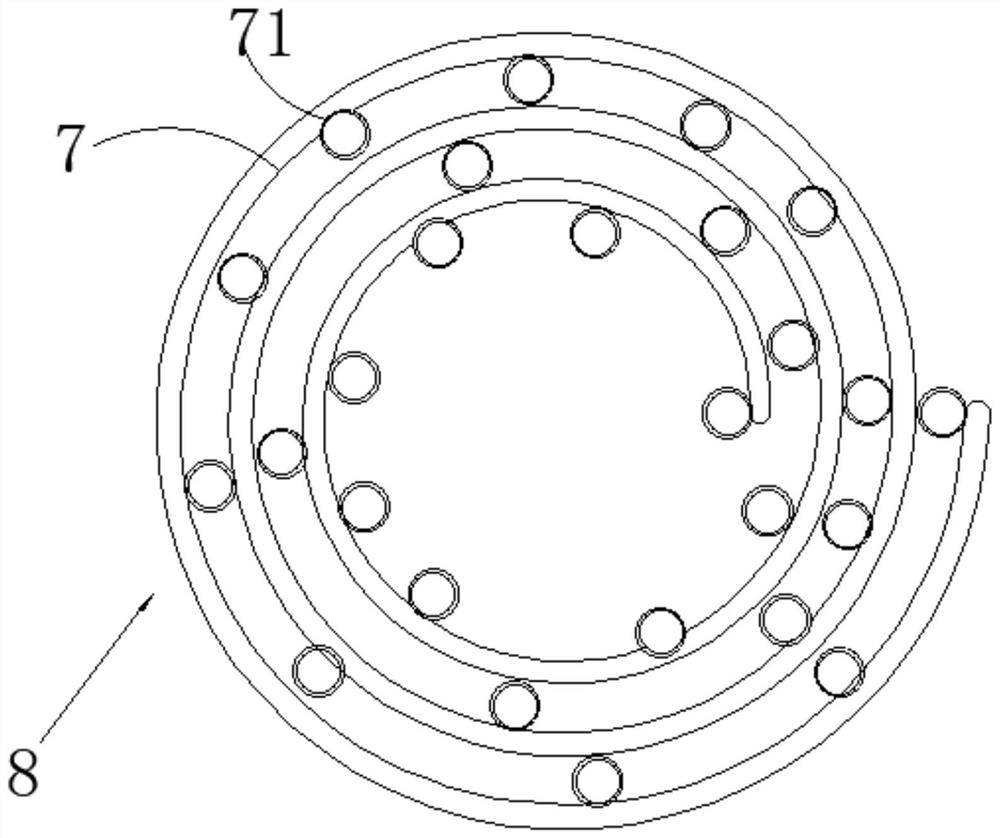

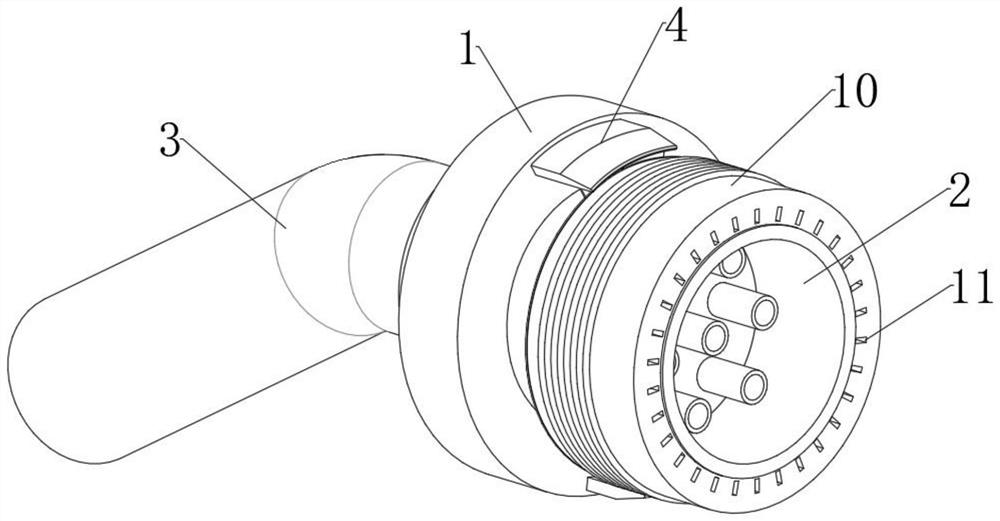

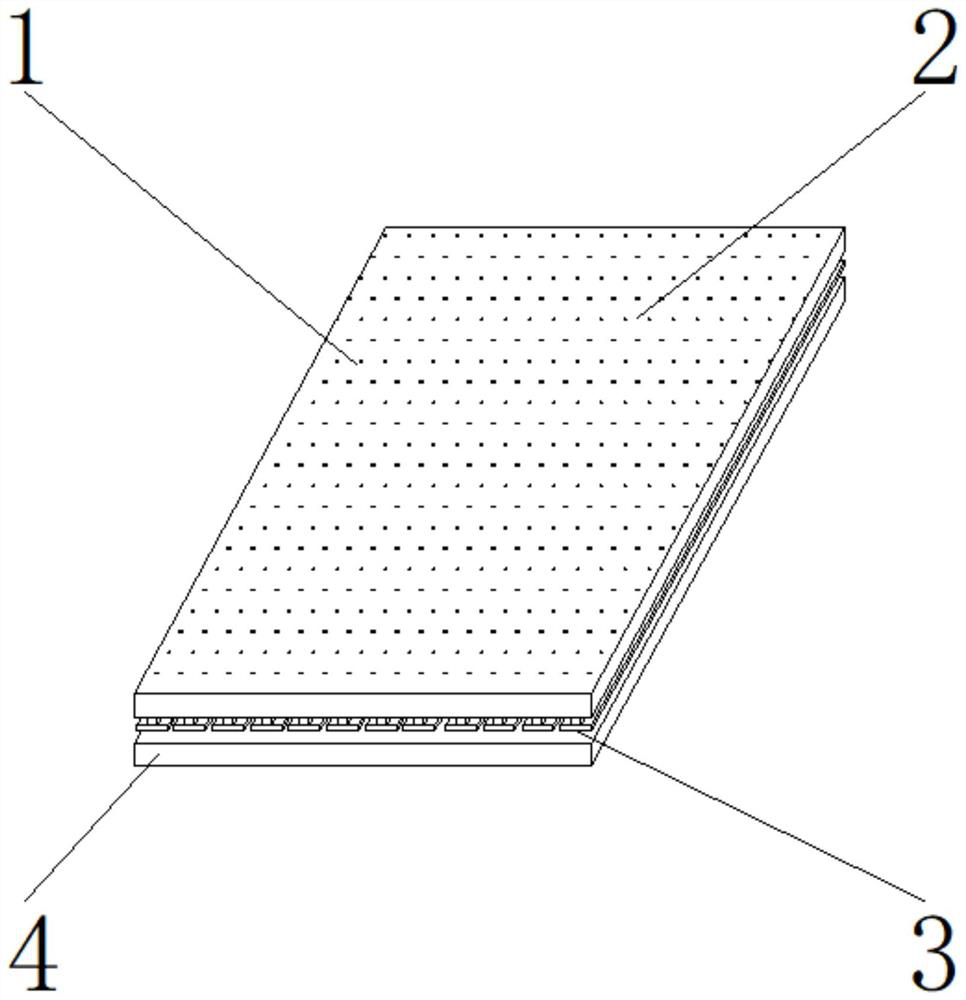

Fireproof and waterproof cable assembly

PendingCN112086235ANot prone to spontaneous combustionPrevent spontaneous combustionClimate change adaptationInsulated cablesSpontaneous combustionElectrical conductor

The invention provides a fireproof and waterproof cable assembly, which comprises a cable joint and a cable body detachably connected with the cable joint, and is characterized in that two ends of thecable body are connected with the cable joint; and the cable body comprises an insulating layer, a central cable wrapped by the insulating layer, and a plurality of peripheral cables surrounding thecentral cable. Each of the central cable and the plurality of peripheral cables comprises a central conductor and an insulating waterproof layer wrapping the central conductor. The insulating waterproof layer is provided with a heat dissipation piece, the heat dissipation piece comprises an elastic isolation piece which is in a spiral ascending shape, the isolation piece is provided with a plurality of supporting pieces at intervals in the spiral ascending direction, and the central cable and the peripheral cables penetrate through the supporting pieces. The technical problem that when heat ofan insulating layer is accumulated to the melting point of the insulating layer, spontaneous combustion occurs, and adjacent cables are further ignited is solved.

Owner:广东澳通特种电缆有限公司

A mixed-material lignite drying and upgrading method and the device used therein

InactiveCN105331417BReduce moistureReduce the temperatureDrying solid materials with heatHearth type furnacesSpontaneous combustionBrown coal

The invention provides a mixing type brown coal drying and upgrading method and a used device. The method includes the steps that raw brown coal is crushed through a crushing device and then sent to a screening device to be screen, screened lump coal with the particle size being over 5-8 mm is sent to a drying device and dried at the temperature of 150-350 DEG C, so that the moisture in the brown coal is lowered to below 5%-10%, dried hot brown coal with the temperature being 50-150 DEG C is sent to a cooing device to be cooled, and the temperature of the dry brown coal is lowered to 40-80 DEG C; the dry brown coal obtained after preliminary cooling is sent to a mixing device, the dry brown coal is mixed with and in contact with crushed raw brown coal or the screened powdered coal with the particle size being 5-8 mm according to the weight ratio of 1 to 20%-60% in the mixing device and generates heat transfer, and finally the upgraded coal with the temperature being 20-40 DEG C is obtained. According to the mixing type brown coal drying and upgrading method and the used device, the brown coal after upgrading can be directly used for being transported or piled and stored, spontaneous combustion does not occur easily, and the calorific value of the brown value is improved.

Owner:CITIC HEAVY INDUSTRIES CO LTD

A new energy charging pile with anti-spontaneous combustion interface

ActiveCN112140934BNot prone to spontaneous combustionPerfect charging serviceCharging stationsElectric vehicle charging technologyRelevant informationNew energy

The invention discloses a new energy charging pile with an anti-spontaneous combustion interface, belonging to the field of new energy charging piles, and a new energy charging pile with an anti-spontaneous combustion interface. It is not easy to cause the battery to accumulate too much heat due to charging the battery for a long time, it is not easy to cause the battery of new energy vehicles to spontaneously ignite, and it is not easy to cause serious threats to the life and property safety of new energy car owners. At the same time, through the Internet of Things technology, the charging records of new energy vehicles are synchronized On the processing terminals of different charging fields, through the shared charging data, the charging service for different car owners can be improved. At the same time, the relevant information of vehicle charging can be sent to the user's mobile terminal through the Internet of Things module, and the health report of the vehicle charging port can be sent to the car owner in time. , when the charging pile interface is frequently overheated and disconnected, it will promptly remind the owner to check the vehicle to eliminate potential safety hazards.

Owner:东莞市牛牛新能源技术有限公司

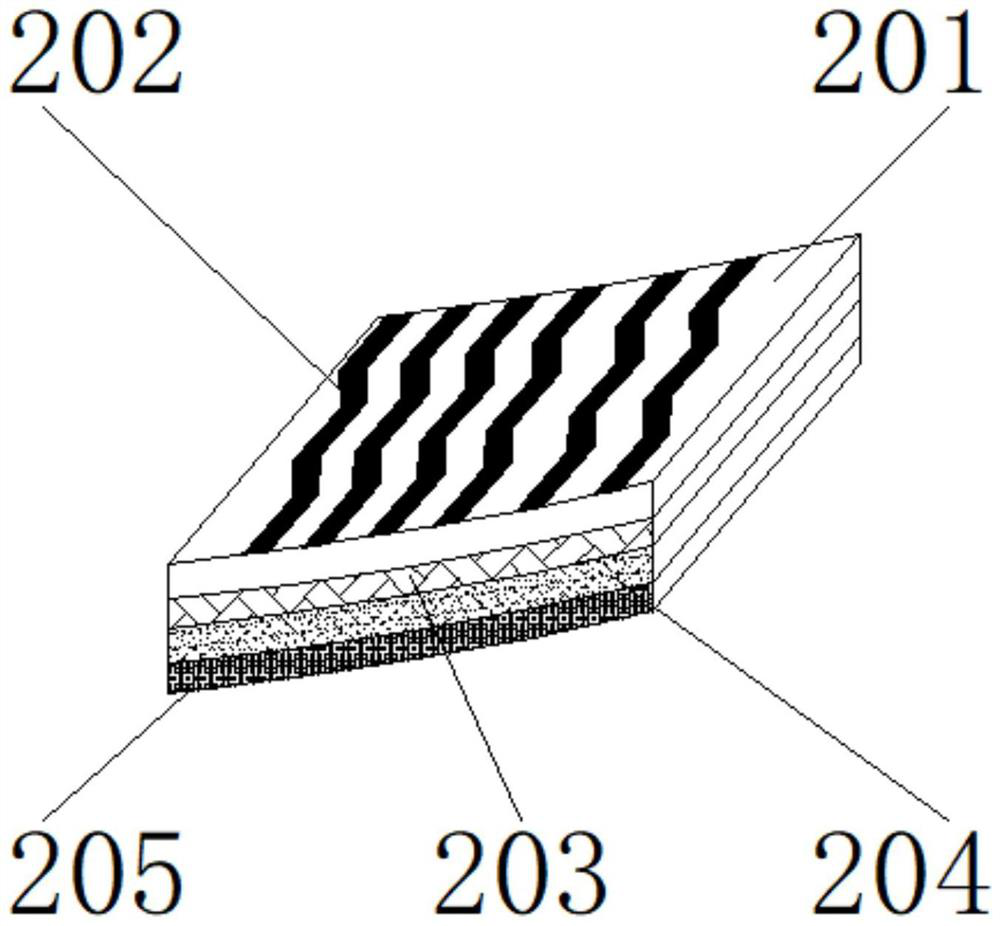

Thermoplastic elastomer material and preparation method thereof

PendingCN114311387AHigh ignition pointIncrease elasticitySynthetic resin layered productsGrain treatmentsMetal fiberElastomer

The invention discloses a thermoplastic elastomer material and a preparation method thereof, and relates to the technical field of thermoplastic elastomers, the thermoplastic elastomer material comprises a main body, the outer surface of the upper end of the main body is provided with a flame retardant coating, the lower end of the main body is provided with an anti-static mechanism, and the lower end of the anti-static mechanism is provided with a protection device. Under the combined action of the colloid, the liquid flame retardant, the solid flame retardant, the accelerant and the styrene coating, the thermoplastic elastomer can have good flame retardance and elasticity, and the liquid flame retardant and the solid flame retardant are added to the surface of the elastomer material, so that the thermoplastic elastomer is not prone to spontaneous combustion; under the combined action of the carbon black coating, the chopped conductive fiber coating, the conductive mica powder coating, the thin film and the polyurethane coating, the antistatic capacity of the elastomer material can be improved, the arranged chopped conductive fiber coating contains carbon fibers and metal fibers, and the carbon fibers and the metal fibers have very low body resistance and are generally presented in a network line shape, so that the antistatic performance of the elastomer material is improved. Therefore, the current is not easy to pass through the elastomer material.

Owner:无锡朴业橡塑有限公司

Rapid powder transferring device for adjacent furnace of power station boiler and using method thereof

PendingCN110195879AShorten the timeImprove powder transfer efficiencyBulk conveyorsLump/pulverulent fuel feeder/distributionPower stationMetallurgy

The invention discloses a rapid powder transferring device for an adjacent furnace of a power station boiler and a using method thereof, and belongs to the technical field of thermal power generation.The rapid powder transferring device comprises a first furnace powder bin, a second furnace powder bin and a pair of powder pumping branch pipes, and a plurality of lower powder outlet pipes which are uniformly distributed communicate between the first furnace powder bin as well as the second furnace powder bin and the pair of powder pumping branch pipes; arc-shaped through holes are formed in the right ends of the lower powder outlet pipes, movable sealing plates are inserted in the lower powder outlet pipes, and the movable sealing plates comprise plugging parts and sealing parts; the plugging parts and the sealing parts are integrally formed, the plugging parts are matched with the lower powder outlet pipes, the sealing parts are matched with the arc-shaped through holes, synchronous frames are arranged on the lower sides of the first furnace powder bin and the second furnace powder bin, and a pair of coaxial connecting rods are fixedly connected between the plurality of movable sealing plates and the inner walls of the synchronous frames; and thus, communication and blocking of the powder pumping branch pipes and the lower powder outlet pipes can be rapidly realized, the timefor mounting and dismounting a plugging blind plate is saved, and the powder transferring efficiency is improved.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Industrial automation production equipment and production method used for lignite fine-drying and quality-improving moulding

The invention relates to industrial automation production equipment and a production method which are used for lignite-drying and quality-improving moulding. The industrial automation production equipment mainly comprises a belt deironing conveyor, a belt conveyor, a coarse grinding machine, a classifying screen, a hoisting machine, main equipment 1-3-stage fine drying machine, a wet-type separating and aggregating device and a dust-removing purifying chamber, wherein a fine lignite dry powder storage silo and a moulding machine are successively arranged and connected in a technological process; and the lignite is converted into briquette, wherein the original all water of lignite is reduced to less than 10wt% from less than 65wt% by virtue of the 1-3-stage fine drying machine, hydrophilicity which is smooth outside and coarse inside and is compact outside and loose inside is changed into hydrophobicity, and surface property is converted into the property similar to excellent bituminite. The equipment provided by the invention has unique and novel structure, high drying efficiency and low cost; a product is difficult to absorb water, spontaneous combustion and heat value are greatly improved, and the problems of weathering, spontaneous combustion, transportation, storage, great investment and high cost are comprehensively solved. The equipment and method provided by the invention can be widely applied to lignite dehydration moulding in power plants at home and aboard and other boilers, and the equipment provided by the invention is dehydration drying and quality improving technical equipment of a new generation.

Owner:何永峰

Fireproof household wiring harness

PendingCN111431108AIncrease distanceNot prone to spontaneous combustionElectrical apparatusEngineeringStructural engineering

The invention provides a fireproof household wiring harness. The fireproof household wiring harness comprises a wiring fixing device and a plurality of cables which penetrate through the wiring fixingdevice and are elastically connected with the wiring fixing device, the wiring fixing devices are arranged at intervals along the length direction of the plurality of cables, and the wiring fixing devices are insulators; wherein each cable is provided with a first elastic piece of which one end is connected with the adjacent cable, and the first elastic piece is an insulator; the wiring fixing device comprises a buffer layer in sliding connection with a plurality of cables, a connecting piece is fixed on the buffer layer, and the connecting piece is in sliding connection with the buffer layer. The connecting piece is an elastic connecting piece; a sliding groove is formed in the surface, close to the cable, of the buffer layer in a sunken mode, and the end, away from the cable, of the connecting piece is slidably connected into the sliding groove. The technical problem that when one electric wire is on fire, the other electric wire close to the electric wire is ignited, so that the whole cable bundle is further ignited, and the whole cable bundle is ignited is solved.

Owner:广东澳通特种电缆有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com