Water-gas shift reaction method

A transformation reaction, water gas technology, applied in chemical instruments and methods, inorganic chemistry, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as high reaction temperature, easy spontaneous combustion of catalysts, poor start-stop stability, etc. Achieve the effect of high conversion rate at low temperature, good technical support, and non-spontaneous combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The specific steps of the method for preparing nano-zirconia provided by the present invention are as follows:

[0022] a) Dissolve the zirconium salt in water and prepare a solution, preferably at least one of zirconium nitrate, zirconyl nitrate, zirconium oxychloride and zirconium chloride;

[0023] b) Add alkali solution under stirring until the specified pH value is reached, and the end point pH value is in the range of 7-12;

[0024] c) Adjust the environment to 0~150℃, add a reflux device to let the precipitate reflux in the alkaline solution for 1~60 hours, and keep the mother liquor pH constant during the whole reflux process;

[0025] d) The precipitate is filtered, washed until no impurity ions, dried, and roasted. The drying temperature is 60-150°C, the drying time is 4 to 48 hours, the calcination temperature is 200-800°C, and the calcination time is 1-12 hours.

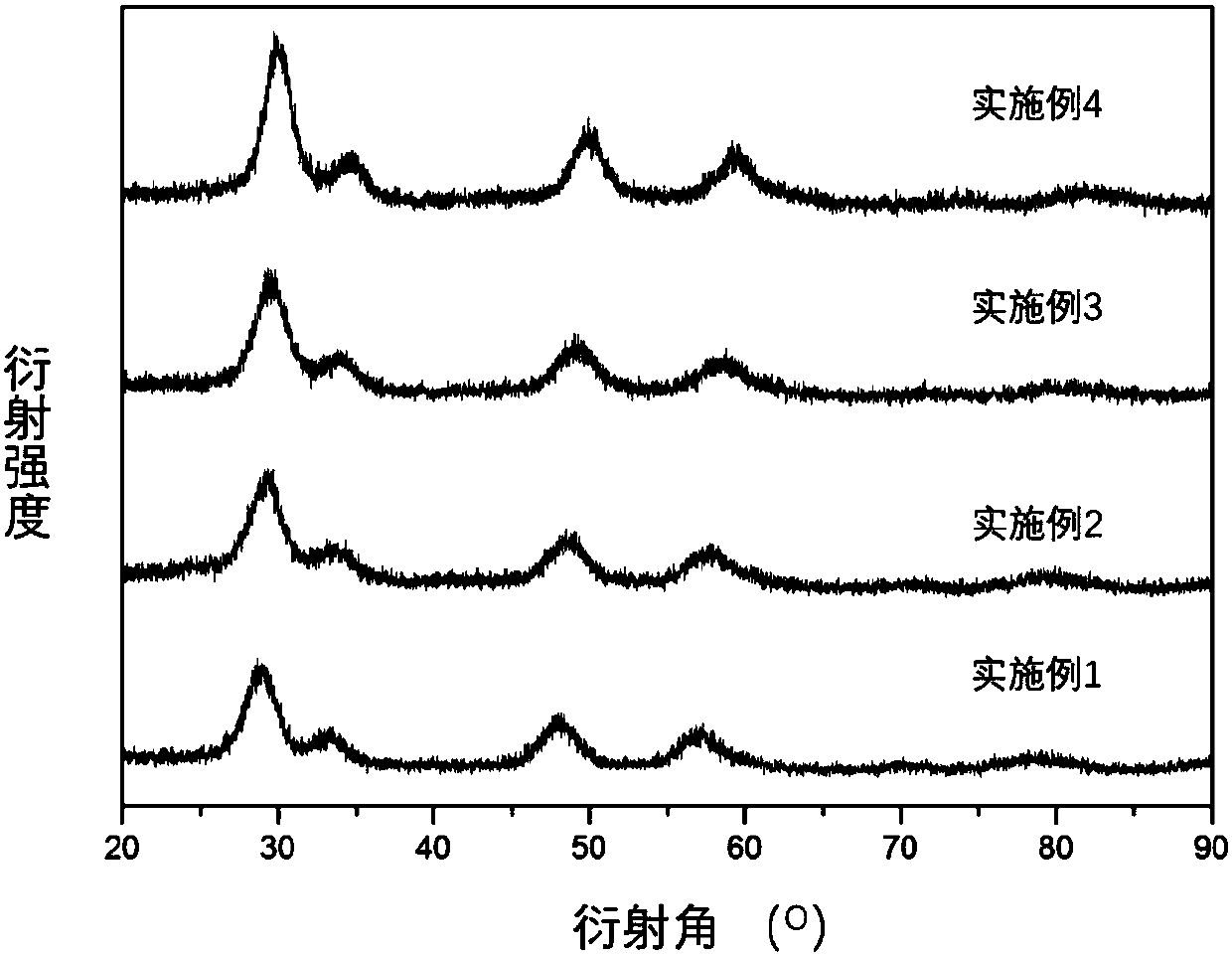

Embodiment 1~4

[0028] Dissolve zirconium nitrate, zirconium oxychloride, oxygen nitrate and zirconium chloride in deionized water to prepare 0.5mol L -1 Turn on the stirring, add concentrated ammonia water (mass fraction 37%) dropwise to pH=9 at a stirring speed of 300rpm, add a reflux device, raise the solution temperature to 100°C, and reflux for 48 hours. The precipitate is filtered and washed to be free of impurity ions, dried at 120°C, and calcined at 500°C for 4 hours to obtain nano-zirconia. Its structural characterization is shown in Table 1.

Embodiment 5~6

[0030] Dissolve zirconium oxychloride in deionized water and prepare 0.5mol L -1 Solution, turn on the stirring, add NaOH(2mol L -1 ) And KOH (2mol L -1 ) When the solution reaches pH=9, add a reflux device, raise the temperature of the solution to 100°C, and reflux for 48 hours. The precipitate is filtered and washed to be free of impurity ions, dried at 120°C, and calcined at 500°C for 4 hours to obtain nano-zirconia. Its structural characterization is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com