Method of testing coal spontaneous combustion tendentiousness by water bath heat insulation

A coal spontaneous combustion and tendency technology, applied in the direction of material thermal development, to achieve the effect of unified classification standard, simple principle and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

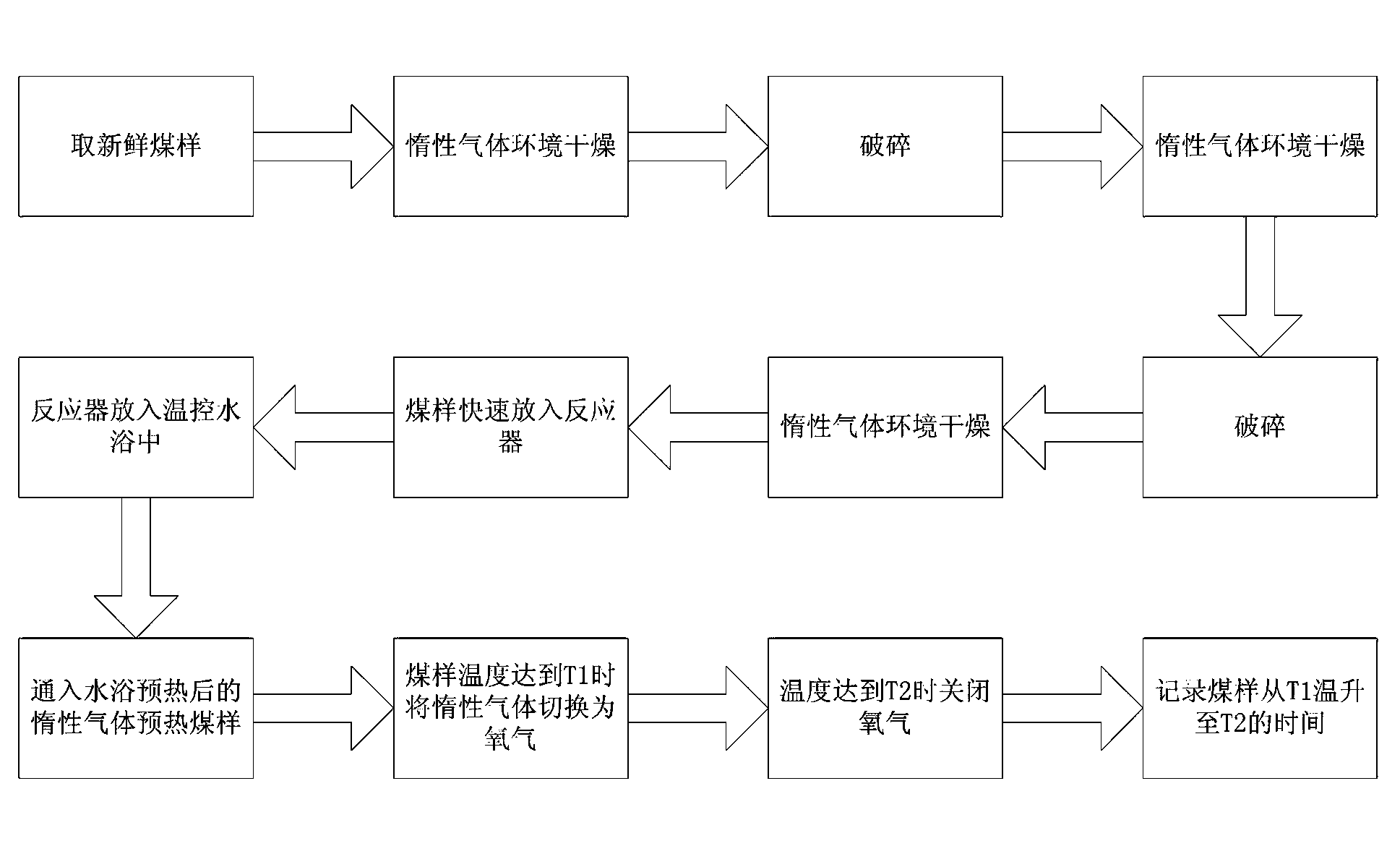

[0015] like figure 1 Shown, the method for water-bath adiabatic test coal spontaneous combustion tendency of the present invention, its flow process is:

[0016] (1) Collect coal samples. In a preferred embodiment, freshly mined coal samples should be taken to ensure that the initial conditions of each coal sample remain the same to the greatest extent possible, and also to ensure that the coal samples are not considered oxidized.

[0017] (2) Sample preparation and drying. The conventional sample preparation method is used to crush the coal samples successively, so that the particle size of each coal sample can be similar. The coal sample obtained from the sample preparation is dried under an inert gas environment to prevent the coal sample from being oxidized during the drying process.

[0018] (3) stake out. The dried coal sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com