Thermoplastic elastomer material and preparation method thereof

A thermoplastic elastomer and modification technology, applied in the field of thermoplastic elastomer materials and their preparation, can solve the problems of weak antistatic ability, poor flame retardancy and elasticity, etc. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

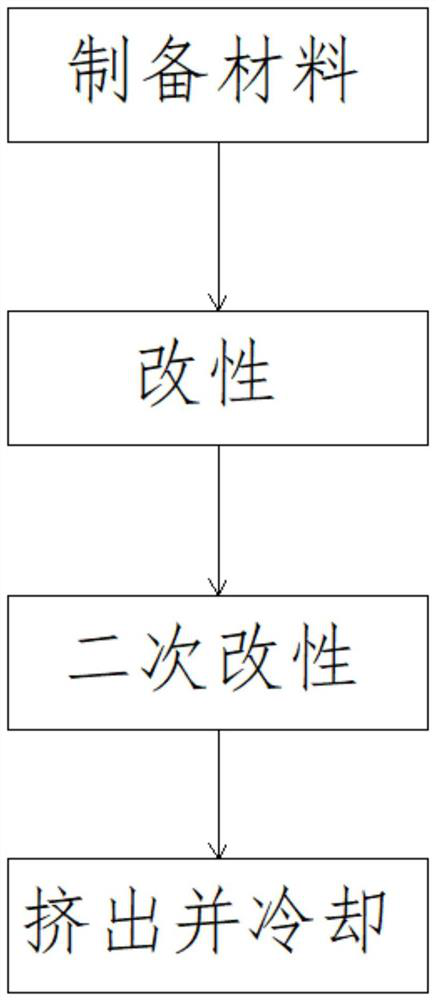

[0031] First aspect, such as Figure 1-5 As shown, the present invention provides a preparation method of a thermoplastic elastomer material, comprising the following steps: Step 1: Prepare the material: cut the rubber into small pieces, wash and treat it for 3 minutes, and then pulverize it by an ultrafine pulverizer, Pass through a 800 mesh sieve to prepare rubber powder.

[0032] Step 2: Modification: Take the polyolefin resin and add it to the mixing equipment at a temperature of 100-200 ° C, and fully melt it; take the rubber powder, polyethylene and polyolefin resin and mix them evenly according to the ratio of 40:40:3, add the mixing In the refining equipment, modification is carried out, wherein the modification temperature is 110°C, and the modification time is usually 15 minutes to obtain modified rubber powder.

[0033] Step 3: Secondary modification: Mix the modified rubber powder, catalyst and cross-linking agent in a ratio of 10:2:1, and then microwave for 16 mi...

Embodiment 2

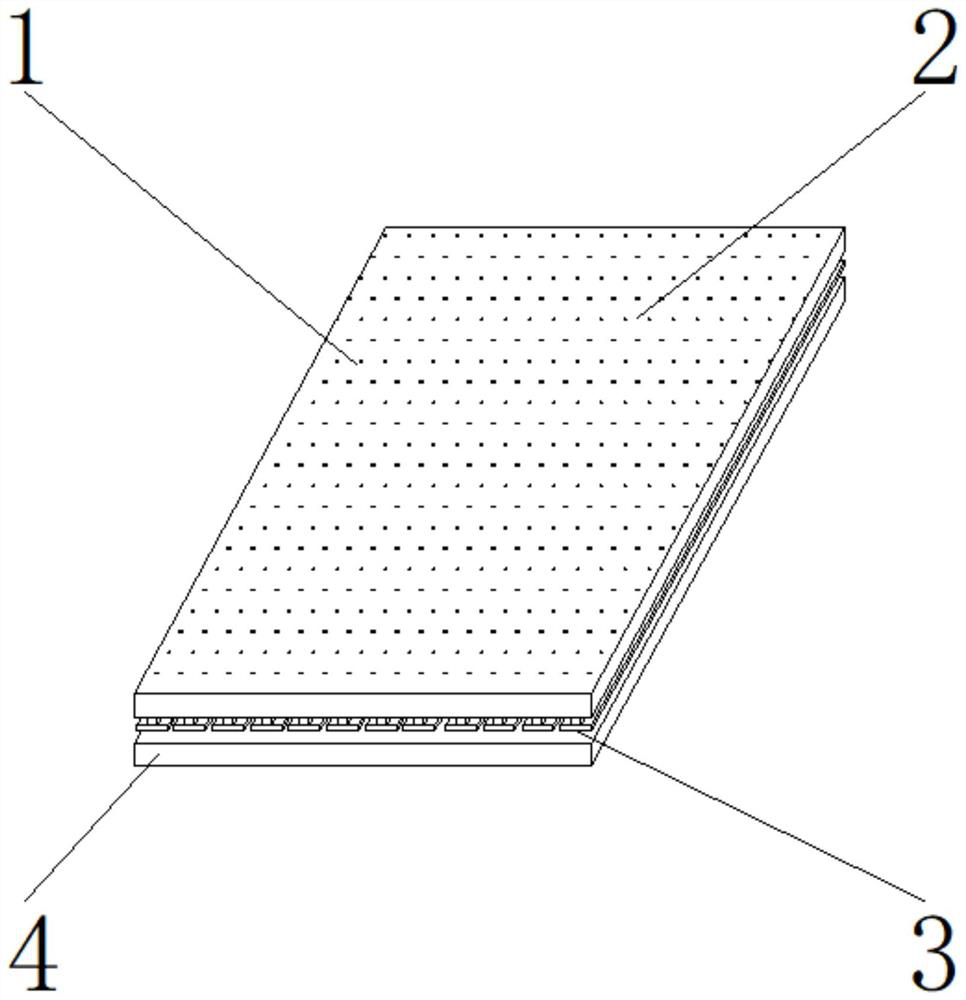

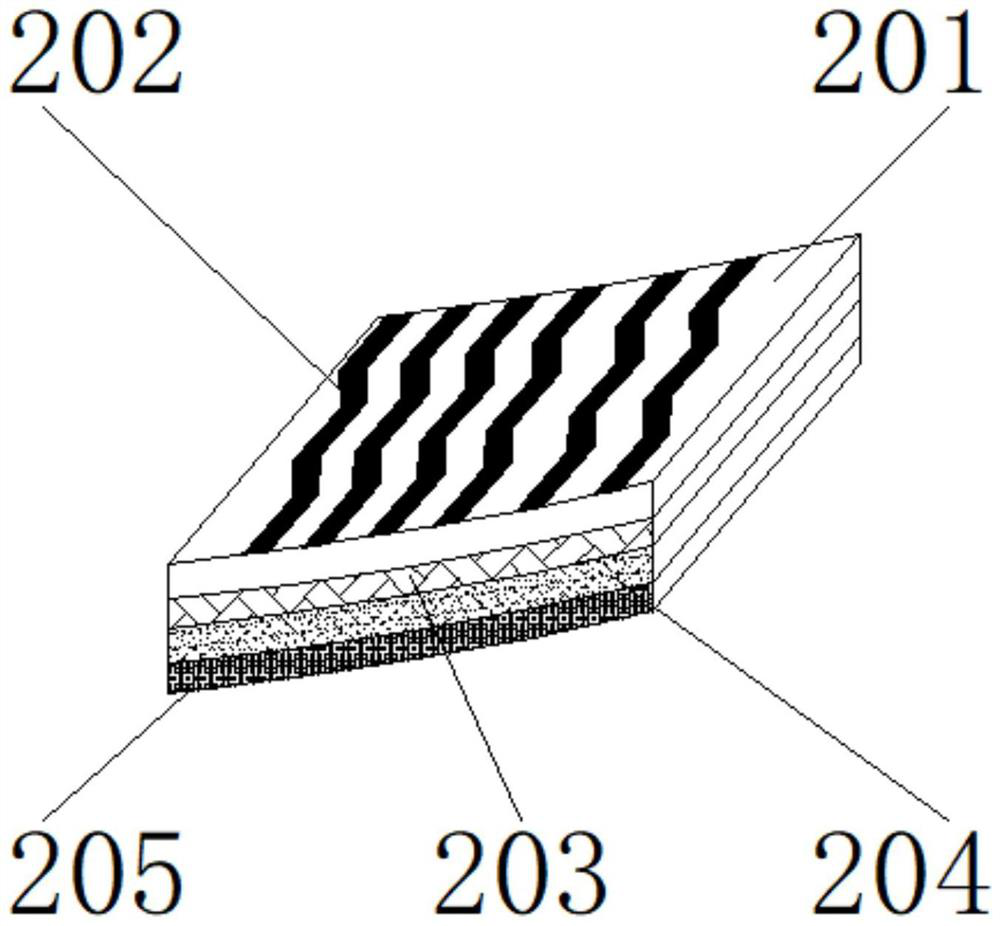

[0036] Second aspect, such as Figure 1-5 As shown, the present invention provides a thermoplastic elastomer material, comprising a main body 1, a flame retardant coating 2 is provided on the outer surface of the upper end of the main body 1, an antistatic mechanism 3 is provided at the lower end of the main body 1, and an antistatic mechanism 3 is provided at the lower end of the main body 1. Protective device 4 is arranged; Flame retardant coating 2 comprises colloid 201, liquid flame retardant 202, solid flame retardant 203, accelerator 204, styrene coating 205, and liquid flame retardant 202 is positioned at the upper end outer surface of colloid 201, solid The flame retardant 203 is located at the lower end of the colloid 201; the upper end of the colloid 201 is fixedly connected with the lower end of the liquid flame retardant 202; There is a flame retardant coating 2, the lower end of the main body 1 is provided with an antistatic mechanism 3, the lower end of the antis...

Embodiment 3

[0039] Such as Figure 1-5 As shown, on the basis of Example 2, the present invention provides a technical solution: preferably, the antistatic mechanism 3 includes a carbon black coating 301, a chopped conductive fiber coating 302, a conductive mica powder coating 303, and a film 304 , polyurethane coating 305, chopped conductive fiber coating 302 is positioned at the upper end of carbon black coating 301, and conductive mica powder coating 303 is positioned at the upper end of chopped conductive fiber coating 302, and polyurethane coating 305 is positioned at the top of carbon black coating 301 The lower end, the film 304 is located at the lower end of the polyurethane coating 305, a fixing glue is arranged between the carbon black coating 301 and the polyurethane coating 305, and the upper end of the carbon black coating 301 is fixedly connected with the upper end of the polyurethane coating 305 through the fixing glue, short Superglue is arranged between the cut conductive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com