Methanation catalyst, preparation method and application thereof

A methanation catalyst, a catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of no hydrogenation reaction, difficulty, etc., Achieve the effects of good low temperature methanation performance, high mechanical strength and low alkali consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

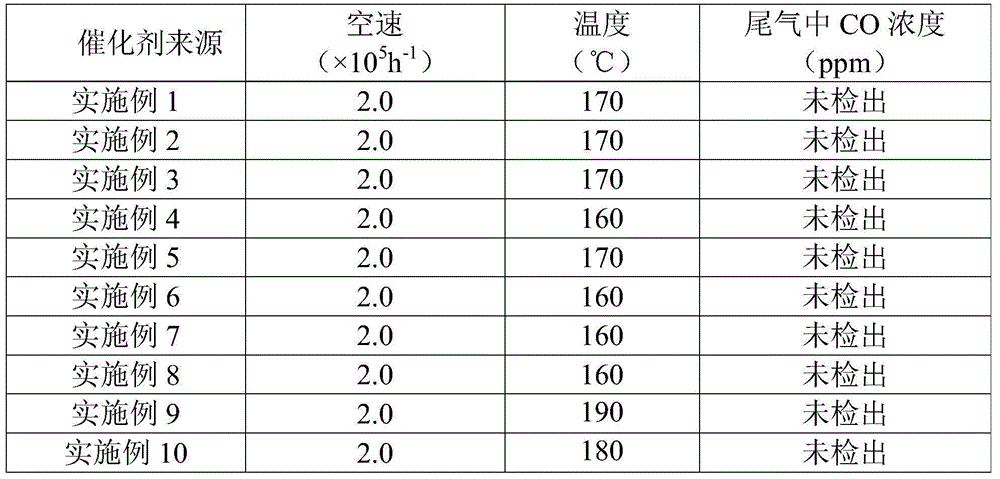

Examples

preparation example Construction

[0013] The invention provides a method for preparing a methanation catalyst, wherein the method comprises: contacting nickel aluminum alloy with alkali in water.

[0014] According to the method of the present invention, in order to further improve the mechanical strength and catalytic performance of the catalyst, it is more preferable that the nickel-aluminum alloy is an amorphous nickel-aluminum alloy.

[0015] According to the preparation method of the present invention, the optional range of the type of the base is wide, in order to further improve the mechanical strength and catalytic performance of the catalyst, preferably the base is an alkali metal hydroxide, more preferably sodium hydroxide and / or Or potassium hydroxide, more preferably sodium hydroxide.

[0016] According to the preparation method of the present invention, the form of the nickel-aluminum alloy can be selected in a wide range. In order to further improve the mechanical strength and catalytic performan...

Embodiment approach

[0022] According to a preferred embodiment of the present invention, the alkali is provided as an alkali solution, and the step of contacting the nickel aluminum alloy with the alkali in water includes:

[0023] The nickel aluminum alloy is mixed with deionized water, and then the alkali solution is added for the contacting.

[0024] According to the preparation method of the present invention, in order to further improve the mechanical strength and catalytic performance of the catalyst, the volume ratio of deionized water to the nickel-aluminum alloy is preferably 6-12:1, preferably 8-10:1.

[0025] According to the preparation method of the present invention, in order to further improve the mechanical strength and catalytic performance of the catalyst, the concentration of the alkali solution is preferably 10-50% by weight, preferably 20-50% by weight.

[0026] According to the preparation method of the present invention, in order to further improve the mechanical strength a...

Embodiment 1

[0040] Add 50 grams of nickel and 50 grams of aluminum into the quartz tube, heat it in a high-frequency furnace until it melts, and alloy it;

[0041] Use an inert gas to spray the alloy liquid from the nozzle under the quartz tube to the copper roller with a rotation speed of 1000 rpm. Cooling water is passed through the copper roller, and the alloy liquid is rapidly cooled (cooling rate is 1500°C / S) The copper roller is thrown out tangentially to form a scale-shaped strip, and the prepared scale-shaped strip is ground into a granular form through a ball mill and sieved to obtain a certain number of catalyst precursors (60-120 mesh);

[0042] Take 20g of catalyst precursor and quantitative deionized water (the volume ratio of deionized water to catalyst precursor is 8:1) and place in a three-necked flask, stir and mix evenly, then slowly add 25% by weight of hydrogen under stirring Sodium oxide aqueous solution (addition rate is 0.042g / (min·20g nickel-aluminum alloy)) is act...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com