Efficient drying and quality-improving device and method for brown coal

A lignite and drying technology, applied in the petroleum industry, solid fuel, fuel and other directions, can solve the problems of unreasonable overall structure design, poor lignite quality improvement effect, increased transportation cost, etc. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0028] Example.

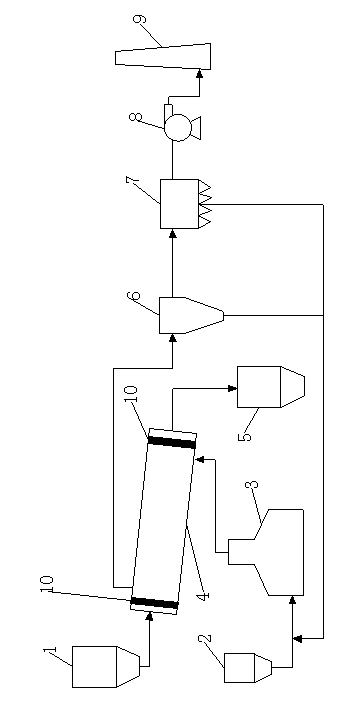

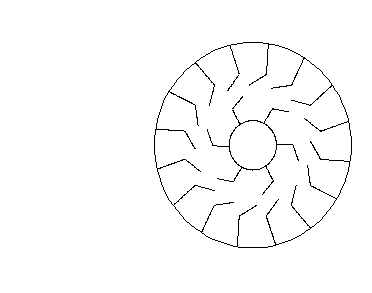

[0029] see Figure 1 to Figure 2 , the lignite efficient drying and upgrading device in this embodiment includes a coal storage bin 1, a fuel bin 2, a hot blast stove 3, a drum dryer 4, a product bin 5, a cyclone dust collector 6, an electric dust collector 7, an induced draft fan 8, The chimney 9 and several pipelines, wherein seals 10 are provided at both ends of the drum dryer 4 , and the drum dryer 4 in the present invention can be provided with a lifting plate structure.

[0030] The included angle between the axis and the horizontal plane in the drum dryer 4 in this embodiment is 3-5 degrees, so that the drum dryer 4 has an inclined structure, such as figure 1 As shown, the left end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com