Modified aluminum hypophosphate flame retardant and preparation method thereof

A technology of aluminum hypophosphite and flame retardant, applied in the field of flame retardants, can solve the problems of poor compatibility, poor dispersion, poor heat resistance of aluminum hypophosphite, etc., to reduce surface polarity, improve heat resistance, and improve reaction cycle short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

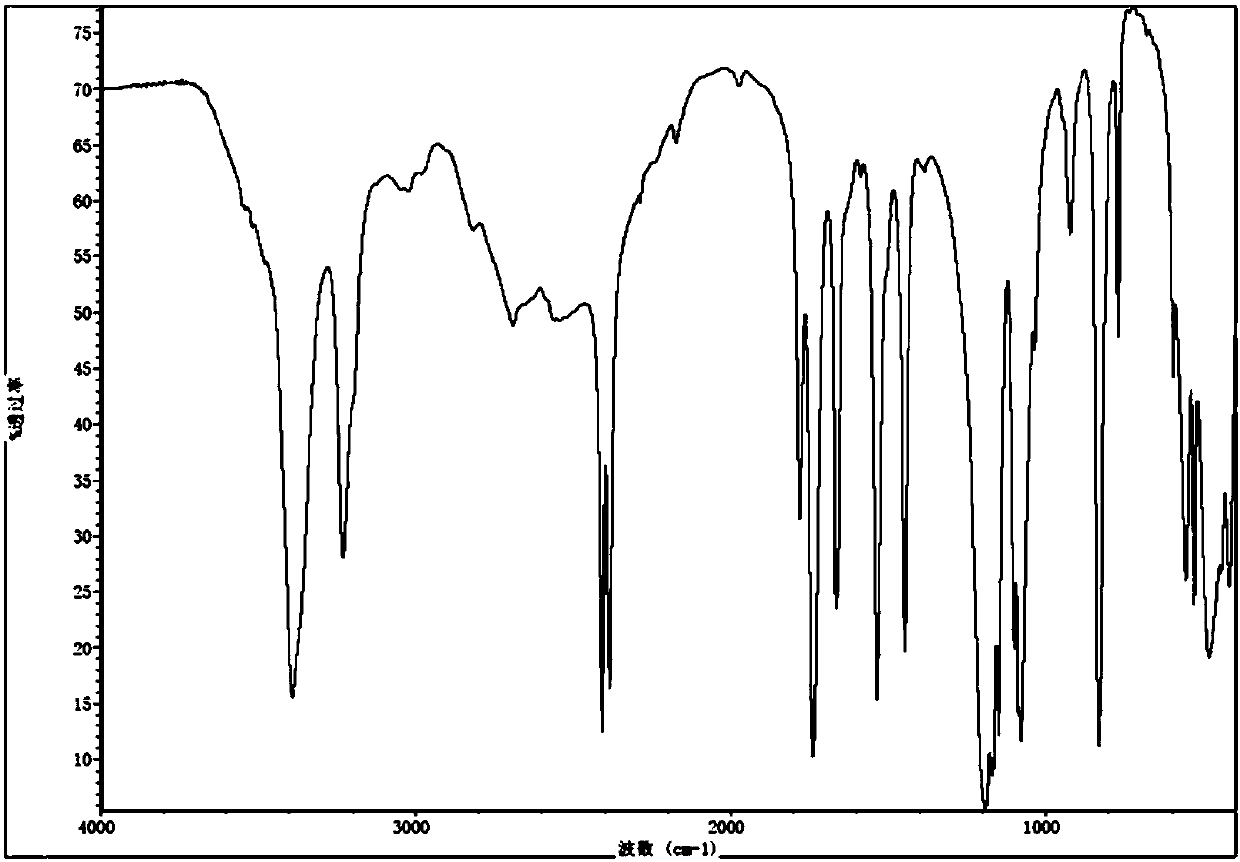

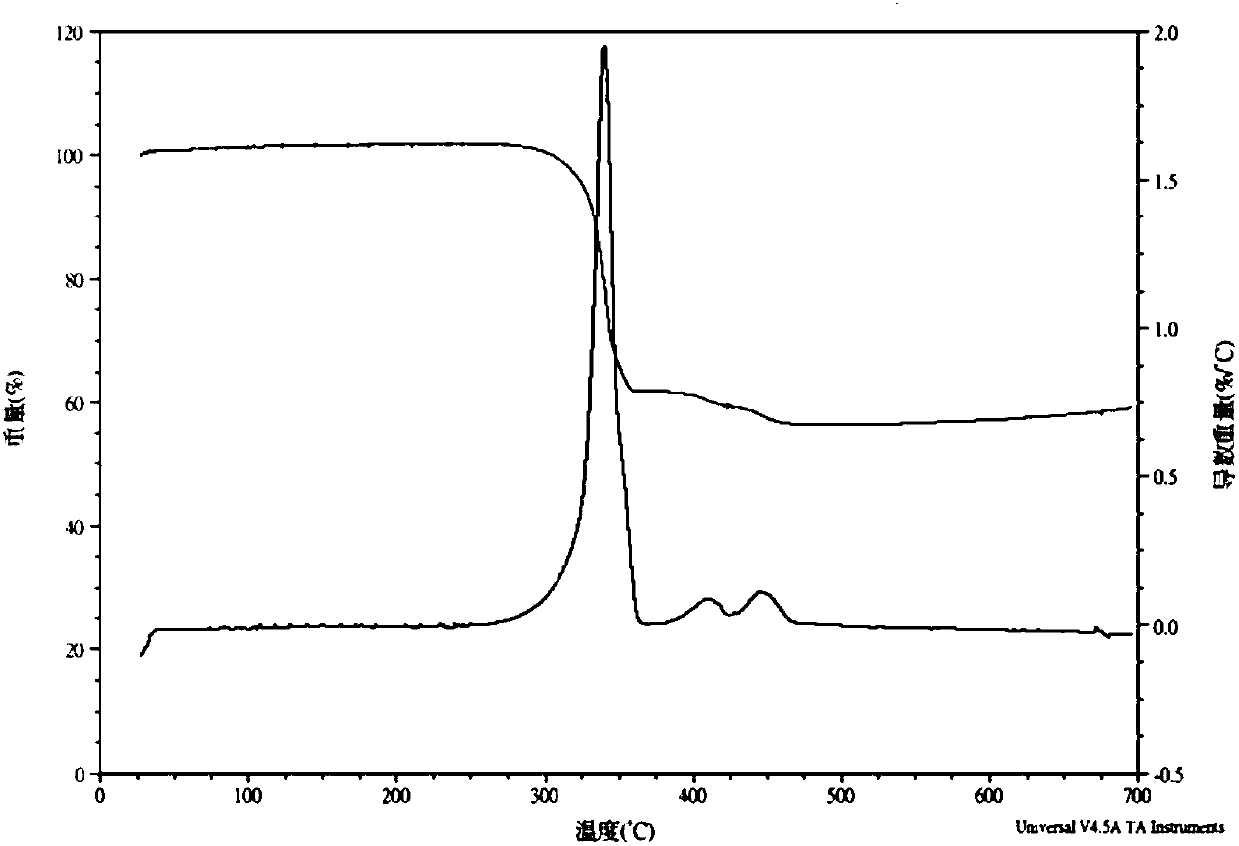

[0050] In a 200L high-pressure reactor with a stirring paddle and a reflux device, add 150L of pure water and 30kg of aluminum hypophosphite, start stirring, then add 0.5kg of sodium lauryl sulfate, stir for 1 hour, and then add 5kg of melamine cyanurate Salt, 0.3kg melamine and 0.178kg cyanuric acid, stir and heat up to 80°C, and finally add 6kg of polyacrylate dropwise, after the dropwise addition, raise the temperature to 180°C and stir for 8 hours, after the reaction, cool the solution to 40°C Perform centrifugation, wash twice with pure water, and finally place the solid obtained by centrifugation in an oven at 130°C to dry to obtain the target product modified aluminum hypophosphite 1, and the product yield is 97.88%. The modified aluminum hypophosphite infrared spectrum prepared by the present embodiment is as follows: figure 1 As shown, the thermogravimetric spectrum is shown as figure 2 shown.

Embodiment 2

[0052] In a 1000L enamel reaction kettle with stirring paddle and reflux device, add 850L pure water and 125kg aluminum hypophosphite, start stirring, then add 6.25kg citric acid, stir for 2 hours, then add 62.5kg polyphosphate melamine salt, stir Raise the temperature to 90°C, and finally add 12.5kg of modified wax. After the dropwise addition, stir and react at a constant temperature for 12 hours. After the reaction, cool the solution to 35°C for centrifugation, wash twice with pure water, and finally place the solid obtained by centrifugation. Dry in an oven at 80°C to obtain the target product, modified aluminum hypophosphite 2, with a yield of 98.5%.

Embodiment 3

[0054]In a 5L four-necked flask with a stirring paddle and a reflux device, add 3.5L of pure water and 350g of aluminum hypophosphite, start stirring, then add 9g of sodium dodecylbenzenesulfonate, stir for 0.5 hours, then add 90g of six Aminocyclotriphosphazene, stir and heat up to 60°C, and finally add 18g of epoxy resin dropwise, heat up to 85°C and stir for 10 hours after the dropwise addition, after the reaction, cool the solution to below 60°C for centrifugation, and use pure Wash twice with water, and finally place the centrifuged solid in an oven at 120°C for drying to obtain the target product, modified aluminum hypophosphite 3, with a product yield of 96.91%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com