Microencapsulated inorganic hypophosphite flame retardant and preparation method thereof

A technology of hypophosphite and microencapsulation, which is applied in the direction of microcapsule preparation and microsphere preparation, which can solve the problems of limiting commercial value and achieve the effects of improved processing performance, good compatibility and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In the reactor, add 9.0kg of inorganic aluminum hypophosphite, 0.6kg calcium stearate and 100kg of water, stir to make it uniformly dispersed, then add 0.5kg of cyanuric acid and 0.1kg of sodium carbonate, and the reaction kettle The temperature was raised to 80°C to dissolve the cyanuric acid. After 20 minutes, 0.55kg melamine and 0.1kg phenyltrichlorosilane were alternately and slowly added to the reaction kettle several times. During this process, hydrogen was oxidized dropwise. Sodium solution controls the pH of the reaction system in the range of 6-8. After the addition, raise the reaction temperature to 100°C, keep stirring at this temperature, and react for 10 hours to obtain a viscous paste, which is filtered and dried 1. After being pulverized, a powdered microencapsulated inorganic aluminum hypophosphite flame retardant product is obtained.

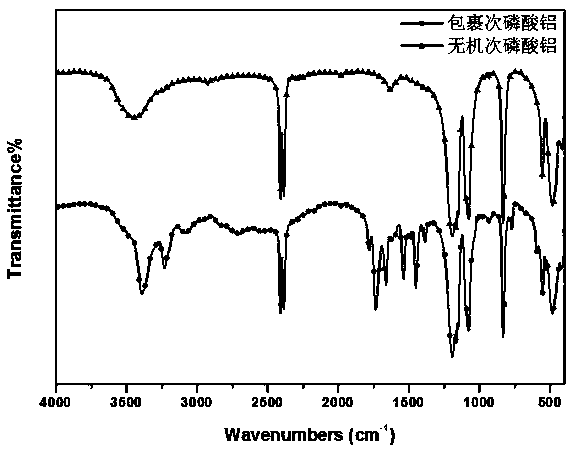

[0041] Such as figure 1 As shown, the microencapsulated inorganic aluminum hypophosphite flame retardant product ...

Embodiment 2

[0045] Add 1.2kg of phosphoric acid to the reaction kettle, preheat at 80°C for 10 minutes, then slowly add 0.4kg of pentaerythritol, raise the temperature to 120°C, start stirring, and get a light yellow viscous liquid after 4 hours of reaction, which is pentaerythritol phosphoric acid ester.

[0046] Get another reactor, add 8.0kg of inorganic aluminum hypophosphite, 0.5kg hexenylbisstearamide and 80kg of water, stir to make the inorganic aluminum hypophosphite evenly disperse, then add 0.4kg of melamine, and adjust the temperature of the reactor Raise it to 80°C to dissolve the melamine. After 20 minutes, slowly add about 1.6kg of pentaerythritol phosphate that has been successfully prepared into the reaction kettle. After the dropwise addition, raise the reaction temperature to 100°C and keep it at this temperature Stir continuously and react for 6 hours, and the viscous paste obtained is filtered, dried and pulverized to obtain a powdery microencapsulated inorganic al...

Embodiment 3

[0048] Add 8kg of inorganic magnesium hypophosphite, 0.5kg sodium tripolyphosphate and 80kg ethyl acetate in the reactor, stir to make the inorganic magnesium hypophosphite evenly disperse, then add 0.3kg cyanuric chloride and 0.2kg sodium carbonate, stir evenly, And the temperature of the reaction kettle was raised to 40°C to dissolve cyanuric chloride, and 1.7kg of tribromophenol was slowly added dropwise to the reaction kettle after 10 minutes, while sodium hydroxide solution was added dropwise to keep the pH value of the system at 6 In the range of -8, after the tribromophenol is added dropwise, the reaction temperature is raised to 70°C, kept stirring at this temperature, and reacted for 4 hours, and the viscous paste obtained is filtered, dried, and pulverized. A powdery microencapsulated inorganic magnesium hypophosphite flame retardant product was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com