Method for manufacturing neodymium iron boron magnet

A NdFeB system technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of easy reunion of fine powder, waste of resources and cost, affecting magnet performance, etc. The effect of reducing production costs and reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a preparation method of an NdFeB magnet, comprising the following steps:

[0038] A) after mixing the NdFeB fine powder and the organic additive described in any one of the above-mentioned technical solutions, obtain the NdFeB fine powder mixture;

[0039] B) after sintering the NdFeB fine powder mixture obtained in step A) and NdFeB powder, an NdFeB magnet is obtained;

[0040] The Fischer grain size of the fine NdFeB powder is less than 2.5 μm.

[0041]In the present invention, firstly, the NdFeB fine powder is mixed with the organic additive provided by the present invention to obtain the NdFeB fine powder mixture; the Fischer particle size of the NdFeB fine powder is preferably less than 2.5 μm, more preferably less than or equal to 2.3 μm, most preferably less than or equal to 2.0 μm; the Fischer particle size of the NdFeB powder is preferably 2.5-4.0 μm, more preferably 2.8-3.7 μm, most preferably 3.0-3.5 μm; the organic additi...

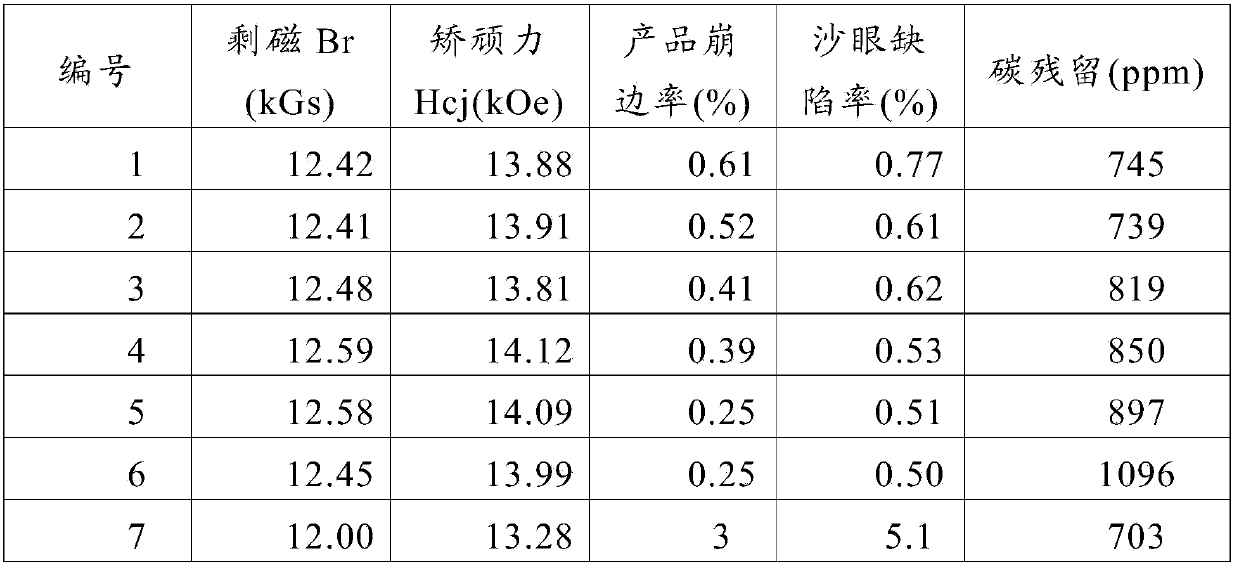

Embodiment 1

[0057] First, take methyl octanoate, liquid paraffin, polybutene with a molecular weight of 400, silane coupling agent KH550 and the rest of the n-pentane solvent by mass percentage to obtain organic additives. See Table 2 for specific mass percentages. Table 2 is the implementation The mass percent composition of the organic additive prepared in example 1.

[0058] The mass percent composition of the organic additive prepared in Table 2 Example 1

[0059]

[0060] Then, weigh Pr-Nd: 30wt%, Dy: 3.5wt%, Al: 0.5wt%, B: 1.0wt%, Cu: 0.1wt%, Co: 1.0wt% and the rest Fe, Alloy flakes with a thickness of 0.15mm were produced by melting and casting by SC process, and NdFeB magnet coarse powder was produced by HD process.

[0061] Then put the NdFeB coarse powder into the jet mill, use compressed nitrogen to grind into fine powder, adjust the parameters of the jet mill, and control the Fischer particle size of the powder to be 2.5-5.0 μm to obtain NdFeB powder.

[0062] Take out th...

Embodiment 2

[0070] First weigh nonanoic acid methyl ester, liquid paraffin, polybutene with a molecular weight of 400, silane coupling agent KH570 and the rest of the n-hexane solvent to obtain organic additives, see Table 4 for specific mass percentages, and Table 4 is for implementation The mass percent composition of the organic additive prepared in example 2.

[0071] The mass percent composition of the organic additive prepared in Table 4 Example 2

[0072]

[0073] Then, weigh Pr-Nd: 30wt%, Dy: 0.5wt%, Al: 1.0wt%, B: 1.0wt%, Cu: 0.1wt%, Co: 1.0wt% and the rest Fe, The alloy flakes with an average thickness of 0.18mm were obtained by melting and casting by SC process, and the NdFeB magnet coarse powder was produced by HD process.

[0074] Then put the NdFeB coarse powder into the jet mill, use compressed nitrogen to grind into fine powder, adjust the parameters of the jet mill, and control the Fischer particle size of the powder to be 3.0-5.0 μm to obtain NdFeB powder.

[0075] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com