Preparation method and application of black phosphorus treated copper-based catalyst

A copper-based catalyst, catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, organic chemistry, etc., can solve the problems of difficult to balance selective conversion rate, low catalytic activity, etc., and achieve excellent safety and treatment methods. Simple, inherently stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

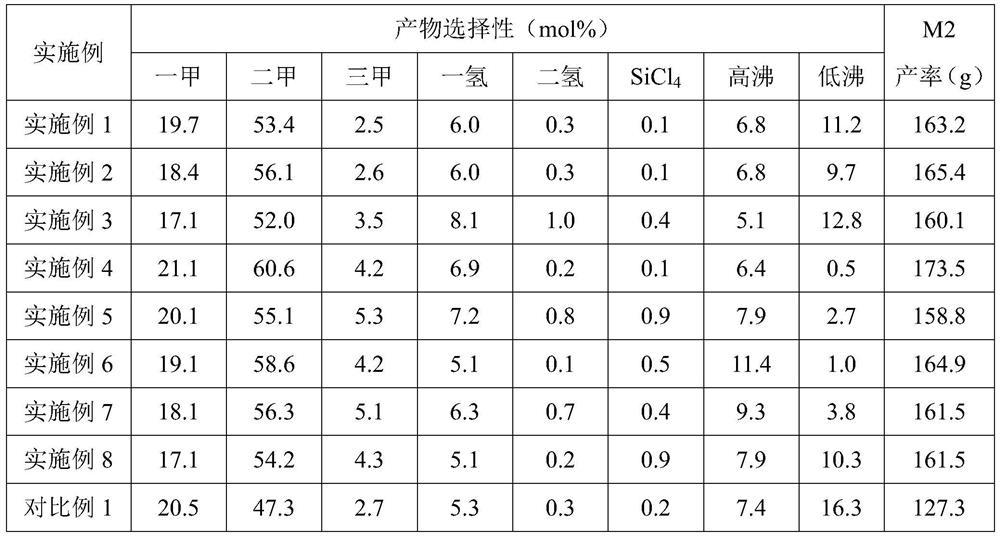

Examples

Embodiment 1

[0027] Take 80g of the fresh copper powder catalyst in the comparison example, add 50mL of black phosphorus dispersion liquid that has been uniformly dispersed by ultrasound by soaking, reflux at 70°C for 10h, then centrifuge, separate and rinse with a mixture of ethanol and water several times. Dry at 50° C. for 12 hours, dry and grind to obtain the copper-based catalyst treated with black phosphorus. Among them, the mass ratio of black phosphorus to copper powder catalyst is 0.01:100.

[0028] The catalyst obtained in Example 1 was used for the direct synthesis of methylchlorosilane. The specific operation is to take 80g of the catalyst, mix it with silicon powder, and put it into a fluidized bed device. The temperature of the sand bath fluidized bed is 350°C, the flow rate of methyl chloride gas is 30mL / min, and the reaction time is 100h.

Embodiment 2

[0030] A copper-based catalyst treated with black phosphorus was prepared with reference to Example 1, the difference being that the mass ratio of black phosphorus to copper powder catalyst was 0.1:100.

[0031] The catalyst obtained in Example 2 was used for the direct synthesis of methylchlorosilane according to the method described in Example 1, and the specific operation method was the same as that of Example 1.

Embodiment 3

[0033] A copper-based catalyst treated with black phosphorus was prepared with reference to Example 1, the difference being that the mass ratio of black phosphorus to copper powder catalyst was 1:100.

[0034]The catalyst obtained in Example 3 was used for the direct synthesis of methylchlorosilane according to the method described in Example 1, and the specific operation method was the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com