Continuous type rubber powder cooling and drying device

A technology for cooling and drying rubber powder, applied in the field of mechanical devices, can solve the problems of secondary pollution, large area for heat dissipation of recycled rubber, and flammability of high-temperature rubber powder stacking. The effect of spontaneous combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

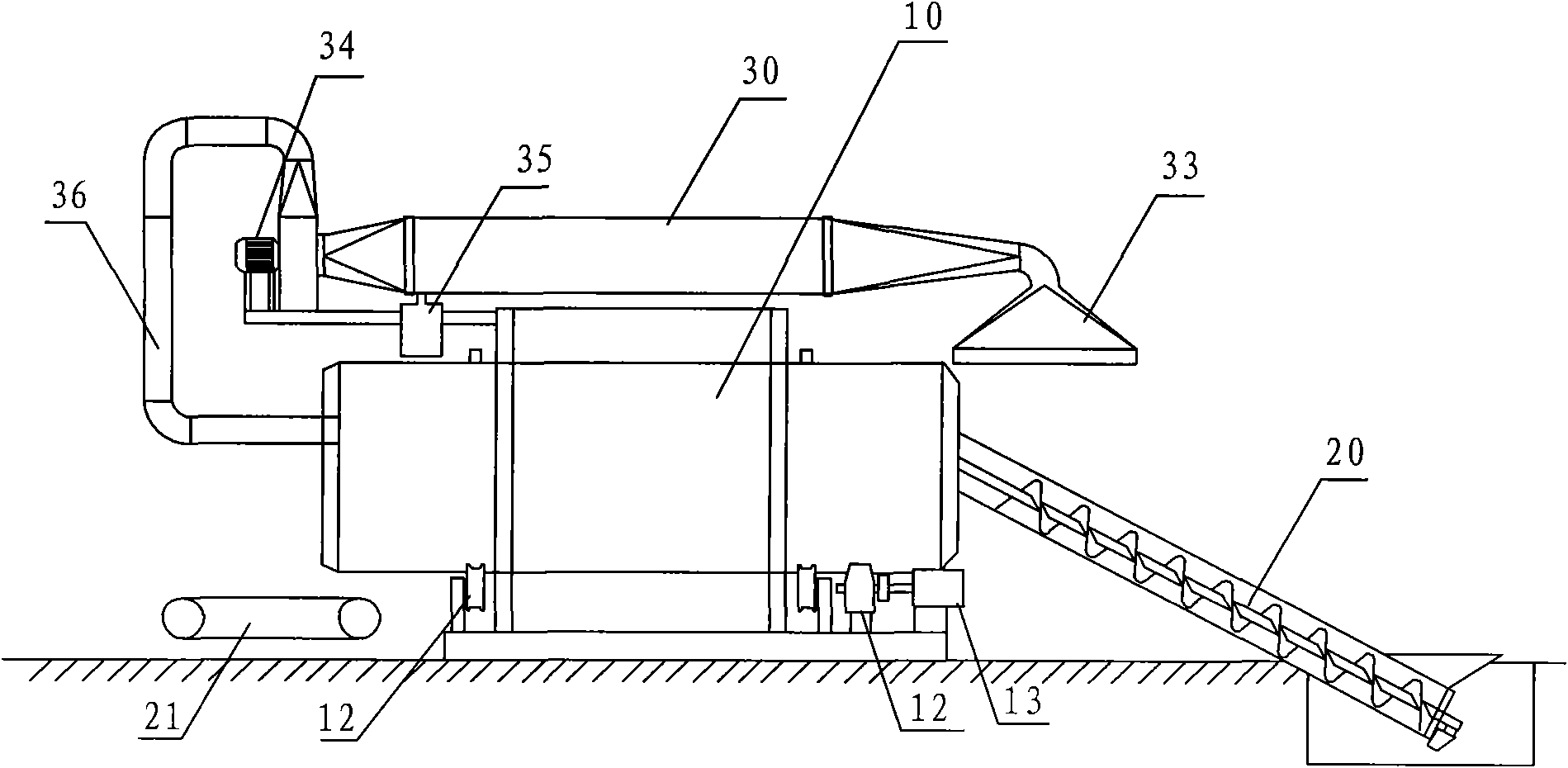

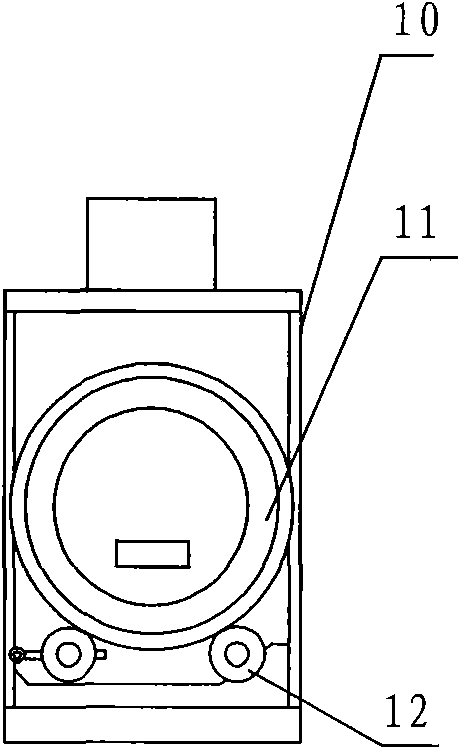

[0020] A cooling drum for rotating and cooling rubber powder, including a drum and a driving mechanism for driving the drum to rotate, and a spiral guide plate is arranged inside the drum;

[0021] The conveying mechanism is connected with the cooling drum, and transports the rubber powder to the feeding end of the cooling drum;

[0022] The flue gas collection and air supply mechanism, which is equipped with a cooler on a pipe equipped with a blower, and the two ends of the pipe are the smoking port at the feeding end of the drum and the blowing port at the discharging end of the drum respectively. The airflow of the air outlet and the air outlet is connected by the pipe and the drum to form a circulating airflow channel.

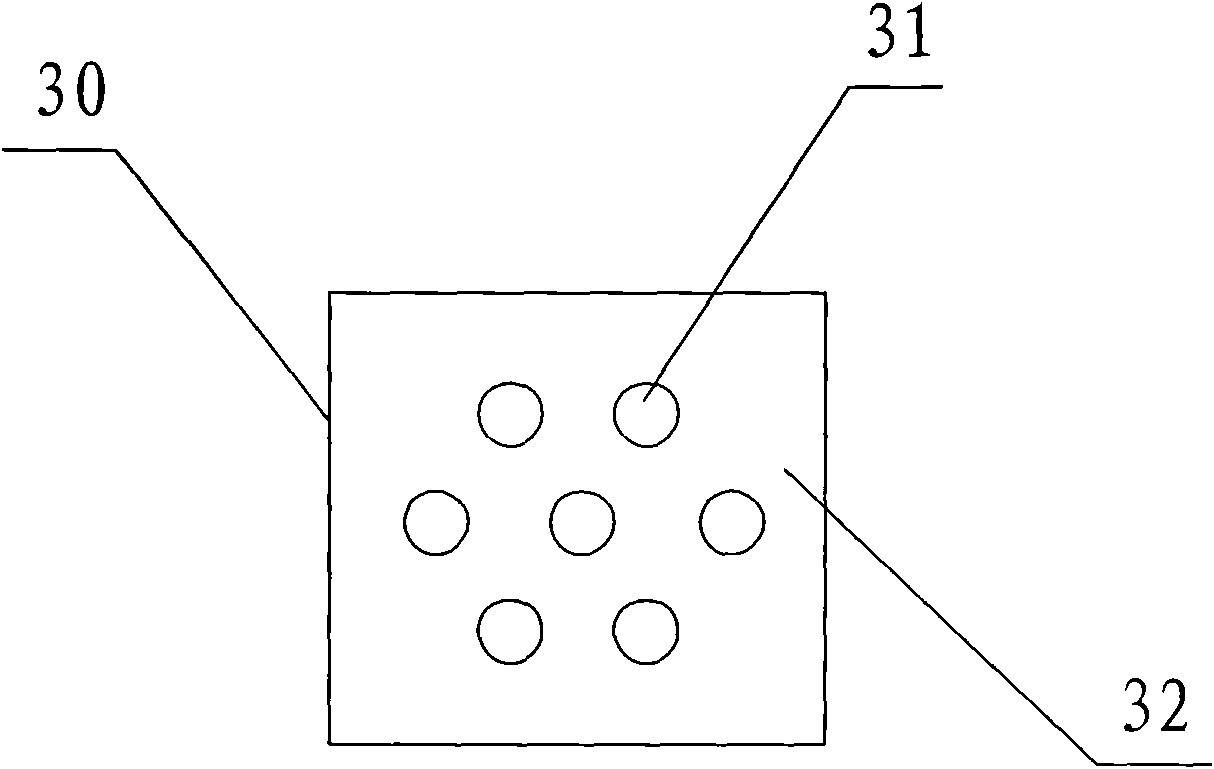

[0023] The cooler is to install a number of air pipes in a water tank, and the two ends of the air pipes are respectively collected on the pipe. The outlet end of the cooler is provided with a collection tank, and the smoke port of the smoke collection and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com