Organic-inorganic hybrid binder, coating comprising the same, and method for forming coating on material surface

A binder and inorganic technology, applied to coatings on the surface of materials, organic-inorganic hybrid binders and coatings including the organic-inorganic hybrid binders, can solve the problems of long heat treatment time, production cost burden, non-compliance with environmental protection, etc., to achieve Reduce manufacturing costs, prolong service life, and avoid thermal oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Preparation of organic-inorganic hybrid binder

[0020] Get 15 grams of chelating agent acrylate-2-ethylhexyl ester (2-ethylhexyl acrylate, 2-EHA) and 40 grams of solvent ethylene glycol monobutyl ether (2-butoxyethanol, BCS) and mix and stir, and in the stirring process Slowly add 60 grams of liquid aluminum alkoxide aluminum n-butoxide and keep stirring. After 4 hours of mixing reaction, organic-inorganic hybrid binder A1 is obtained.

[0021] Take 25 grams of chelating agent acetylacetone (acetylaceton, ACAC) and 40 grams of solvent n-butyl alcohol (n-butylalcohol, NBA) and mix and stir, and slowly add 60 grams of liquid aluminum alkoxide aluminum n-propoxide during stirring And keep stirring, after 10 hours of mixing reaction, the organic-inorganic hybrid binder A2 is obtained.

[0022] Get 40 grams of chelating agent ethylenediaminetetraacetic acid (ethylenediaminetetraacetic acid, EDTA) and 40 grams of solvent toluene (toluene) and mix and stir, and sl...

Embodiment 2

[0023] Example 2: Preparation of coatings with high temperature oxidation resistance

[0024] Get 85 grams of organic-inorganic hybrid binder A1, 15 grams of surface-modified aluminum paste (that is, aluminum metal sheets with a side length size of about 10 nanometers are agglomerated, and the surface of the aluminum metal sheet is coated with After the solid mass of petroleum naphtha) and 1 gram of polycaprolactone polyol-polyethyleneimine block copolymer are mixed with each other, stir with high-speed stirring (about 1000rpm) for 2 hours to make it uniformly dispersed, and then Then filter with a 50-mesh filter, and the coating B1 with high temperature oxidation resistance can be obtained from the filter after filtering through the filter.

[0025] Get 100 grams of organic-inorganic hybrid binder A2, 100 grams of surface-modified aluminum paste (that is, aluminum metal sheets with a side length size of about 10 nanometers are agglomerated, and the surface of the aluminum met...

Embodiment 3

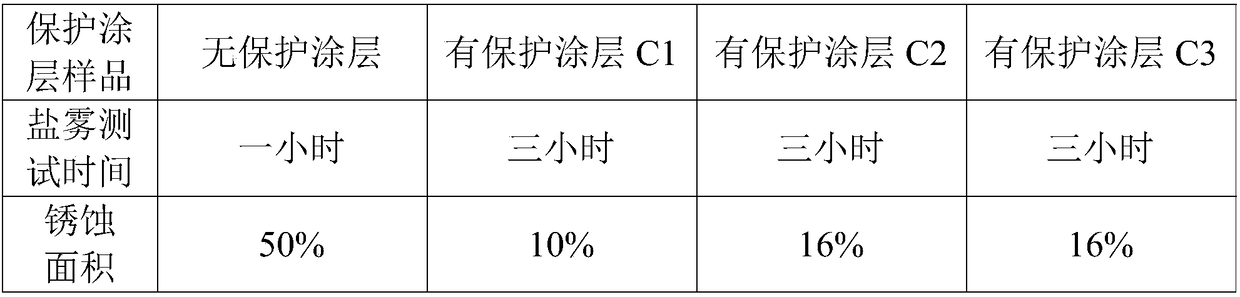

[0028] Embodiment three: the various coatings B1, B2, B3 with high temperature oxidation resistance obtained by the embodiment two are prepared protective coatings on the surface of carbon steel

[0029] Coating B1 with high temperature oxidation resistance is coated on the surface of carbon steel by roller coating, and then baked at a high temperature of 250°C for 30 seconds, so that the coating B1 with high temperature oxidation resistance is cured on the surface of carbon steel A protective coating C1 is formed, and the thickness of the protective coating C1 is controlled at about 1 μm.

[0030]Coating B2 with high temperature oxidation resistance is coated on the surface of carbon steel by roller coating, and then baked at a high temperature of 350 ° C for 1 minute, so that the coating B2 with high temperature oxidation resistance is cured on the surface of carbon steel A protective coating C2 is formed, and the thickness of the protective coating C2 is controlled at about...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com