Supersonic mixing reinforcing device

A booster device and supersonic technology, applied in jet propulsion devices, rocket engine devices, combustion methods, etc., can solve the problems of large flow resistance, poor adaptability, difficult installation, etc., and achieve the effect of enhanced mixing and improved mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The embodiments of the present invention will be further described in detail below in conjunction with the drawings.

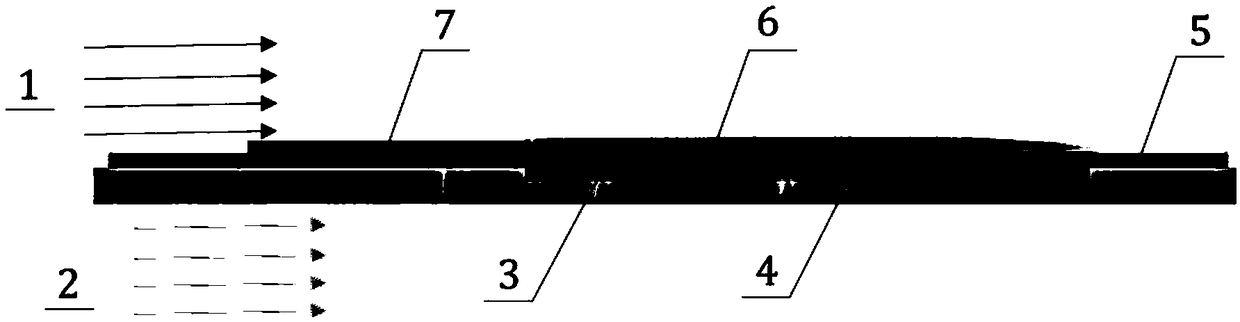

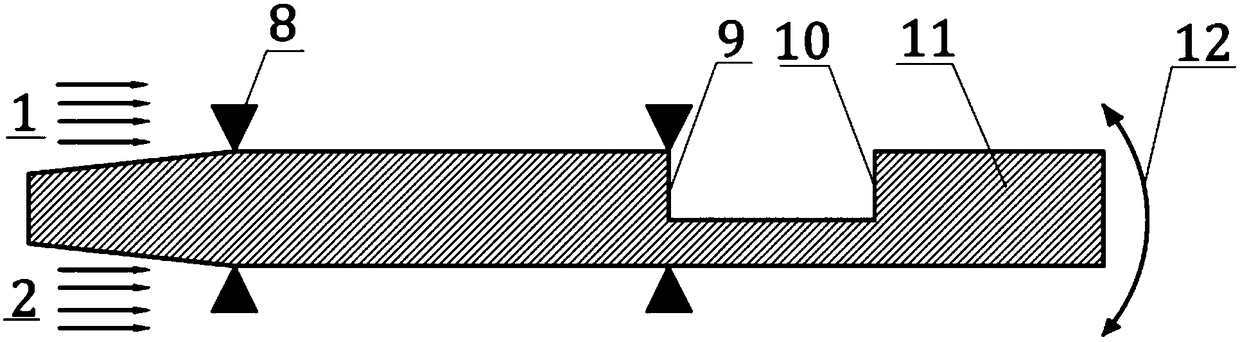

[0043] image 3 It is a schematic diagram of the structure of the present invention. The supersonic mixing enhancement device is arranged in the combustion chamber, and the mixing enhancement plate 15 is fixedly supported between the intake passage and the gas passage through a fixed fulcrum 8. Above the mixing enhancement plate 15 is an air inlet through which supersonic incoming air 1 flows, and below the mixing enhancement plate 15 is a gas channel through which supersonic rich combustion gas 2 flows.

[0044] The upper surface of the mixing enhancement plate 15 is provided with a cavity 16 recessed from the upper surface to the lower surface. A section of the mixing enhancement plate after the cavity 16 to the end of the mixing enhancement plate is called the shaking plate 11. Incoming air 1 flows above the mixing enhancement plate 15 along the length d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com