Composite balancing earth-pressure shielding machine

A technology of earth pressure balance and shield machine, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., to achieve the effect of improving flow plastic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

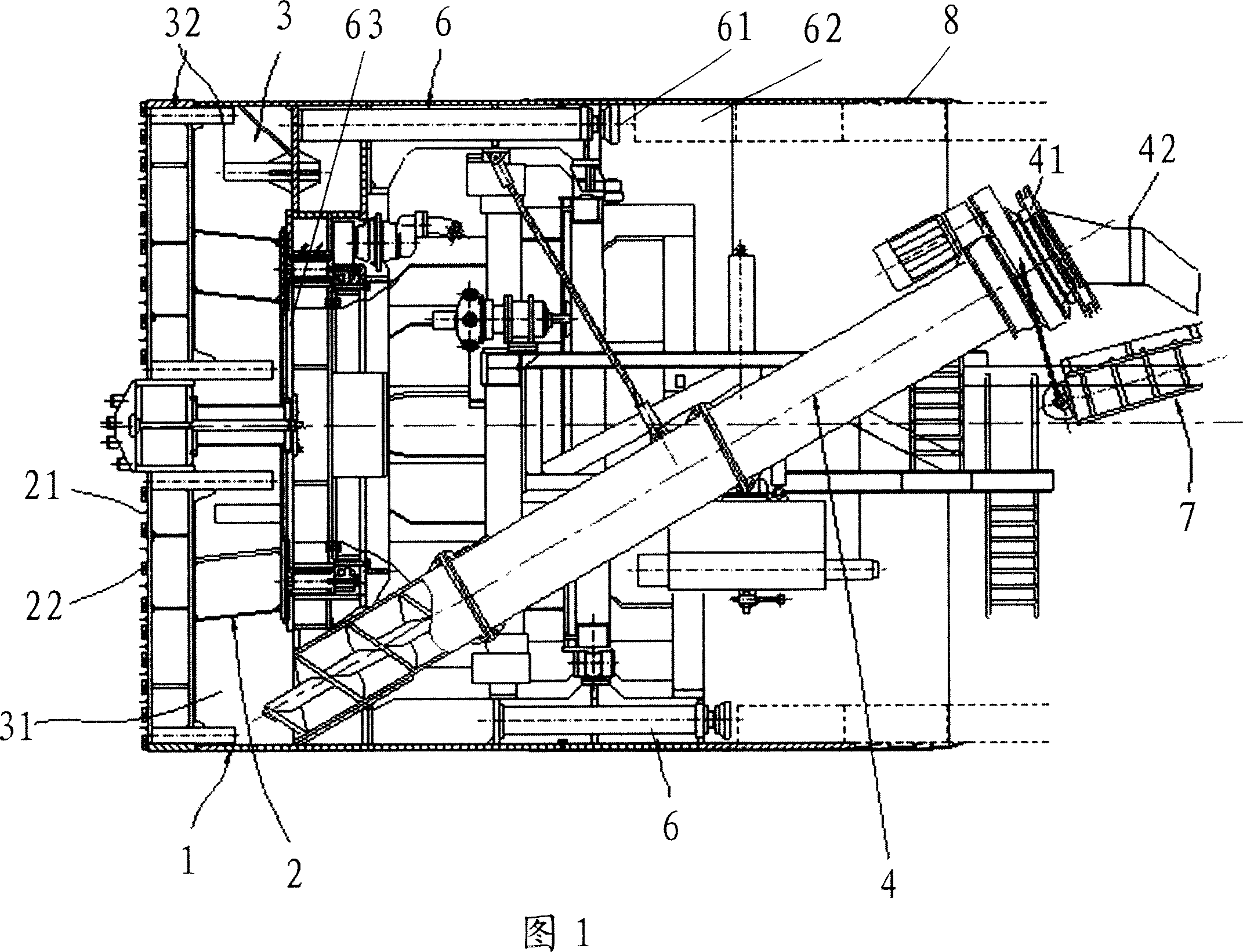

[0023] The shield machine provided by the present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited thereto.

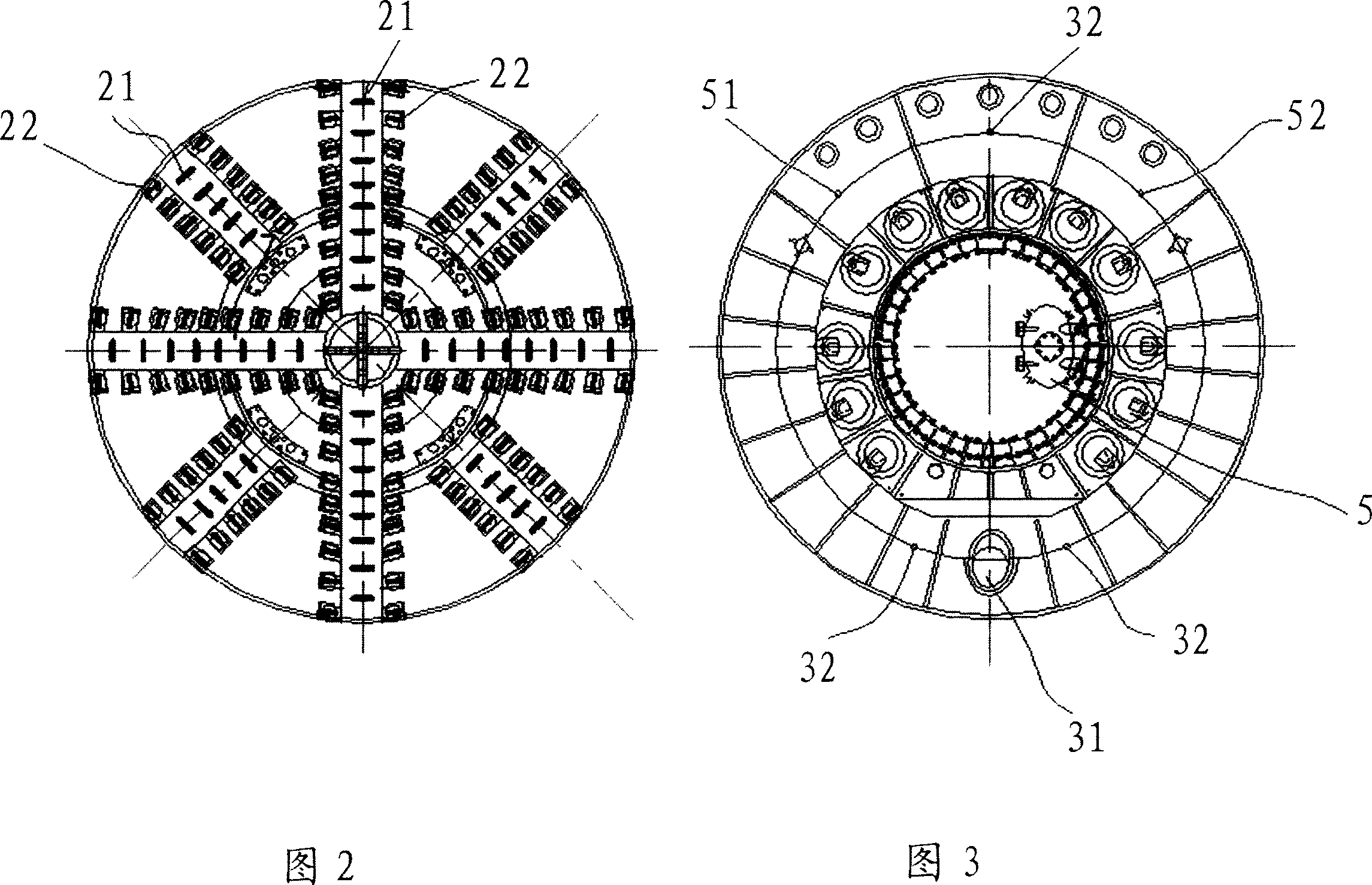

[0024] As shown in Figures 1 and 2, the composite earth pressure balance shield machine according to the present invention includes a casing 1, the front end of which is a cutter head 2; 22, where the blade edge of the cutting knife 22 is slightly behind the tearing knife 21. The tearing knife 21 is mainly aimed at unweathered block stones, such as unweathered tuff, by extruding and self-rolling, to break relatively hard block stones. Run into soft soil layer, tearing knife 21 loses its effect, this moment relies on cutting knife 22, under the rotation of cutterhead 2, cuts soft soil. The actual shield tunneling process is completed under the joint action of these two knives.

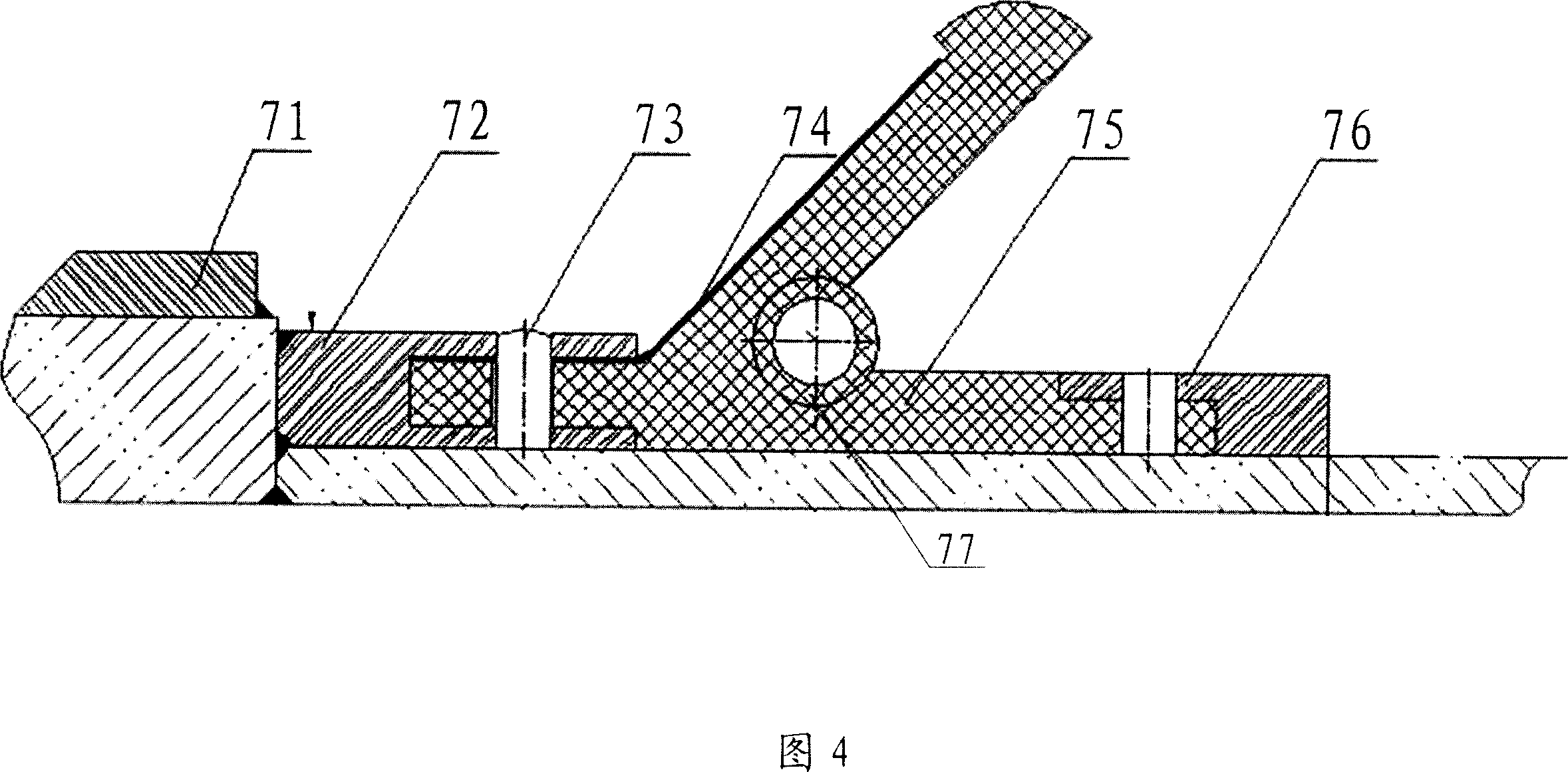

[0025] Referring to Fig. 1 and Fig. 3, the cutter head 2 rear portion is the soil bin 3, and the soil bin 3 bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com