Residue soil improvement system of shield tunneling machine

A technology of muck improvement and shield machine, which is applied in the direction of earth square drilling, mining equipment, tunnels, etc. It can solve the problems of poor fluidity of dregs, unfavorable discharge of muck, and blockage of soil bins by mud, and achieve good flow plasticity and small Effects of friction resistance and low water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

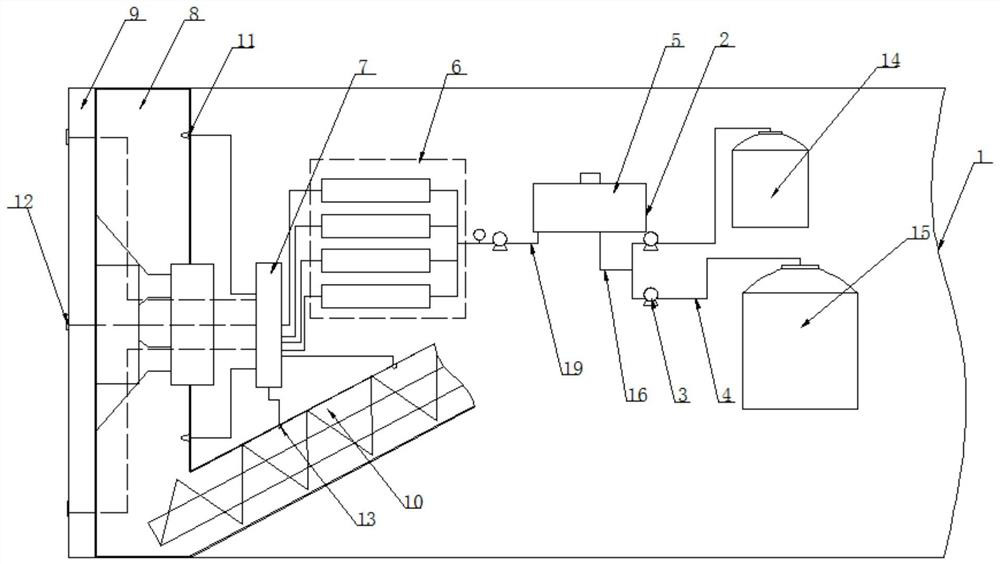

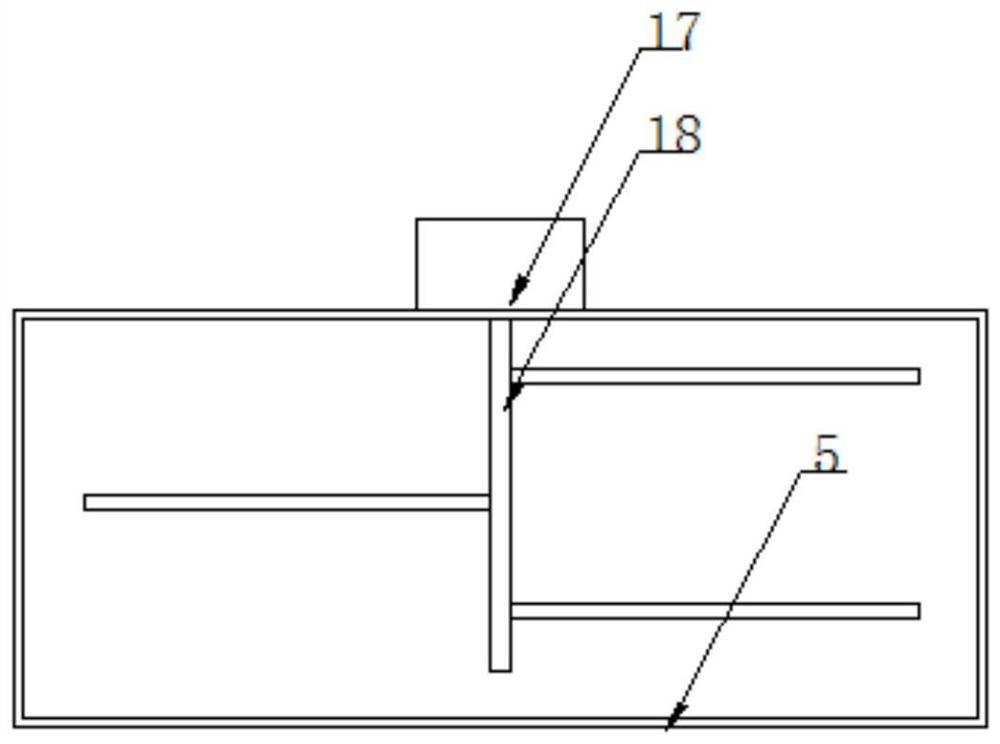

[0028] like Figure 1-2 As shown, a shield machine muck soil improvement system includes a shield machine body 1, and the front end of the shield machine body 1 is provided with a cutter head 9, a soil bin 8 and a screw conveyor 10, and the soil bin 8 is located in the cutter head 9. The rear side is connected with the discharge flow channel on the cutter head 9. The screw conveyor 10 is fixedly installed at the bottom of the rear side of the soil bin 8 and communicated with the bottom of the soil bin 8. There is also a foam system 2 for injecting foaming agent into the muck to improve it, wherein the foam system 2 includes:

[0029] The raw material supply assembly, including the foaming agent storage tank 14 and the solvent water storage tank 15, is used to supply the foam processing raw materials to the front end of the foam system 2, and the two are respectively connected to the inlet end of the infusion header 16 through an infusion branch pipe 4, and two A quantitative ...

Embodiment 2

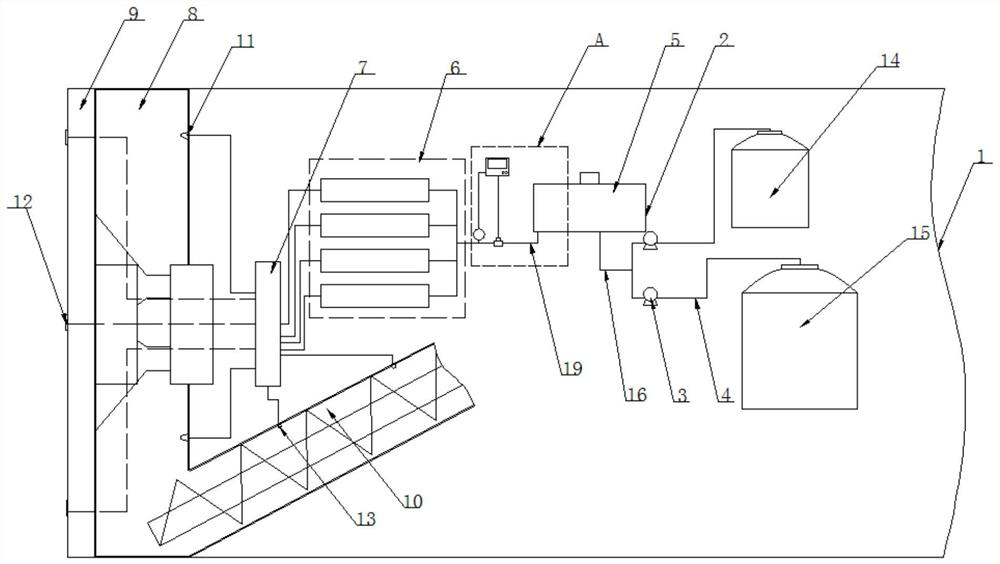

[0041] In order that the foam system 2 can quantitatively spray the foaming agent according to the actual amount of the excavated slag, as well as the slag soil quality and water content of the excavation surface, so as to achieve the best improvement effect of the slag, this embodiment is described in Example 1. 1 to make further improvements, such as Figure 3-4 As shown, a quantitative controller 22 is also fixedly installed in the shield machine body 1, which is respectively connected with the flow sensor 21 and the infusion pump 20 to receive and accumulate the flow value of the flow sensor 21, and when the accumulated value reaches the required value When the set quantitative control value is set, the infusion pump 20 is controlled to work.

[0042] The total injection volume of the foaming agent of the foam injection component of the cutter head, the foam injection component of the soil bin, and the foam injection component of the conveyor is 300-600L per cubic slag.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com