A method for decomposing chromite by fluidization at low temperature and normal pressure

A low temperature and normal pressure, chromite technology, applied in the direction of improving process efficiency, can solve the problems of large equipment investment and high pressure, and achieve the effects of low reaction temperature, lower alkali concentration and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

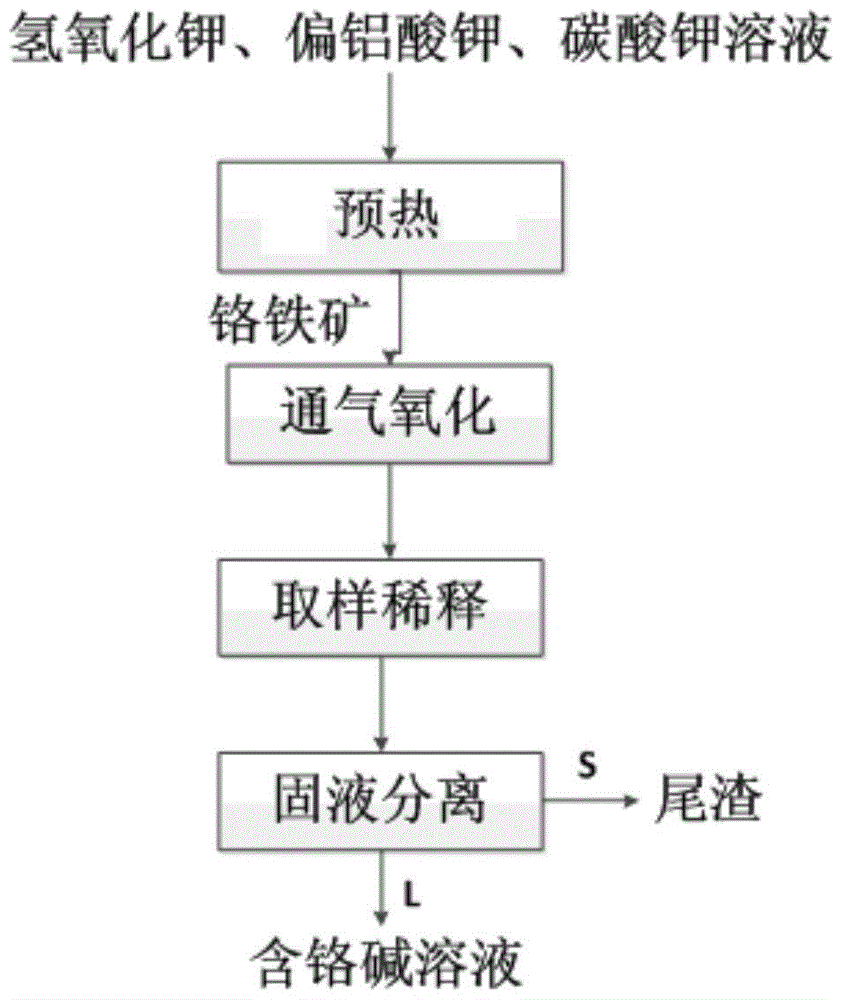

[0043] A method for fluidized decomposition of chromite at low temperature and normal pressure, comprising the following steps:

[0044] 1) Prepare an aqueous solution of potassium hydroxide, potassium carbonate, and potassium metaaluminate with a certain concentration, add it to the fluidized bed reactor, and preheat it to 100°C. The contents of potassium hydroxide, potassium carbonate and potassium metaaluminate in this solution are 40%, 10% and 5% respectively. The chromite ore screened into 200 mesh or less is mixed with the solution, wherein the mass ratio of potassium hydroxide to chromite is 10:1, i.e. 7kg of chromite and 120L of potassium hydroxide mixed solution;

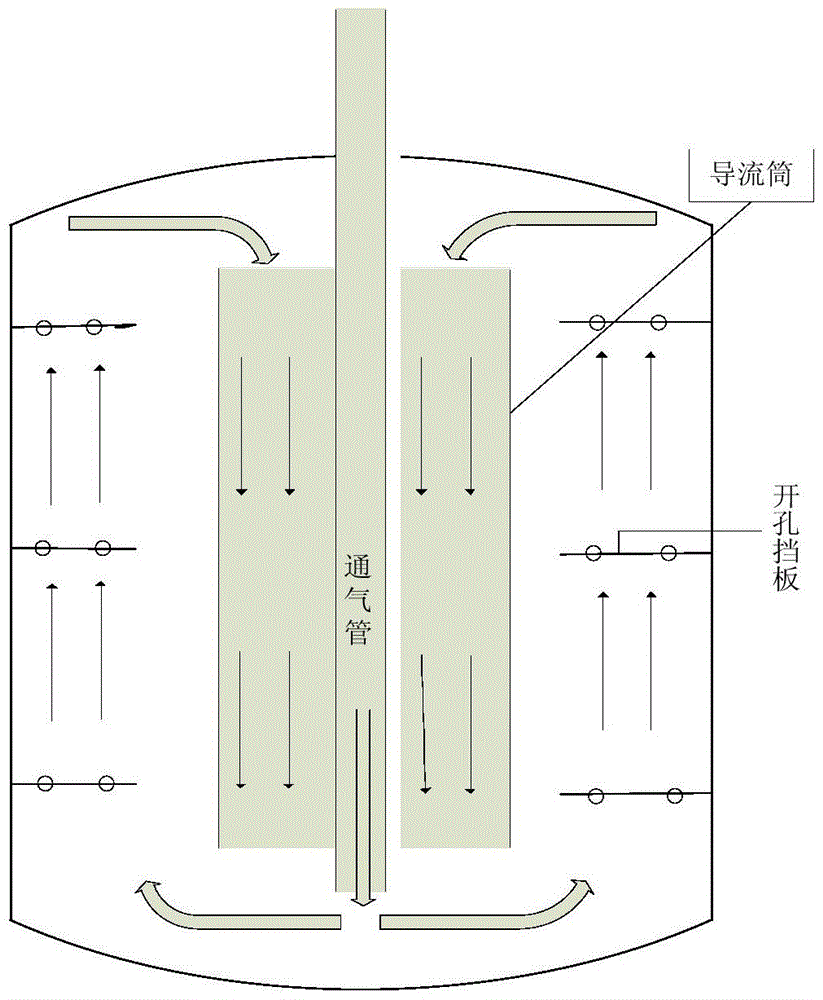

[0045] 2) Continue to heat the fluidized bed reactor, turn on the compressed air, and control the air flow at 10m 3 / h, maintain at 240°C for 10h, the air flow rate is not less than 12m 3 / h;

[0046] 3) Cool down and sample for dilution, dilute to the concentration of potassium hydroxide in the reaction...

Embodiment 2

[0048] 1) Configure a certain concentration of potassium hydroxide, potassium carbonate, and potassium metaaluminate aqueous solution, add it to the fluidized bed reactor, and preheat it to 100°C. The contents of potassium hydroxide, potassium carbonate, and potassium metaaluminate in the solution are 50% respectively. %, 10%, 0%. The chromite ore screened into 200 mesh or less is mixed with the solution, wherein the mass ratio of potassium hydroxide to chromite is 5:1, i.e. chromite 18kg, potassium hydroxide mixed solution 120L;

[0049] 2) Continue to heat the fluidized bed reactor, and turn on the compressed air to control the air flow at 10m 3 / h, maintain at 255°C for 8h, the air flow is not less than 12m 3 / h;

[0050] 3) Cool down and sample for dilution, dilute to the concentration of potassium hydroxide in the reaction slurry is 300g / L, filter and separate the mixed slurry at about 80°C to obtain iron-rich tailings and chromium-containing lye, wash and dry the taili...

Embodiment 3

[0052] 1) Configure a certain concentration of potassium hydroxide, potassium carbonate, and potassium metaaluminate aqueous solution, add it to the fluidized bed reactor, and preheat it to 100°C. The contents of potassium hydroxide, potassium carbonate, and potassium metaaluminate in the solution are 50% respectively. %, 10%, 5%. . The chromite ore screened into 200 mesh or less is mixed with the solution, wherein the mass ratio of potassium hydroxide to chromite is 3:1, i.e. 30kg of chromite and 120L of potassium hydroxide mixed solution;

[0053] 2) Continue to heat the fluidized bed reactor, and turn on the compressed air to control the air flow at 10m 3 / h, maintained at 285°C for 6h, the air flow is not less than 16m 3 / h;

[0054] 3) Cool down and take samples to dilute, dilute to the reaction slurry potassium hydroxide concentration of 120g / L, filter and separate the mixed slurry at about 100°C to obtain iron-rich tailings and chromium-containing lye, and wash and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com