Method for producing monopentaerythritol, bipentaerythritol and tripentaerythritol

A technology of dipentaerythritol and tripentaerythritol is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., and can solve the problems of low yield of tripentaerythritol, low total yield, decline in total yield, etc. The effect of aldehyde utilization rate, less disproportionation reaction and less heat release of chemical reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

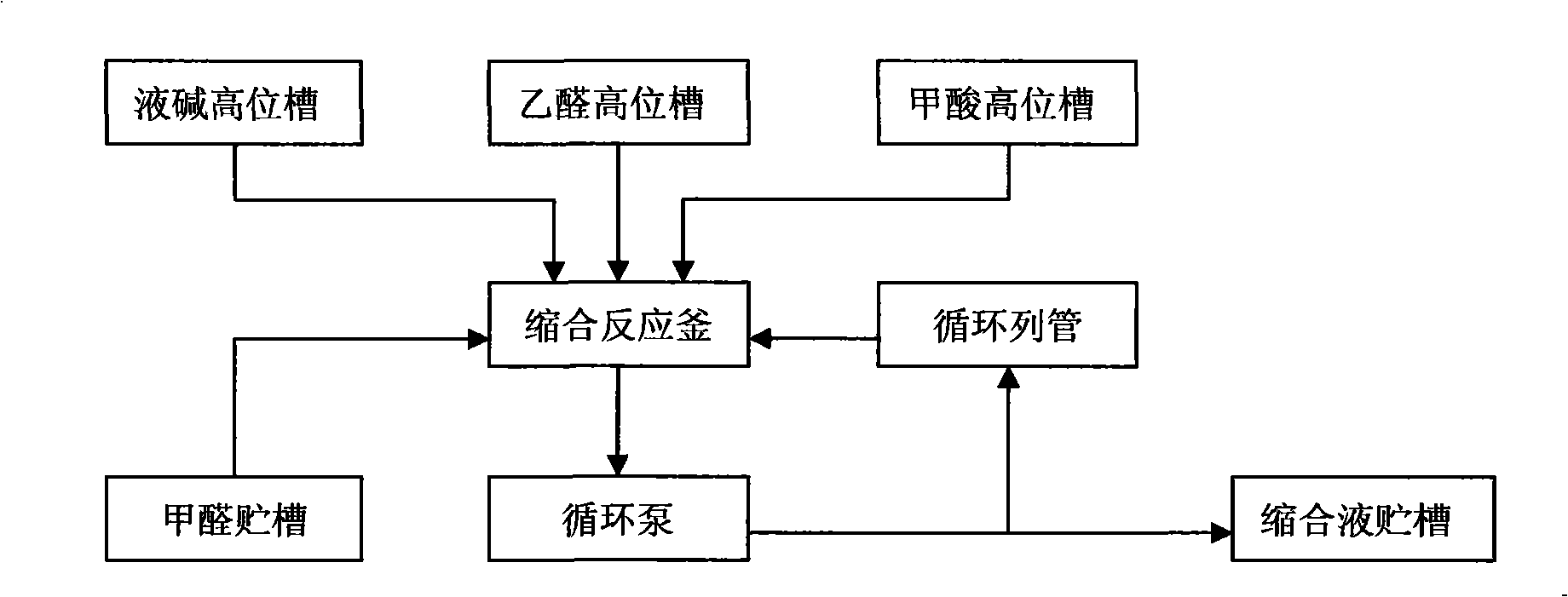

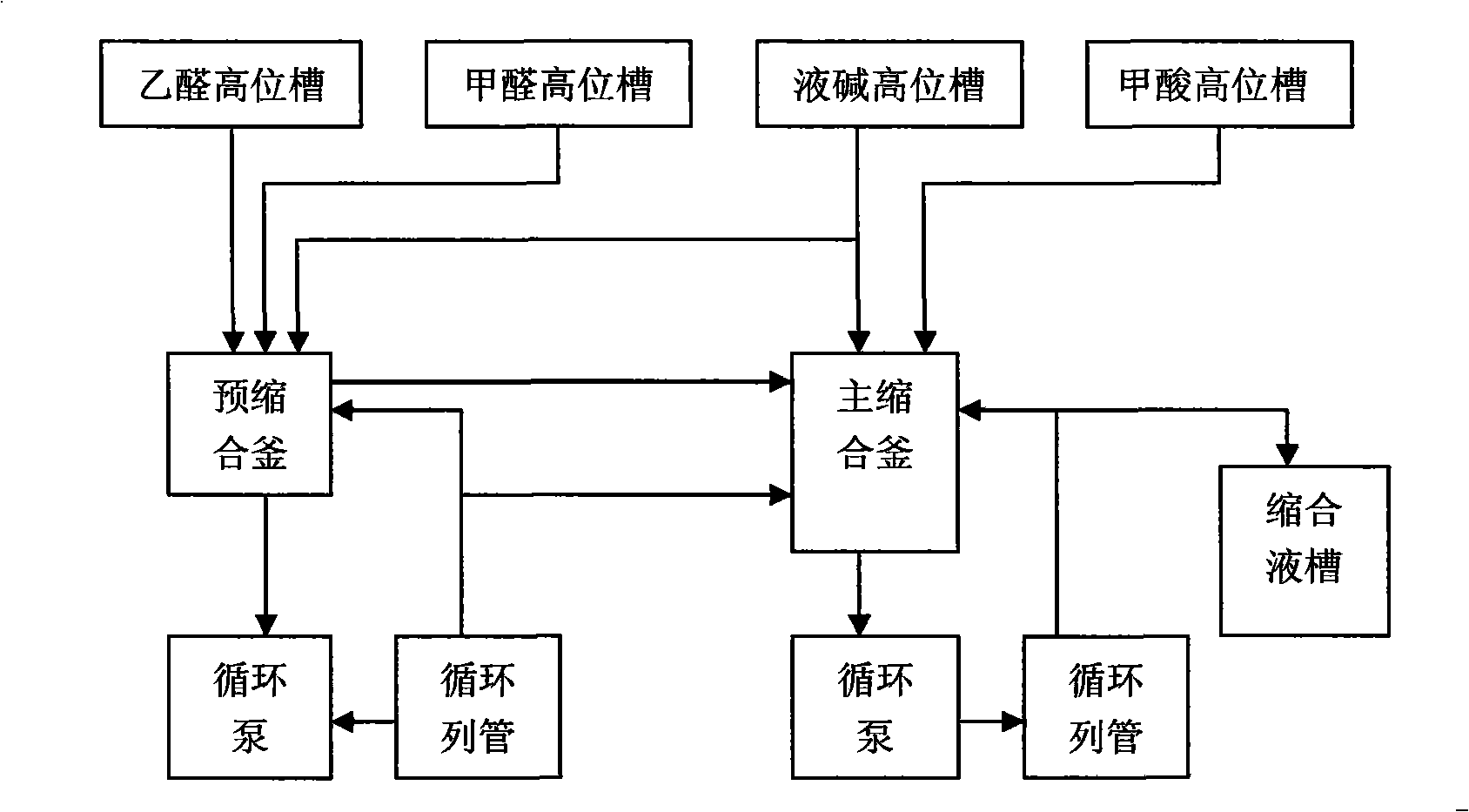

Method used

Image

Examples

Embodiment 1

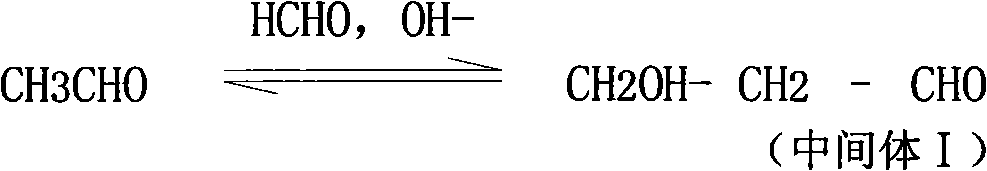

[0049]Take mass fraction 98% acetaldehyde 10Kmol, 12% formaldehyde solution 40Kmol, 32% sodium hydroxide 11Kmol, 85% formic acid appropriate amount and add respectively in acetaldehyde high level tank, formaldehyde high level tank, liquid caustic soda high level tank, formic acid high level tank, precondensation The nitrogen in the kettle and the main condensation kettle is pressurized to 0.05MPa, and then all the formaldehyde and acetaldehyde are evenly put into the precondensation kettle within 90 minutes, and the formaldehyde is 2 minutes earlier than the acetaldehyde; when the material in the precondensation kettle is full , then start the precondensation tank agitator and circulating pump and start adding sodium hydroxide, the amount of sodium hydroxide added is based on maintaining the pH value of the reaction solution in the precondensation tank at 8, and the temperature of the precondensation tank is controlled to be 35 °C; During the feeding process, the reaction liqui...

Embodiment 2

[0051] Take the mass fraction of 98% acetaldehyde 10Kmol, 15% formaldehyde solution 45Kmol, 32% sodium hydroxide 11.5Kmol, 85% formic acid and add appropriate amount to the acetaldehyde high-level tank, formaldehyde high-level tank, liquid alkali high-level tank, formic acid high-level tank, pre-condensation The nitrogen in the kettle and the main condensation kettle is pressurized at 0.08MPa, and all the formaldehyde and acetaldehyde are fed within 30 minutes. The temperature is controlled at 55°C, and the other steps are the same as in Example 1.

Embodiment 3

[0053] Take the mass fraction of 98% acetaldehyde 10Kmol, 18% formaldehyde solution 50Kmol, 32% sodium hydroxide 12Kmol, 85% formic acid in appropriate amount and add them to the acetaldehyde high level tank, formaldehyde high level tank, liquid alkali high level tank, formic acid high level tank respectively, pre-condensation kettle , The nitrogen in the main condensation tank is pressurized to 0.10MPa, all the formaldehyde and acetaldehyde are fed within 60 minutes, the pH value of the reaction liquid in the pre-condensation tank is maintained at 8.5, the temperature is controlled at 30°C, and the temperature of the main condensation tank is controlled Be 60 ℃, other steps are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com