A kind of preparation method of eggshell membrane polypeptide

An eggshell membrane and shell membrane separation technology, applied in the food field, can solve the problems of product separation and purification, waste water treatment burden, poor water solubility of keratin, potential safety hazards, etc., achieve good antioxidant activity, product safety, and avoid toxic and harmful reagents. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Preparation of raw materials: Wash and sterilize the collected eggshells, separate the shell membranes through a shell membrane separator, dry the obtained eggshell membranes at 50°C for 8 hours, then pulverize them, and pass through a 100-mesh sieve to obtain eggshell membranes. Shell powder.

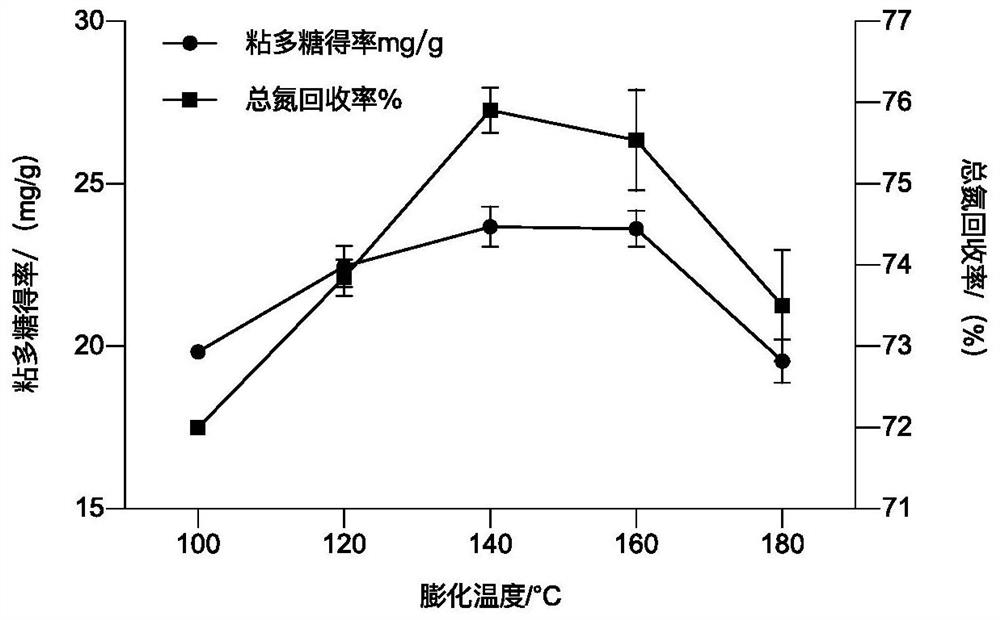

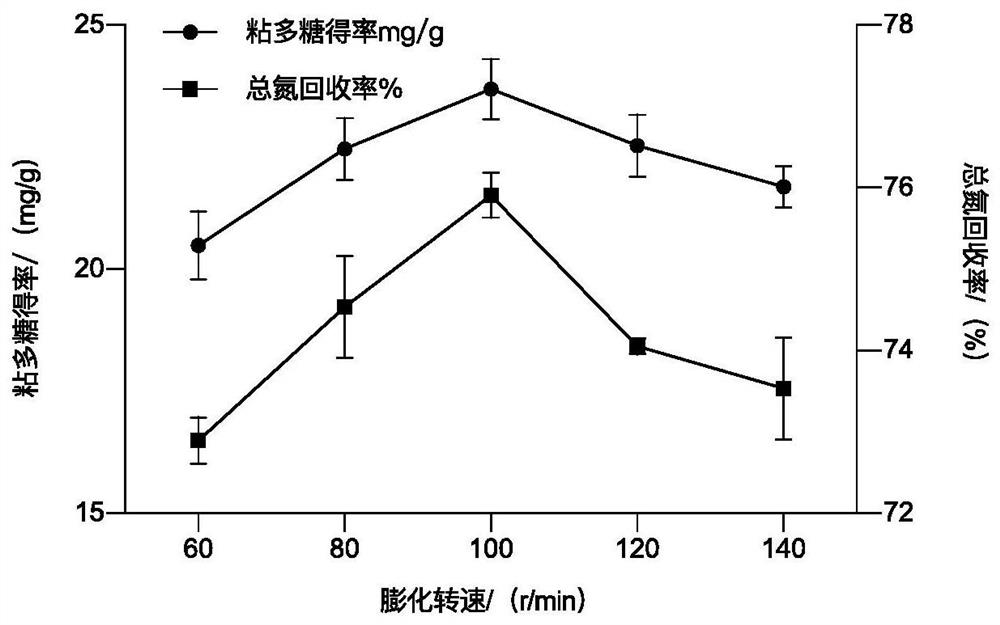

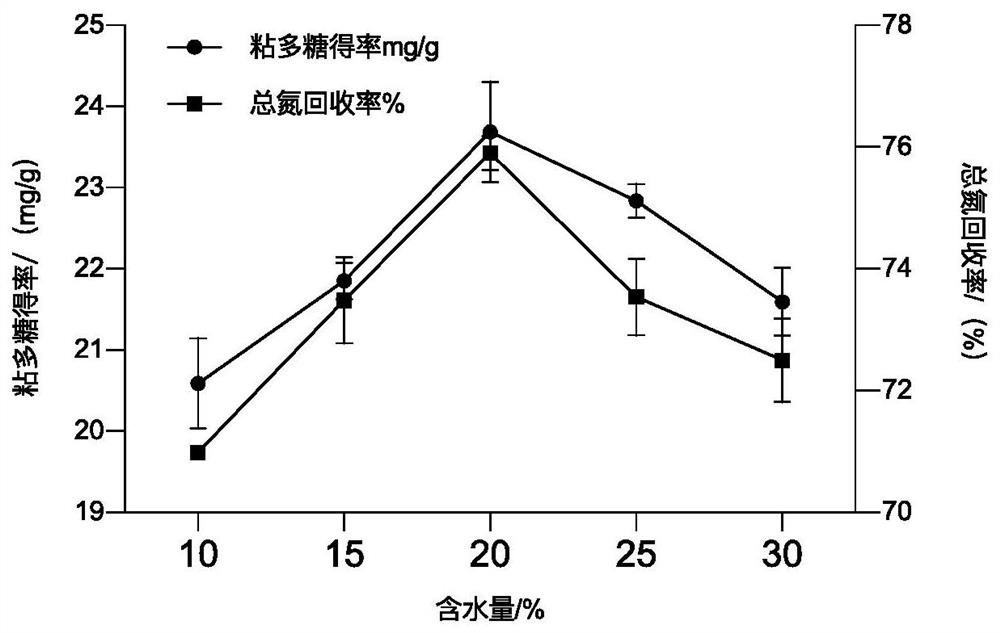

[0046] (2) Pretreatment: adjust the water content of the eggshell membrane powder obtained in step (1) to be 20%, control the screw speed to be 100r / min, carry out extrusion and puffing treatment at a temperature of 140°C, and obtain the eggshell After the puffed film is crushed and passed through a 60-mesh sieve, it is treated with a dilute alkali solution. The eggshell membrane powder that has been extruded, crushed and sieved is mixed with 0.1M NaOH at a temperature of 30°C at a solid-to-liquid ratio of 1:15 (w / w), and stirred at a constant temperature for 3 hours to obtain a mixture.

[0047] (3) Enzymolysis: adjust the temperature of the mixture obtained in step (2) to...

Embodiment 2

[0054] (1) Preparation of raw materials: Wash and sterilize the collected eggshells, separate the shell membranes through a shell membrane separator, dry the obtained eggshell membranes at 50°C for 6 hours, and then crush them to eggshell membranes with a particle size of 100 mesh powder.

[0055] (2) Pretreatment: adjust the water content of the eggshell membrane powder obtained in step (1) to be 20%, control the screw speed to be 100r / min, carry out extrusion and puffing treatment at a temperature of 140°C, and obtain the eggshell After the puffed film is crushed and passed through a 60-mesh sieve, it is treated with a dilute alkali solution. The eggshell membrane powder after extrusion, crushing and sieving was mixed with 0.25M NaOH at a temperature of 30°C at a solid-to-liquid ratio of 1:15 (w / w), and stirred at a constant temperature for 6 hours to obtain a mixture.

[0056] (3) Enzymolysis: adjust the temperature of the mixture obtained in step (2) to 55° C., and add al...

Embodiment 3

[0063] (1) Preparation of raw materials: Wash and sterilize the collected eggshells, separate the shell membranes through a shell membrane separator, dry the obtained eggshell membranes at 55°C for 8 hours, then pulverize them, and pass through a 100-mesh sieve to obtain eggshell membranes. Shell powder.

[0064] (2) Pretreatment: adjust the water content of the eggshell membrane powder obtained in step (1) to 20%, control the screw speed to 100r / min, carry out extrusion and puffing treatment at a temperature of 140°C, and obtain the eggshell After the puffed film is crushed and passed through a 60-mesh sieve, it is treated with a dilute alkali solution. The eggshell membrane powder that has been extruded, crushed and sieved is mixed with 0.1M NaOH at a temperature of 30°C at a solid-to-liquid ratio of 1:15 (w / w), and stirred at a constant temperature for 3 hours to obtain a mixture.

[0065] (3) Enzymolysis: adjust the temperature of the mixture obtained in step (2) to 55° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com