Method of continuous culture of anaerobic bacterium

A culture method, anaerobic bacteria technology, applied in the direction of bacteria, biochemical equipment and methods, microorganisms, etc., can solve the problems of decreased productivity, decreased bacterial activity, unstable fermentation, etc., to improve quality, increase purity, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

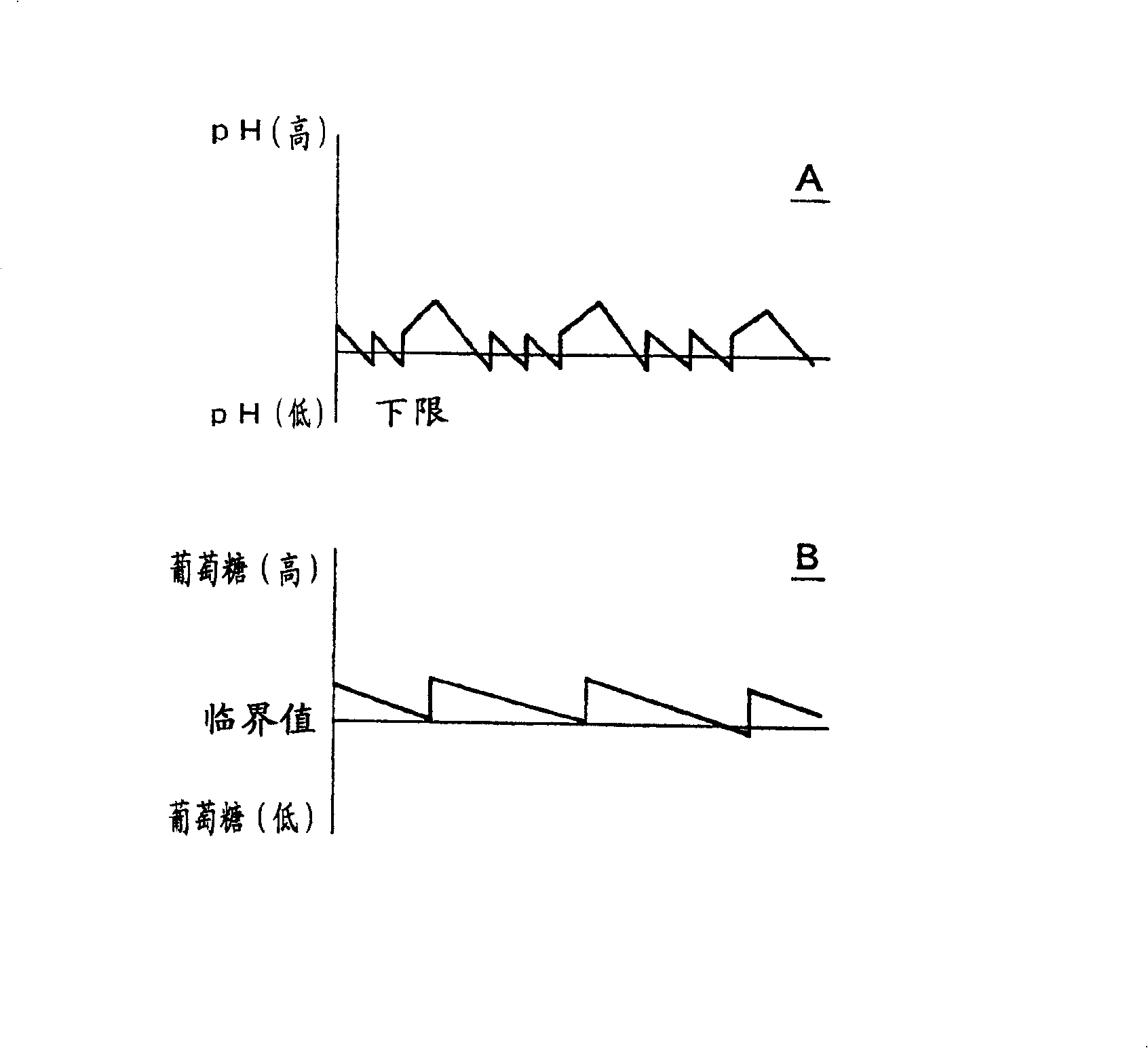

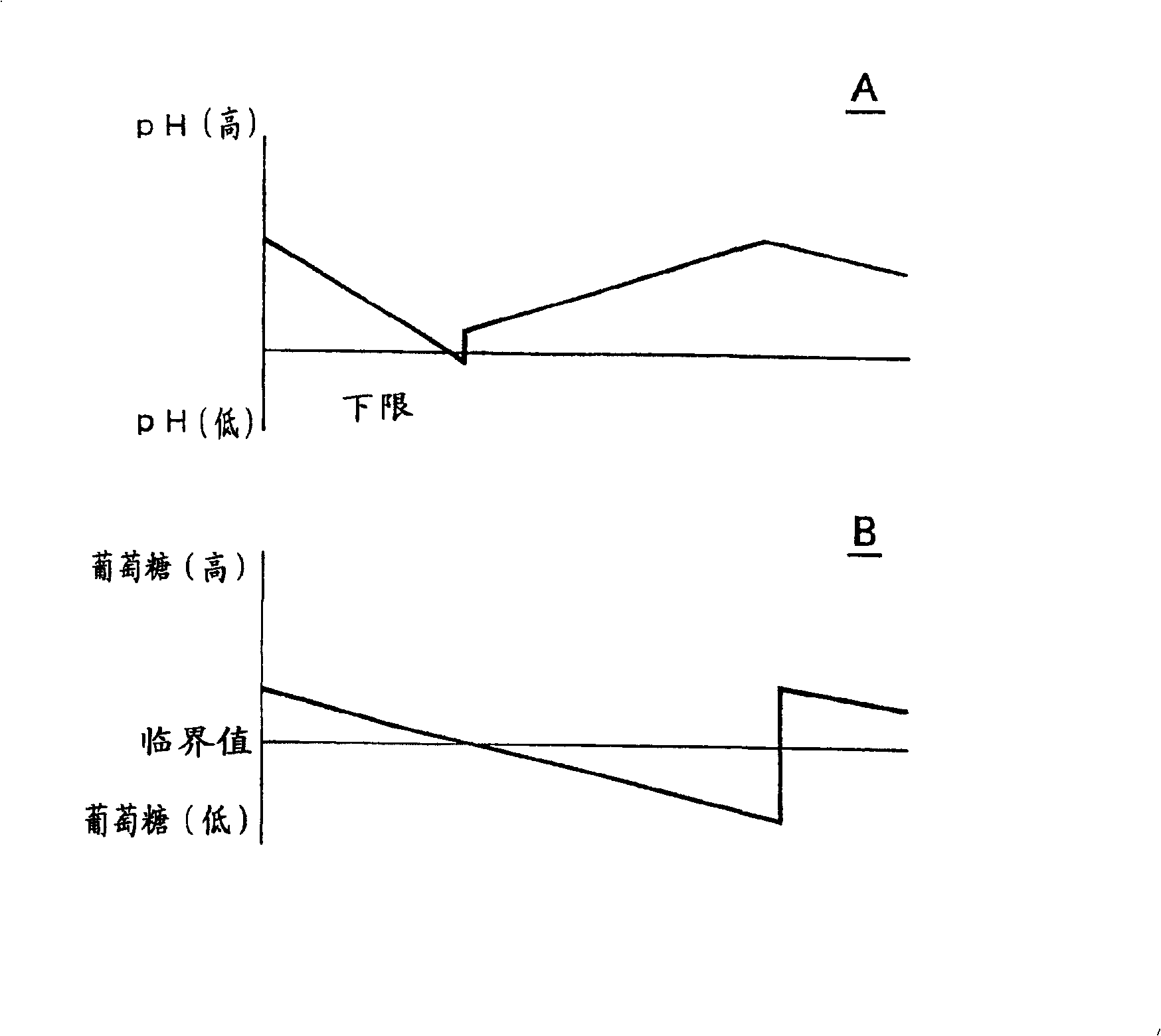

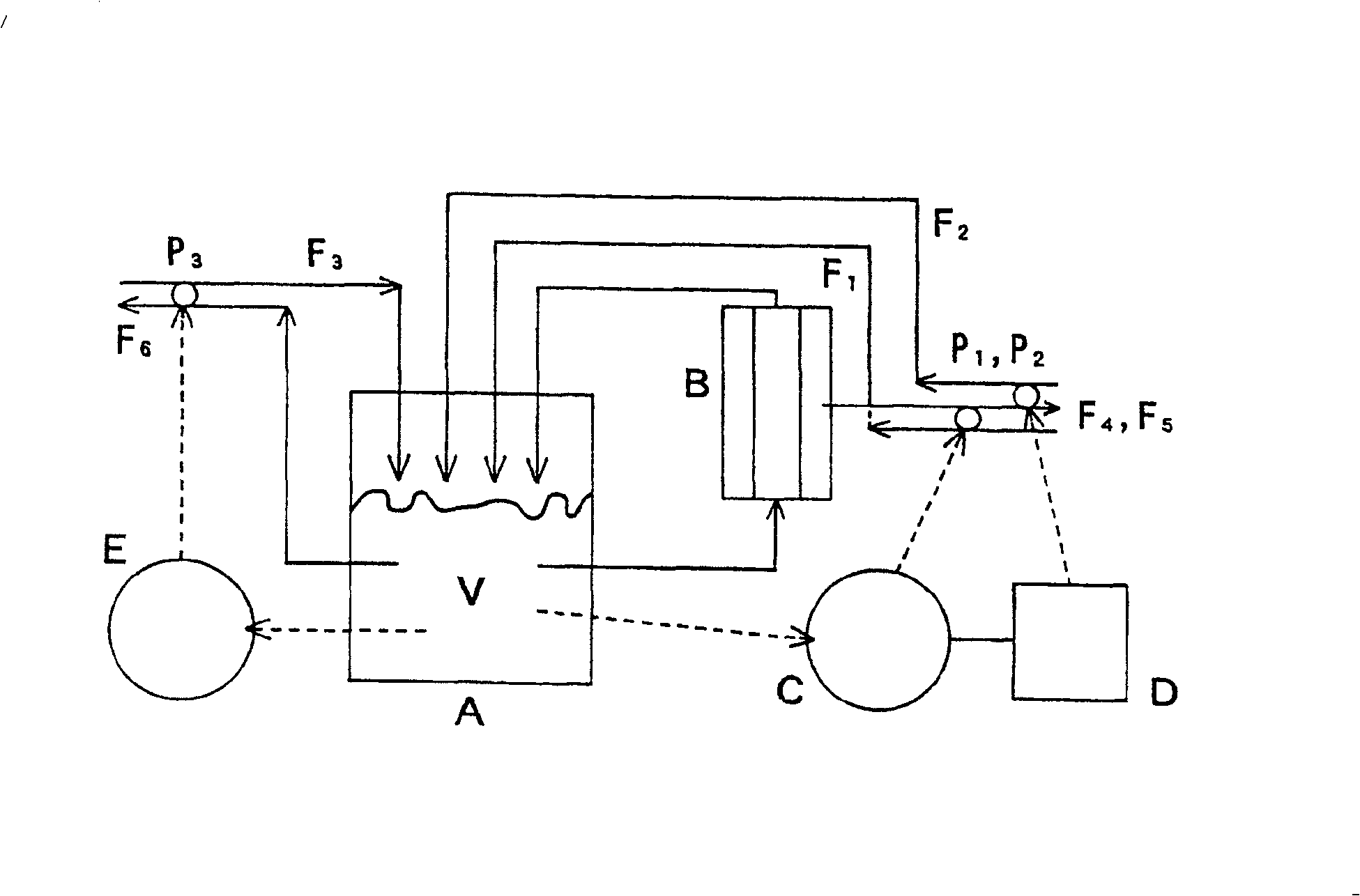

[0031] Lactococcus lactis (Lactococcus lactis) I0-1 (JCM7638) independently isolated by the inventor was used. Bacteria that were statically cultured on TGC medium (Difco) that were stored at -85°C were used as inoculum, and inoculated in 100 ml of a solution consisting of 3% glucose, 0.5% yeast extract, 0.5% peptone, and 1% NaCl. The culture medium that was dispensed into the Erlenmeyer flask and sterilized by autoclaving at 120° C. for 5 minutes was used as a seed. Composition and system of culture equipment for lactic acid fermentation image 3 as shown. The main fermentation medium is glucose 5%, yeast extract 0.5%, peptone 0.5%, NaCl 1%, and the sterilization conditions are the same as above. The main fermenter is a glass tank with a full capacity of 1 liter, and a stirrer with a magnetic stirring bar is arranged inside, and the stirrer is slowly stirred at a rotation speed of about 400 rpm. The whole tank was immersed in a water bath, and warm water at 37°C was circul...

Embodiment 2

[0043] Lactococcus lactis (Lactococcus lactis) I0-1 (JCM7638) independently isolated by the inventor was used. Bacteria that were statically cultured on TGC medium (Difco) that were stored at -85°C were used as inoculum, and inoculated in 100ml of a solution consisting of 3% glucose, 0.5% yeast extract, 0.5% peptone, and 1% NaCl. The culture medium that was dispensed into the Erlenmeyer flask and autoclaved at 120° C. for 5 minutes, and cultured for 8 hours was used as a seed. The system configuration of the culture device used was the same as that shown in Example 1. The main fermenter is a glass tank with a full capacity of 1 liter, and a stirrer with a magnetic stirrer is installed inside, and the stirrer is slowly stirred at a rotation speed of about 400 rpm. The whole tank is immersed in a water bath, and the temperature of the culture is controlled at 37°C by circulating warm water at 37°C. A composite glass electrode for pH measurement was installed in the tank, and t...

Embodiment 3

[0048] The bacteria used is Zymomonas mobilis NRRLB-14023. Use the bacteria stored at -85°C to inoculate the bacteria obtained by static culture on the YM medium as the inoculum, and inoculate it in a mixture of glucose 100g, yeast extract 10g, KH 2 PO 4 1g, (NH 4 ) 2 SO 4 1g, Mg(SO 4 )·7H 2 O 0.5 g was dissolved in 1 l of deionized water, and 100 ml was dispensed into a Erlenmeyer flask and subjected to high-pressure sterilization at 120°C for 5 minutes in the culture medium, and the culture cultured for about 8 hours was taken as the bacterial species (seed). System configuration and image 3as shown. That is, the main fermenter is a glass tank with a full capacity of 1 liter, and a stirrer with a magnetic stirrer is installed inside, and the stirring is performed slowly at a rotation speed of about 400 rpm. The entire tank is immersed in a water bath, and the temperature of the culture is controlled by circulation of warm water at 37°C. A composite glass electrode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com