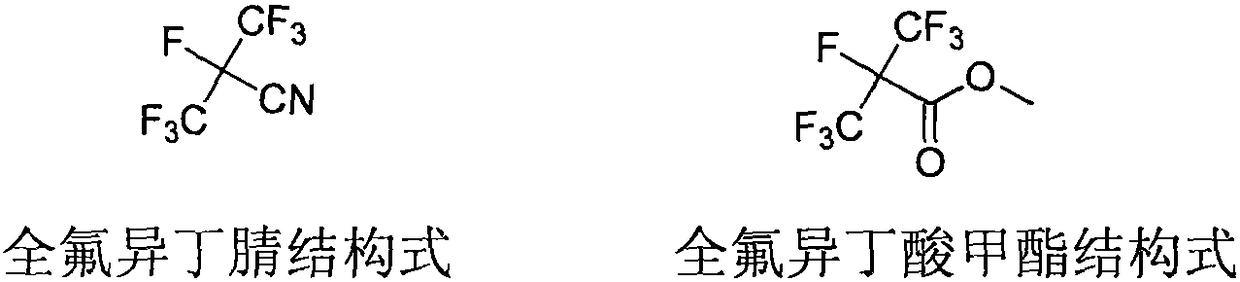

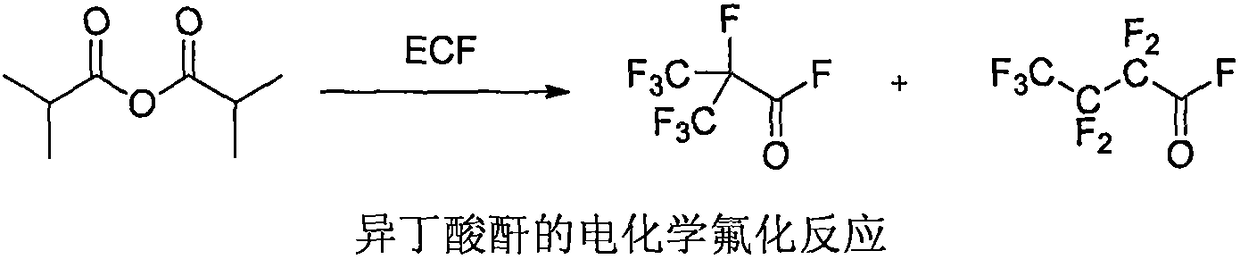

Method for preparing perfluoromethyl isobutyrate by electrochemical fluorination

A perfluoromethyl isobutyrate, electrochemical technology, applied in the direction of electrolysis process, electrolysis components, electrolysis organic production, etc., can solve the problems of difficult operation, complicated distillation and purification process, large proportion of by-products, etc., and achieve reaction selection The effect of good performance, high yield, and no isomer by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Put 800g of methacrylic anhydride into an electrochemical reactor containing 10kg of anhydrous hydrogen fluoride at 0°C, control the operating voltage of the electrochemical reactor to 4.5V-5.0V, and the current density at 5-10mA / cm 2 , the system temperature was maintained at 0-5°C. During the reaction process, the gaseous product generated was passed through the gas phase outlet of the reactor, and slowly passed into a reaction kettle containing 1L of methanol and 530g of anhydrous sodium fluoride, and fully reacted for 3 hours at room temperature. After the reaction was finished, the reaction solution was filtered, and the unreacted methanol was removed by distillation from the obtained filtrate, leaving 1055 g of colorless and transparent liquid methyl heptafluoroisobutyrate. The product was characterized by gas chromatography and no methyl heptafluoro-n-butyrate by-product was detected. The purity of methyl heptafluoroisobutyrate is 90.41%, the reaction selectivity...

Embodiment 2

[0022] Put 1kg of methacrylic acid into the electrochemical reactor containing 17kg of anhydrous hydrogen fluoride at 0°C, control the operating voltage of the electrochemical reactor to 5.0V-10V, and the current density at 25-30mA / cm 2 , the system temperature was maintained at 0-5°C. During the reaction process, the gaseous product produced was passed through the gas phase outlet of the reactor, and slowly passed into a reaction kettle containing 1L of methanol and 595g of anhydrous sodium fluoride, and fully reacted for 3 hours at room temperature. After the reaction, the reaction liquid was filtered, and the unreacted methanol was removed by distillation from the obtained filtrate, leaving 1105g of colorless and transparent liquid methyl heptafluoroisobutyrate, and the product was characterized by gas chromatography without detecting the by-product of methyl heptafluorobutyrate , purity 91.22%, reaction selectivity 38.05%, product yield 38.05%. 1 H NMR (500 MHz, CDCl 3 )...

Embodiment 3

[0024] Put 500g of methacryloyl chloride into an electrochemical reactor containing 5kg of anhydrous hydrogen fluoride at 0°C, control the operating voltage of the electrochemical reactor to 6.0V-10V, and the current density at 15-30mA / cm 2 , the system temperature was maintained at -10 to 1°C. During the reaction process, the gaseous product generated was passed through the gas phase outlet of the reactor, and slowly passed into a reaction kettle containing 1L of methanol and 250g of anhydrous sodium fluoride, and fully reacted for 2 hours at room temperature. After the reaction, the reaction liquid was filtered, and the obtained filtrate was distilled to remove unreacted methanol, leaving 458g of colorless and transparent liquid methyl heptafluoroisobutyrate, and the product was characterized by gas chromatography without detecting methyl heptafluoro-n-butyrate as a by-product , purity 93.03%, reaction selectivity 39.06%, product yield 39.06%. 1 H NMR (500 MHz, CDCl 3 )δ4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com