Hydrogenation catalyst and application thereof

A hydrogenation catalyst and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, inorganic chemistry, etc., can solve problems such as desorption of unfavorable reaction products, increased consumption of anthraquinone, etc. To achieve the effect of improving the activity and reaction selectivity and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

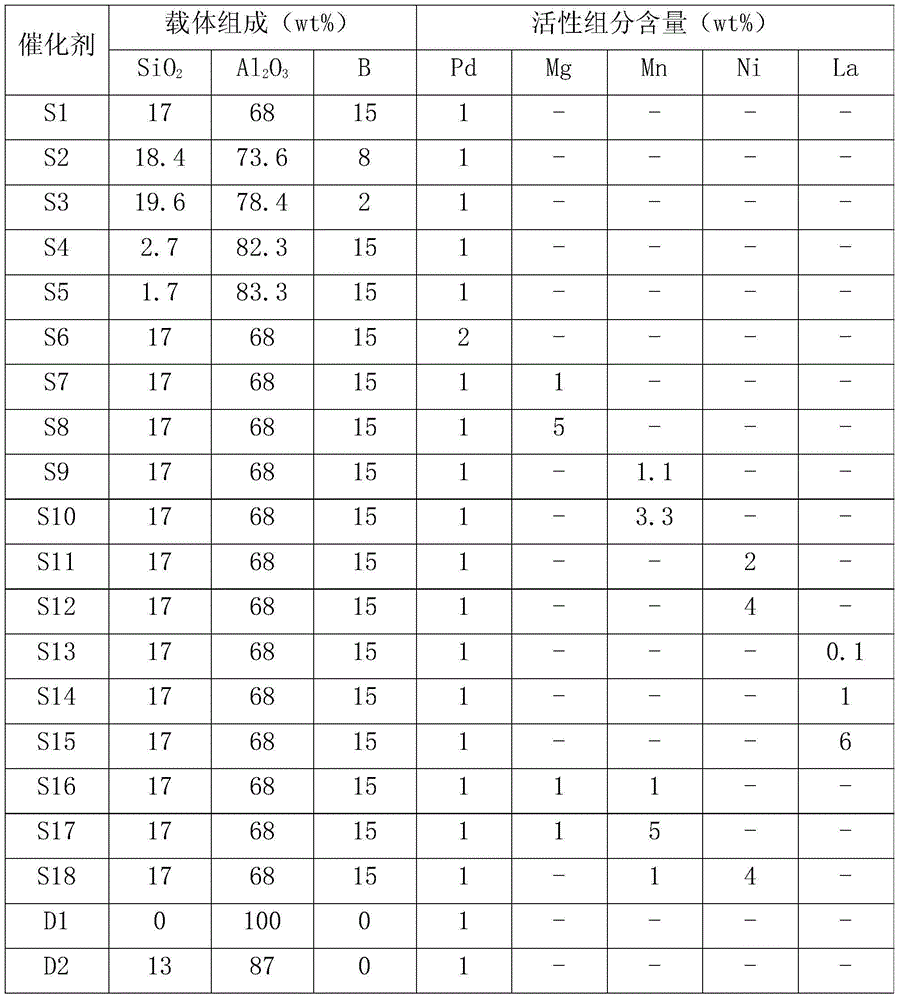

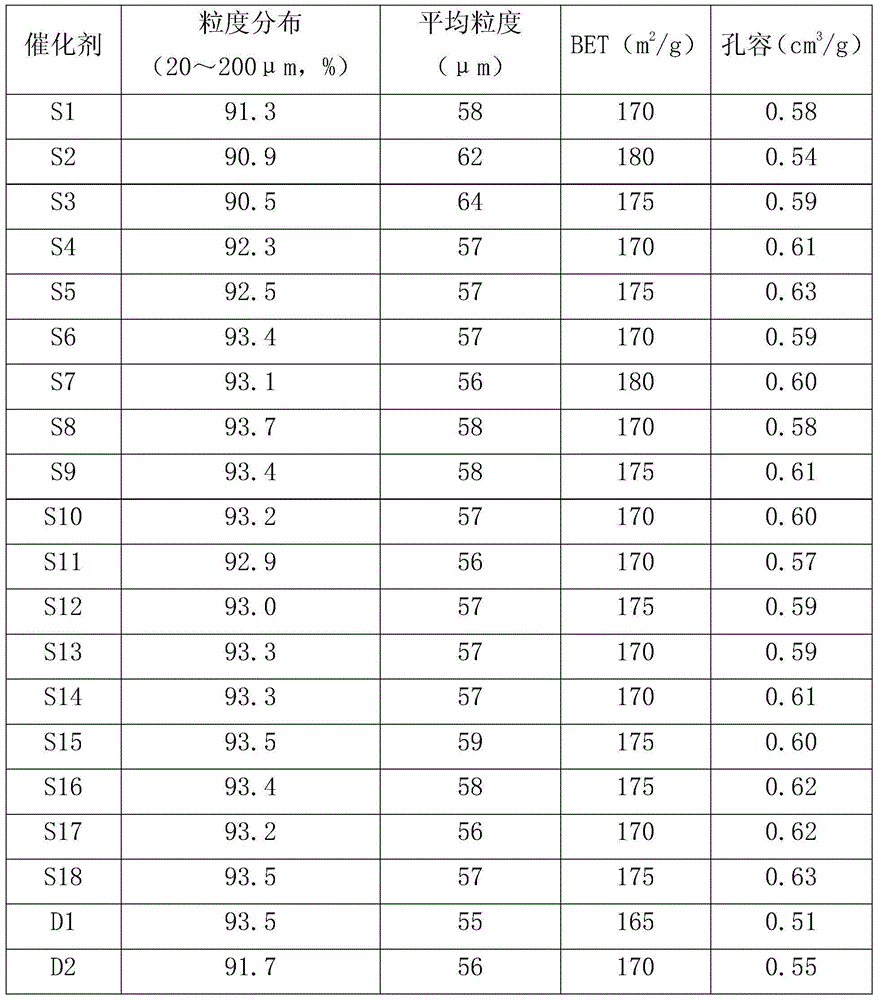

Embodiment 1

[0033] (1) Carrier preparation

[0034] Add 5kg deionized water in the stirred kettle, add 300g pseudo-boehmite (Germany Condea company, SB, the same below), after stirring and mixing evenly, add silica sol (Qingdao Ocean Chemical Co., Ltd., 40wt%, the same below), so that the silicon-aluminum mass ratio is SiO 2 :Al 2 o 3 =1:4, continue stirring to mix evenly. Take 272.6 g of boric acid (Beijing Huawei Raycus Chemical Co., Ltd., AR) powder, add it to the above slurry, stir and mix evenly to obtain a mixed slurry. The mixed slurry is dried and formed by spray drying equipment. The operating conditions of spray drying are hot air inlet temperature 250°C and exhaust air outlet temperature 150°C. The solid particle powder obtained after spray drying was calcined at 550° C. for 8 hours to obtain the desired carrier.

[0035] (2) Catalyst preparation

[0036] Dissolve 0.168g of palladium chloride (Sinopharm Reagent, AR, the same below) in 10mL of deionized water, take 10g of...

Embodiment 2

[0038] (1) Carrier preparation

[0039] Add 5kg of deionized water into the stirred tank, start stirring and add 300g of pseudo-boehmite, after stirring and mixing evenly, add silica sol, so that the mass ratio of silicon to aluminum is SiO 2 :Al 2 o 3=1:4, continue stirring to mix evenly. Take 134g of boric acid powder, add it into the above slurry, stir and mix evenly to obtain a mixed slurry. The mixed slurry is dried and formed by spray drying equipment. The operating conditions of spray drying are hot air inlet temperature 300°C and exhaust air outlet temperature 200°C. The solid particle powder obtained after spray drying was calcined at 600° C. for 5 hours to obtain the desired carrier.

[0040] (2) Catalyst preparation

[0041] Dissolve 0.168g of palladium chloride in 10mL of deionized water, take 10g of the carrier obtained in step (1), disperse the carrier into the palladium chloride solution, soak at room temperature for 10h, then dry at 100°C for 4h, and then ...

Embodiment 3

[0043] (1) Carrier preparation

[0044] Add 5kg of deionized water into the stirred tank, start stirring and add 300g of pseudo-boehmite, after stirring and mixing evenly, add silica sol, so that the mass ratio of silicon to aluminum is SiO 2 :Al 2 o 3 =1:4, continue stirring to mix evenly. Take 31.5 g of boric acid powder, add it to the above slurry, stir and mix evenly to obtain a mixed slurry. The mixed slurry was dried and formed by spray drying equipment. The spray drying operating conditions were hot air inlet temperature 350°C and exhaust air outlet temperature 250°C. The solid particle powder obtained after spray drying was calcined at 550° C. for 8 hours to obtain the desired carrier.

[0045] (2) Catalyst preparation

[0046] Dissolve 0.168g of palladium chloride in 10mL of deionized water, take 10g of the carrier obtained in step (1), disperse the carrier into the palladium chloride solution, soak at 40°C for 8h, then dry at 80°C for 10h, and then Calcined at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com