An electrochemical fluorination electrolyzer

A fluorinated electrolytic cell and electrochemical technology, applied in the field of electrochemistry, can solve the problems of small effective electrolysis area, decreased electrolysis efficiency, and time-consuming, and achieve the effects of large effective electrolysis area, reduced labor intensity, and high space utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

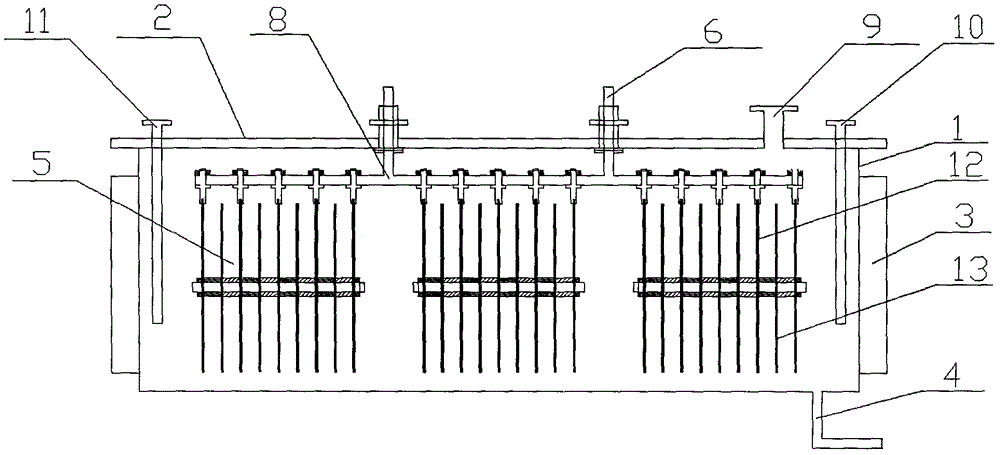

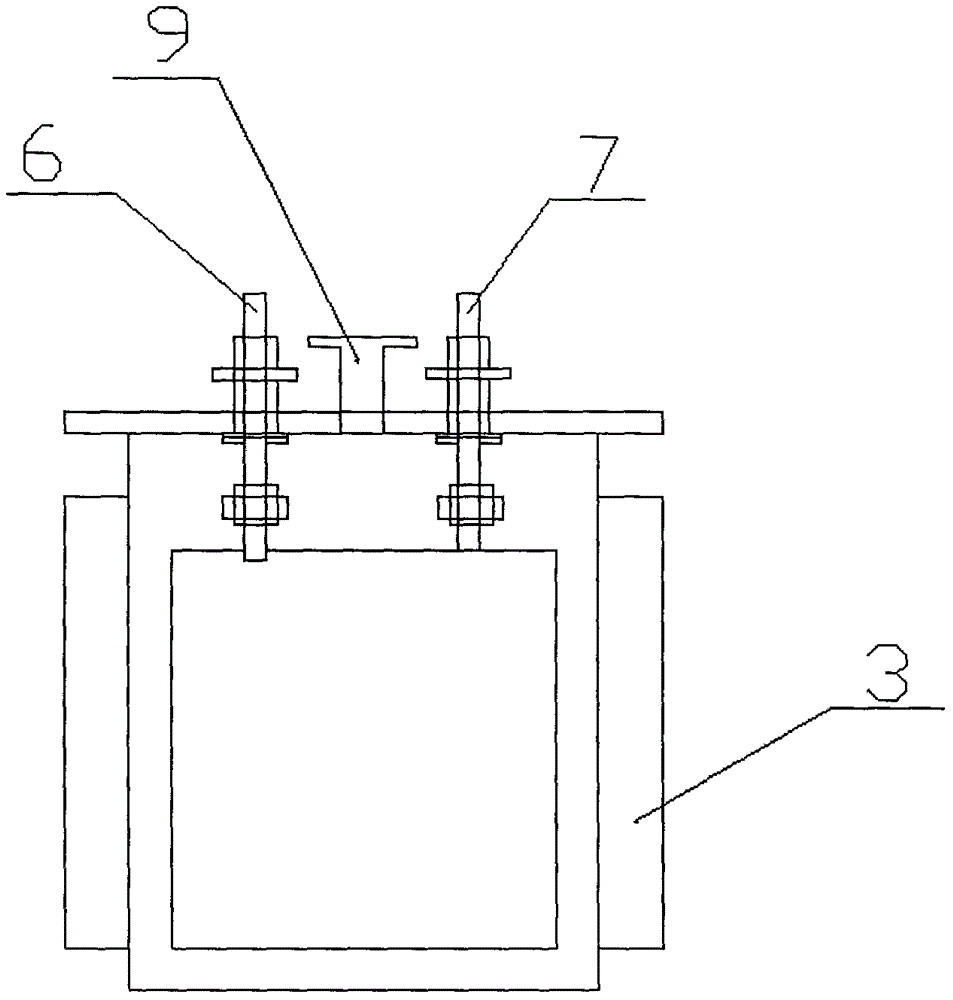

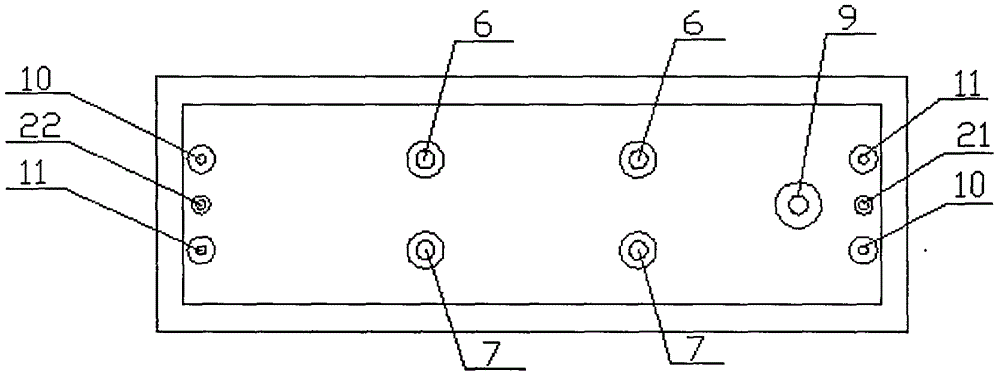

[0025] Taking the electrolytic fluorination of methanesulfonyl chloride as an example, 51 nickel electrode plates, nickel beams, rods and nickel nuts with a thickness of 2mm were polished with a wire wheel brush before use. It is divided into 3 groups of electrode groups, one anode conductive beam, one cathode conductive beam, each electrode group has 17 electrode plates (9 anodes, 8 cathodes), and the threaded PTFE fixed shaft 15 The electrode plate is fixed through the center hole 19 of the plate, and the cathode and anode plates are insulated with a 10mm thick annular polytetrafluoroethylene insulating pad 17, and the distance between the electrode plates is 10mm. Fix the electrodes with Teflon insulating nuts 16 at both ends of the fixed shaft, and then pass the electrode screws 20 on the top of the cathode and anode electrode plates through the hollow structure in the middle of the nickel conductive beam 8, and use nickel conductive nuts 18 for fastening, after measuring ...

Embodiment 2

[0027] Taking the electrolytic fluorination of sulfolane as an example to produce perfluorobutylsulfonyl fluoride products, the cell assembly process is the same as in Example 1, the distance between the electrode plates is 5mm, and the electrolysis parameters are controlled: electrolysis concentration 7%, current 4.5-6.5V, current Density 20mA / cm 2 , the temperature is 10°C. During the process, the HF solution of sulfolane with a certain concentration in the proton tank is added through the feeding port, and the perfluorobutylsulfonyl fluoride generated during the electrolysis process is deposited on the bottom, and the crude product is collected through the bottom discharge valve and then washed with alkali, washed with water, dried, Distillation, the product yield reaches 48.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com