Novel low-resistance chlor-alkali industrial ion-conducting membrane and preparation method thereof

An ion-conducting membrane, a technology for the chlor-alkali industry, applied in the field of new low-resistance chlor-alkali industrial ion-conducting membranes and its preparation, can solve problems such as increased membrane resistance and increased tank pressure, and achieve reduced adhesion, lowered tank voltage, and improved process Simple and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

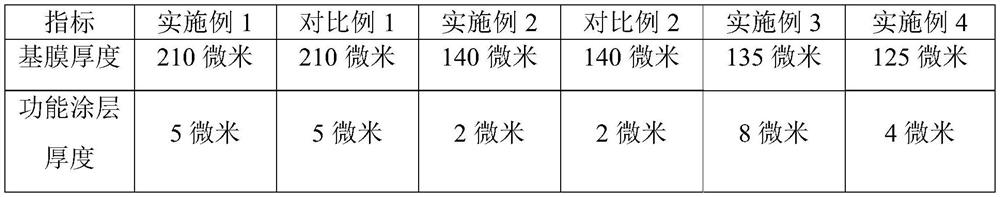

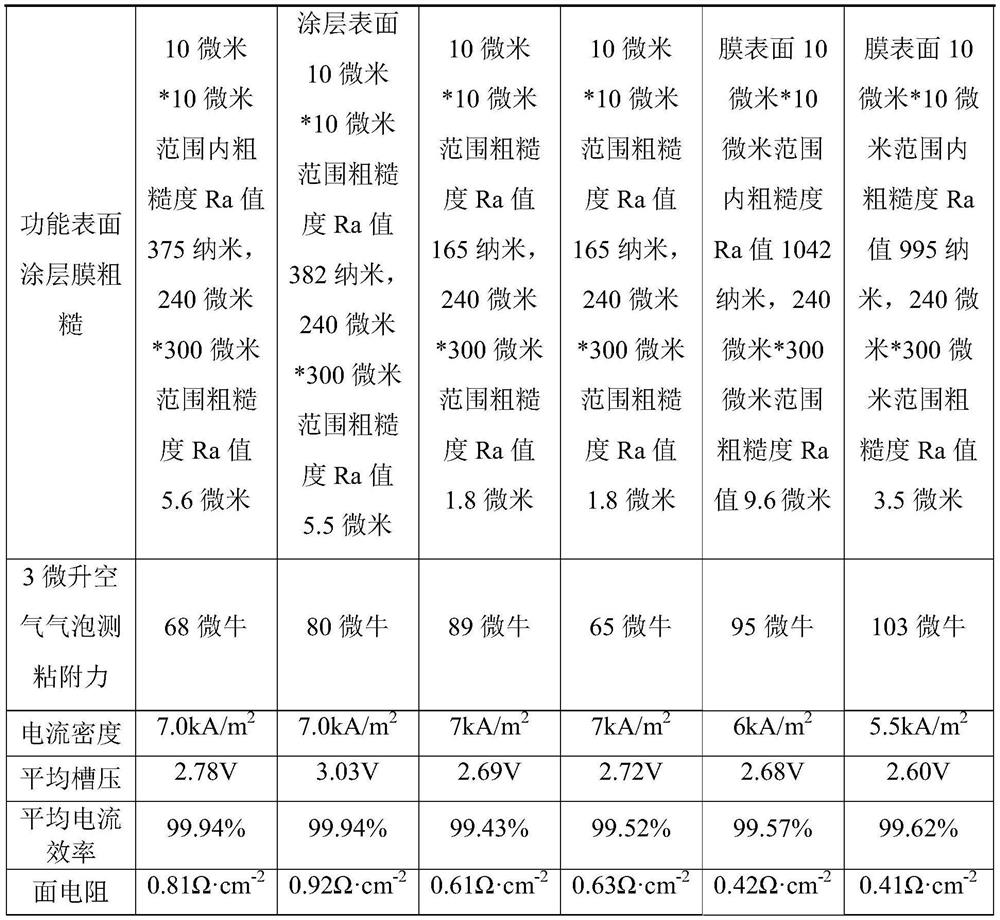

Embodiment 1

[0043] The novel low-resistance chlor-alkali industrial ion-conducting membrane shown in Example 1 consists of the first perfluorocarboxylic acid-perfluorosulfonic acid polymer composite layer, perfluorocarboxylic acid polymer layer, perfluoropolymer reinforced network and functional The surface coating is composed of a surface coating; wherein, the functional surface coating is a porous rough structure composed of a perfluorinated ion polymer, and the perfluoropolymer reinforced mesh is composed of polytetrafluoroethylene and silk.

[0044] The preparation method of the novel low-resistance chlor-alkali industrial ion-conducting membrane described in this embodiment 1 is prepared by the following steps:

[0045] (1) Adopt the perfluorosulfonic acid resin of IEC=1.0mmol / g and the perfluorocarboxylic acid resin of IEC=0.8mmol / g to obtain material A through melt granulation according to mass ratio 10:1, then adopt material A and IEC= 0.8mmol / g perfluorocarboxylic acid resin is m...

Embodiment 2

[0059] The novel low-resistance chlor-alkali industrial ion-conducting membrane shown in Example 2, perfluorosulfonic acid polymer layer, the second perfluorocarboxylic acid-perfluorosulfonic acid polymer composite layer, perfluoropolymer reinforced net and functional surface Coating composition; Among them, the functional surface coating is a porous rough structure composed of perfluoroionic polymers, and the perfluoropolymer reinforced mesh is composed of polytetrafluoroethylene and silk.

[0060] The preparation method of the novel low-resistance chlor-alkali industrial ion-conducting membrane described in this embodiment 2 is prepared by the following steps:

[0061] (1) Use IEC=1.0mmol / g perfluorosulfonic acid resin and IEC=0.8mmol / g perfluorocarboxylic acid resin to obtain material A through melt granulation at a mass ratio of 1:100, and then use material A and IEC= 1.0mmol / g perfluorosulfonic acid resin is mixed and co-extruded to form a perfluoroion exchange resin base...

Embodiment 3

[0076] The new low-resistance chlor-alkali industrial ion-conducting membrane described in this embodiment 3 consists of the first perfluorocarboxylic acid-perfluorosulfonic acid polymer composite layer, the second perfluorocarboxylic acid-perfluorosulfonic acid polymer composite layer, It is composed of perfluoropolymer reinforced net and functional surface coating; among them, the functional surface coating is a porous rough structure composed of perfluoropolymer, and the perfluoropolymer reinforced net is composed of non-woven polymer and protein fiber. into.

[0077] The preparation method of the novel low-resistance chlor-alkali industrial ion-conducting membrane described in this embodiment 3 is prepared by the following steps:

[0078](1) Use IEC=1.0mmol / g perfluorosulfonic acid resin and IEC=0.8mmol / g perfluorocarboxylic acid resin to obtain material A through melt granulation at a mass ratio of 10:1, using IEC=1.0mmol / g The perfluorosulfonic acid resin and the perflu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com