Patents

Literature

143 results about "Fluorosulfuric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorosulfuric acid (IUPAC name: sulfurofluoridic acid) is the inorganic compound with the chemical formula HSO₃F. It is one of the strongest acids commercially available. The formula HSO₃F emphasizes its relationship to sulfuric acid, H₂SO₄; HSO₃F is a tetrahedral molecule. It is a colourless liquid, although commercial samples are often yellow.

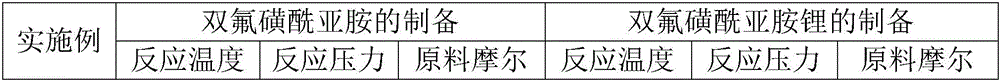

Preparation method of difluoro-sulfimide and lithium difluoro-sulfimide

InactiveCN106365132AFew reaction stepsSimple processNitrosyl chlorideAmidosulfonic acidChemical synthesisDistillation

The invention relates to a preparation method of difluoro-sulfimide and lithium difluoro-sulfimide, and belongs to the field of fluorine chemical synthesis. The preparation method comprises the steps that difluoro-sulfimide is obtained by adding fluoro-sulfoxide into a mixture of sulfamic acid or amino sulfonyl fluoride and fluorosulfuric acid for reacting and then subjected to recrystallization and filtration which are conducted at the temperature of minus 100 DEG C to 16 DEG C and / or reduced / normal-pressure distillation and purification which are conducted at the temperature of 60 DEG C to 169 DEG C; difluoro-sulfimide and a lithium-containing substance react in a solvent to obtain lithium difluoro-sulfimide, and then recrystallization, filtration and purification are conducted. According to the preparation method, difluoro-sulfimide can be prepared through one step, lithium difluoro-sulfimide is obtained through lithiation, and the prepared products can be purified; few steps are needed, the technology is simple, the process is easy to control, the requirement on production devices is low, the production efficiency, the product yield and the purity are high, and large-scale production and application can be achieved.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

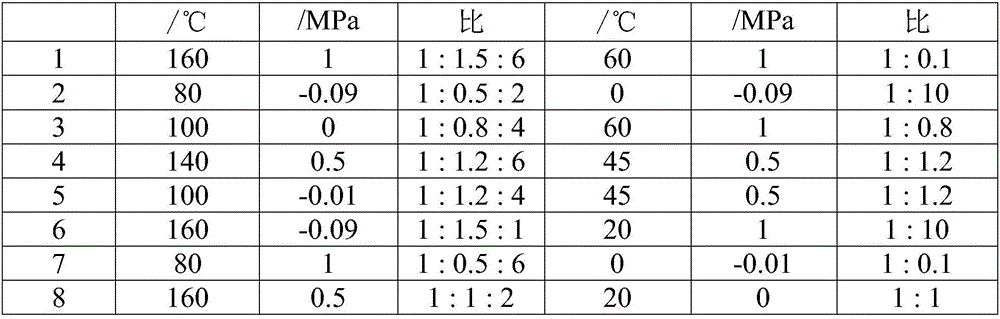

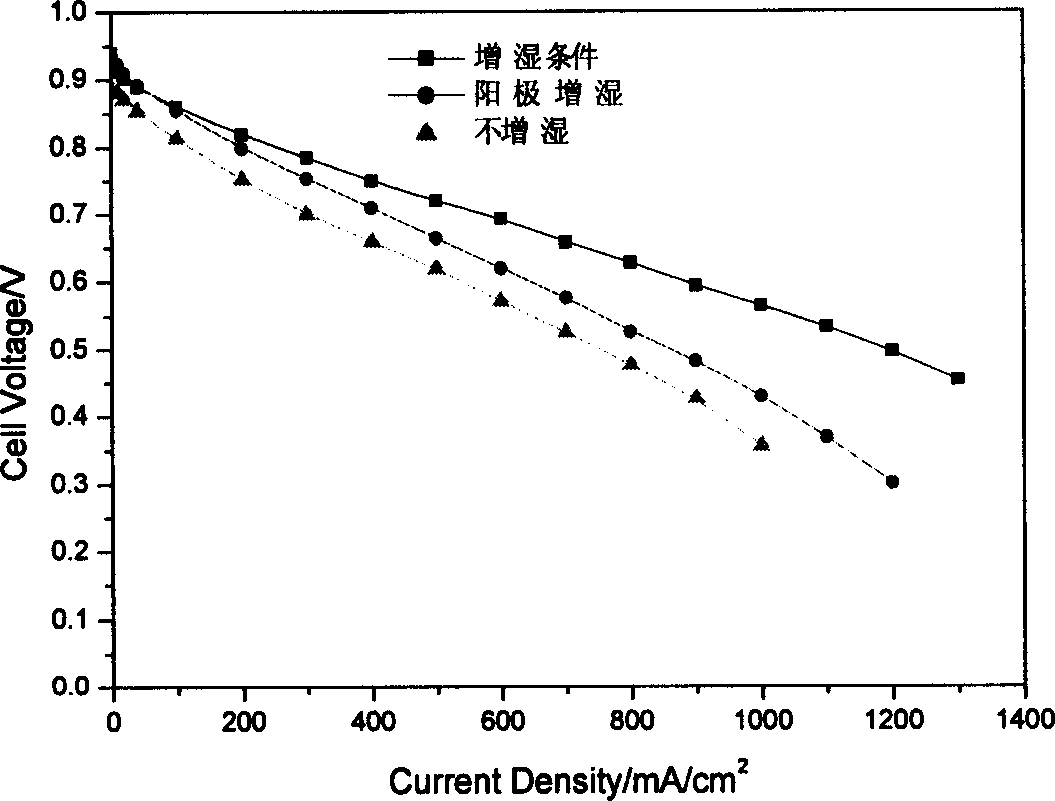

Process for preparing self-humidifying composite proton exchange film for fuel cell

InactiveCN1464580AEasy to operateSimple preparation processSolid electrolyte fuel cellsFuel cell detailsAlcoholOrganic solvent

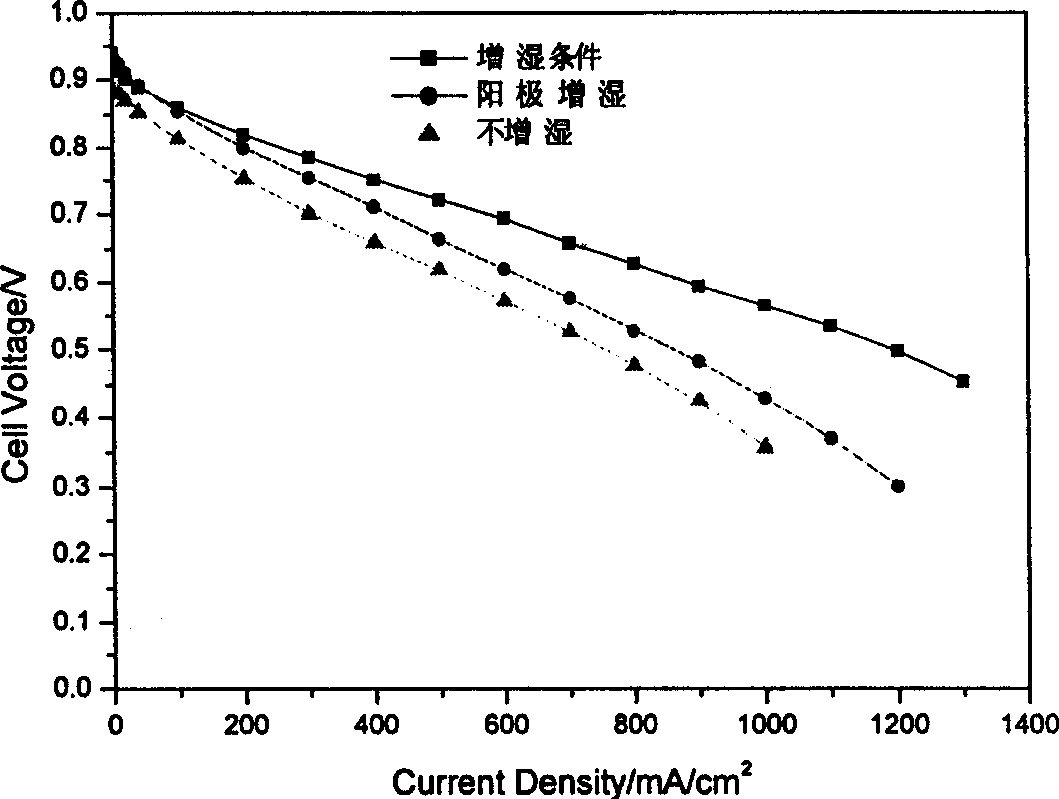

The present invention discloses a process for preparing self-humidifying composite proton exchange membrane for fueling battery comprising, adding heat dissolving all fluorosulfuric acid film into the low boiling point organic alcohol and water dissolvent, forming all fluorosulfuric acid resin solution, adding the carrying type catalyst and high boiling point organic dissolvent containing Pt into the all fluorosulfuric acid resin solution, dropping the solution on the surface of the organic porous membrane, heating up and storing under vacuum.

Owner:SUNRISE POWER CO LTD

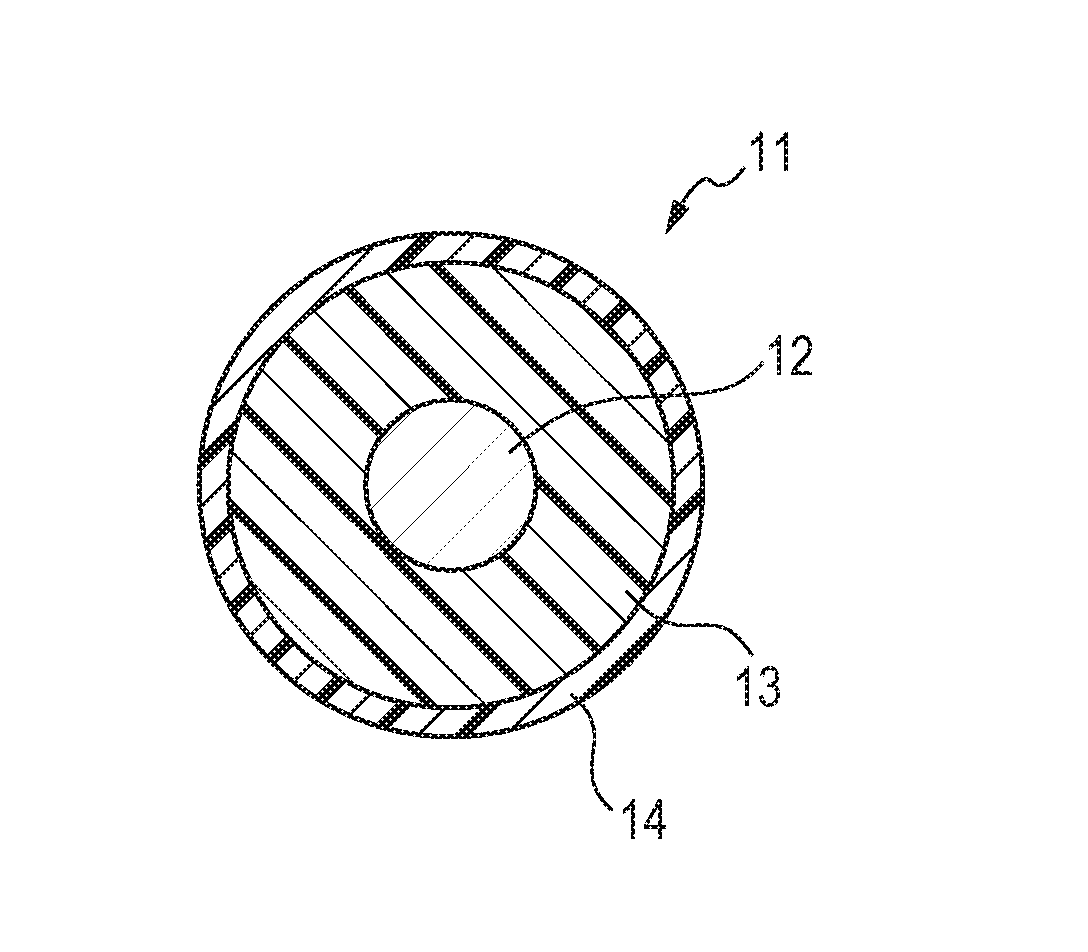

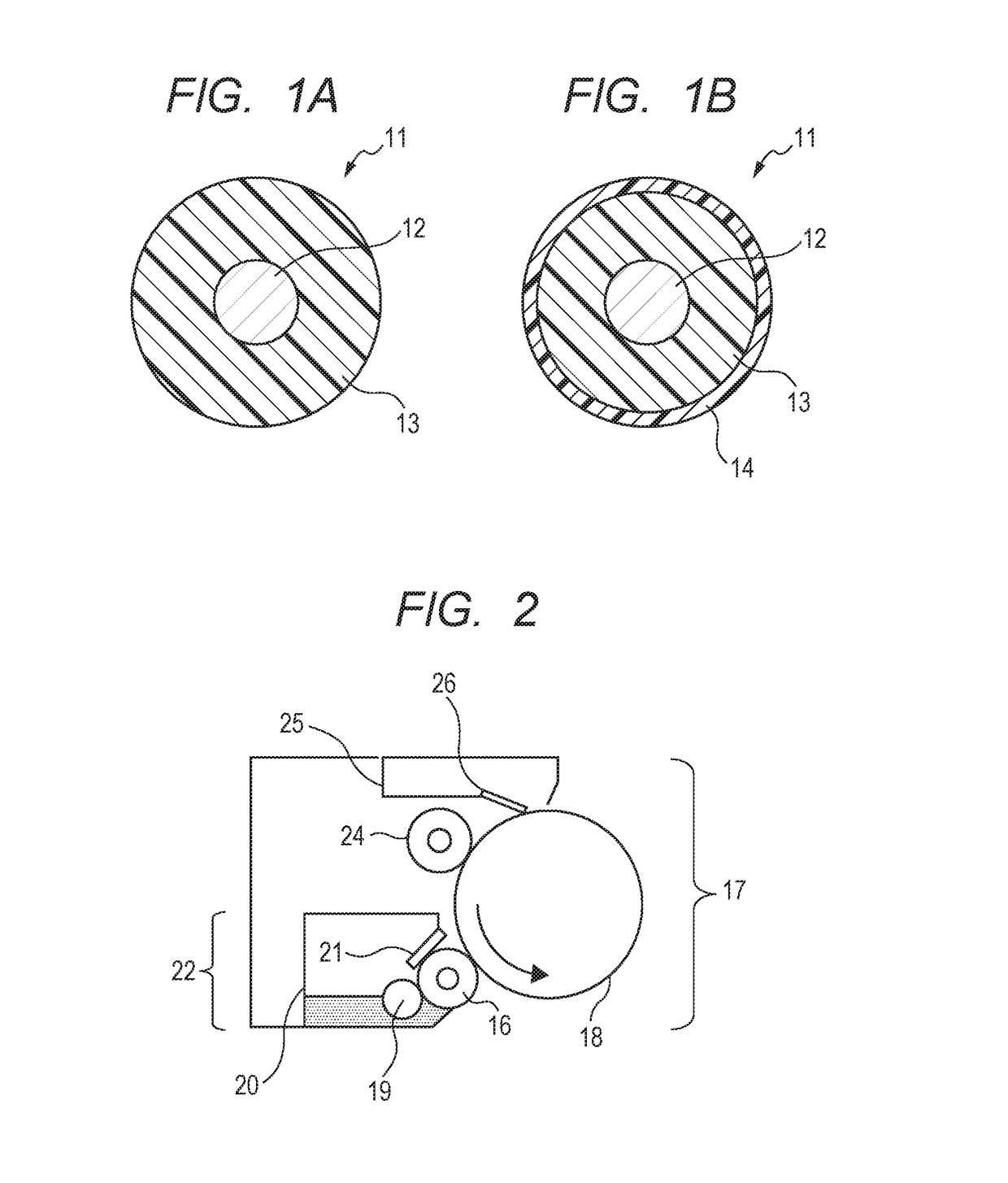

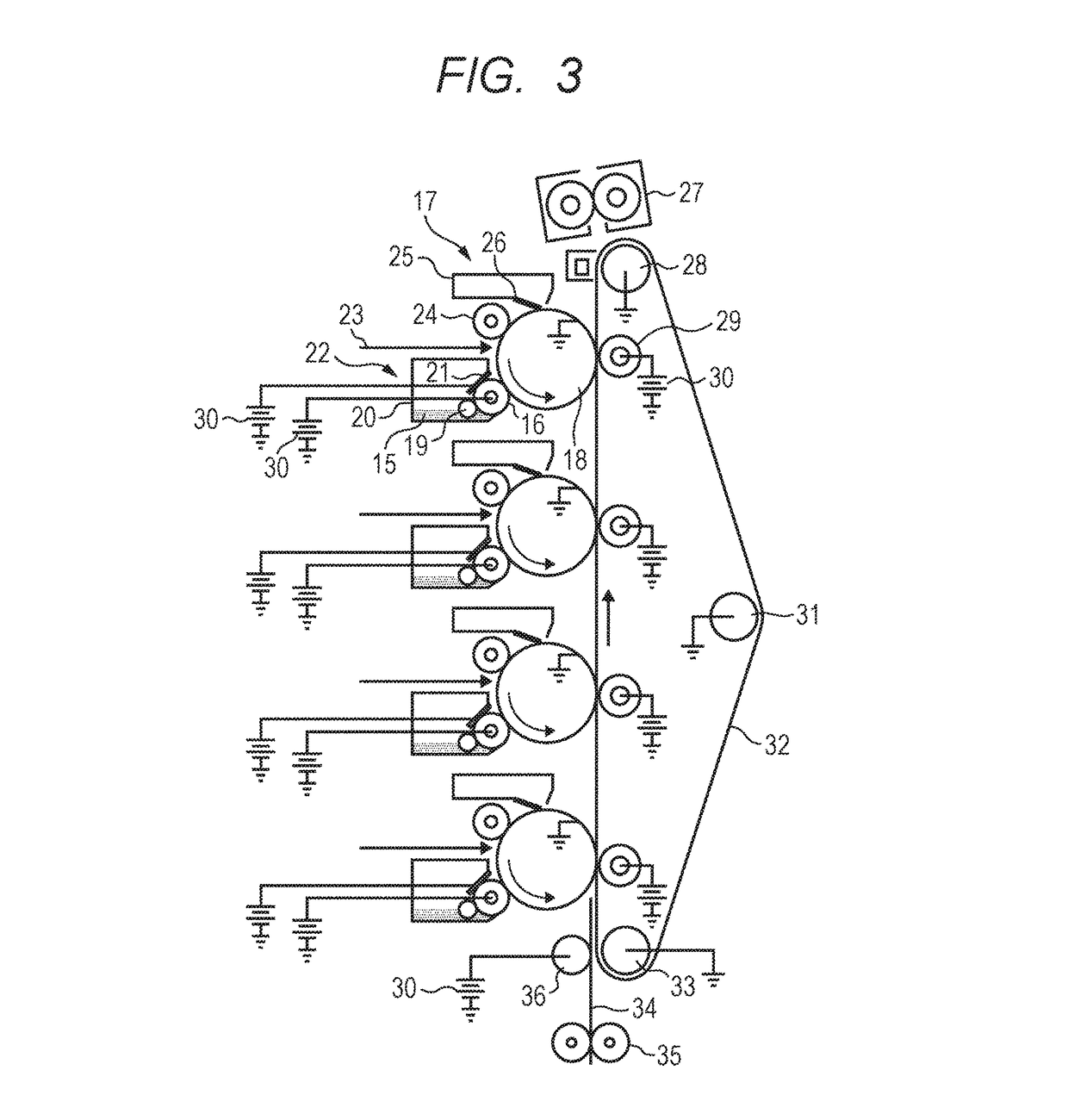

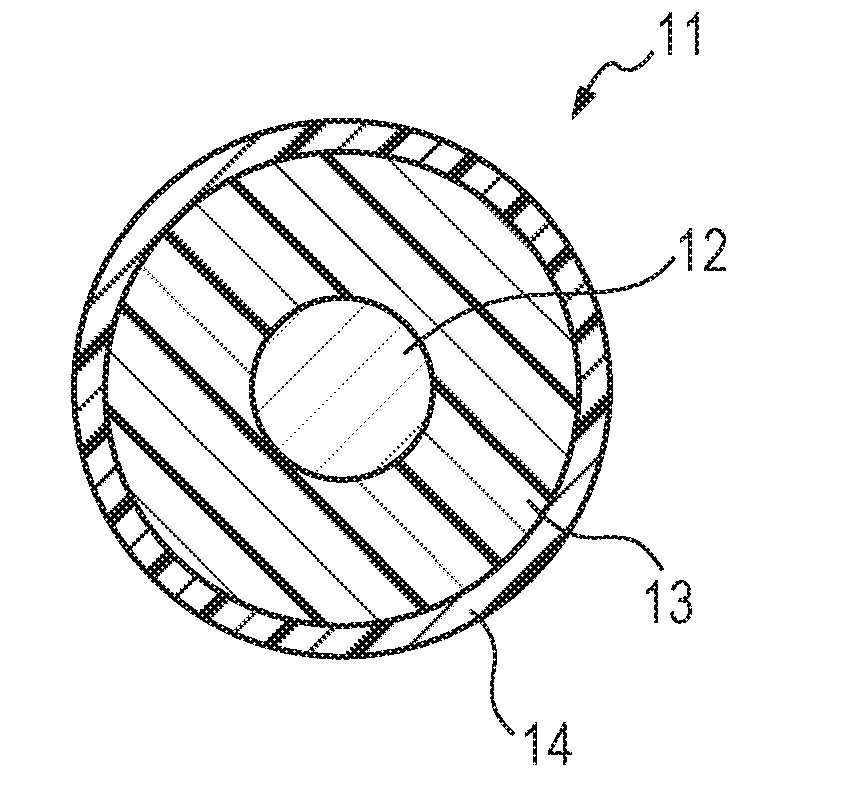

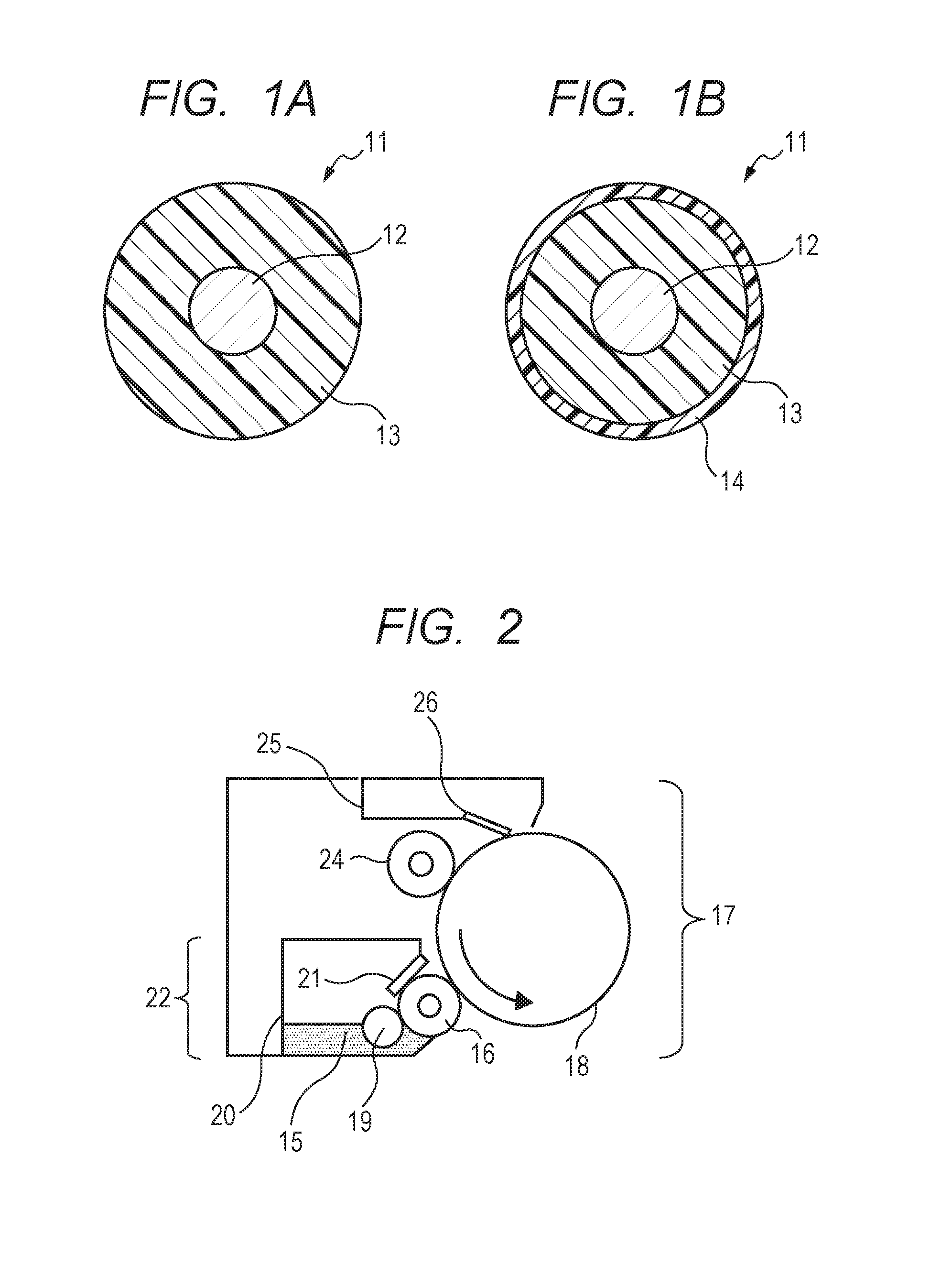

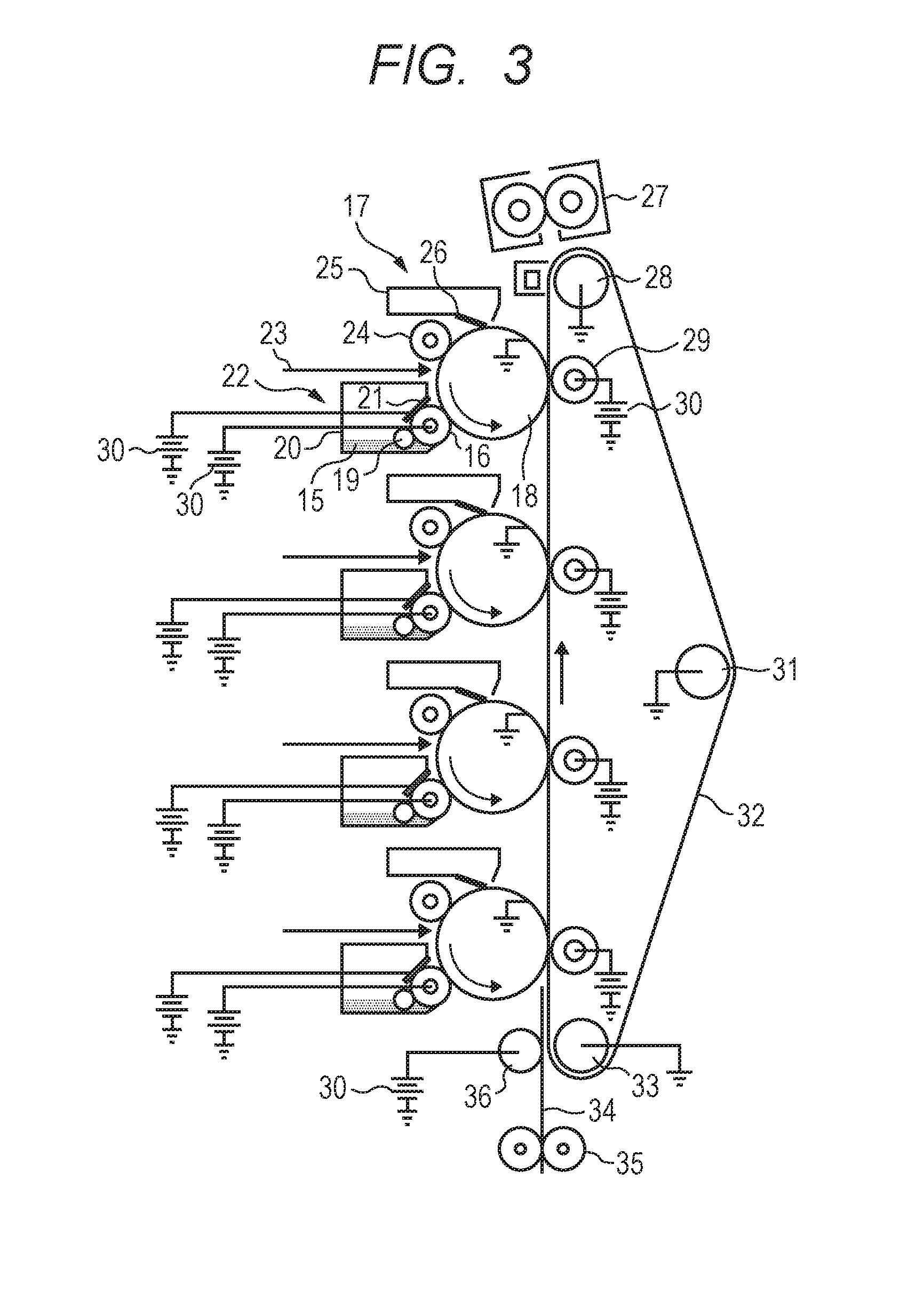

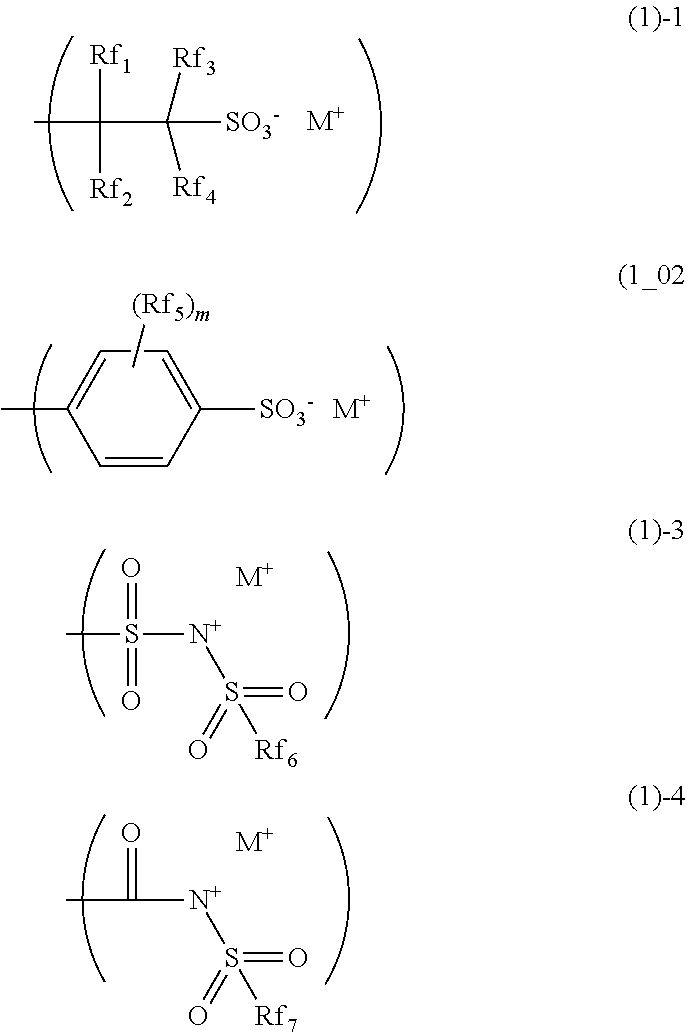

Member for electrophotography and method of producing the member, process cartridge, and electrophotographic apparatus

ActiveUS10108129B2Pretreated surfacesElectrographic process apparatusAlkaline earth metalPhosphoric acid

Provided is a member for electrophotography that is not reduced in charge-providing performance even by its long-term storage and use under a high-temperature and high-humidity environment, and is hence conducive to the formation of a high-quality electrophotographic image. The member for electrophotography includes: an electroconductive substrate; and an electroconductive layer, in which: the electroconductive layer contains a resin having a cationic organic group in a molecule thereof and an anion; a total sum of contents of an alkali metal and an alkali earth metal in the electroconductive layer is 500 ppm or less; and the anion includes at least one selected from the group consisting of a fluorosulfonate anion, a fluorocarboxylate anion, a fluorosulfonylimide anion, a fluorosulfonylmethide anion, a fluoroalkylfluoroborate anion, a fluorophosphate anion, a fluoroantimonate anion, and a fluoroarsenate anion.

Owner:CANON KK

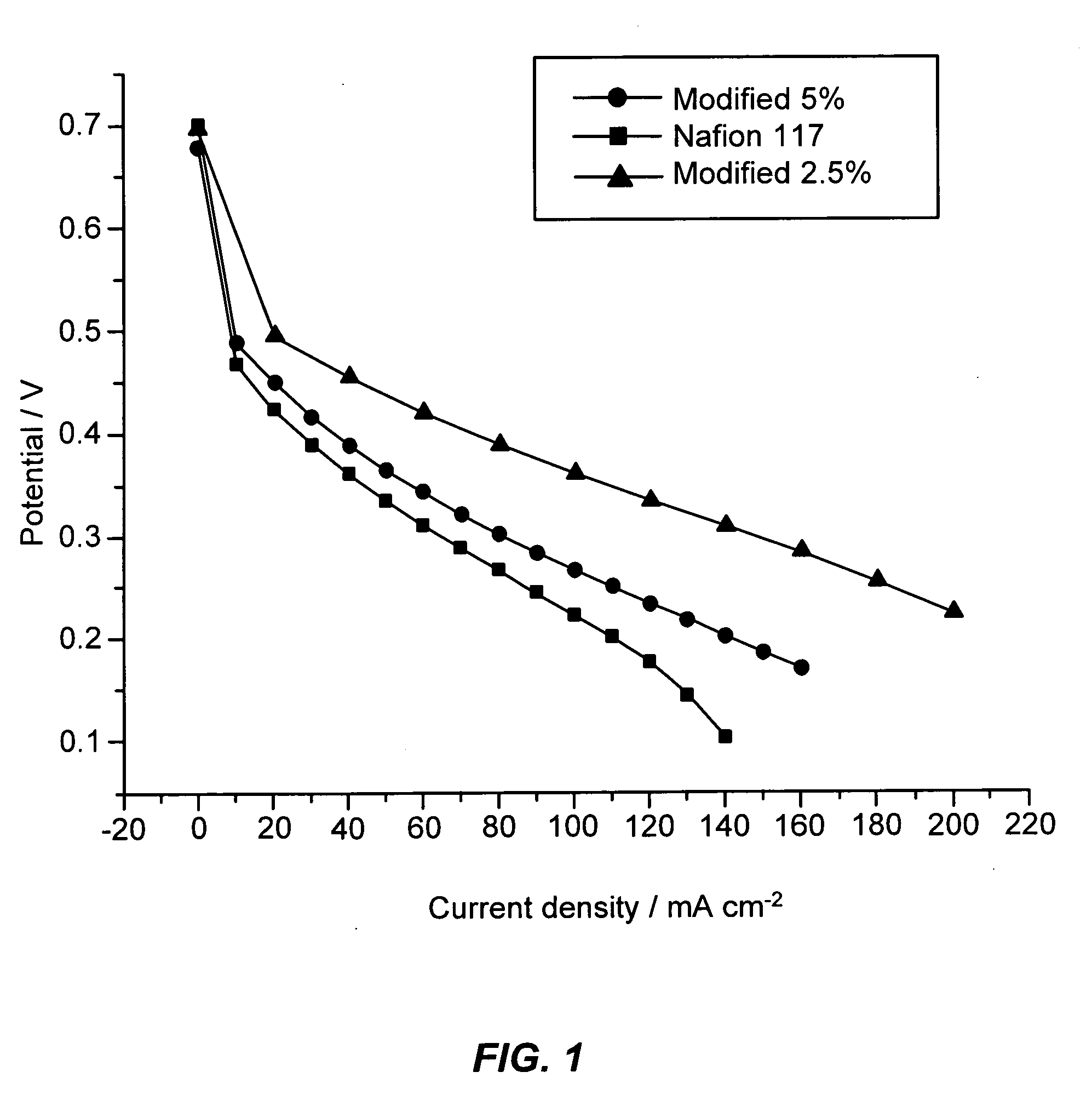

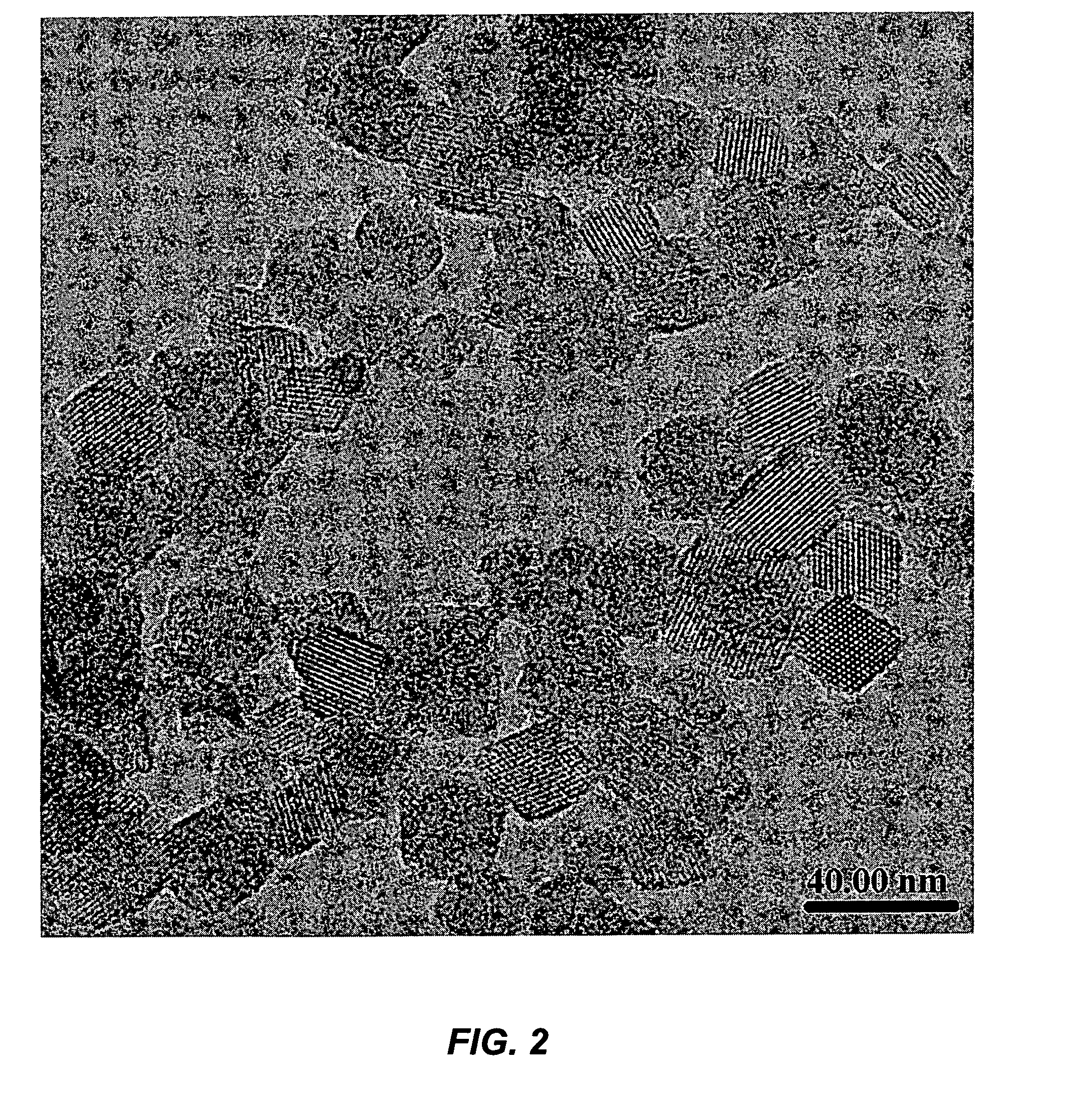

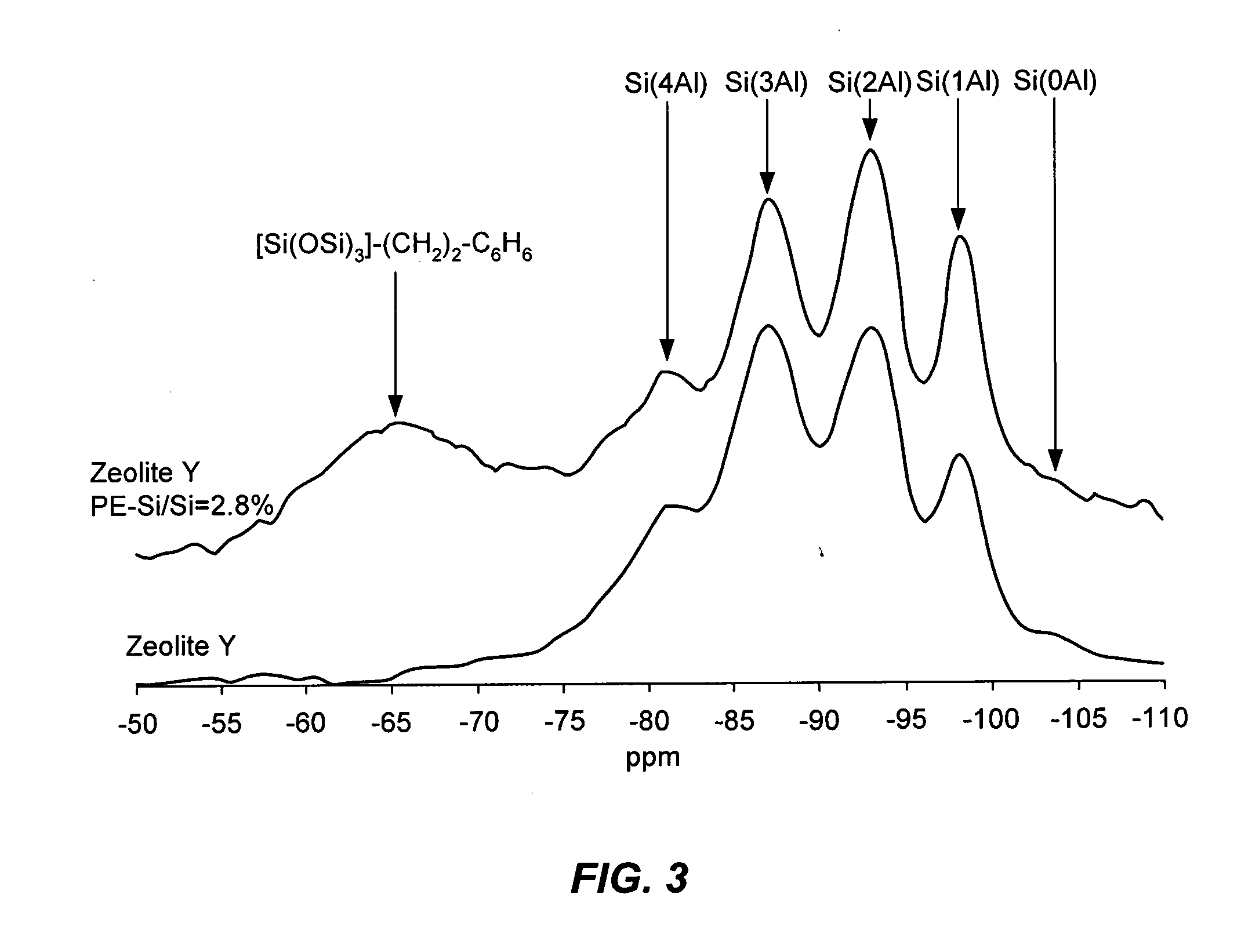

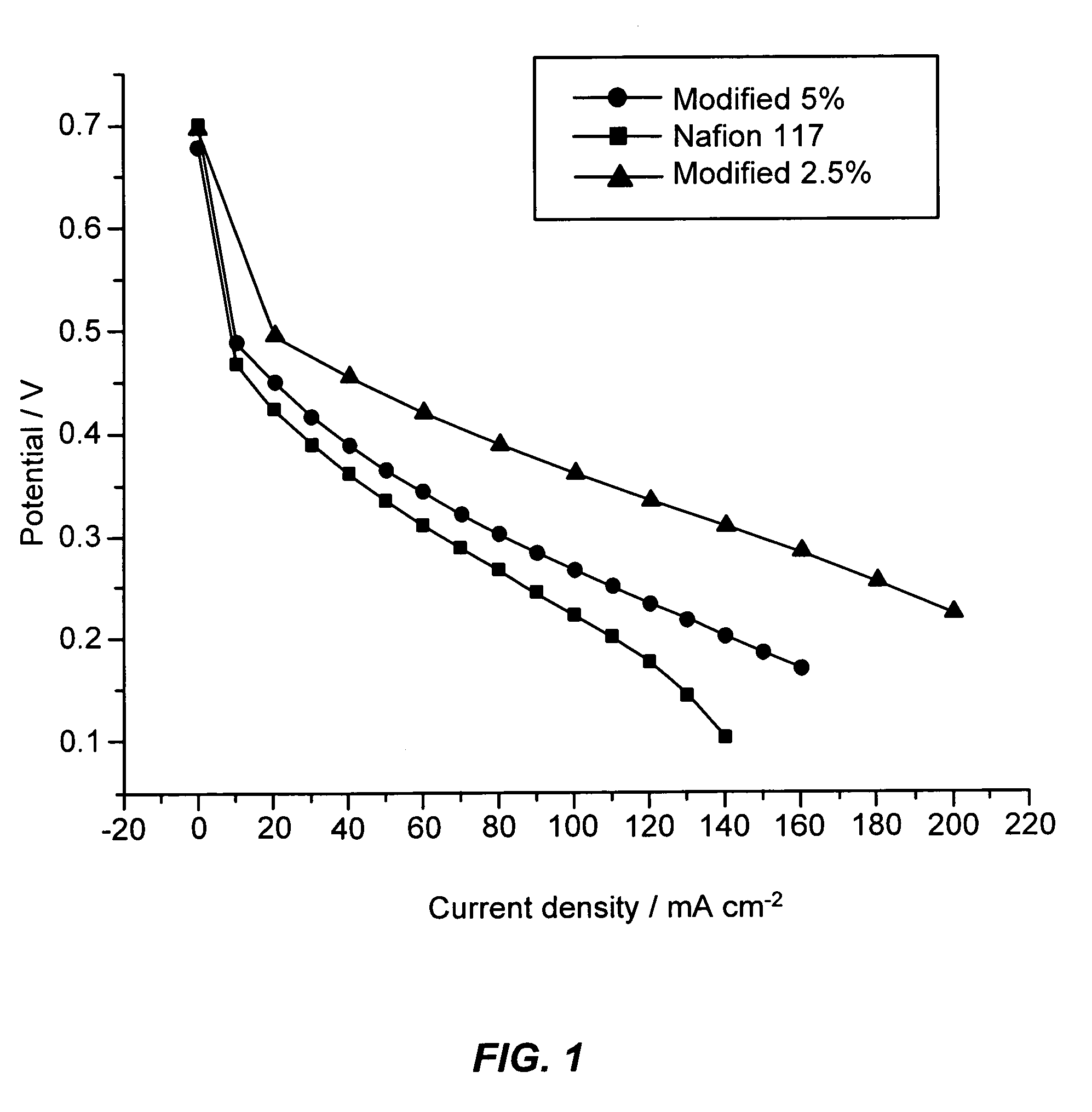

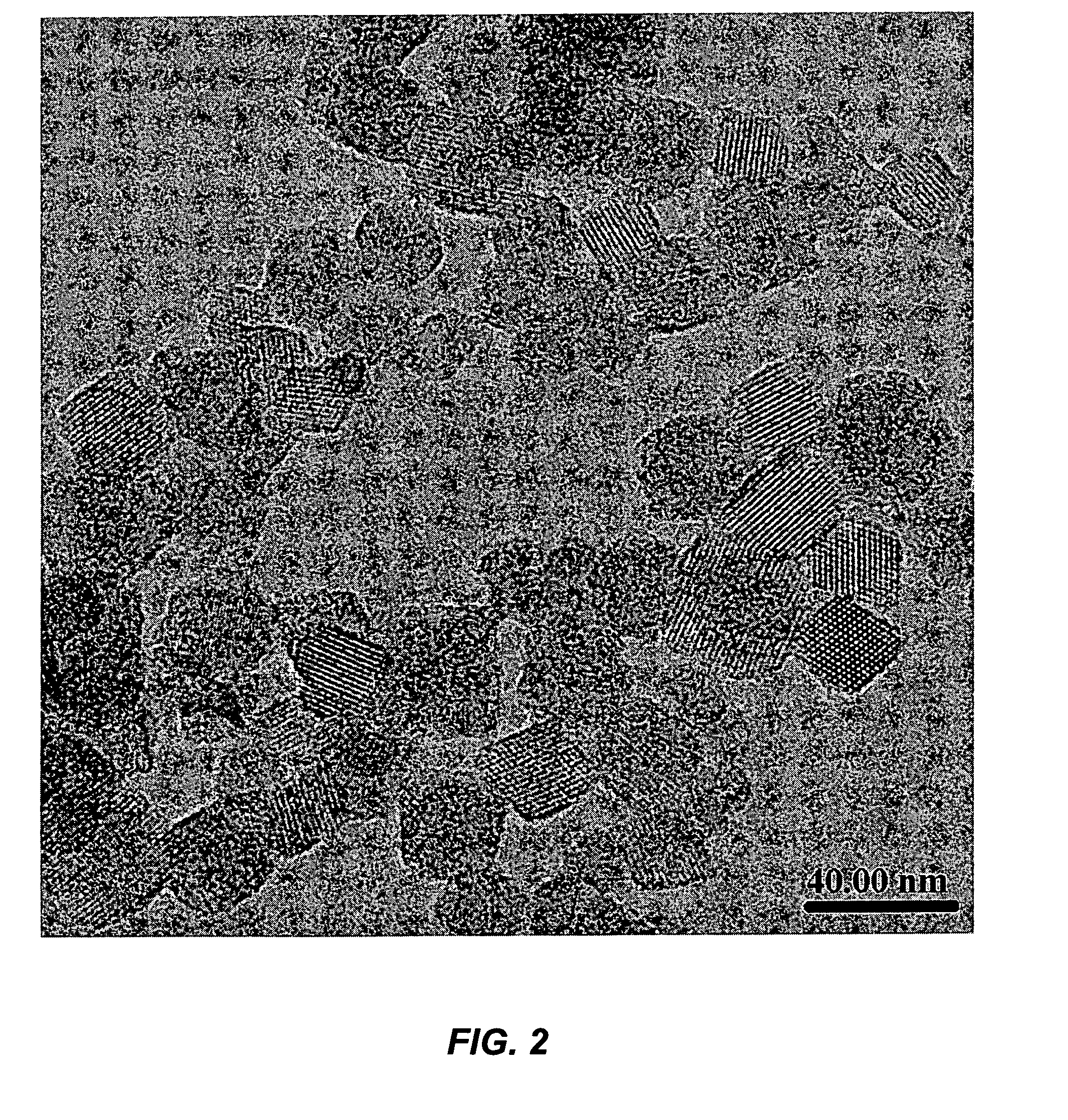

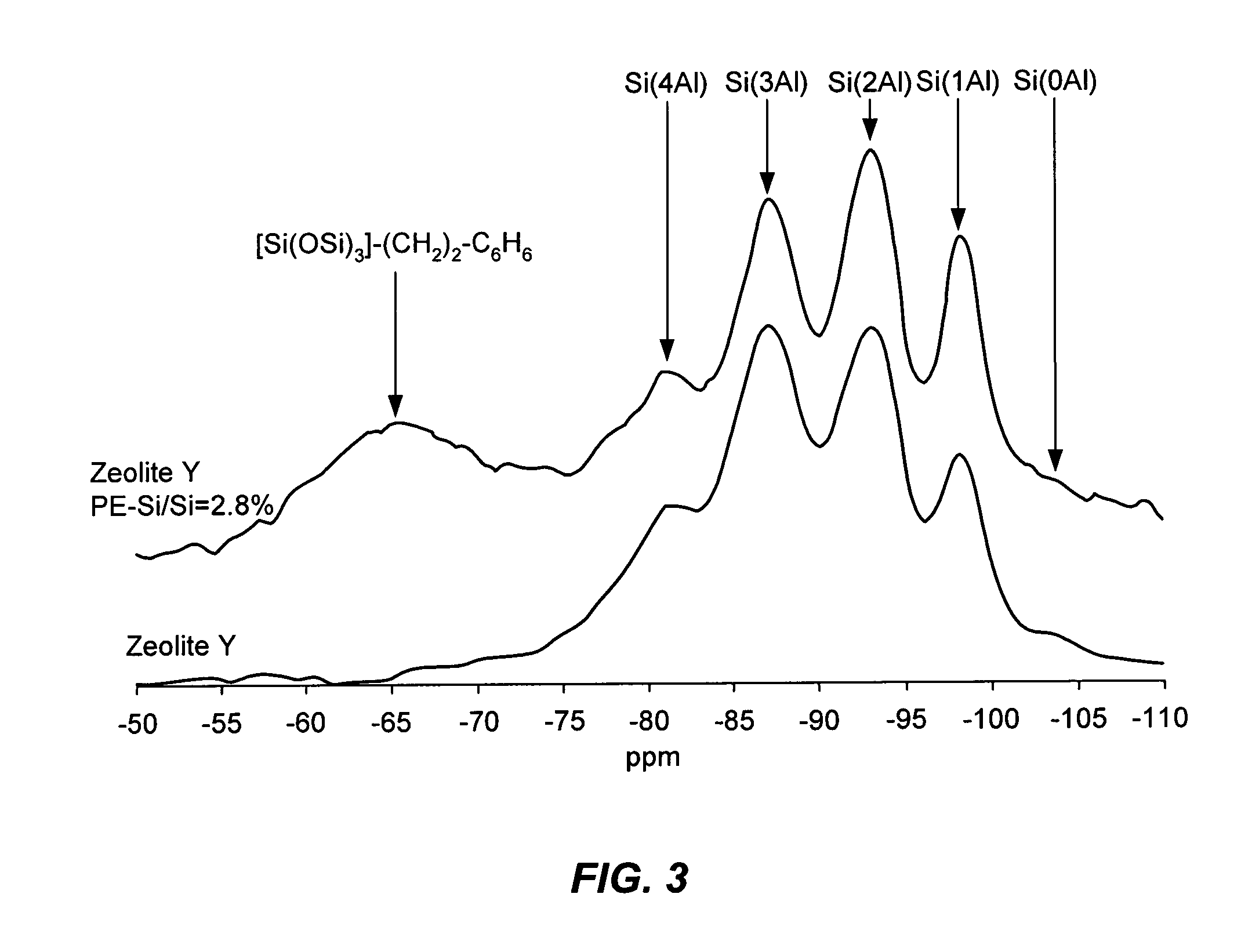

Polymer-zeolite nanocomposite membranes for proton-exchange-membrane fuel cells

InactiveUS20060034757A1Improve proton conductivityImprove oxidation efficiencyMaterial nanotechnologyAluminium compoundsPolymer networkProton

A suite of polymer / zeolite nanocomposite membranes. The polymer backbone is preferably a film forming fluorinated sulfonic acid containing copolymer, such as a Teflon type polymer, a perfluorinated polymer, or a perfluorinated polymer with sulfonic groups. The zeolites formed in accordance with the present invention and which are used in the membranes are plain, phenethyl functionalized and acid functionalized zeolite FAU(Y) and BEA nonocrystals. The zeolite nanocrystals are incorporated into polymer matrices for membrane separation applications like gas separations, and in polymer-exchange-membrane fuel cells. For the purpose of developing zeolite-polymer nanocomposite membranes, the zeolite nanocrystals are size-adjustable to match the polymer-network dimensions.

Owner:RGT UNIV OF CALIFORNIA

Method for producing lithium fluorosulfonate, lithium fluorosulfonate, nonaqueous electrolytic solution, and nonaqueous electrolytic solution secondary battery

ActiveUS20140038062A1High yieldLower internal impedanceCell electrodesOrganic electrolyte cellsElectrolytic agentPhysical chemistry

The present invention relates to a method for producing lithium fluorosulfonate which comprises reacting a lithium salt and fluorosulfonic acid in a nonaqueous solvent, wherein the lithium salt is a lithium salt not generating water through the reaction step.

Owner:MU IONIC SOLUTIONS CORP +1

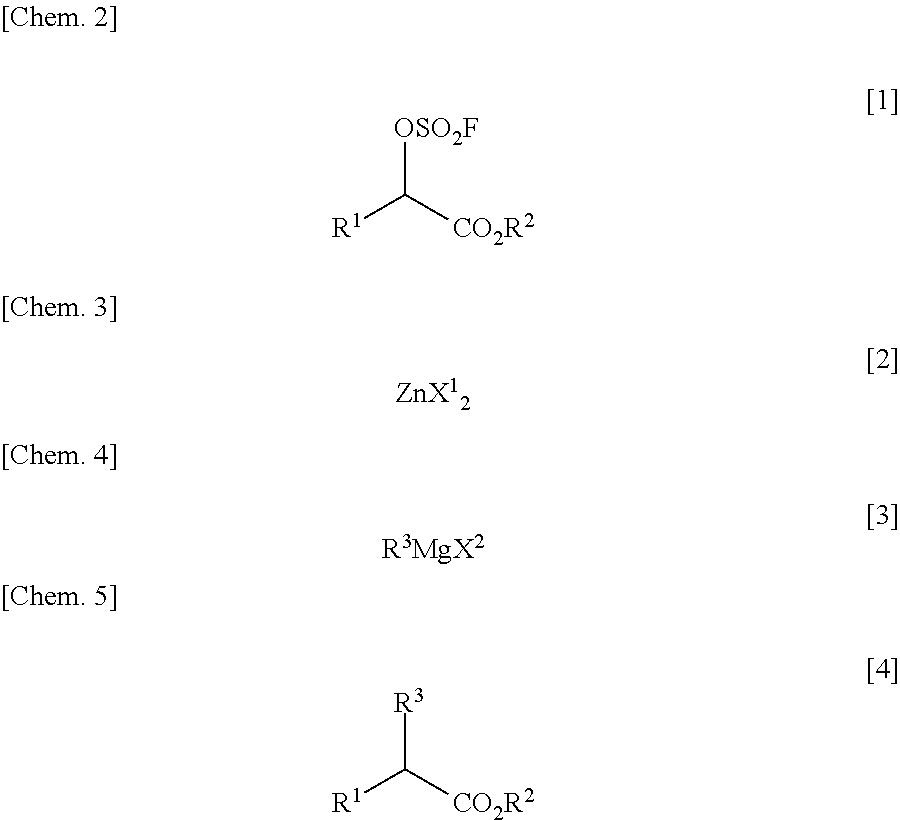

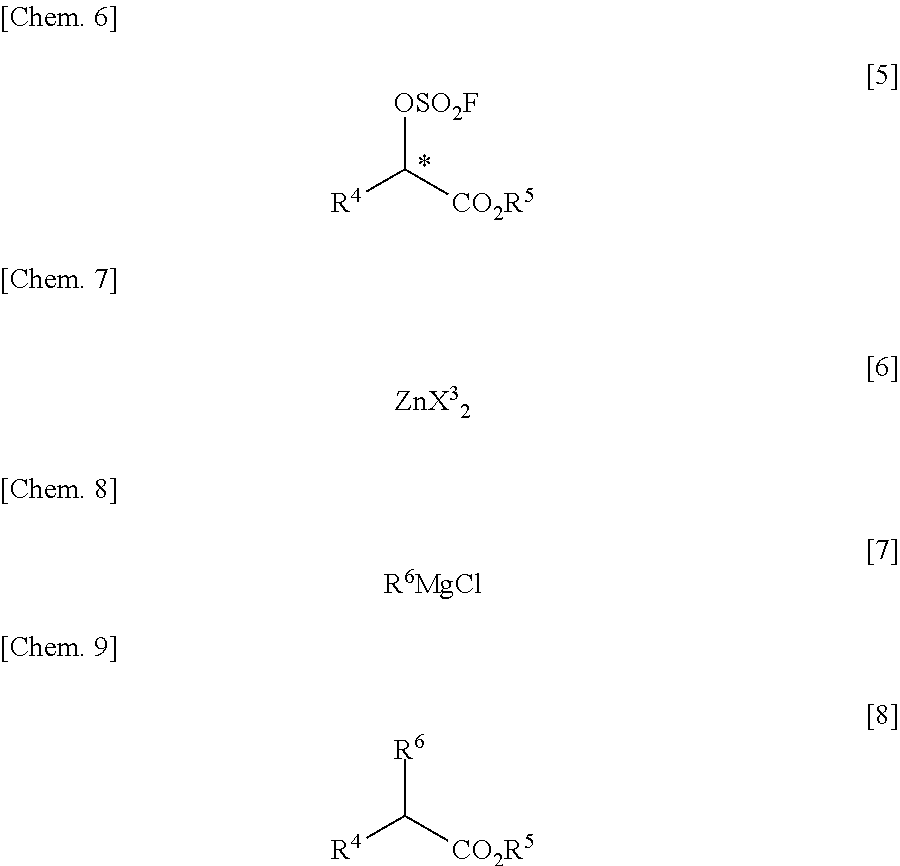

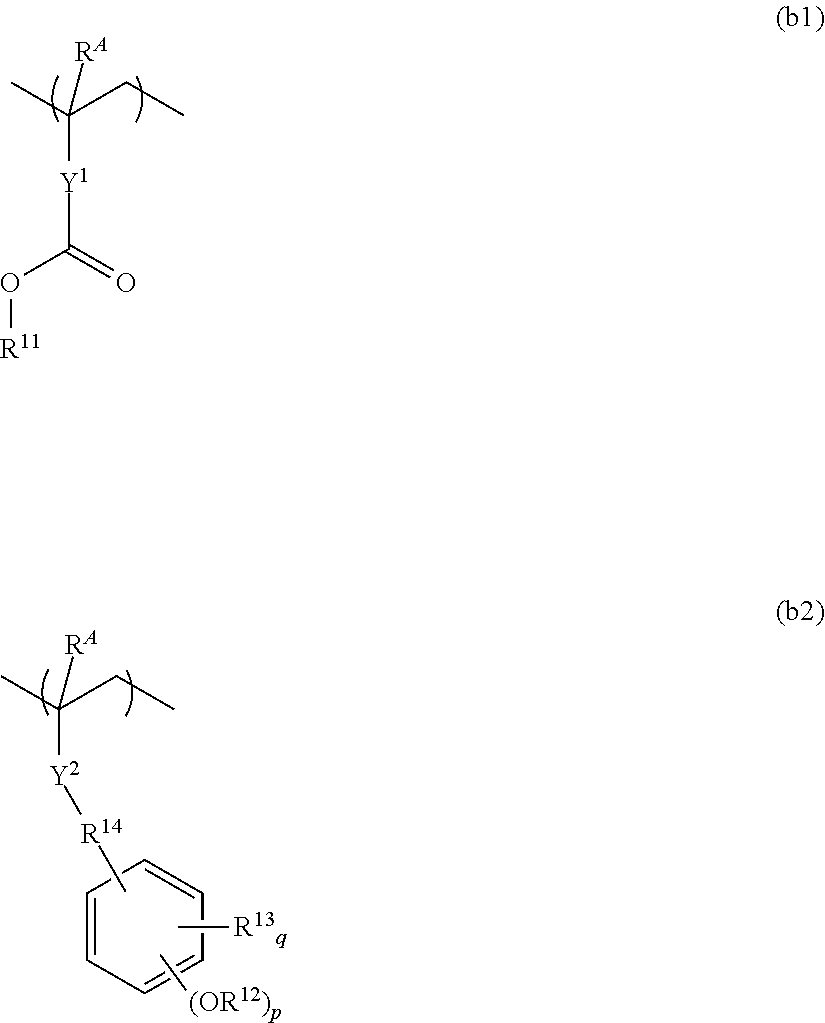

Process for Producing alpha Substituted Ester

InactiveUS20110213176A1Low costEffective combinationOrganic compound preparationSulfuric acid esters preparationGrignard reagentTriflic acid

There is provided a process for producing an α-substituted ester by reaction of a fluorosulfuric acid ester of α-hydroxyester with a Grignard reagent in the presence of a zinc catalyst. It is newly found that the reaction for production of α-substituted esters, in which the raw reaction substrate is limited to expensive trifluoromethanesulfonic acid esters, can proceed favorably with the use of fluorosulfuric acid esters suitable for mass-production uses. By the use of the fluorosulfuric acid ester high in optical purity, it is possible to obtain the α-substituted ester with high optical purity upon inversion of the asymmetric carbon configuration. The process of the present invention can solve all of the prior art problems and can be applied for industrial uses.

Owner:CENT GLASS CO LTD

Member for electrophotography and method of producing the member, process cartridge, and electrophotographic apparatus

ActiveUS20160187809A1Pretreated surfacesElectrographic process apparatusAlkaline earth metalPhosphoric acid

Provided is a member for electrophotography that is not reduced in charge-providing performance even by its long-term storage and use under a high-temperature and high-humidity environment, and is hence conducive to the formation of a high-quality electrophotographic image. The member for electrophotography includes: an electroconductive substrate; and an electroconductive layer, in which: the electroconductive layer contains a resin having a cationic organic group in a molecule thereof and an anion; a total sum of contents of an alkali metal and an alkali earth metal in the electroconductive layer is 500 ppm or less; and the anion includes at least one selected from the group consisting of a fluorosulfonate anion, a fluorocarboxylate anion, a fluorosulfonylimide anion, a fluorosulfonylmethide anion, a fluoroalkylfluoroborate anion, a fluorophosphate anion, a fluoroantimonate anion, and a fluoroarsenate anion.

Owner:CANON KK

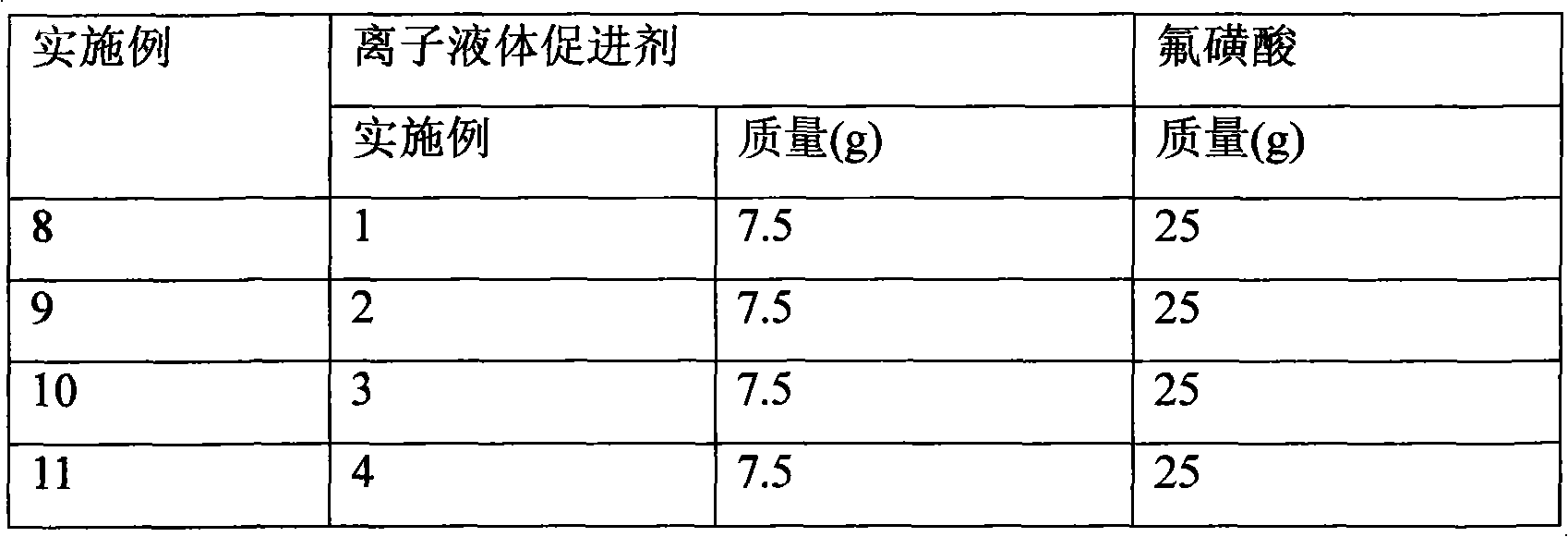

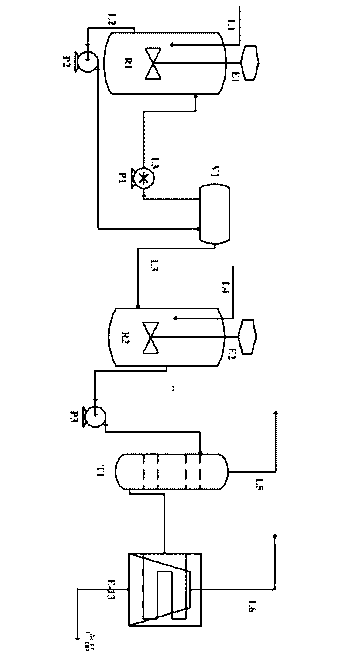

Method for producing alkylation gasoline by taking ionic liquid as accelerator of fluorosulphonic acid

InactiveCN101851526AEasy to separateLow costOrganic-compounds/hydrides/coordination-complexes catalystsLiquid hydrocarbon mixtures productionChemical industryIonic liquid

The invention relates to a method for producing high-octane gasoline by accelerating catalytic conversion of fluorosulphonic acid into isobutene butylene with a novel ionic liquid in the field of chemical industry. The ionic liquid has an A+B- molecular structure, wherein the cation A+ has an imidazole, pyridine, quaternary ammonium salt, quaternary phosphorus salt cation structure or the like; the anion B- has a BF4-, PF6-, CF3SO3- structure or the like; and the ionic liquid can be a single ionic liquid or a mixed ionic liquid. By accelerating the catalytic conversion of the fluorosulphonic acid into the isobutene butylene with the ionic liquid, the alkylation gasoline can be produced at high selectivity under certain reaction conditions; and when the reaction is finished, the acidic ionic liquid catalyst can be conveniently separated from the alkylate by a simple process. Compared with the conventional sulfuric acid process and the conventional hydrogen fluoride process, the process has the advantages of mild reaction conditions, high selectivity of C8, low catalyst cost and high safety for use and is an environment-friendly new process.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

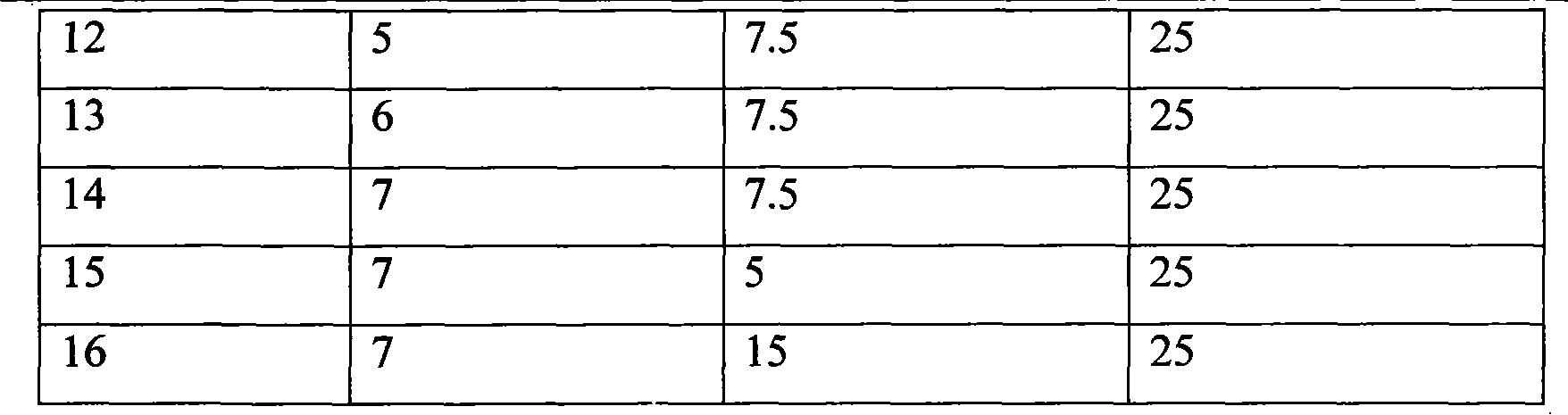

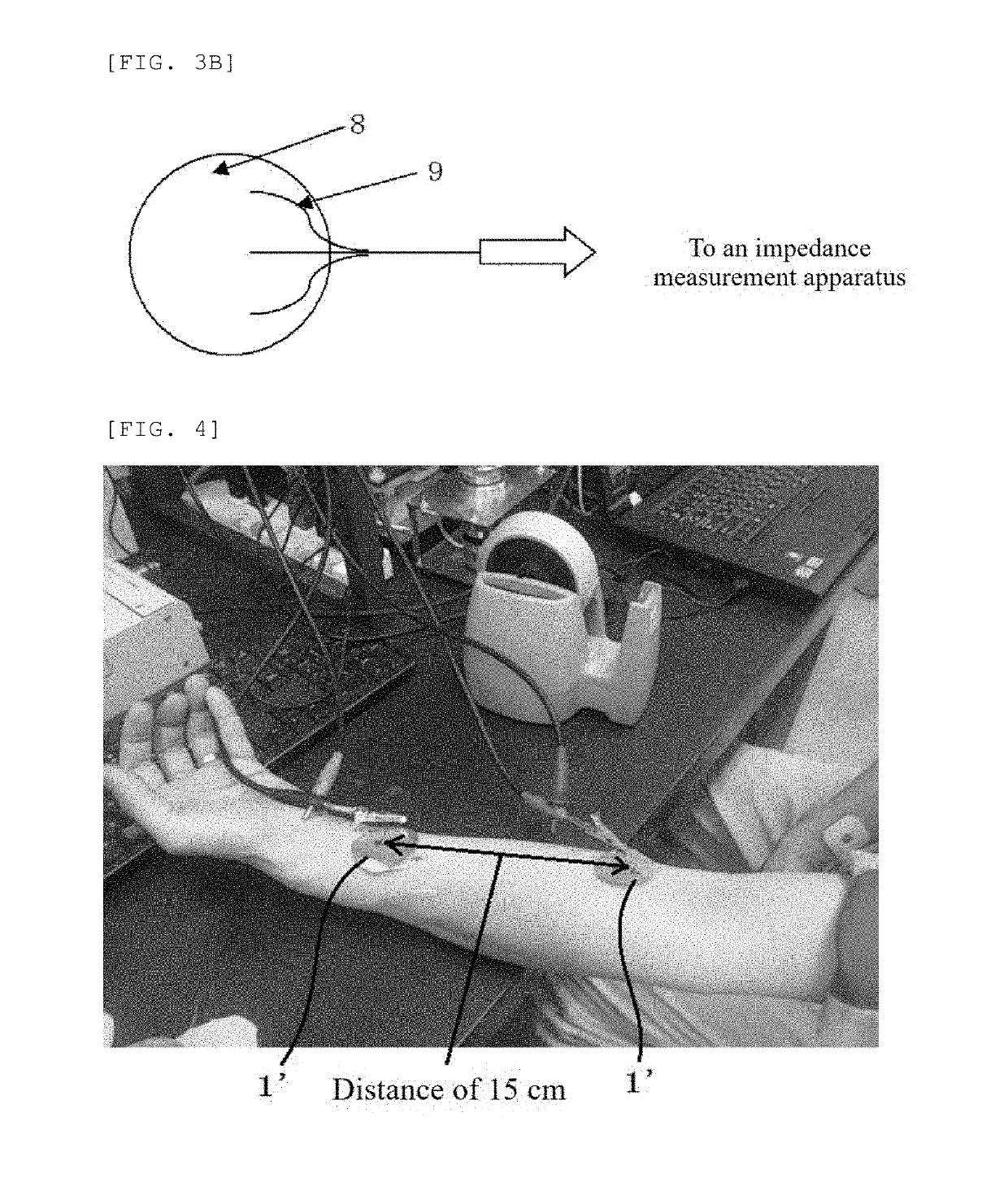

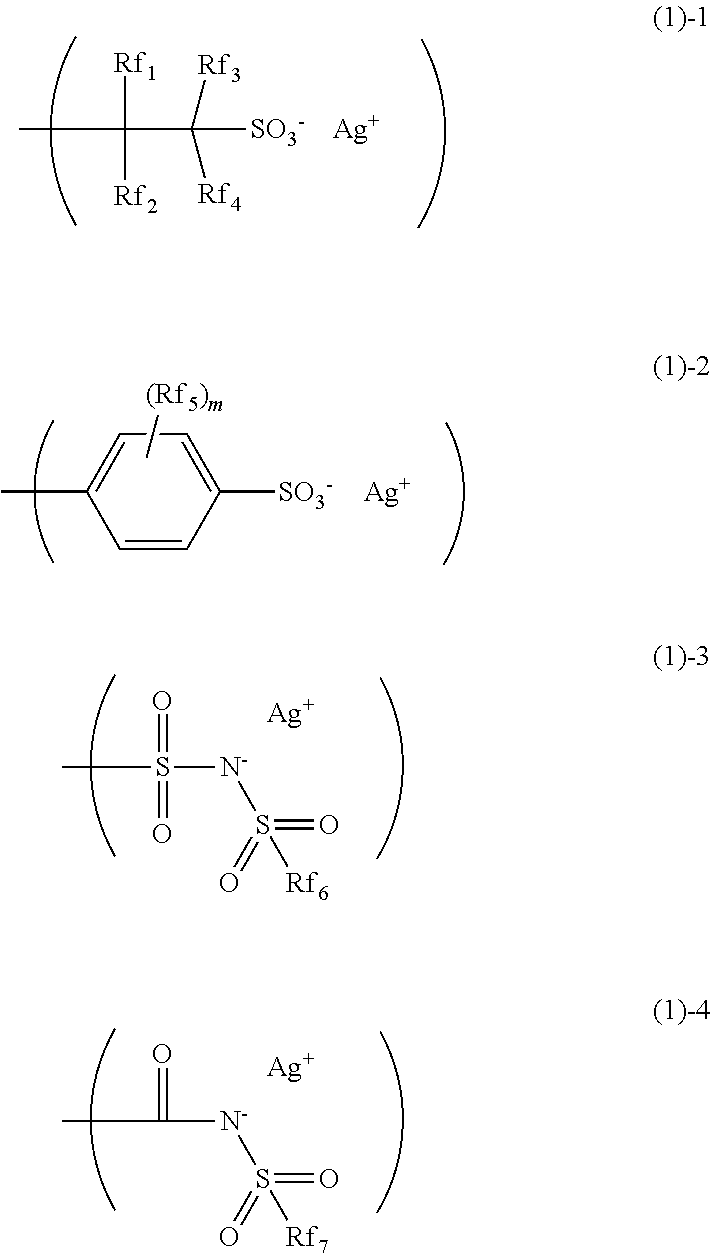

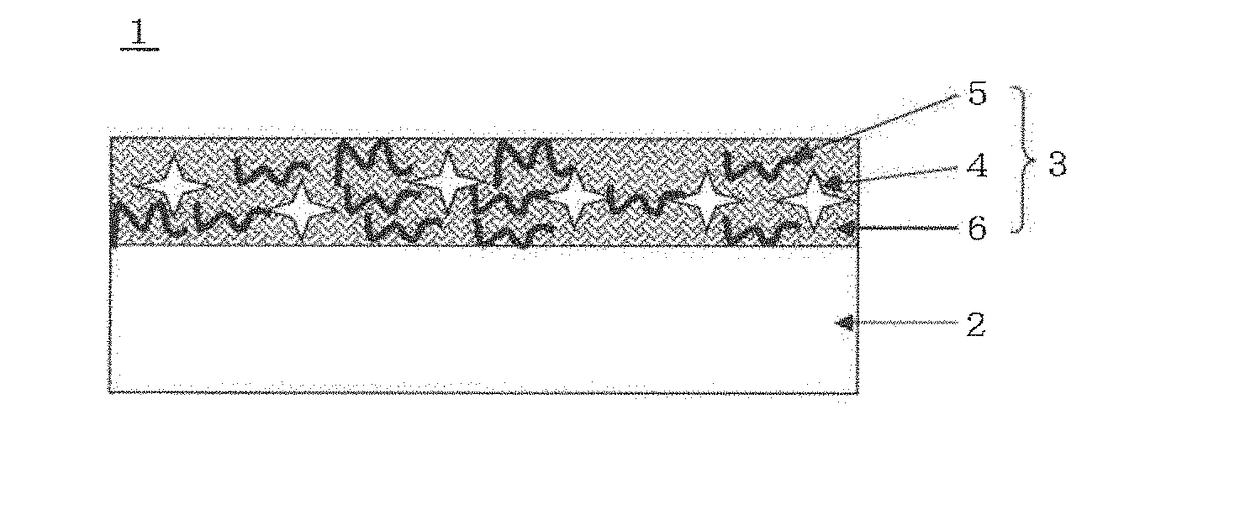

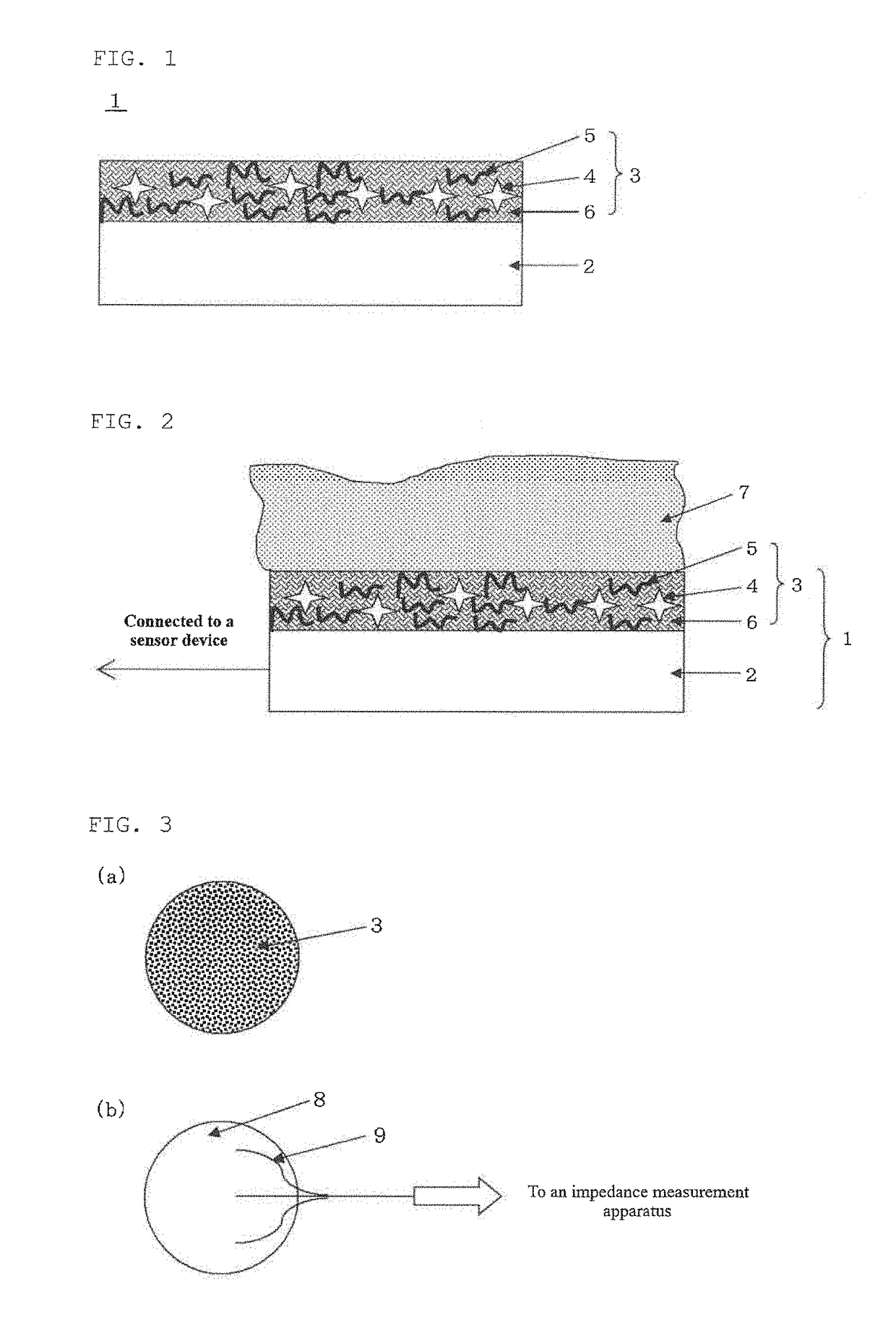

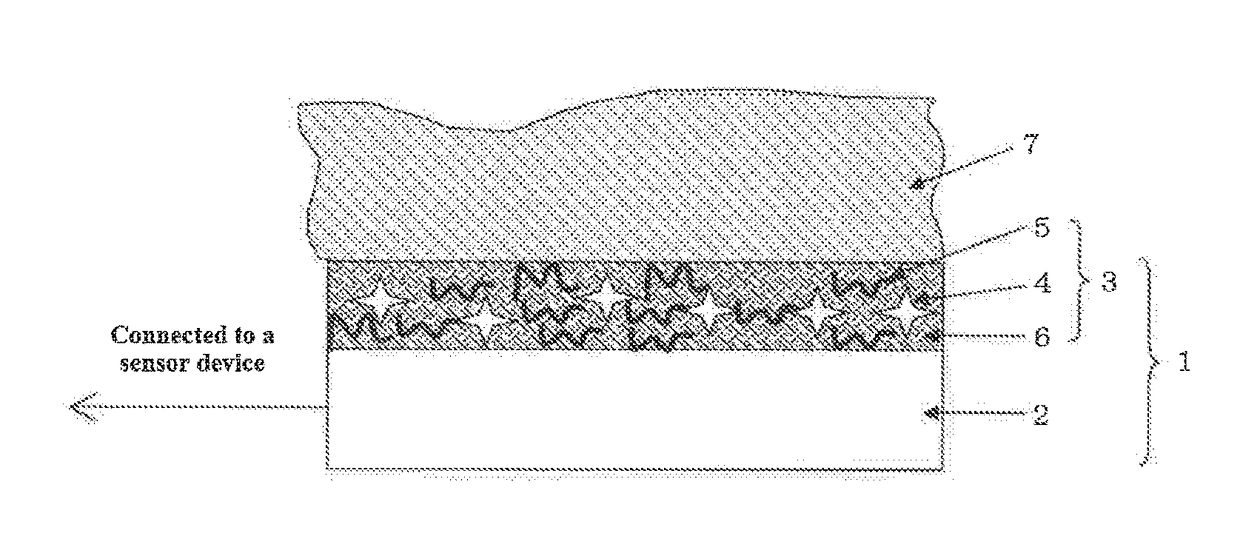

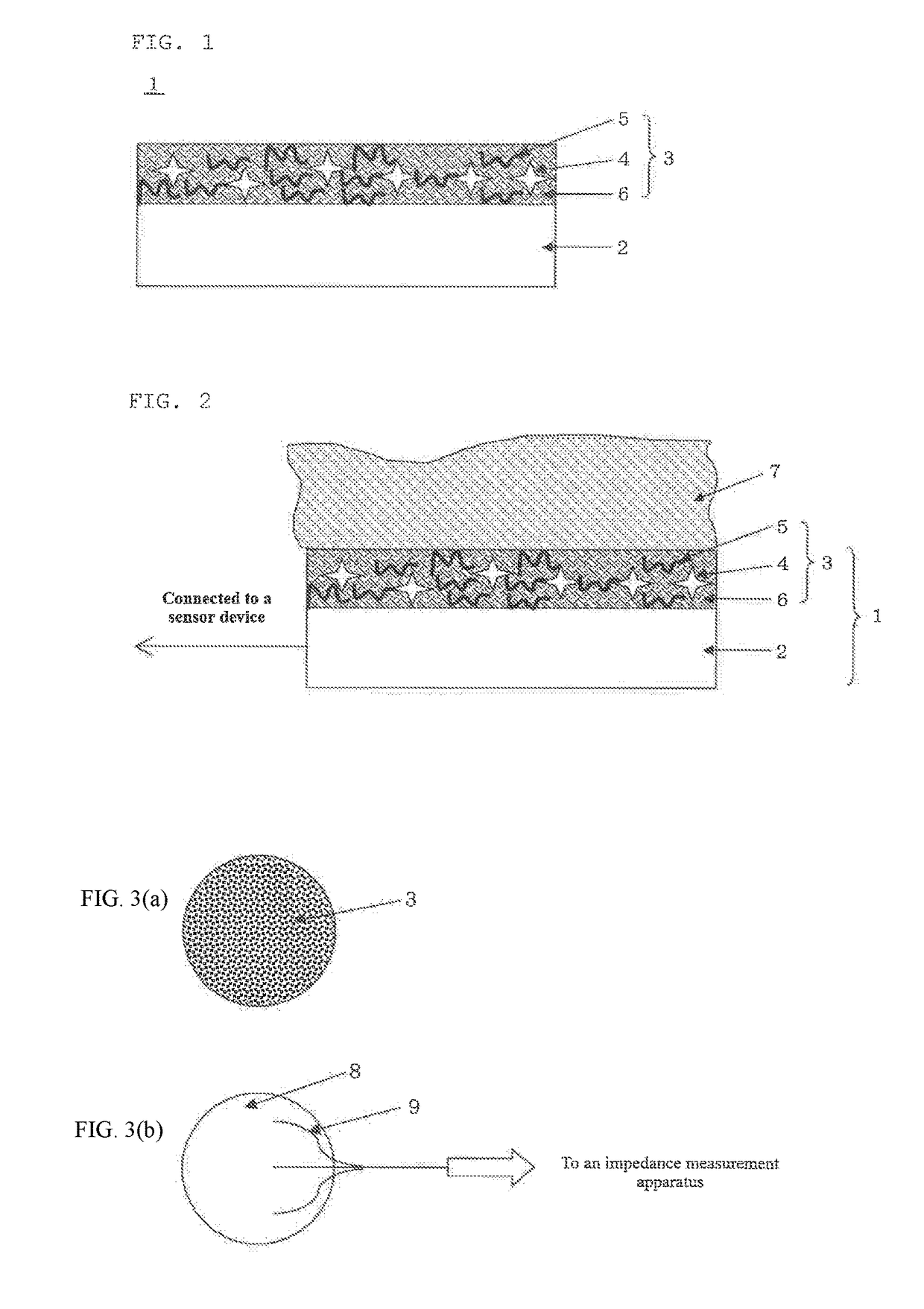

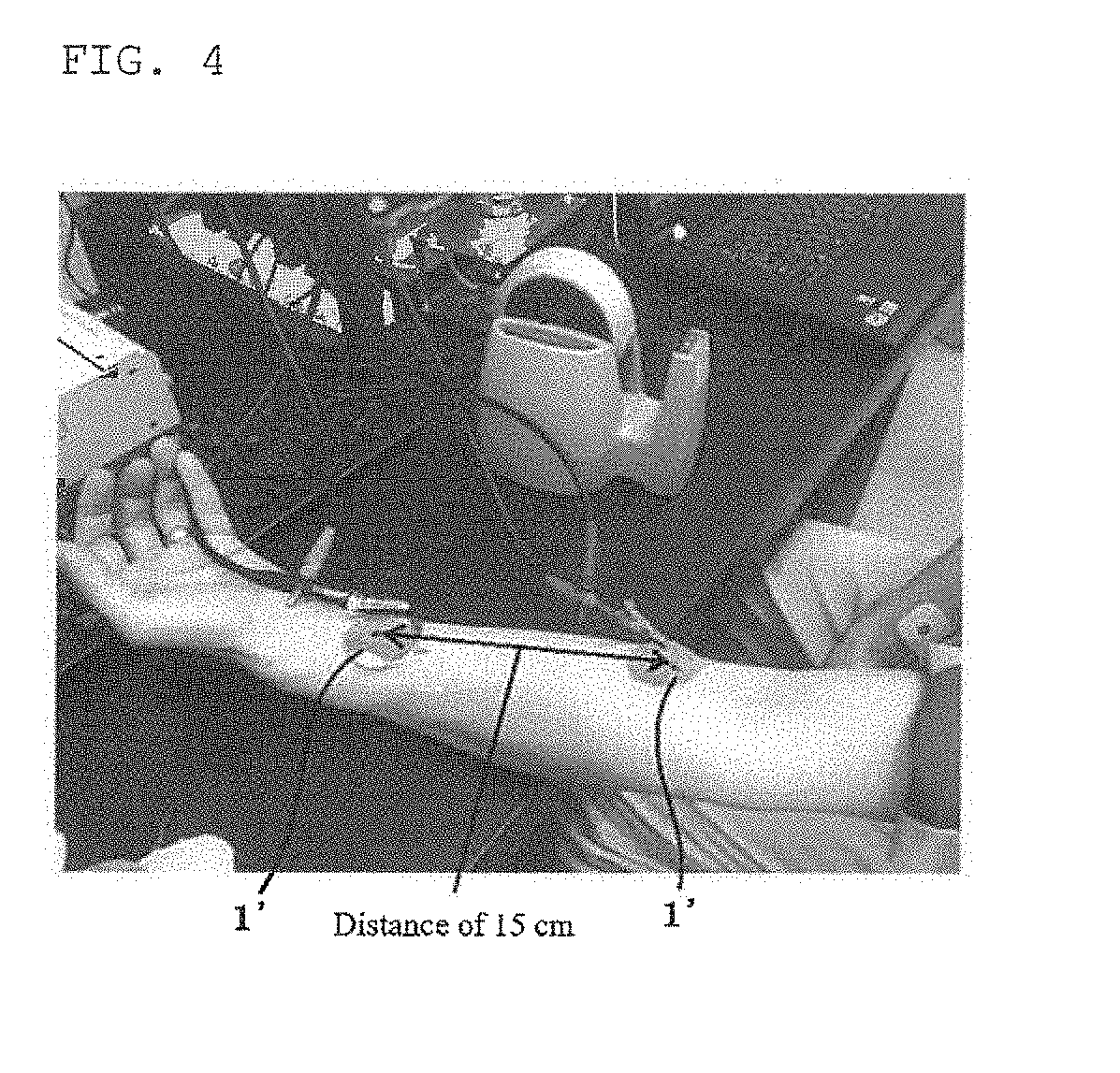

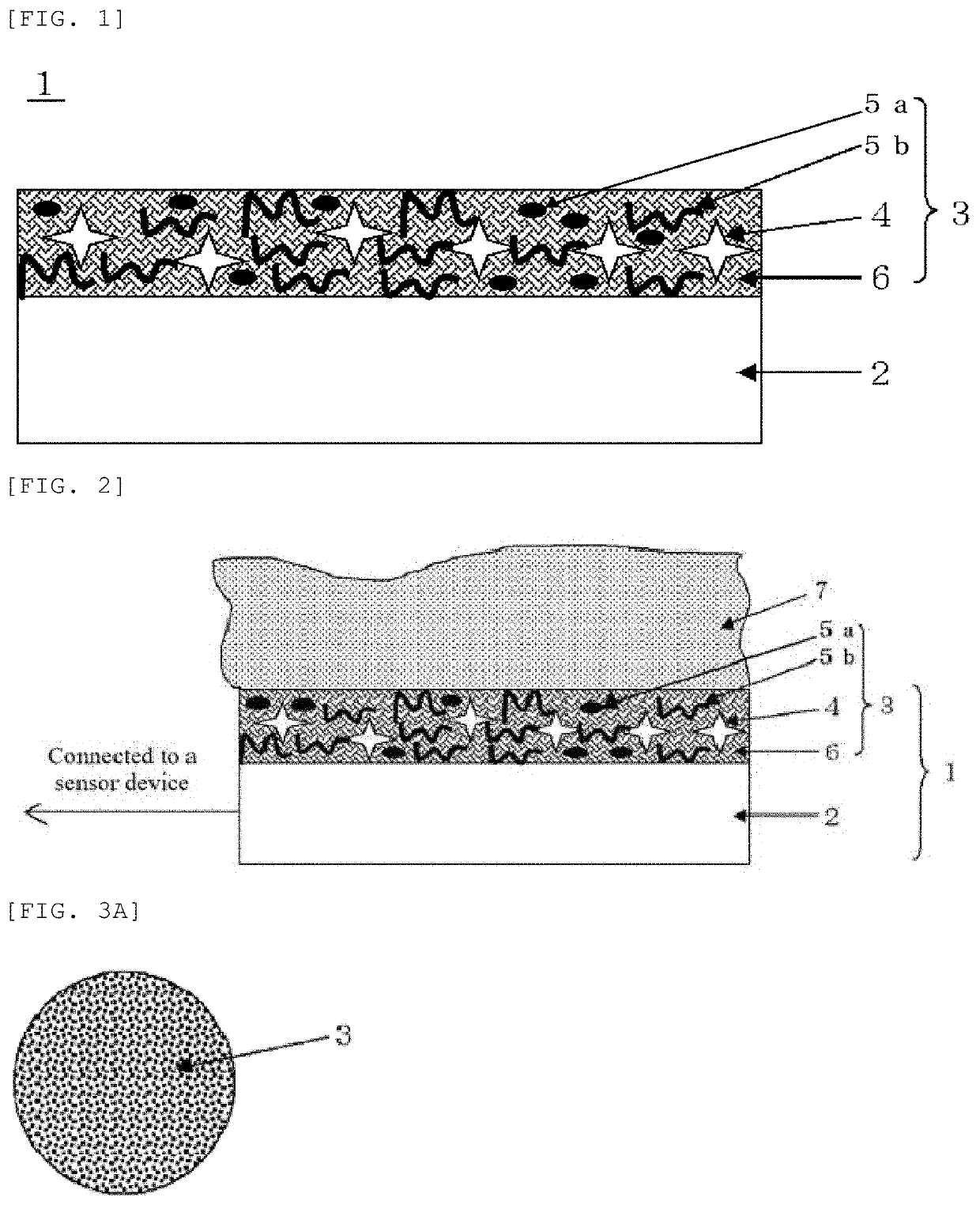

Bio-electrode composition, bio-electrode, and method for manufacturing a bio-electrode

PendingUS20190298891A1Improve conductivityLight weightElectrocardiographySurgeryBiocompatibility TestingContact layer

The present invention provides a bio-electrode composition including: (A) an ionic material; and (B) a resin other than the component (A); wherein the component (A) contains both of a repeating unit-a having a structure of any of silver salts of fluorosulfonic acid, fluorosulfonimide, and fluorosulfonamide; and a repeating unit-b having silicon. This can form a living body contact layer for a bio-electrode that is excellent in electric conductivity and biocompatibility, light in weight, manufacturable at low cost, and free from large lowering of the electric conductivity even when it is wetted with water or dried. The present invention also provides a bio-electrode in which the living body contact layer is formed from the bio-electrode composition, and a method for manufacturing the bio-electrode.

Owner:SHIN ETSU CHEM IND CO LTD

Adhesive composition, bio-electrode, method for manufacturing a bio-electrode, and salt

ActiveUS20180086948A1Efficient conductionImprove conductivityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesConductive materialsBiocompatibility

Owner:SHIN ETSU CHEM IND CO LTD

Process for preparing self-humidifying composite proton exchange film for fuel cell

InactiveCN1181585CEasy to operateSimple preparation processSolid electrolyte fuel cellsFuel cell detailsAlcoholOrganic solvent

Owner:SUNRISE POWER CO LTD

Adhesive composition, bio-electrode, and method for manufacturing a bio-electrode

ActiveUS20180085019A1Efficient conductionImprove conductivityElectrocardiographyNon-macromolecular adhesive additivesBiocompatibility TestingConductive materials

An adhesive composition including a resin and an electro-conductive material, wherein the electro-conductive material is one or more salts selected from sodium salt, potassium salt, and calcium salt having two fluorosulfonic acid structures per molecule and 5 or more carbon atoms shown by formula (1): −O3S—Y—La-A-Lb-Y—SO3− (Mn+)2 / n (1), wherein, A represents a divalent hydrocarbon group having 1-30 carbon atoms and optionally substituted by a heteroatom or optionally interposed by a heteroatom; La and Lb each represent a linking group like an ether group, ester group; Y represents an alkylene group having 2-4 carbon atoms, containing 1-6 fluorine atoms, and optionally containing a carbonyl group; Mn+ represents any of Na+, K+, Ca2+. This can form a living body contact layer for a bio-electrode with excellent electric conductivity, biocompatibility, and light weight, which can be manufactured at low cost and without large lowering of electric conductivity even when it is wetted with water or dried.

Owner:SHIN ETSU CHEM IND CO LTD

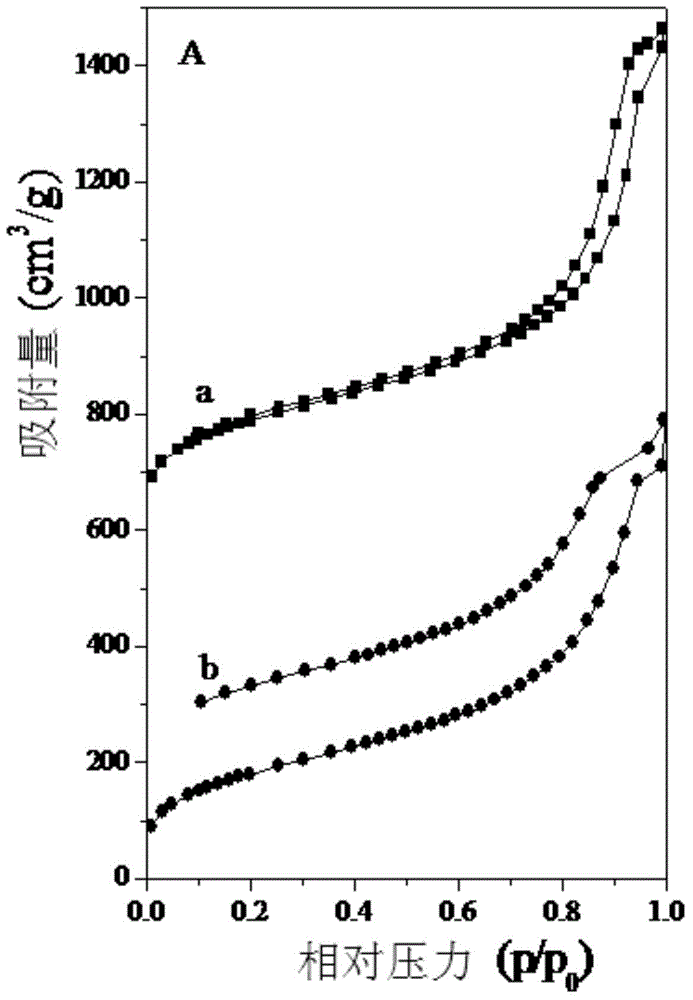

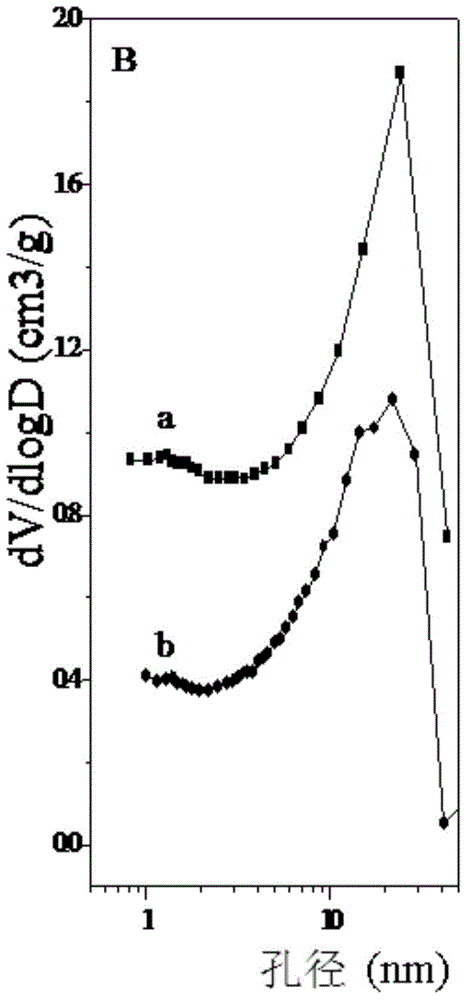

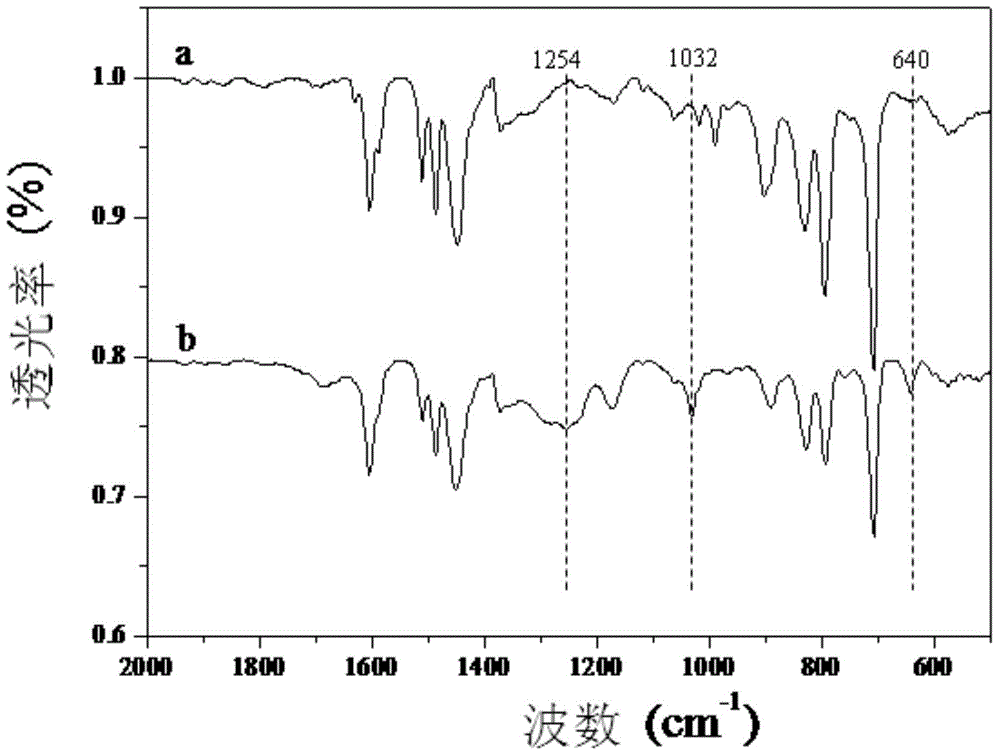

Nanometer porous and super-hydrophobic skeleton strong solid acid material and preparing method thereof

InactiveCN103819598AIncrease the degree of cross-linkingImprove stabilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsBenzeneBenzoyl peroxide

The invention provides a nanometer porous and super-hydrophobic skeleton strong solid acid material and a preparing method thereof. The preparing method comprises the following steps: a, polymerizing divinyl benzene under a solvothermal condition, wherein benzoyl peroxide is used as an initiator, polymerizing is carried out at a temperature between 80DEG C and 180DEG C for 12-48h, 7-25mL of corresponding solvent is used each time when 2g of divinyl benzene monomer is used, and the mass ratio of the initiator to the divinyl benzene is 0.015-0.0375; b, adding a solvent to the nanometer porous polydivinyl benzene material which is prepared in the step a, and adding a sulfonating agent to carry out sulfonating, wherein carbon tetrachloride or methylbenzene is used as the solvent, trifluoromethane sulfonic acid or fluorosulfuric acid is used as the sulfonating agent, the volume ratio of the solvent to the sulfonating agent is 10:1, the mass ratio of the PDVB (Polydivinyl Benzene) to the sulfonating agent is (5-10):1, and sulfonating is carried out in a range between 80DEG C and 110DEG C for 12-36h.

Owner:SHAOXING UNIVERSITY

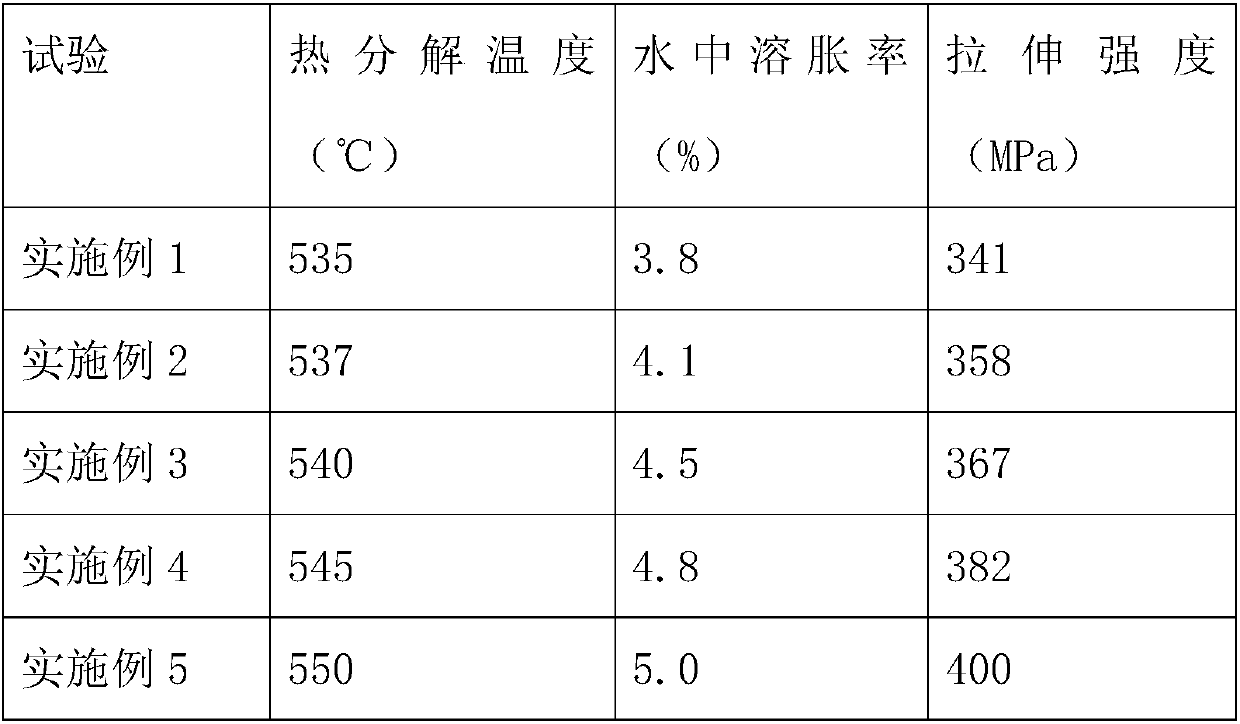

Preparation method of modified perfluorosulfonic acid proton exchange membrane for fuel battery

ActiveCN107946620AThe preparation process is not complicatedLow costFuel cellsPerfluorosulfonic acidToluene

Owner:NANTONG DUOQIAN NEW MATERIAL SCI & TECH CO LTD

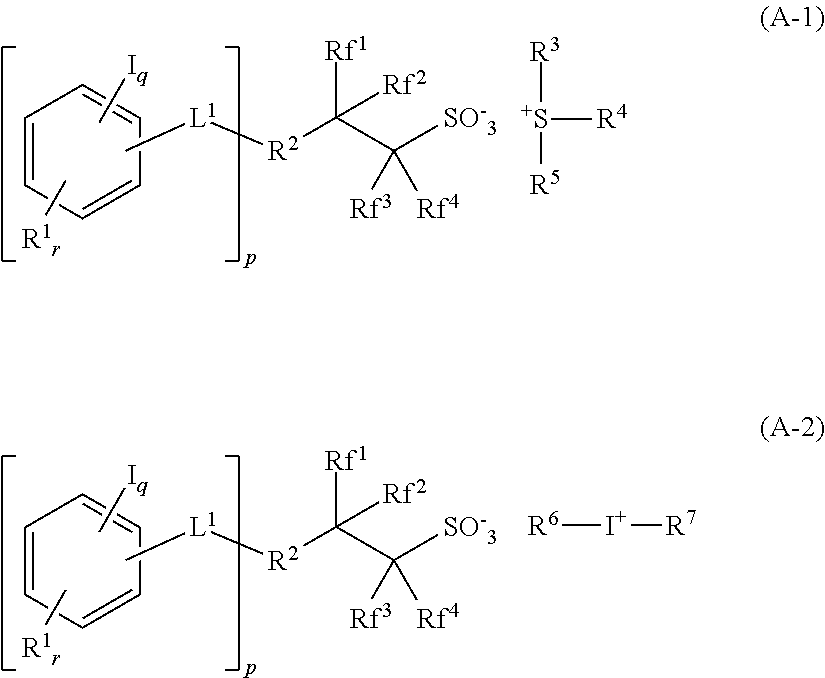

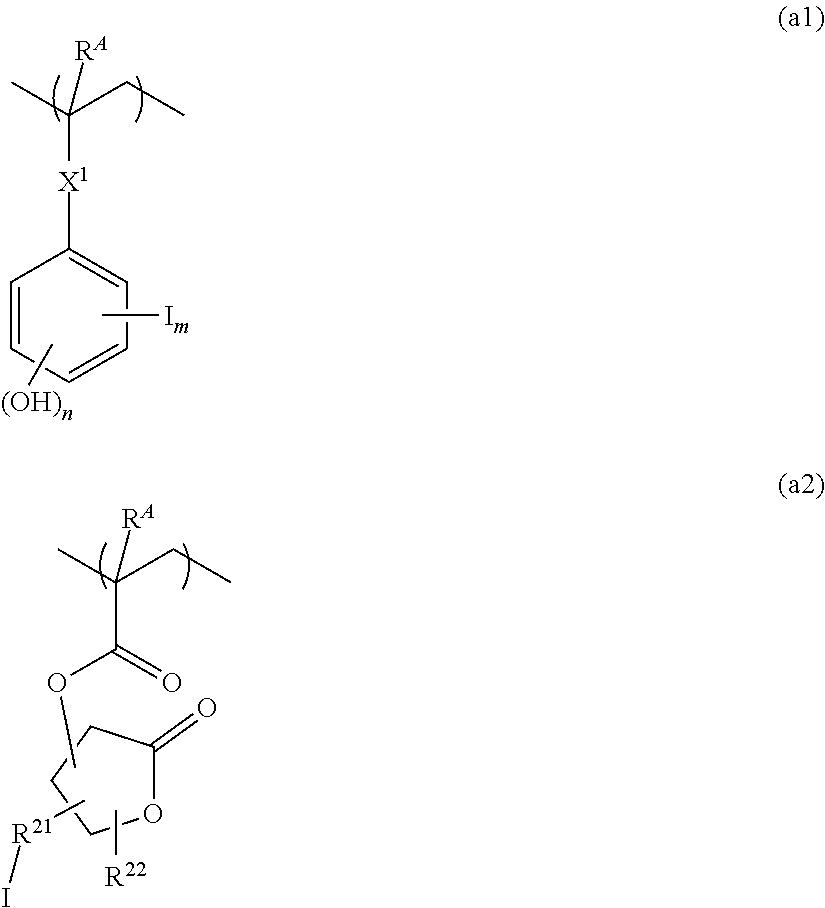

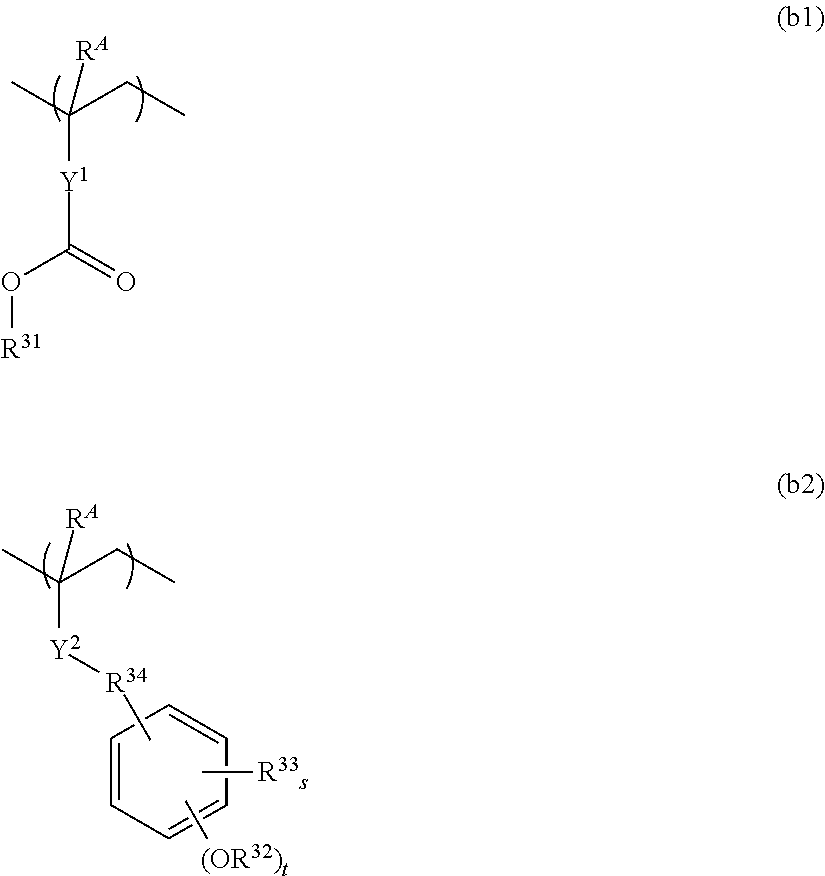

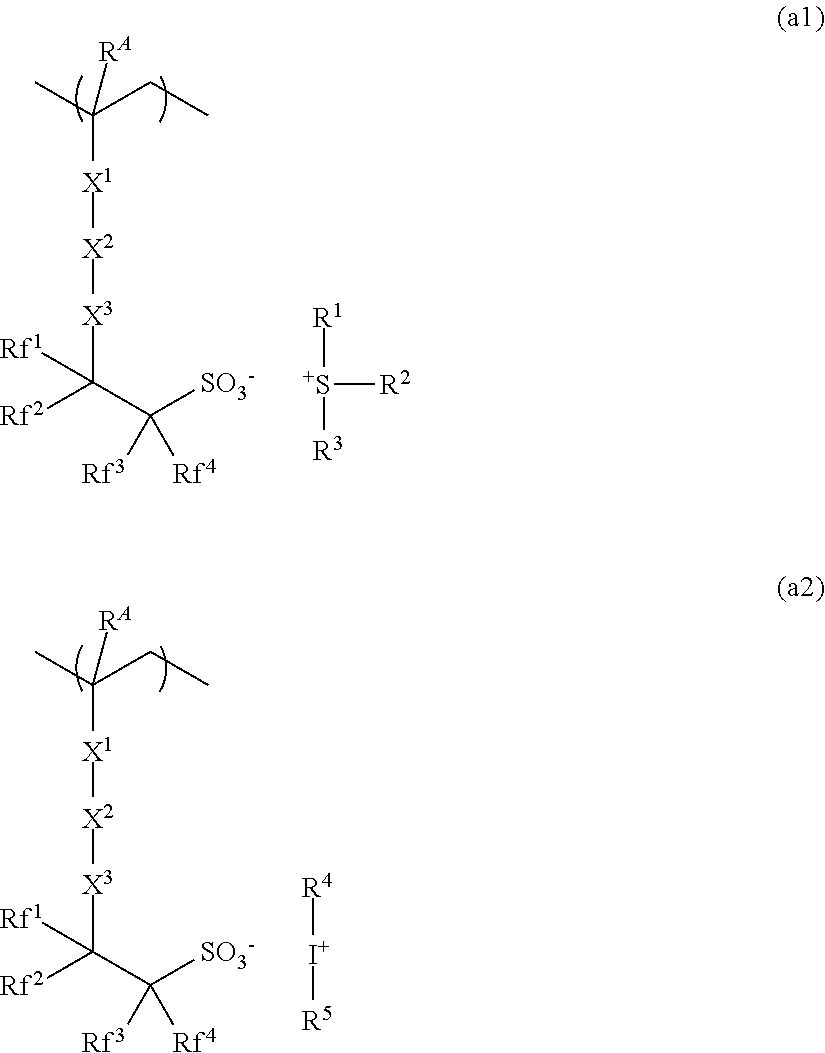

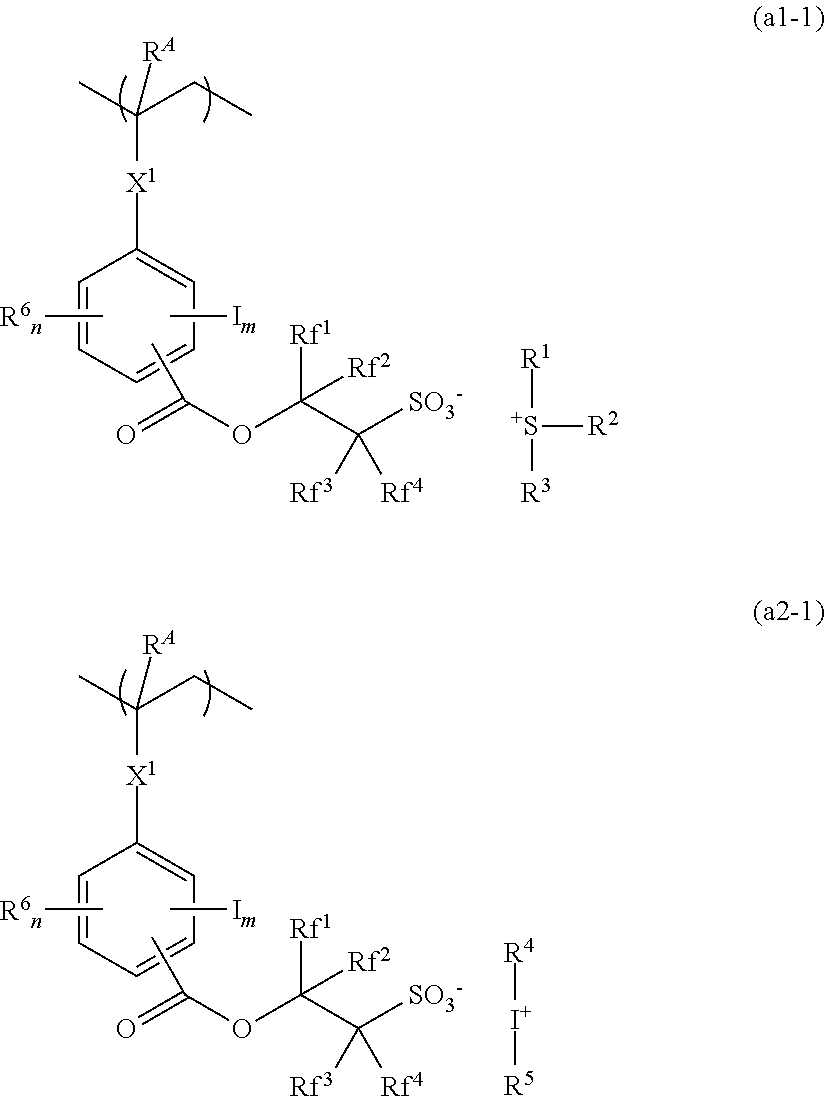

Resist composition and patterning process

ActiveUS20190094690A1High atomic weightGenerate efficientlyPhotosensitive material processingCoatingsBenzenePolymer science

A resist composition is provided comprising a base polymer containing an iodized polymer, and an acid generator containing a sulfonium salt and / or iodonium salt of iodized benzene ring-containing fluorosulfonic acid. When processed by lithography, the resist composition exhibits a high sensitivity, low LWR and improved CDU independent of whether it is of positive tone or negative tone.

Owner:SHIN ETSU CHEM IND CO LTD

Method of lowering permeability of proton exchange film methy alcohol contg fluorine sulfonic acid

InactiveCN1601790AAssembled preciselyHigh alcohol inhibition efficiencyPrimary cell electrodesFuel cell detailsPhotochemistryPolymer

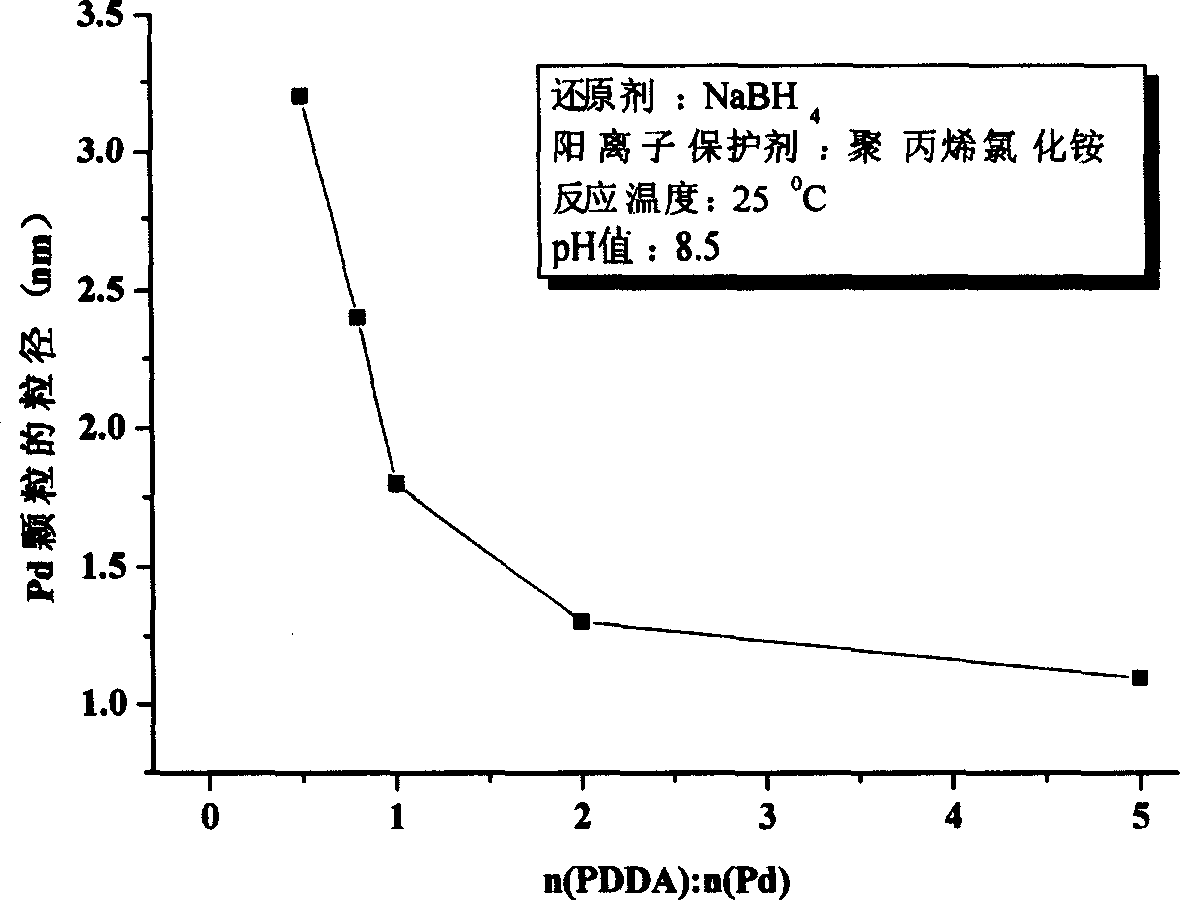

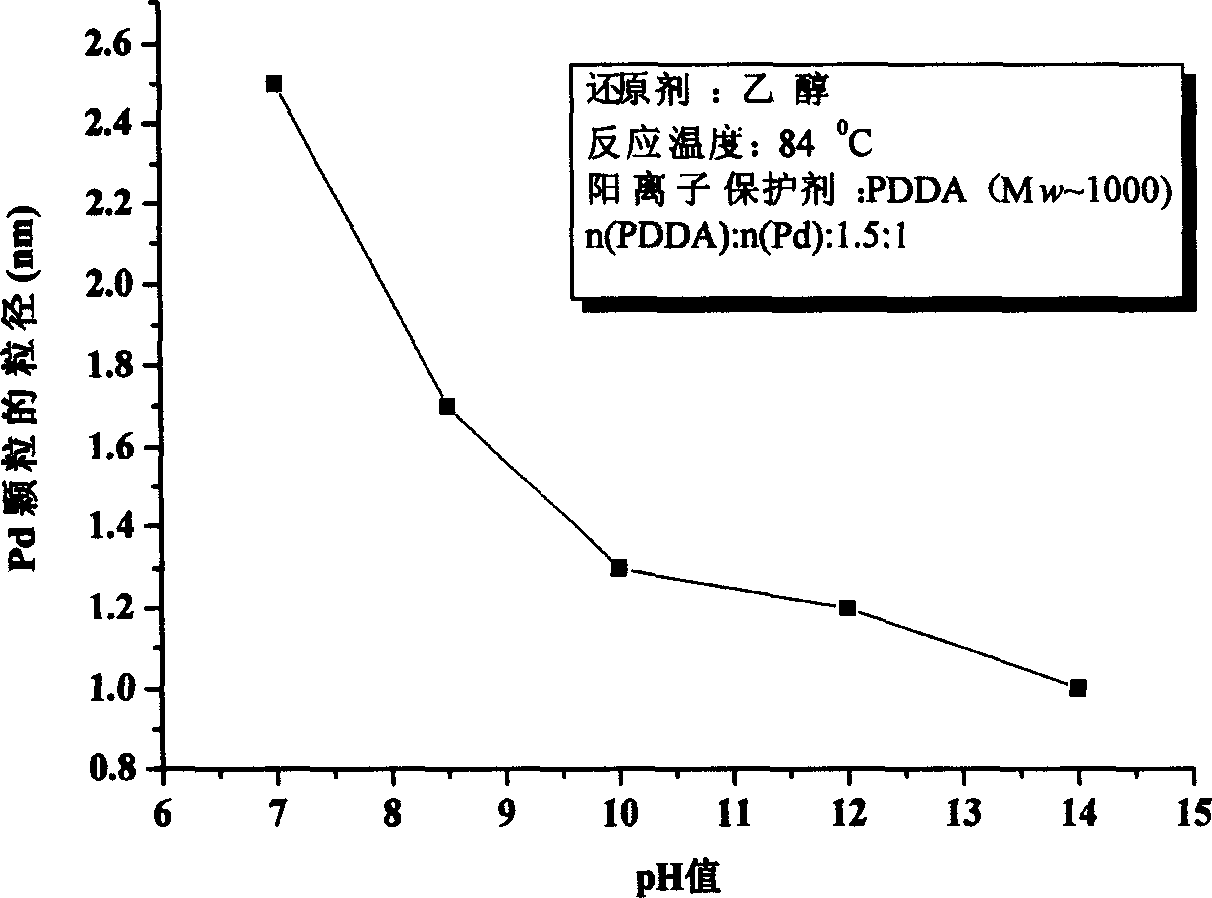

The method includes steps: first, positive ionized Nano Pd granules is synthesized from Pd salt deoxidized in aqueous solution of cation polymer in ammonium class and reducing agent; then, fluorosulfuric acid type proton exchange membrane is dipped in water decentralization liquid of positive ionized Nano Pd granules; thus, Pd granules are static self-assembled to exit and entrance of sulfonic acid radical group in methanol infiltration channels formed on surface of proton exchange membrane so as to reduce penetrability of methanol to membrane. Advantages are: less loading noble metal Pd, and no inference on proton conducting power basically.

Owner:WUHAN UNIV OF TECH

Preparation method of lithium fluorosulfonate

ActiveCN112739652AIncrease optionalitySimple and safe operationSecondary cellsLithium halidesFluorosulfonateIon calcium

The invention discloses a preparation method of lithium fluorosulfonate, which comprises the following steps: (1) taking metal fluorosulfonate (MFSO3) with the purity of >=98.5% as a raw material, and carrying out metathesis exchange reaction with organic lithium salt in an ester, alcohol, nitrile or amide solvent; (2) generating insoluble organic metal salt precipitate, pumping in vacuum, extracting by using a poor solvent of an organic metal salt, filtering, separating, concentrating under reduced pressure, adding a low-polarity aprotic solvent into the concentrated solution, standing, crystallizing, and carrying out vacuum drying to obtain the high-purity lithium fluorosulfonate product. The preparation method of the high-purity lithium fluorosulfonate is simple in post-reaction treatment method, high in product yield, high in purity and capable of effectively reducing the content of impurities such as potassium ions, sodium ions, calcium ions, chloride ions and moisture in the product. The preparation method provided by the invention has the characteristics of simple operation steps, reasonable production cost, high safety, wide substrate selection range, low cost and high product purity.

Owner:ZHUHAI LEE & MAN MATERIALS SCI CO LTD +1

Resist composition and patterning process

ActiveUS20180335696A1High sensitivityLow LWRPhotomechanical coating apparatusPhotomechanical exposure apparatusPolymer scienceFluorosulfuric acid

A resist composition contains a polymer-bound acid generator, specifically a polymer comprising recurring units derived from a sulfonium or iodonium salt having a polymerizable unsaturated bond and containing iodine in the linker between the polymerizable unsaturated bond and a fluorosulfonic acid. The resist composition offers a high sensitivity and improved CDU independent of whether it is of positive or negative tone.

Owner:SHIN ETSU CHEM IND CO LTD

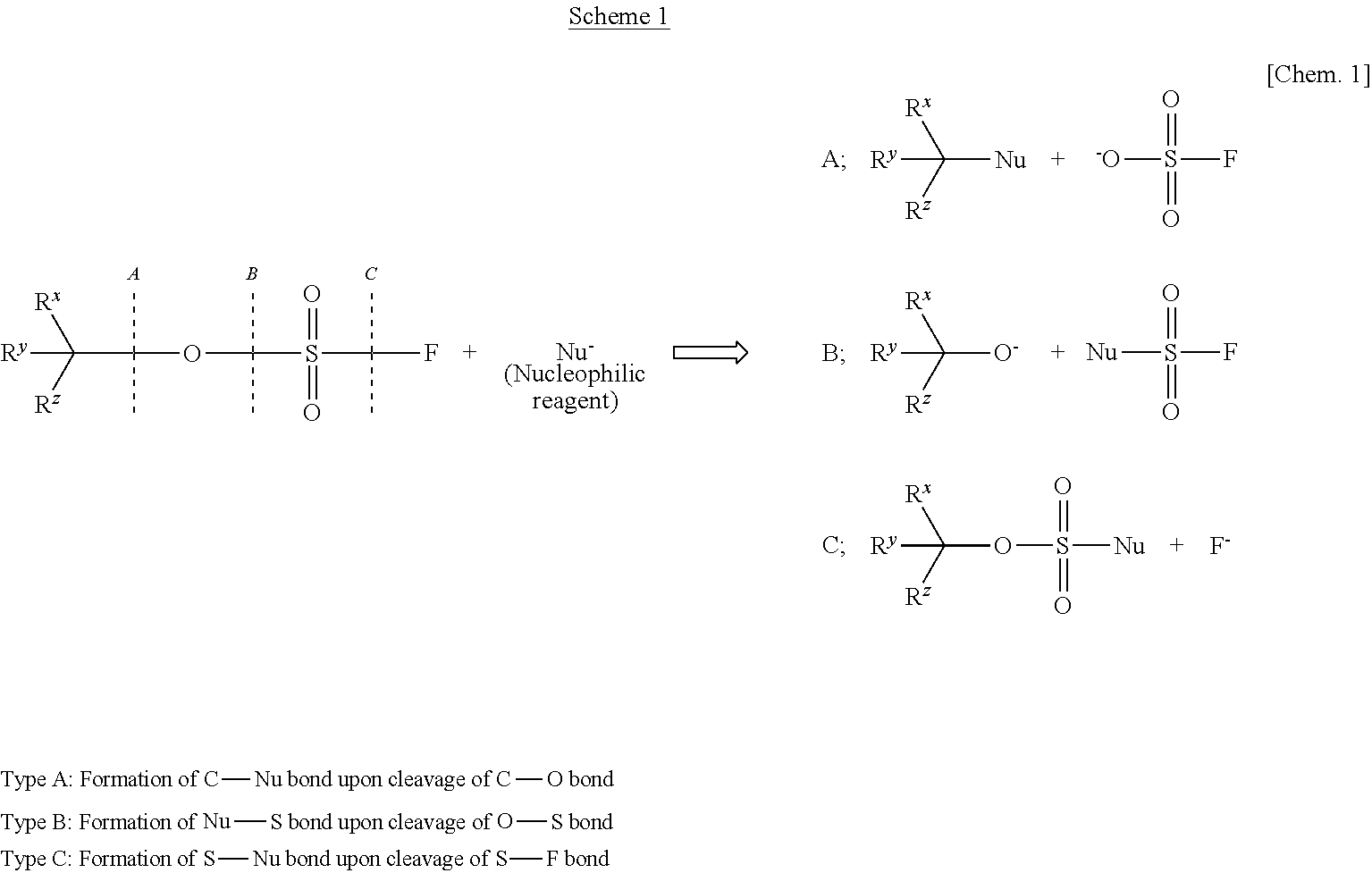

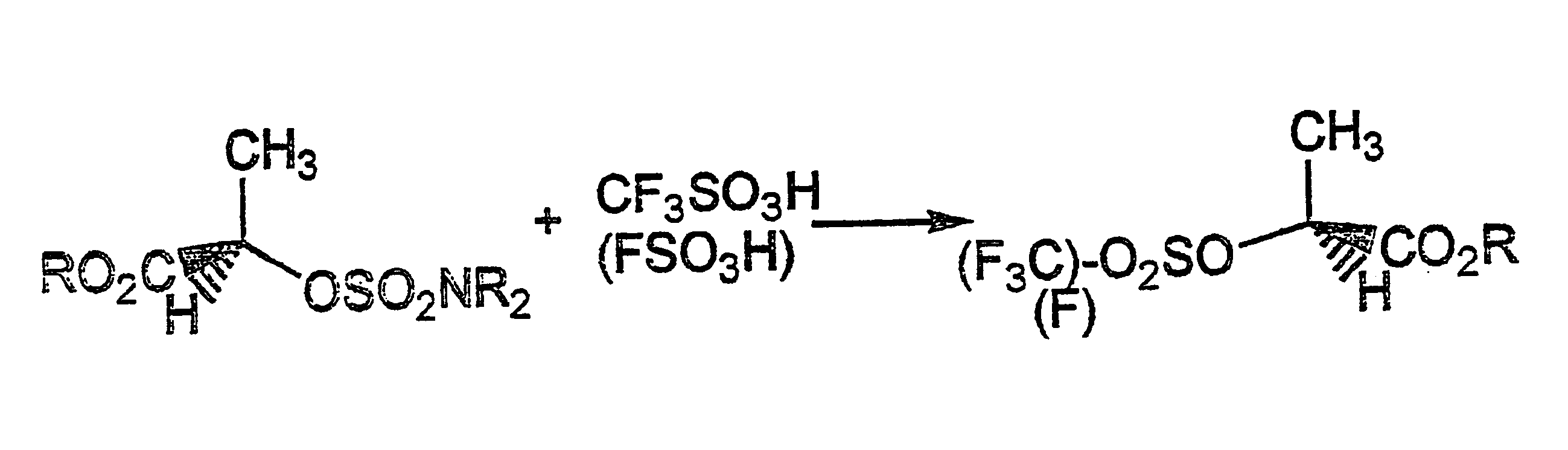

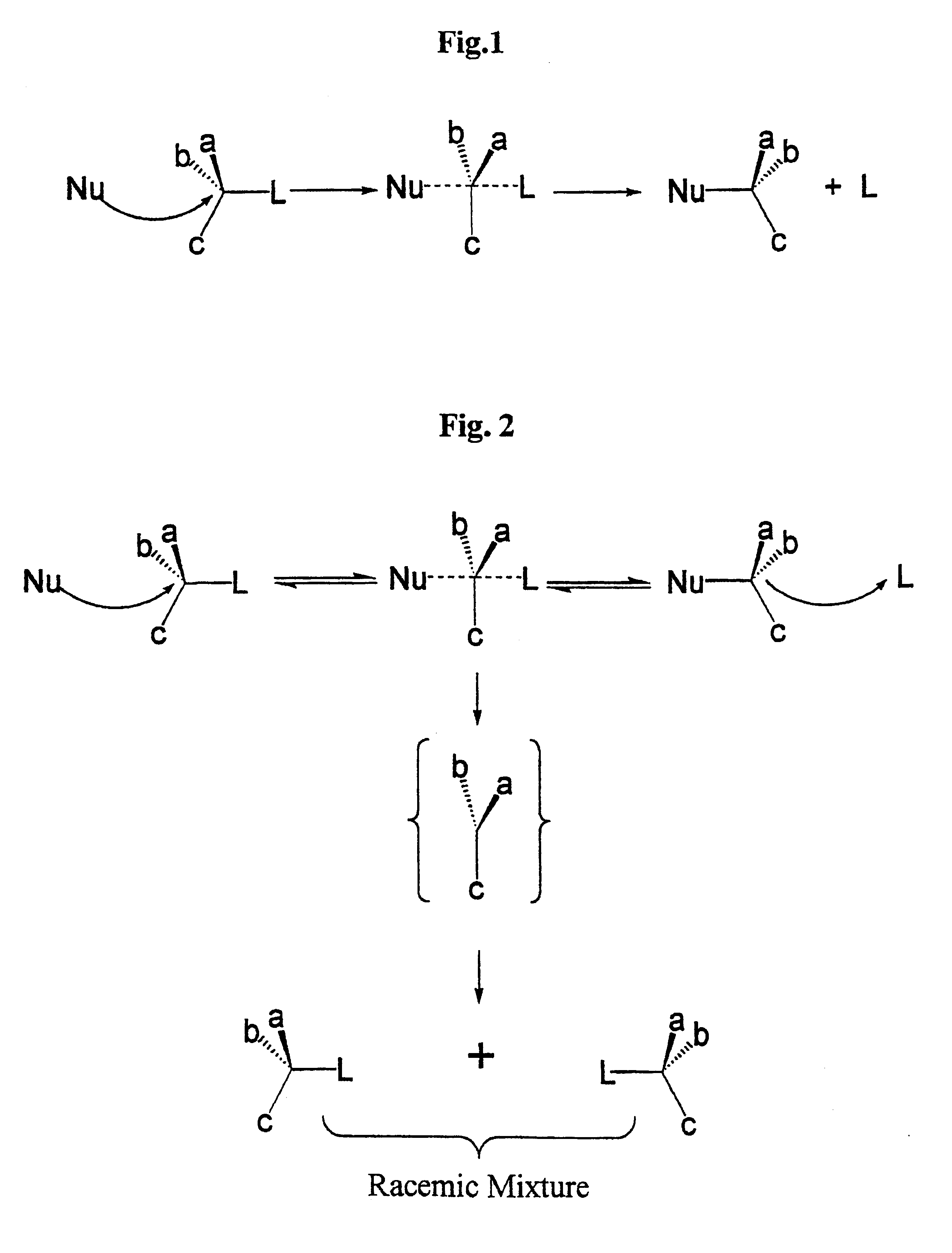

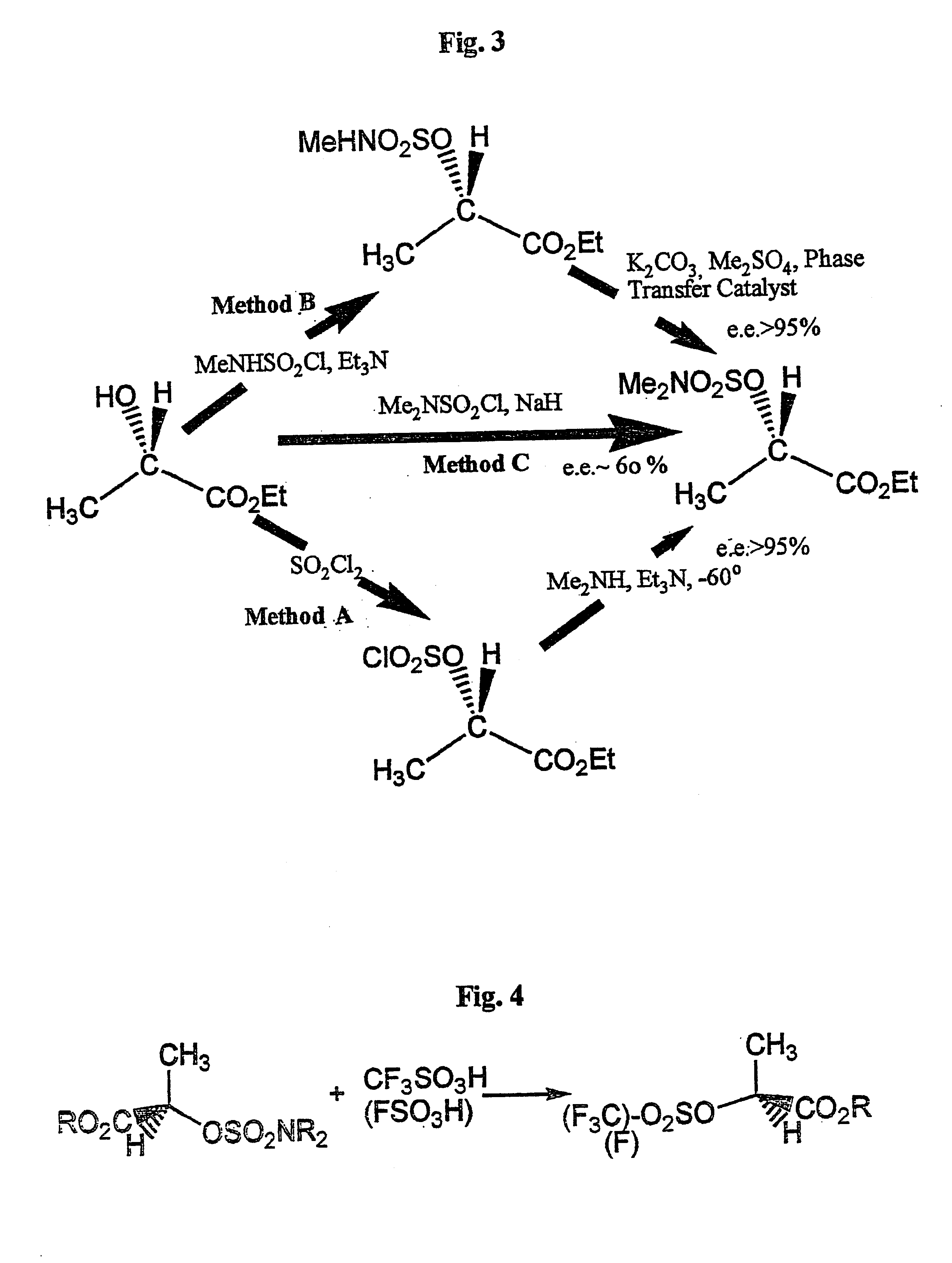

Conversion of a hydroxy group in certain alcohols into a fluorosulfonate ester or a trifluoromethylsulfonate ester

InactiveUS6395918B1Easy to disassembleOrganic compound preparationOrganic chemistry methodsSulfonateAlcohol

The present invention provides a method of converting a hydroxy group in alcohols containing an electron withdrawing group into perfluoroalkane sulfonate and fluorosulfonate esters, which are good leaving groups, with inversion of configuration where the hydroxyl-bearing carbon is chiral. The method consists of converting an alcohol to an O--N,N-dialkylsulfamate ester and reacting it with a perfluoroalkansulfonic or fluorosulfonic acid. The method has applications in the synthesis of pharmaceutical and agrochemical compounds.

Owner:LOEWENTHAL HANS JACOB EDGAR +1

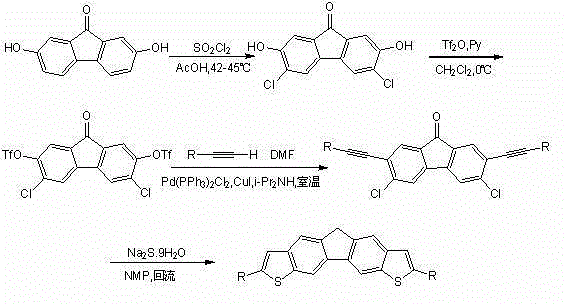

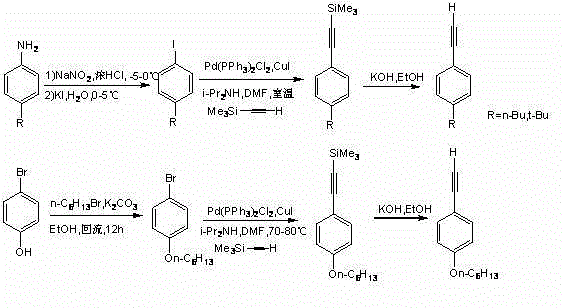

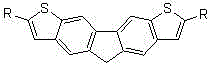

Bithienofluorene, its derivative and preparation method

The invention discloses bithienofluorene, its derivative and a preparation method. The compounds are characterized in that: a fluorene ring is in connection with thieno rings, and the 2- position of thiophene has a substituent group, which can be hydrogen, alkyl or aryl. The preparation method consists of: taking 2, 7-dyhydroxyl-9-fluorenone as a raw material, employing sulfonyl chloride to conduct chlorination so as to synthesize 3, 6-dichloro-2, 7-dyhydroxyl-9-fluorenone; and then adopting trifluoromethanesulfonic anhydride to carry out esterification, and performing a Sonogashira coupling reaction to obtain series of 2, 7-disubstituted ethynyl-3, 6-dichloro-9-fluorenone, and finally conducting ring closing by sodium sulfide and reduction to obtain bithienofluorene and its derivative. The series of compounds involved in the invention provides a new option for organic field effect transistor materials, and the preparation method provides a new method for aromatic ketone carbonyl reduction.

Owner:EAST CHINA NORMAL UNIV

Bio-electrode composition, bio-electrode, and method for manufacturing bio-electrode

ActiveUS20200315476A1Improve conductivityLow costBioelectric signal measurementCell electrodesContact layerSodium salt

A bio-electrode composition includes (A) an ionic material and (B) a silicon material powder. The component (A) is a polymer compound containing a repeating unit-a having a structure selected from an ammonium salt, a sodium salt, a potassium salt, and a silver salt of any of fluorosulfonic acid, fluorosulfonimide, and N-carbonyl-fluorosulfonamide. Thus, the present invention provides a bio-electrode composition capable of forming a living body contact layer for a bio-electrode that is excellent in electric conductivity and biocompatibility, is light-weight, can be manufactured at low cost, and can control significant reduction in the electric conductivity even when the bio-electrode is wetted with water or dried; a bio-electrode including a living body contact layer formed of the bio-electrode composition; and a method for manufacturing the bio-electrode.

Owner:SHIN ETSU CHEM IND CO LTD

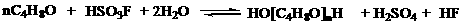

Process for preparing 1, 1, 1-trifluoroethane and 1, 1, 1-difluoro chloroethane

InactiveCN1634816AReduce generationExtended service lifePreparation by halogen halide additionNiobiumAntimony

The present invention discloses a method for preparing 1,1,1-trifluoroethane and 1,1,1-difluorochloroethane. In the existence of liquid phase fluorinated catalyst and additive, VDC and hydrogen fluoride are reacted in liquid phase. The liquid phase fluorinated catalyst is selected from halide of metal antimony, tin, titanium, tantalum, niobium or fluorosulfuric acid or chlorosultonic acid. The additive comprises at least one kind of phenolic compound, and can be added with organic phosphorus compound. The inventive method can effectively reduce tarry matters generation, thereby prolonging useful life of the catalyst and improving its efficiency.

Owner:苏州联氟化学有限公司

Method for removing trace impurities in lithium bis (fluorosulfonyl) imide

The invention relates to a method for removing trace impurities in lithium bis (fluorosulfonyl) imide, which comprises the following steps: (1) adding a good solvent into a mixture of lithium bis (fluorosulfonyl) imide and an inert solvent, and filtering to provide a first filtrate; (2) adding an impurity removal agent into the filtrate to form a mixed solution, and filtering to provide a second filtrate; and (3) carrying out reduced pressure distillation on the second filtrate to provide a finished product of the bis (fluorosulfonyl) imide lithium salt. The indexes of the lithium bis (fluorosulfonyl) imide salt finished product accord with one or a combination of more of the following items: the ion chromatography content is greater than or equal to 99.5%, sulfate radical impurity anions are less than or equal to 100ppm, fluorine ion impurity anions are less than or equal to 200ppm, sulfamic acid content anions are less than or equal to 10ppm, fluorine sulfonic acid impurity anions are less than or equal to 10ppm, acidic impurities are less than or equal to 100ppm, the turbidity of the 10% dimethyl carbonate solution is smaller than or equal to 20 mg / L, and the chromaticity is smaller than or equal to 20 Hazen.

Owner:ZHANGJIAGANG HUASHENG CHEM CO LTD

Fluorine-containing sulfonate electrolyte additive, electrolyte containing additive and lithium ion battery

ActiveCN112054241AImprove wettabilityImprove low temperature discharge performanceSecondary cells servicing/maintenanceOrganic electrolytesElectrolytic agentSulfonate

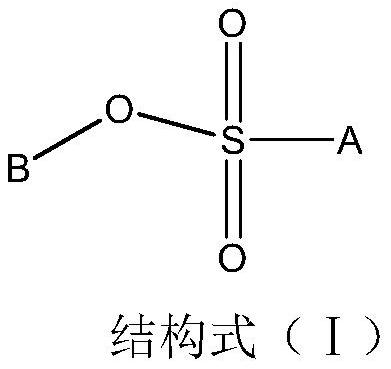

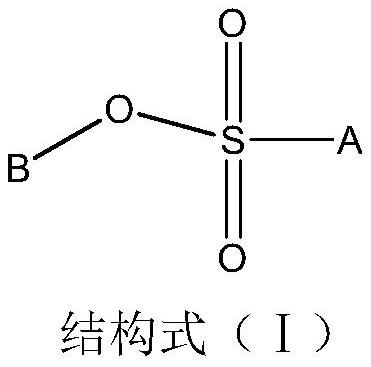

The invention discloses a fluorine-containing sulfonate electrolyte additive, an electrolyte containing the additive and a lithium ion battery, the electrolyte additive comprises the following structural formula I, A can be one of benzene ring, pyridine and silane; B may be a fluoroalkyl group. In addition, the general structural formula of the fluorine-containing alkyl in the structural formula is CaFmHn, a is equal to 1-6, n is greater than or equal to 0, m is greater than or equal to 1, and m + n is 2a + 2. The additive can react on the positive electrode and the negative electrode of the battery to form a stable interface film on the surface of the electrode, so that the cyclic gas production of the electrolyte is effectively inhibited, the cycle performance and the low-temperature discharge performance of the electrolyte under high voltage are improved, and particularly, the excellent performance of the lithium cobalt oxide and NCM ternary system lithium ion battery under high temperature and high voltage can be ensured.

Owner:GUANGZHOU TINCI MATERIALS TECH

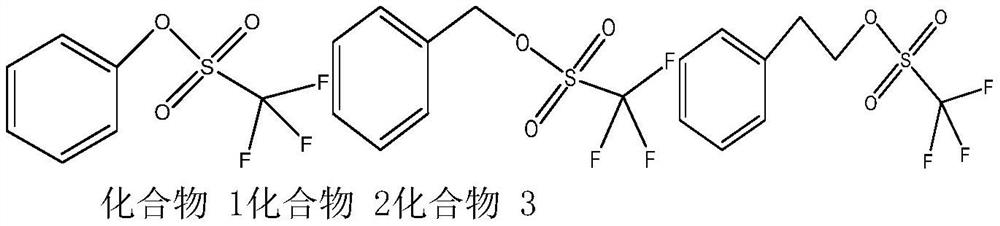

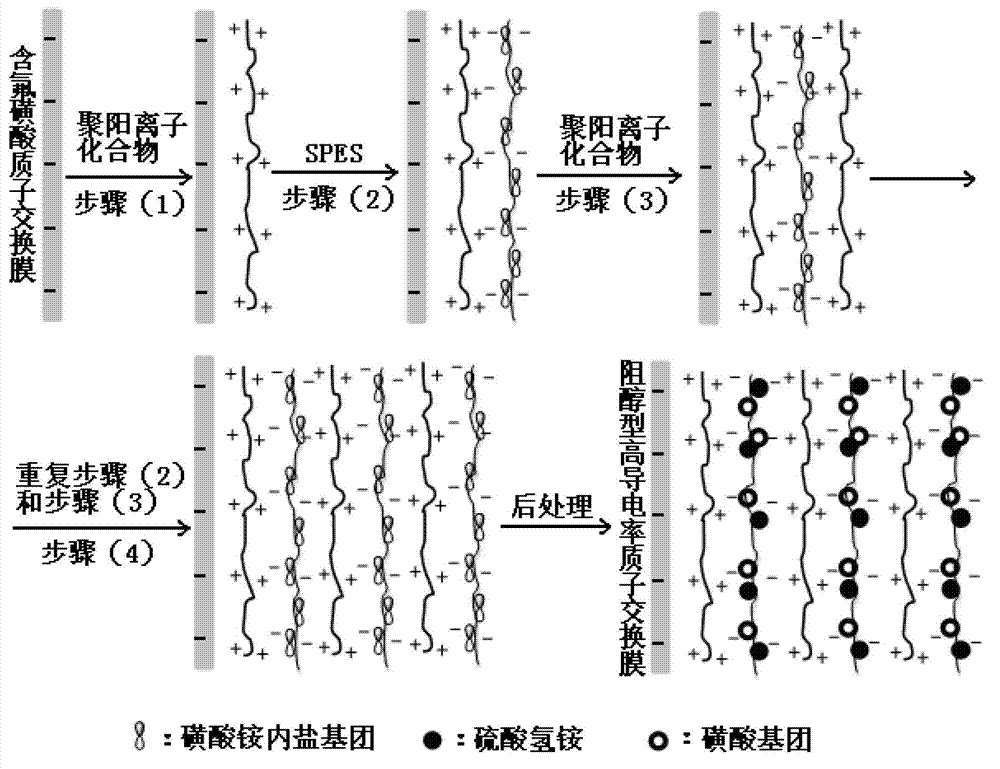

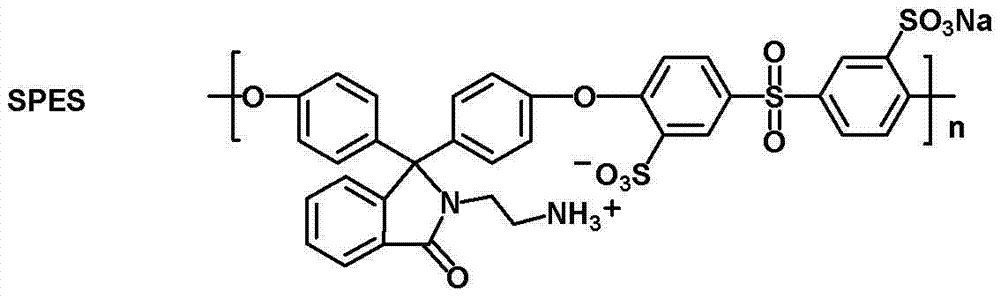

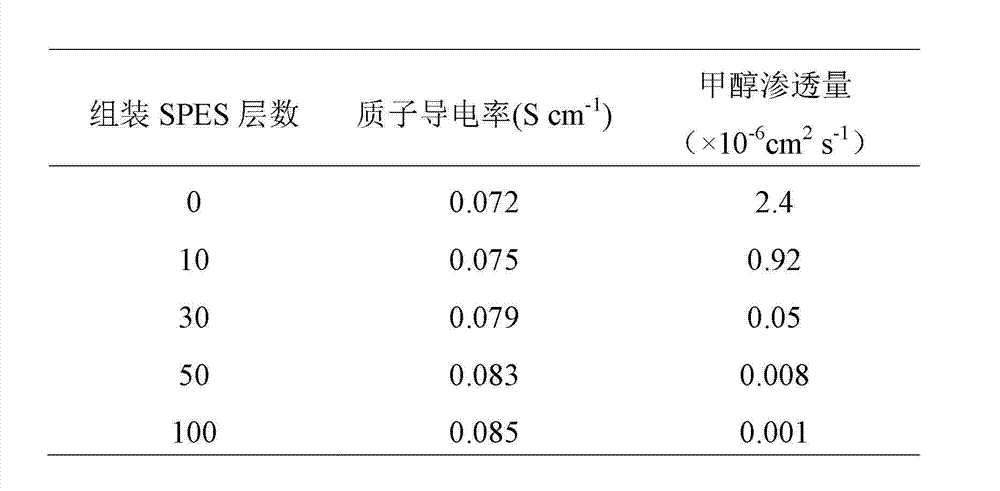

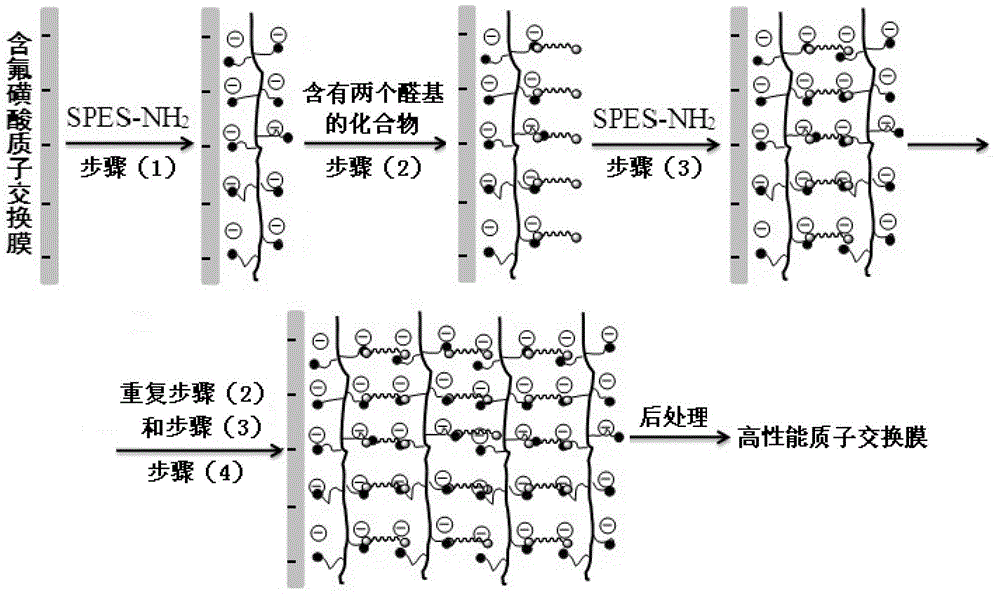

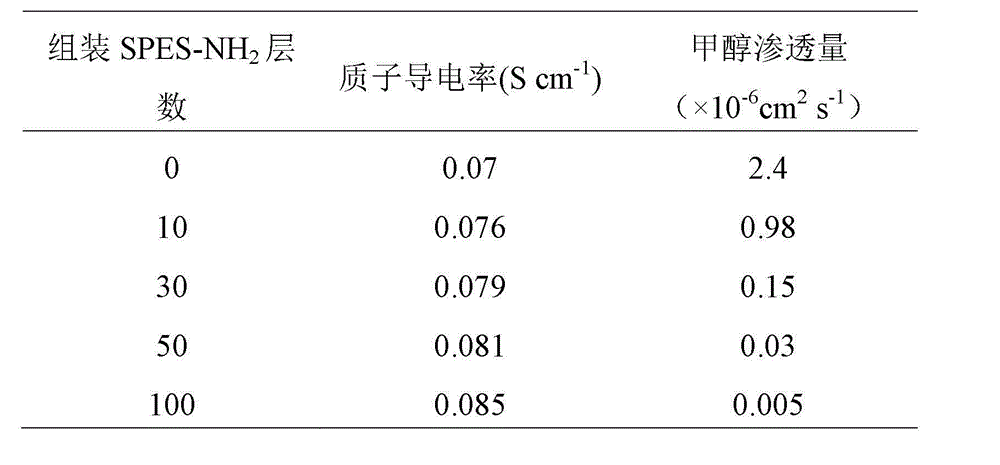

Method for preparing methanol-resisting high-conductivity proton exchange membrane

ActiveCN102922863AHigh proton conductivityReduce penetrationLamination ancillary operationsLaminationMethanolChemistry

The invention provides a method for preparing a methanol-resisting high-conductivity proton exchange membrane, relates to the technical field of fuel cell diaphragms, and solves the problem that the methanol permeability of a proton exchange membrane containing fluorosulfuric acid is high and reduces along with proton conductivity. The method comprises the steps of soaking the proton exchange membrane which is pre-processed and contains fluorosulfuric acid into 0.1%-5% by weight of polyelectrolyte SPES aqueous solution containing asymmetric electric charges at the temperature of 20-80 DEG C for 10-40 minutes, using deionized water to wash off SPES on the membrane surface, using nitrogen to blow the membrane dry, soaking the membrane into 0.05%-10% by weight of polycation compound aqueous solution at the temperature of 20-60 DEG C for 10-40 minutes, using the deionized water to flush off a compound on the membrane surface, using the nitrogen to blow the membrane dry, repeating the process, and assembling 5-100 layers of membranes to prepare the methanol-resisting high-conductivity proton exchange membrane. By means of the method, the methanol permeating amount can be reduced, and simultaneously the proton conductivity can be improved.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

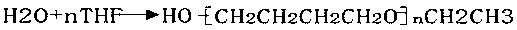

Polymerization method of polytetrahydrofuran single alcohol and diol mixture

The invention relates to a polytetrahydrofuran preparation and purification method using alcamines substances or single alcohol substance and water as a end-capping reagent, especially relates to a polymerization method of polytetrahydrofuran single alcohol and diol mixture. The invention employs the problem that the polytetrahydrofuran diol prepared by the fluosulfonic acid method, the acetic anhydride-perchloric acid method and the concentrated sulfuric acid method has wide distribution and high viscosity, and the product should be melted by higher temperature for usage, and if the heteropoly acid method is out of control, the gel will be appeared. The invention provides a new method which employs a certain amount of hydramine or single alcohol as the end-capping reagent to prepare polytetrahydrofuran, and uniform mixing of the polytetrahydrofuran and the polytetrahydrofuran diol prepared by the end-capping reagent water can be used as a novel raw material widely applied in the fields of spandex fiber, polyurethane elastomer, ester and ether copolymerization elastomer, petrochemical industry, spaceflight, etc.

Owner:杭州三隆新材料有限公司

Method for preparing lithium fluorosulfonate by using organic metal lithium reagent

The invention discloses a method for preparing lithium fluorosulfonate by using an organometallic lithium reagent, which comprises the following steps: (1) slowly mixing and reacting the organometallic lithium reagent serving as a lithium source with fluorosulfonic acid under a low-temperature condition in the presence of perfluorohexane serving as a solvent to obtain a lithium fluorosulfonate crude product; and washing the crude product with a reaction solvent for 5 times; (2) carrying out vacuum pumping on the crude product, adding a poor organic solvent of lithium fluorosulfonate, washing for three times, and carrying out vacuum pumping on the poor organic solvent to obtain a solid; (3) adding carbonate, nitrile and alcohol organic solvents into the solid, extracting, filtering, concentrating, adding a low-polarity aprotic solvent into the concentrated solution, and carrying out static crystallization; and (4) filtering the crystals again, and carrying out vacuum drying to obtain the lithium fluorosulfonate product. The preparation steps are carried out without water under the protection of inert gas. According to the preparation method provided by the invention, the lithium fluorosulfonate can be prepared, the yield is high, the product quality is stable, and the content of impurities such as potassium ions, sodium ions, calcium ions, fluorine ions, sulfate ions and water in the product can be effectively reduced.

Owner:LEE & MAN CHEM CO LTD

Polymer-zeolite nanocomposite membranes for proton-exchange-membrane fuel cells

InactiveUS7691514B2Reducing anode CO poisoningImprove proton conductivityMaterial nanotechnologyAluminium compoundsPolymer networkProton

A suite of polymer / zeolite nanocomposite membranes. The polymer backbone is preferably a film forming fluorinated sulfonic acid containing copolymer, such as a Teflon type polymer, a perfluorinated polymer, or a perfluorinated polymer with sulfonic groups. The zeolites formed in accordance with the present invention and which are used in the membranes are plain, phenethyl functionalized and acid functionalized zeolite FAU(Y) and BEA nonocrystals. The zeolite nanocrystals are incorporated into polymer matrices for membrane separation applications like gas separations, and in polymer-exchange-membrane fuel cells. For the purpose of developing zeolite-polymer nanocomposite membranes, the zeolite nanocrystals are size-adjustable to match the polymer-network dimensions.

Owner:RGT UNIV OF CALIFORNIA

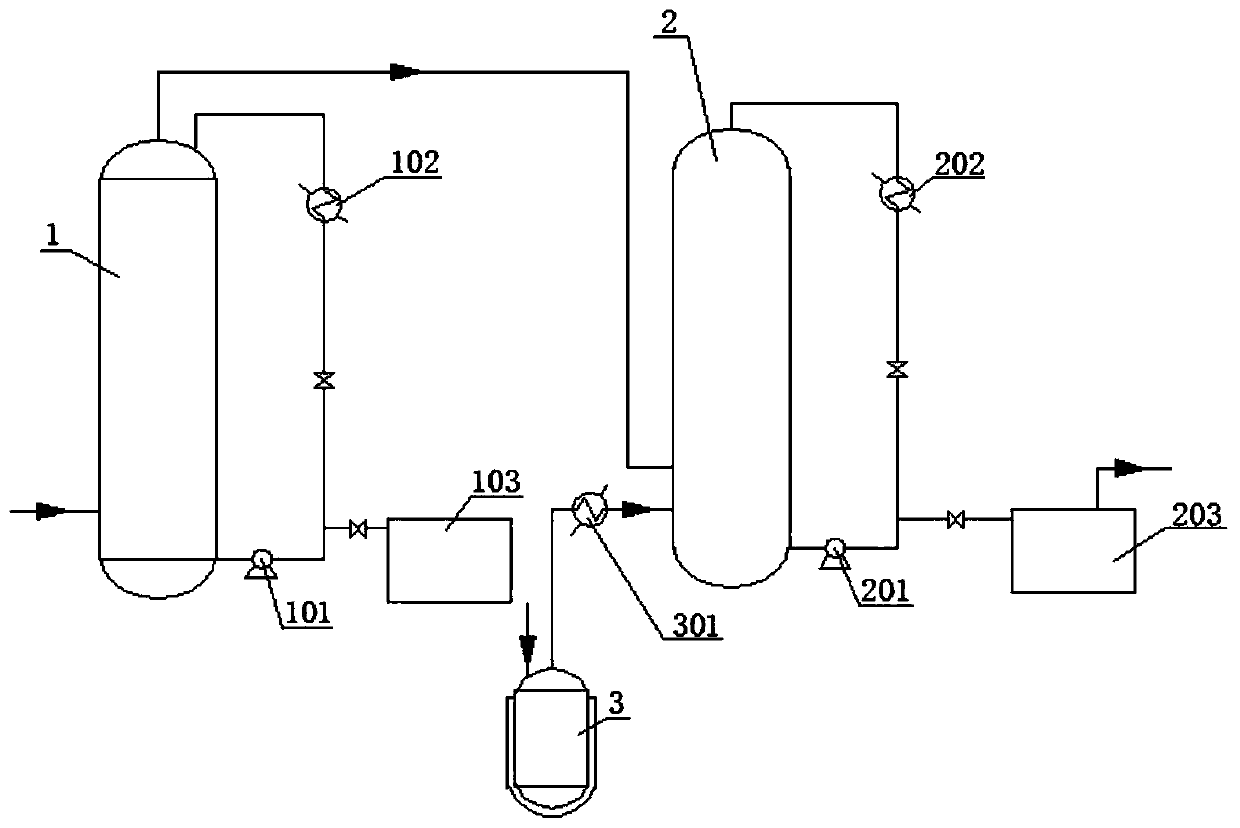

Treatment method and device for lithium hexafluorophosphate synthesis tail gas

PendingCN110683519ARealize resource utilizationSolve the defects of high environmental pressurePhosphorus halides/oxyhalidesFluorosulfonic acidChlorosulfuric acidPhosphoric acid

The invention provides a treatment method and device for lithium hexafluorophosphate synthesis tail gas, belonging to the technical field of tail gas treatment. The treatment method comprises the following steps: absorbing hydrogen fluoride in tail gas by using chlorosulfonic acid, absorbing hydrogen chloride in the tail gas by using sulfur trioxide, and returning phosphorus pentafluoride in the tail gas to a lithium hexafluorophosphate synthesis process for reuse. The treatment device comprises a first-stage absorption tower which internally adopts circulating liquid chlorosulfonic acid as areaction medium and is used for absorbing hydrogen fluoride in the tail gas, and a secondary absorption tower which is used for supplying the liquid sulfur trioxide for a reaction with hydrogen chloride in the tail gas. According to the invention, hydrogen fluoride in the tail gas is absorbed by a reaction with chlorosulfonic acid; a reaction with sulfur trioxide is performed to adsorb hydrogen chloride in the tail gas and to generate chlorosulfonic acid; and hydrochloric acid is not generated in the whole process, the defect of high environmental protection pressure caused by production of alarge amount of hydrochloric acid in the prior art is overcome, the produced chlorosulfonic acid and fluorosulfonic acid are important chemical raw materials, and resource utilization of mixed acid isrealized.

Owner:湖北迈可凯科技有限公司

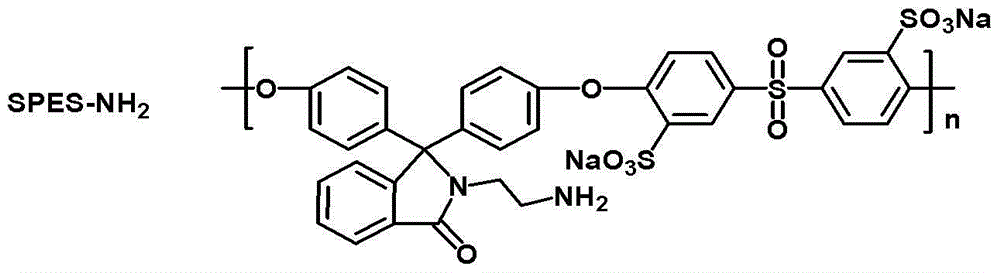

Preparation method of high-performance proton exchange membrane

ActiveCN102916204AEasy transferImprove conductivityCell component detailsFuel cell detailsPolyelectrolyteProton

The invention discloses a preparation method of a high-performance proton exchange membrane, relates to the technical field of a fuel cell membrane, and solves the problem that the methanol permeabiliy of the proton exchange membrane containing fluorosulfuric acid is high and is reduced along with the proton conductivity. The method comprises the steps of: dipping the pre-processed proton exchange membrane containing fluorosulfuric acid into 0.1-5wt% of sulfonated polyelectrolyte SPES-NH2 aqueous solution, soaking for 10-40 minutes at 20-80 DEG C; rinsing the SPES-NH2 at the surface of the membrane by deionized water, blowing by nitrogen, then dipping the membrane into 0.05-10wt% of compound aqueous solution containing two aldehyde groups, soaking for 10-40 minutes at 20-60 DEG C; rinsing the compound at the surface by the deionized water, blowing by the nitrogen, repeating the processes and assembling into 5-100 layers to obtain the high-performance proton exchange membrane disclosed by the invention. According to the method disclosed by the invention, the methanol permeability can be reduced and the proton conductivity can be improved.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com