Treatment method and device for lithium hexafluorophosphate synthesis tail gas

A technology of lithium hexafluorophosphate and synthetic tail gas, which is applied in the direction of lithium hexafluorophosphate, fluorosulfonic acid, lithium compounds, etc., can solve the problems of high pressure on environmental protection, and achieve the effects of low cost, reduced emissions, and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

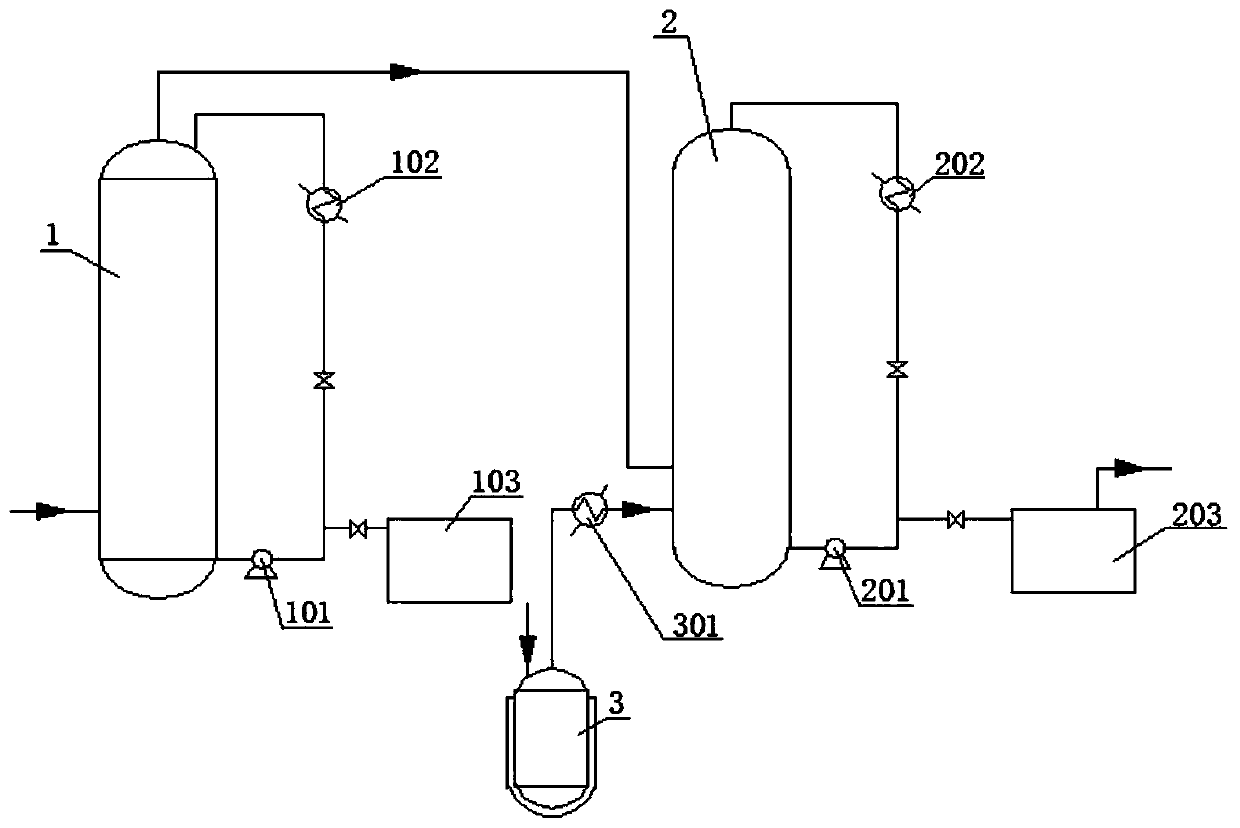

[0026] In this embodiment, an exhaust gas treatment device for synthesis of lithium hexafluorophosphate is provided, such as figure 1 As shown, it includes: a primary absorption tower 1, a liquid sulfur trioxide generating assembly, and a secondary absorption tower 2. The inside of the primary absorption tower 1 uses circulating liquid chlorosulfonic acid as the reaction medium for absorbing hydrogen fluoride in the tail gas; the liquid sulfur trioxide generating assembly is used to heat and condense fuming sulfuric acid to form liquid sulfur trioxide; secondary absorption Tower 2 is connected with the output end of the liquid sulfur trioxide generating assembly, and is used for reacting the liquid sulfur trioxide with the hydrogen chloride in the tail gas.

[0027] Specifically, the first-stage absorption tower 1 is connected with a circulation component to circulate the liquid chlorosulfonic acid, thereby promoting reaction absorption. The circulation assembly of this embodime...

Embodiment 2

[0033] This embodiment provides a method for processing tail gas from the synthesis of lithium hexafluorophosphate. The processing device in Example 1 is used to contain 20% HF, 75% HCl and 5% PF. 5 The tail gas is passed into the first-stage absorption tower 1, and the circulating liquid chlorosulfonic acid is used as the reaction medium in the tower. Hydrogen fluoride reacts with chlorosulfonic acid to generate fluorosulfonic acid. The pressure in the first-stage absorption tower 1 is controlled to be 0.01MPa and the reaction temperature is 10 ℃. The reaction medium is circulated in the first-stage absorption tower 1 through the first circulation pump 101 to promote reaction absorption, and the reaction medium passes through the first heat exchanger 102 to remove the reaction heat. When the content of the fluorosulfonic acid product produced by the reaction reaches more than 98%, it is put into the fluorosulfonic acid tank 103 from the outlet of the primary absorption tower 1....

Embodiment 3

[0039] The difference between Example 3 and Example 2 is that the reaction pressure in the first-stage absorption tower 1 is controlled to be 0.1MPa and the reaction temperature is 40°C, and the reaction pressure in the second-stage absorption tower 2 is controlled to be 0.3MPa and the reaction temperature is 40°C. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com