Method for producing alkylation gasoline by taking ionic liquid as accelerator of fluorosulphonic acid

A technology for alkylating gasoline and ionic liquids, applied in chemical instruments and methods, production of liquid hydrocarbon mixtures, petroleum industry, etc., can solve problems such as poor effects, and achieve the effects of simple process, low catalyst cost, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

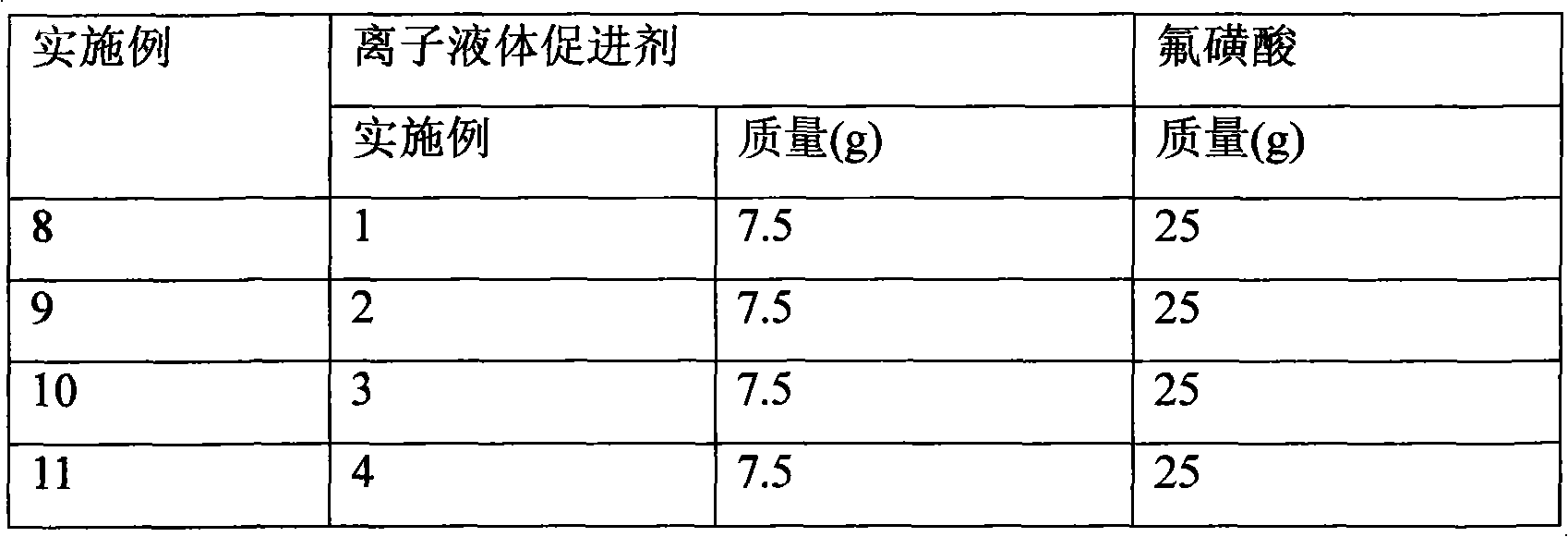

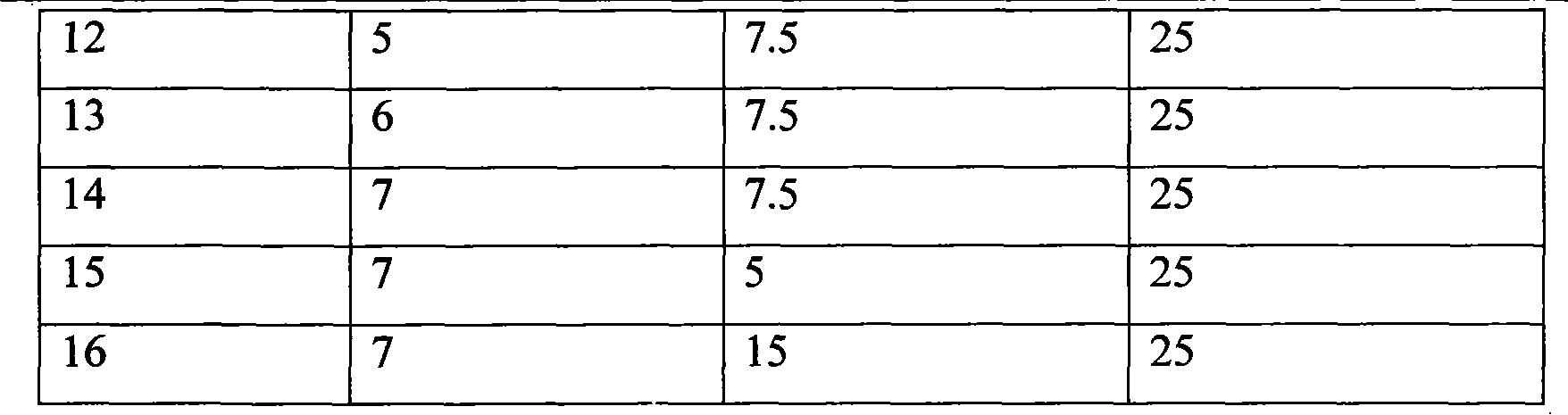

Examples

Embodiment 1

[0015] Add 0.5 mol (68 g) of butyl sultone to an equimolar solution of N-butylimidazole in toluene, and stir at 40° C. for 24 hours to make the reaction complete. After cooling and washing, a white powder zwitterion was obtained. Then equimolar trifluoromethanesulfonic acid was slowly added to the aqueous solution of zwitterions, and stirred at 40°C for 48 hours. Then after washing, rotary evaporation to remove water and dry to obtain 3-butyl-1-(4-butylsulfonic acid)-imidazole trifluoromethanesulfonic acid ionic liquid.

Embodiment 2

[0017] Add 0.5 mole of N-methylimidazole into slightly excess 1-bromobutane, reflux and stir for 2 hours, then react at room temperature for 72 hours. The upper solution was poured out, and the lower solution was recrystallized three times with acetonitrile / ethyl acetate solution. Rotary evaporation to remove water and dry to obtain 3-butyl-1-methylimidazolium bromide. Add 0.5 mol of 3-butyl-1-methylimidazolium bromide to a slightly excess aqueous solution of potassium hexafluorophosphate. Stir at room temperature for 24 hours. Separate layers, take the product layer, wash with water, and dry to obtain 3-butyl-1-methylimidazolium hexafluorophosphate ionic liquid.

Embodiment 3

[0019] Add 0.5 mol (68 g) of butyl sultone into an equimolar solution of pyridine in toluene, and stir at 40° C. for 24 hours to make the reaction complete. After cooling and washing, a white powder zwitterion was obtained. Then equimolar tetrafluoroboric acid was slowly added into the aqueous solution of zwitterions, and stirred at 40° C. for 48 hours. Then, after washing, rotary evaporation removes water and dries to obtain butylsulfonic acid pyridinium tetrafluoroborate ionic liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| research octane number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com