Patents

Literature

42 results about "Reid vapor pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reid vapor pressure (RVP) is a common measure of the volatility of gasoline and other petroleum products. It is defined as the absolute vapor pressure exerted by the vapor of the liquid and any dissolved gases/moisture at 37.8 °C (100 °F) as determined by the test method ASTM-D-323, which was first developed in 1930 and has been revised several times (the latest version is ASTM D323-15a). The test method measures the vapor pressure of gasoline, volatile crude oil, jet fuels, naphtha, and other volatile petroleum products but is not applicable for liquefied petroleum gases. ASTM D323-15a requires that the sample be chilled to 0-1 degrees Celsius and then poured into the apparatus; for any material that solidifies at this temperature, this step cannot be performed. RVP is commonly reported in kilopascals or pounds per square inch and represents volatization at atmospheric pressure because ASTM-D-323 measures the gauge pressure of the sample in a non-evacuated chamber.

Fuels for internal combustion engines

InactiveUS6858048B1Emission reductionSafer land environmentLiquid carbonaceous fuelsFuel additivesKeroseneOctanol

Mixed alcohols can be used as a fuel additive in gasoline, diesel, jet fuel or as a neat fuel in and of itself. The mixed alcohols can contain C1-C5 alcohols, or in the alternative, C1-C8, or higher, alcohols in order to boost energy content. The C1-C5 mixed alcohols contain more ethanol than methanol with amounts of propanol, butanol and pentanol. C1-C8 mixed alcohols contain the same, with amounts of hexanol, heptanol and octanol. A gasoline-based fuel includes gasoline and the mixed alcohols. A diesel based fuel includes diesel and the mixed alcohols. A jet fuel includes kerosene and the mixed alcohols. The neat fuel of the mixed alcohols has an octane number of at least 109 and the Reid Vapor Pressure is no greater than 5 psi. The gross heat of combustion is at least 12,000 BTU's / lb.

Owner:STANDARD ALCOHOL COMPANY OF AMERICA

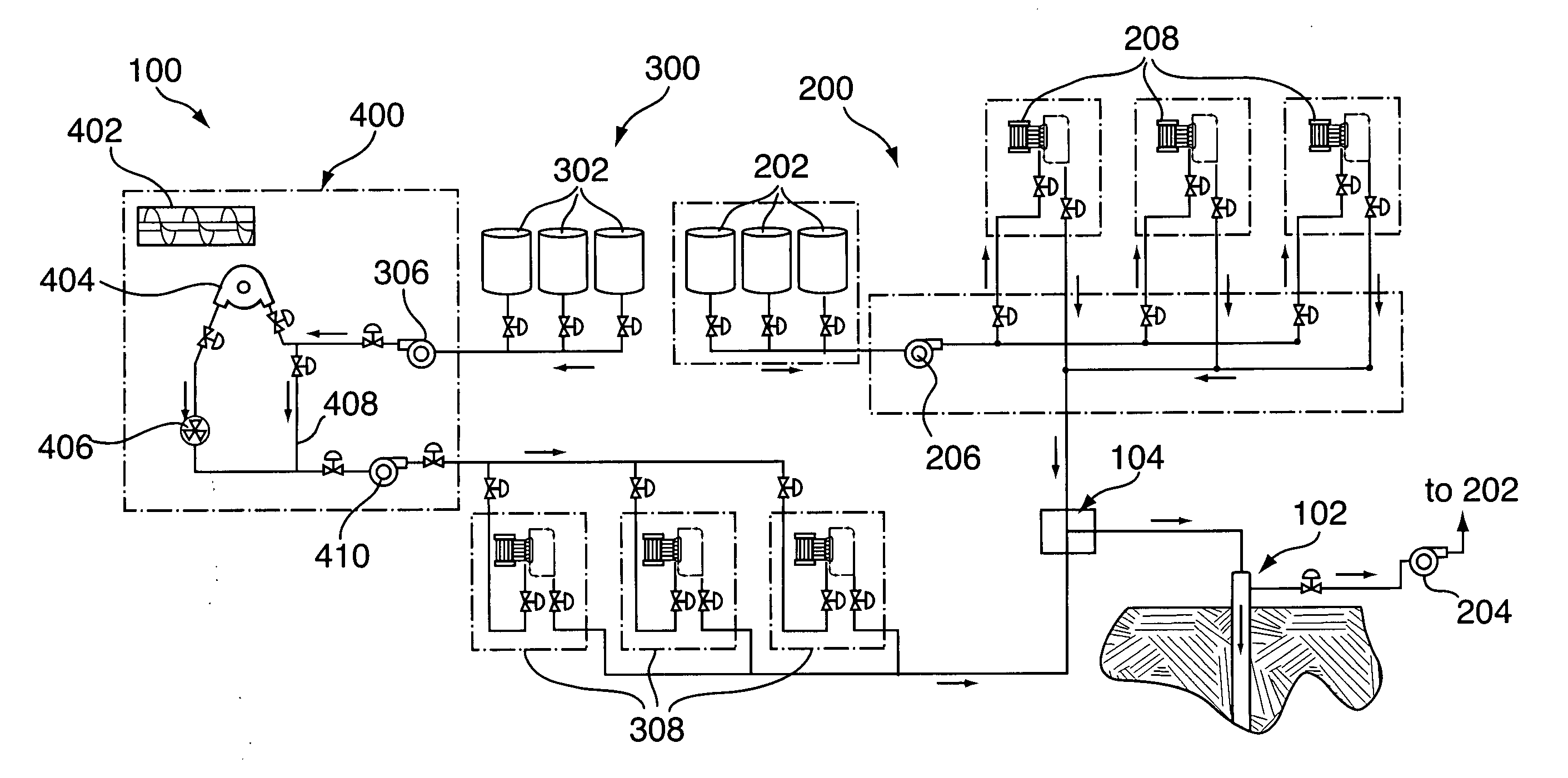

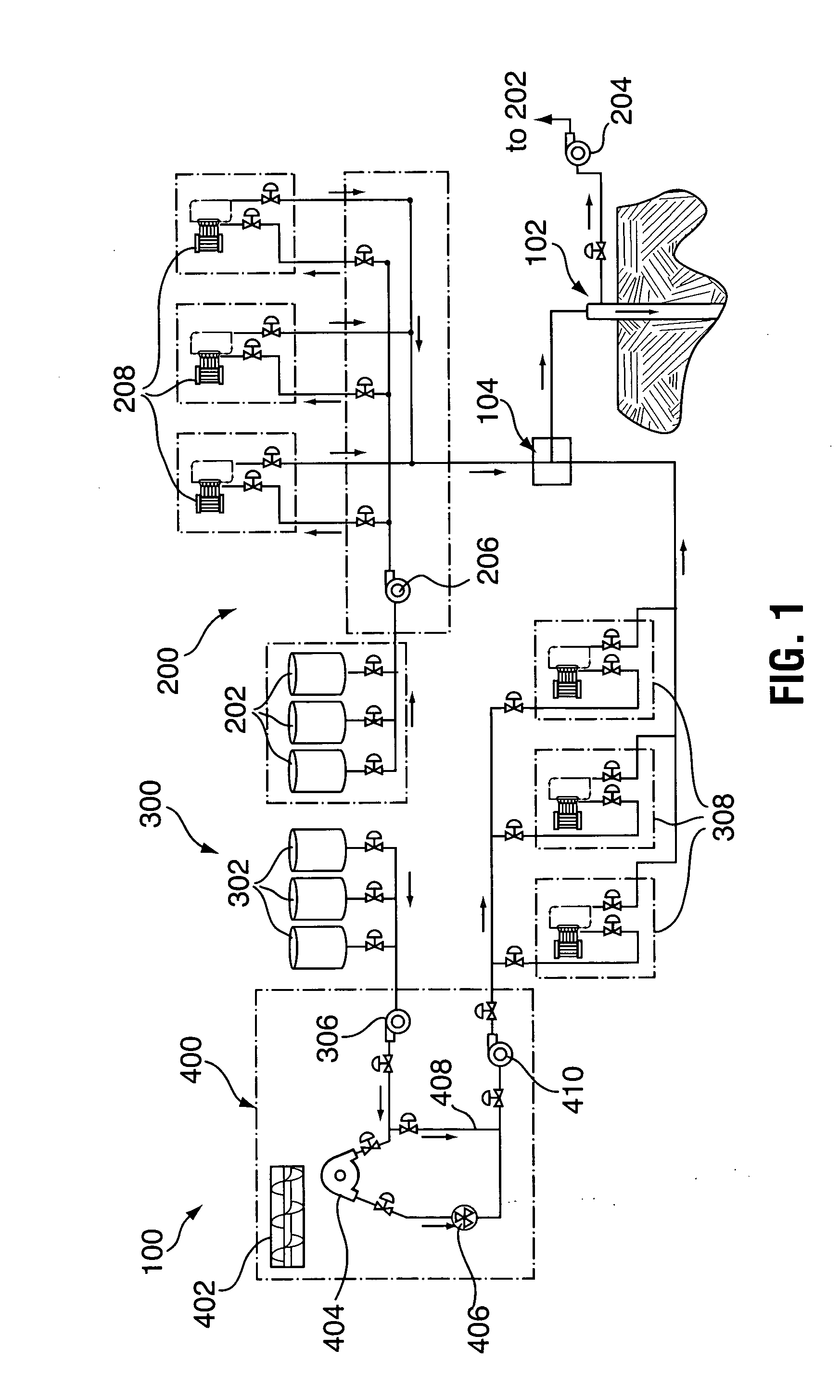

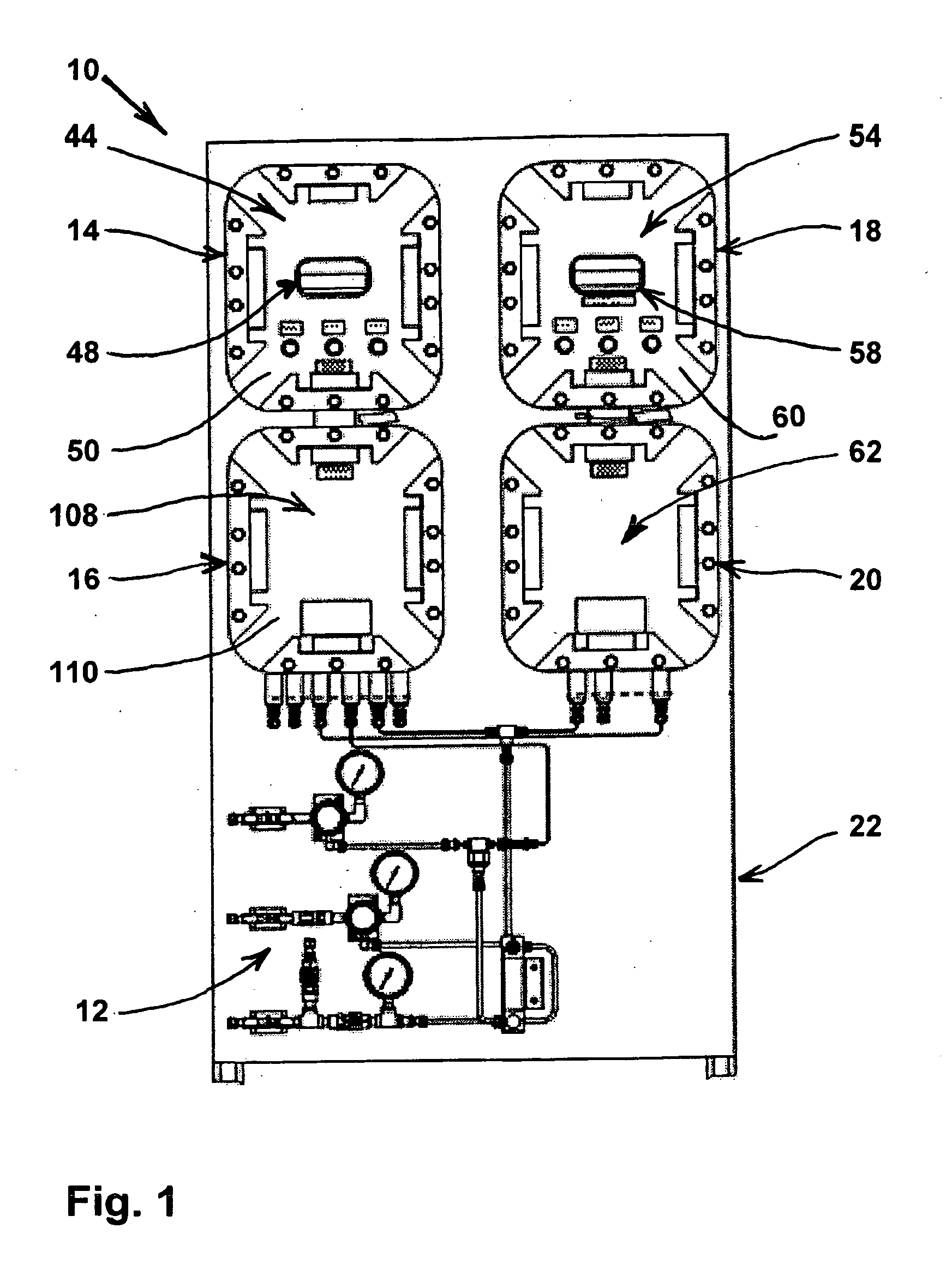

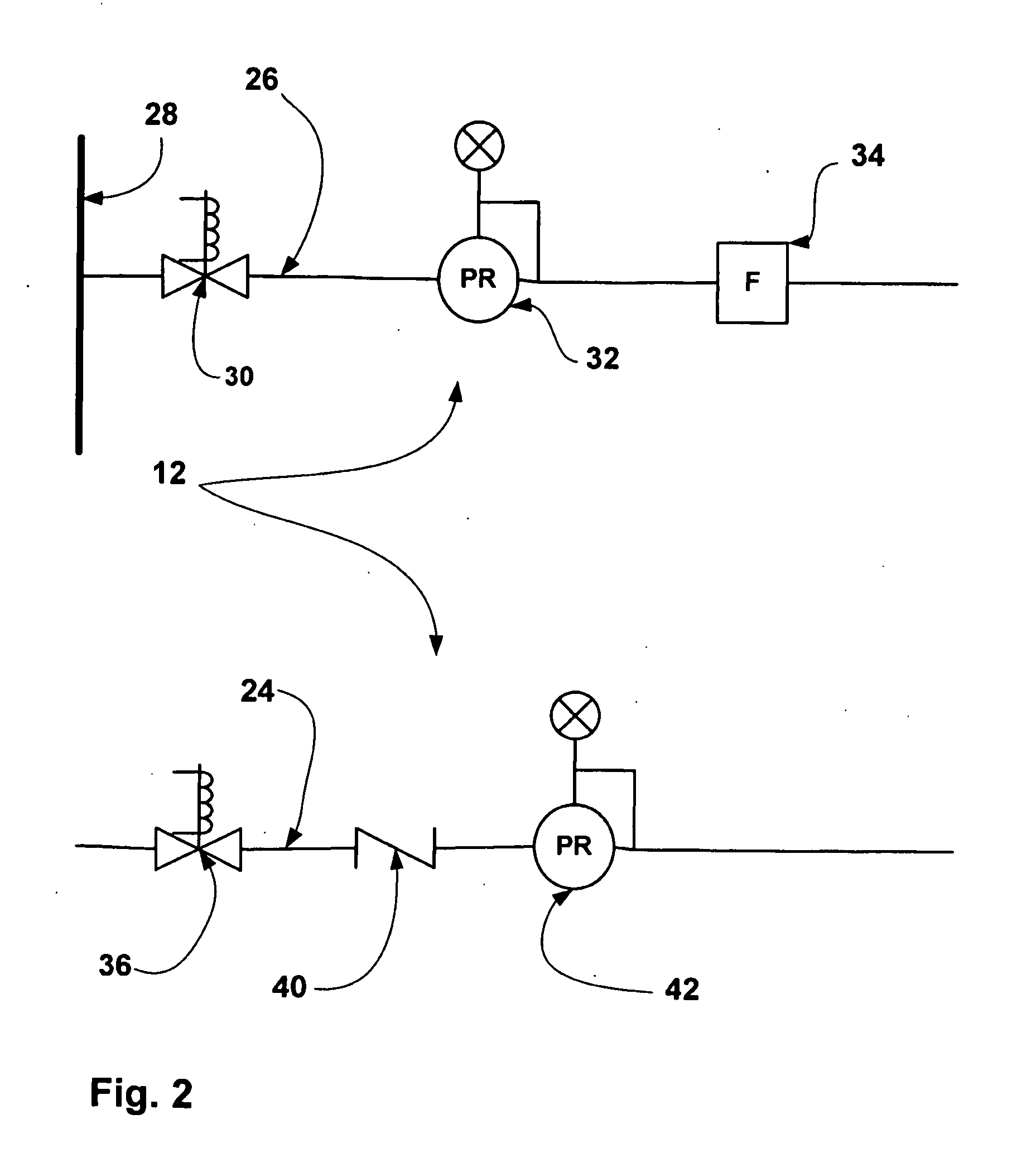

Split stream oilfield pumping system utilitzing recycled, high reid vapor pressure fluid

InactiveUS20100326663A1Safe and economic recyclingEconomic savingsDrilling rodsFlexible member pumpsVaporizationEngineering

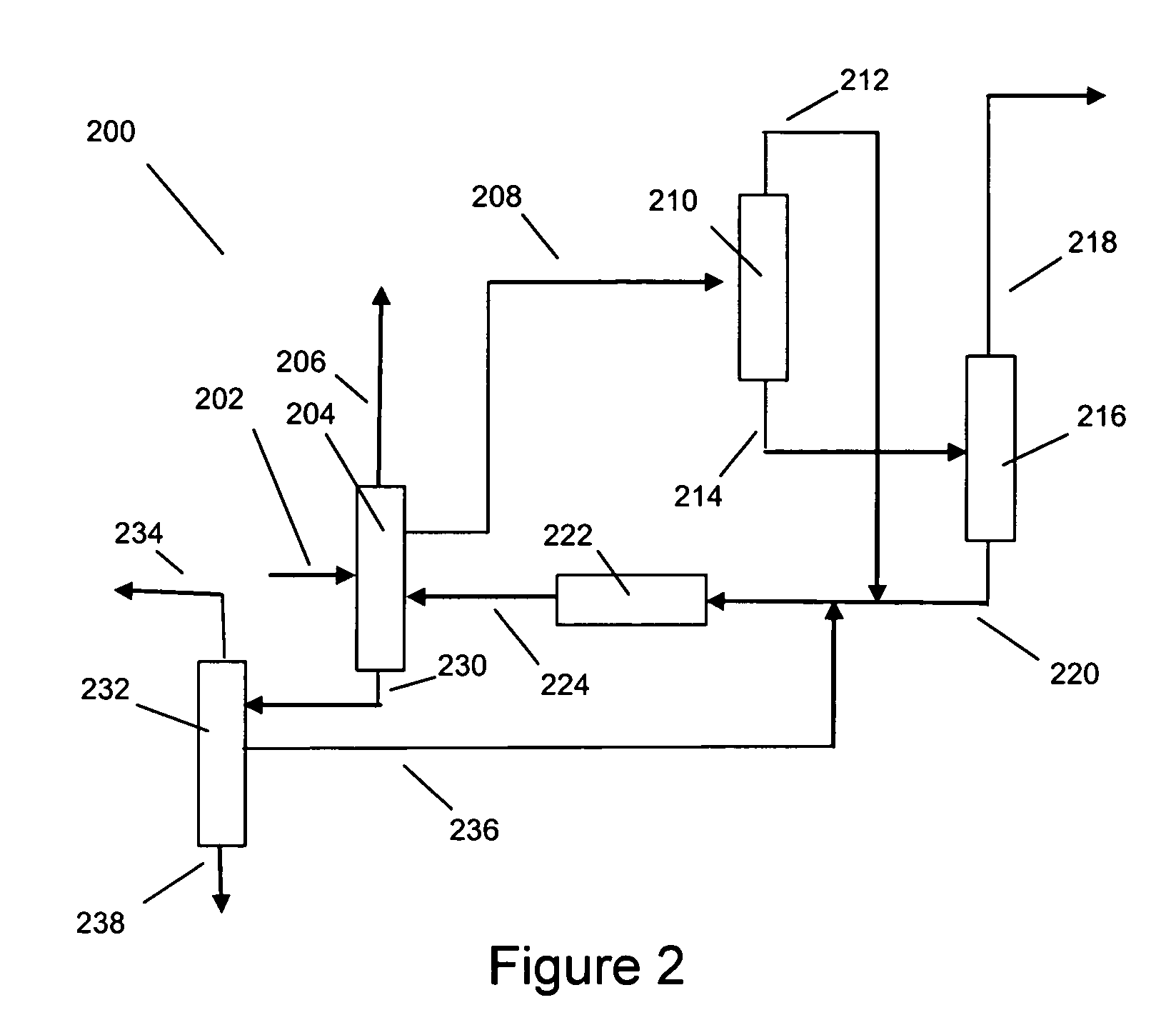

The present invention relates to a split stream oilfield pumping system which utilizes recycled high Reid vapor pressure production fluids. The oilfield system is made up of two separate fluid streams: a first recycled fluid stream and a second new fluid stream. The recycled fluid stream is enclosed to reduce or eliminate vaporization of the recycled fluid, which typically will have a Reid vapor pressure >14 kPa. Wellbore treatment additives are added to the new fluid stream, and the resultant treatment fluid is mixed with the recycled fluid in a common manifold to provide a final wellbore treatment fluid to be delivered to the wellhead.

Owner:CALFRAC WELL SERVICES

Processes for making higher octane motor fuels having a low reid vapor pressure from naphtha boiling range feedstocks

ActiveUS7485768B1Low vapor pressureLower energy requirementsHydrocarbon by hydrogenationCatalytic naphtha reforming2-methylbutaneNaphtha

Owner:UOP LLC

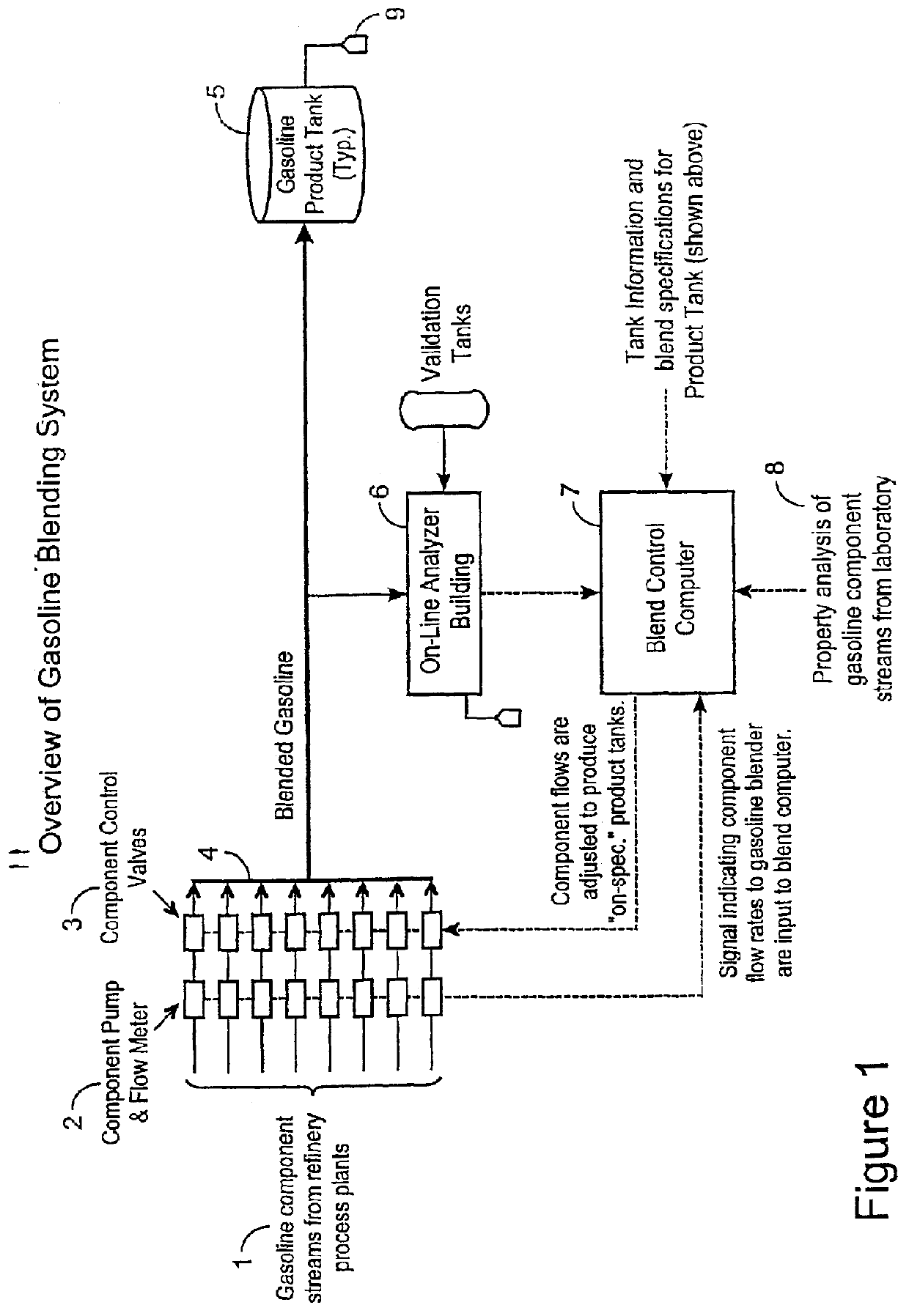

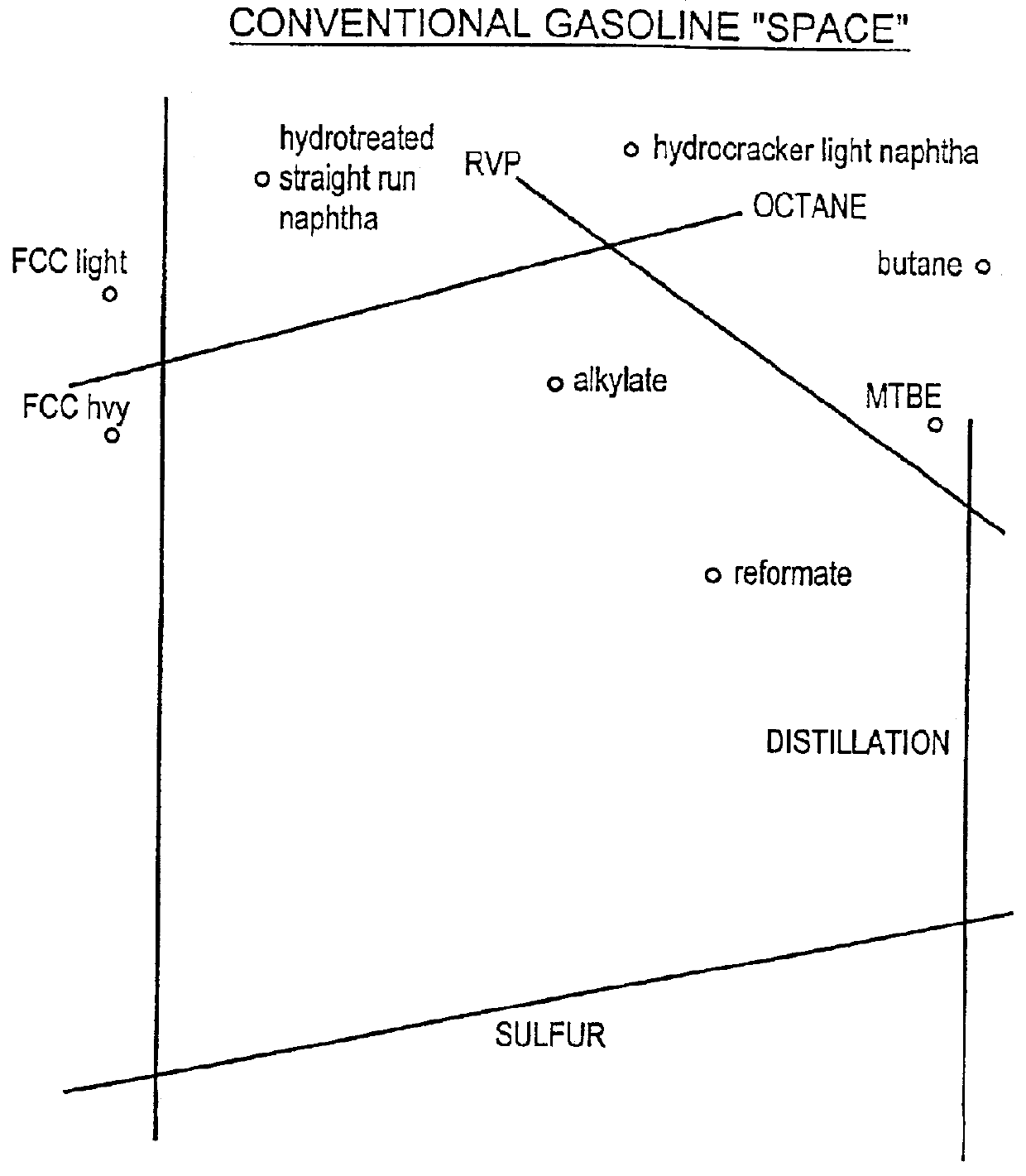

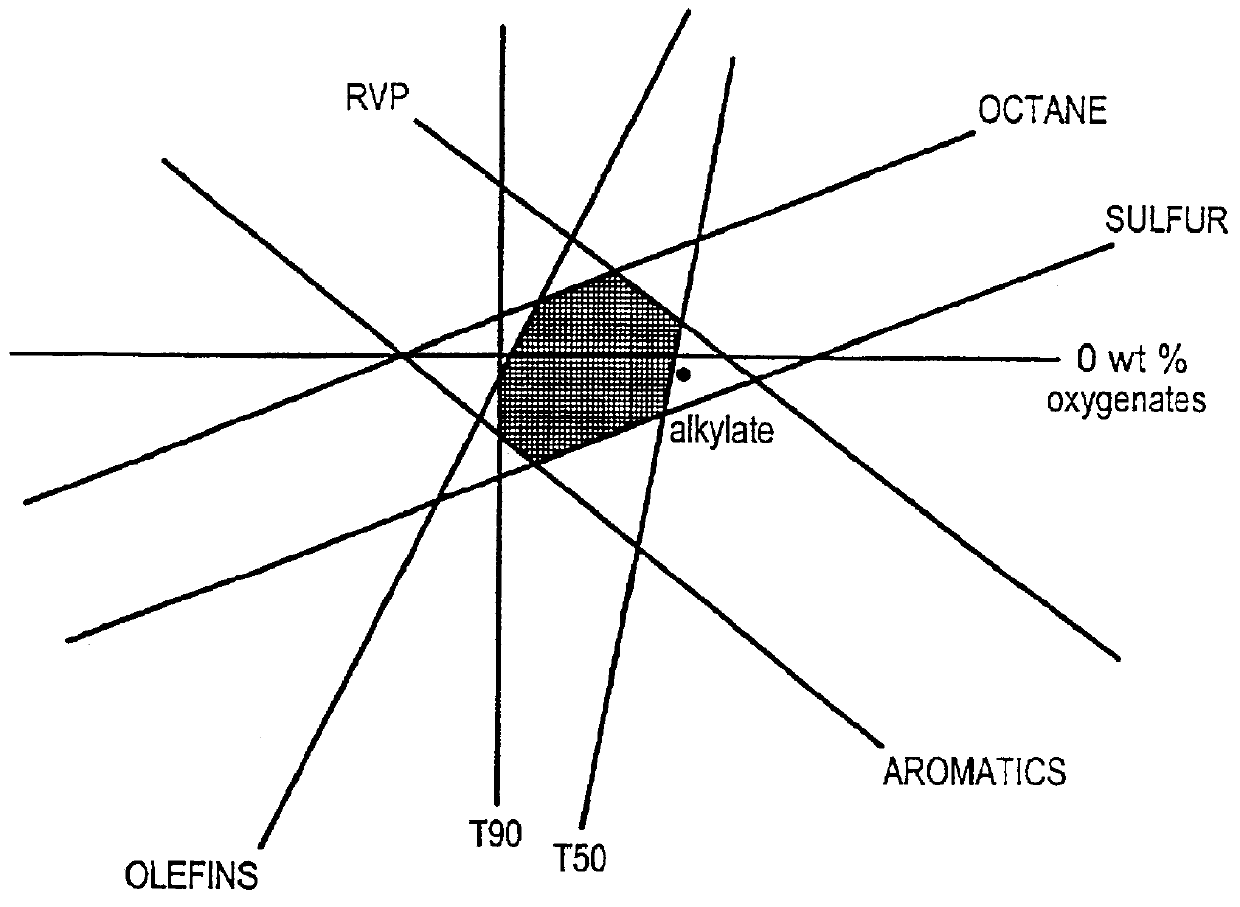

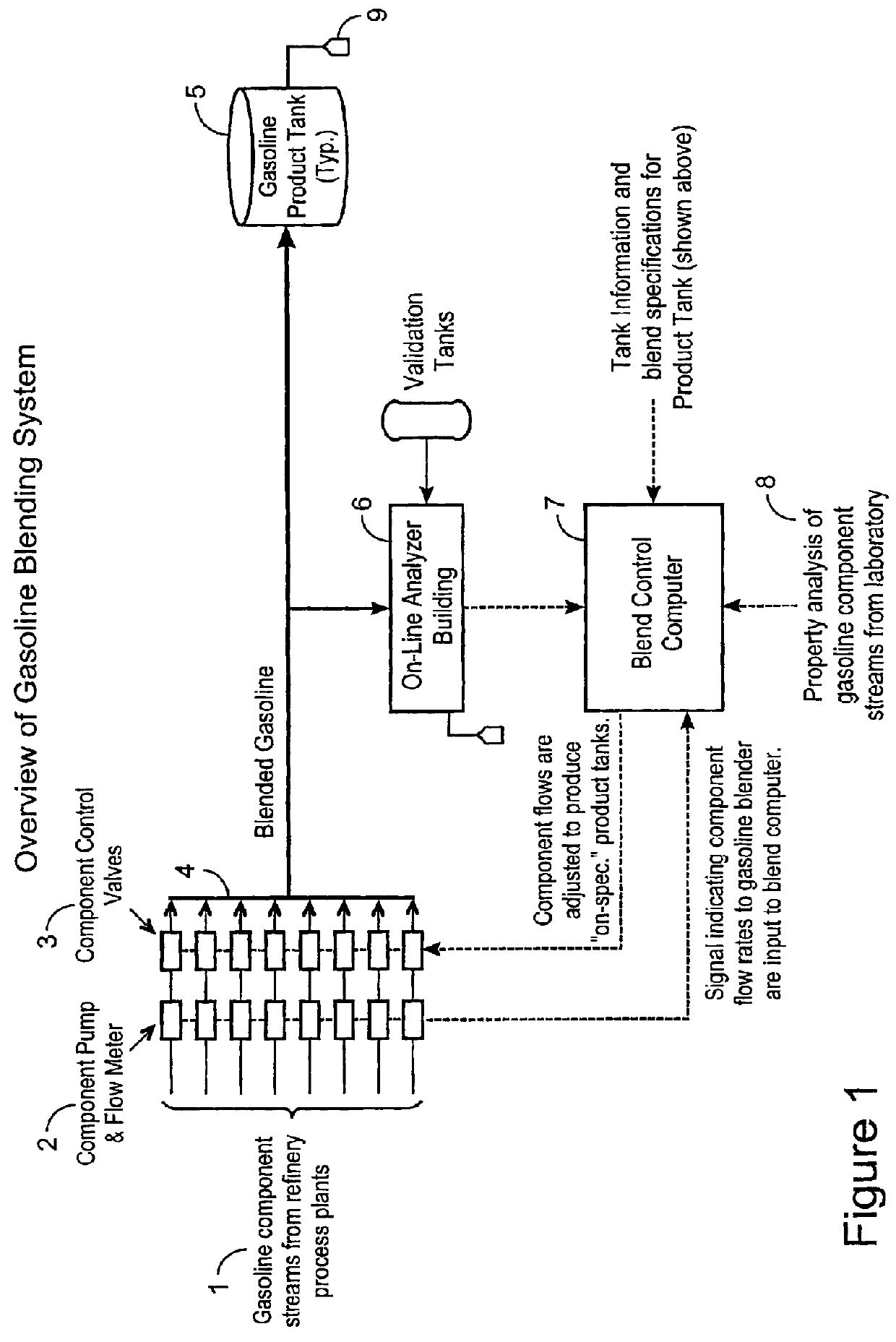

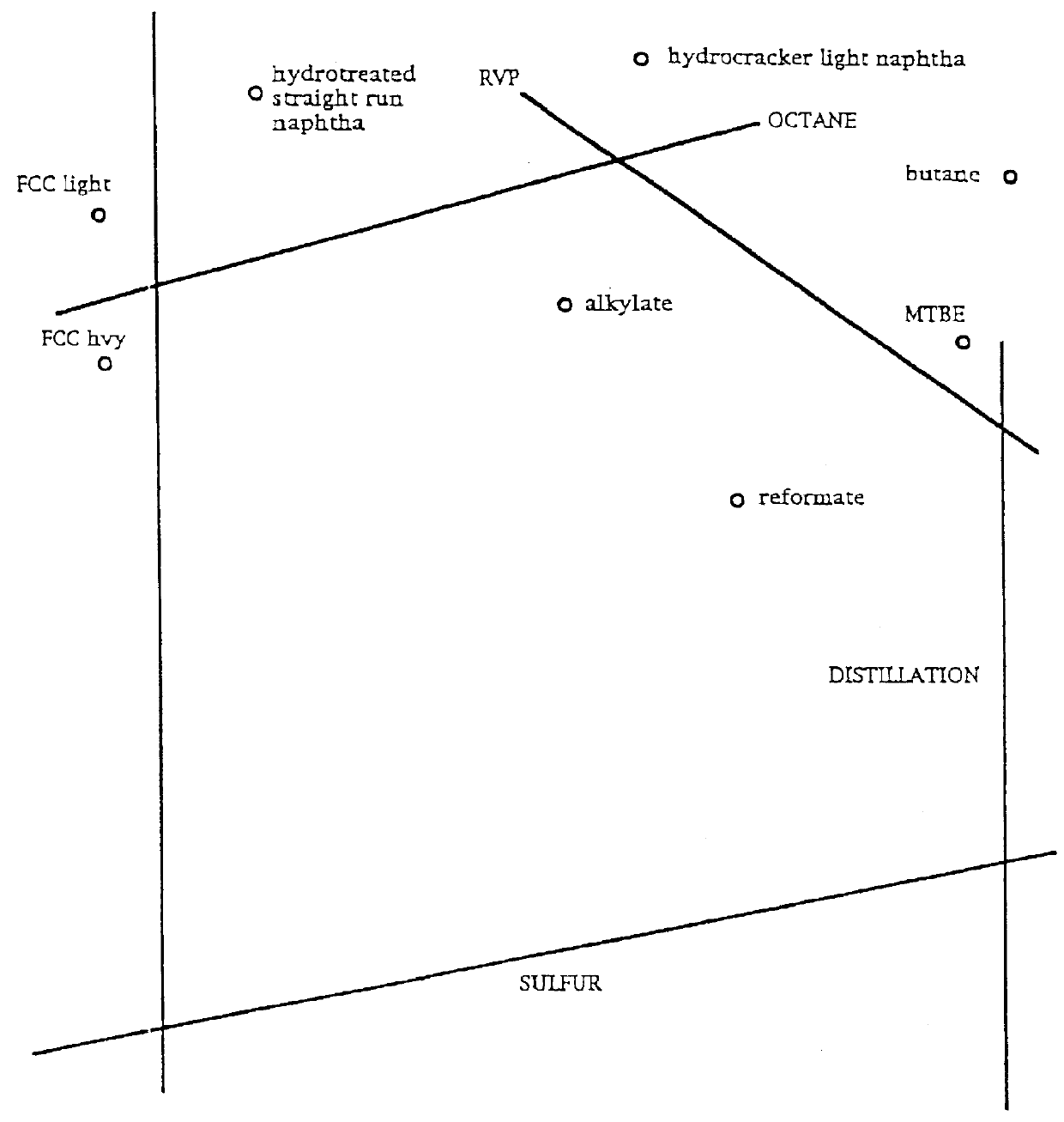

Blending of economic, ether free winter gasoline

InactiveUS20050022446A1Suitable for useMaintain complianceLiquid carbonaceous fuelsControl mannerGasoline

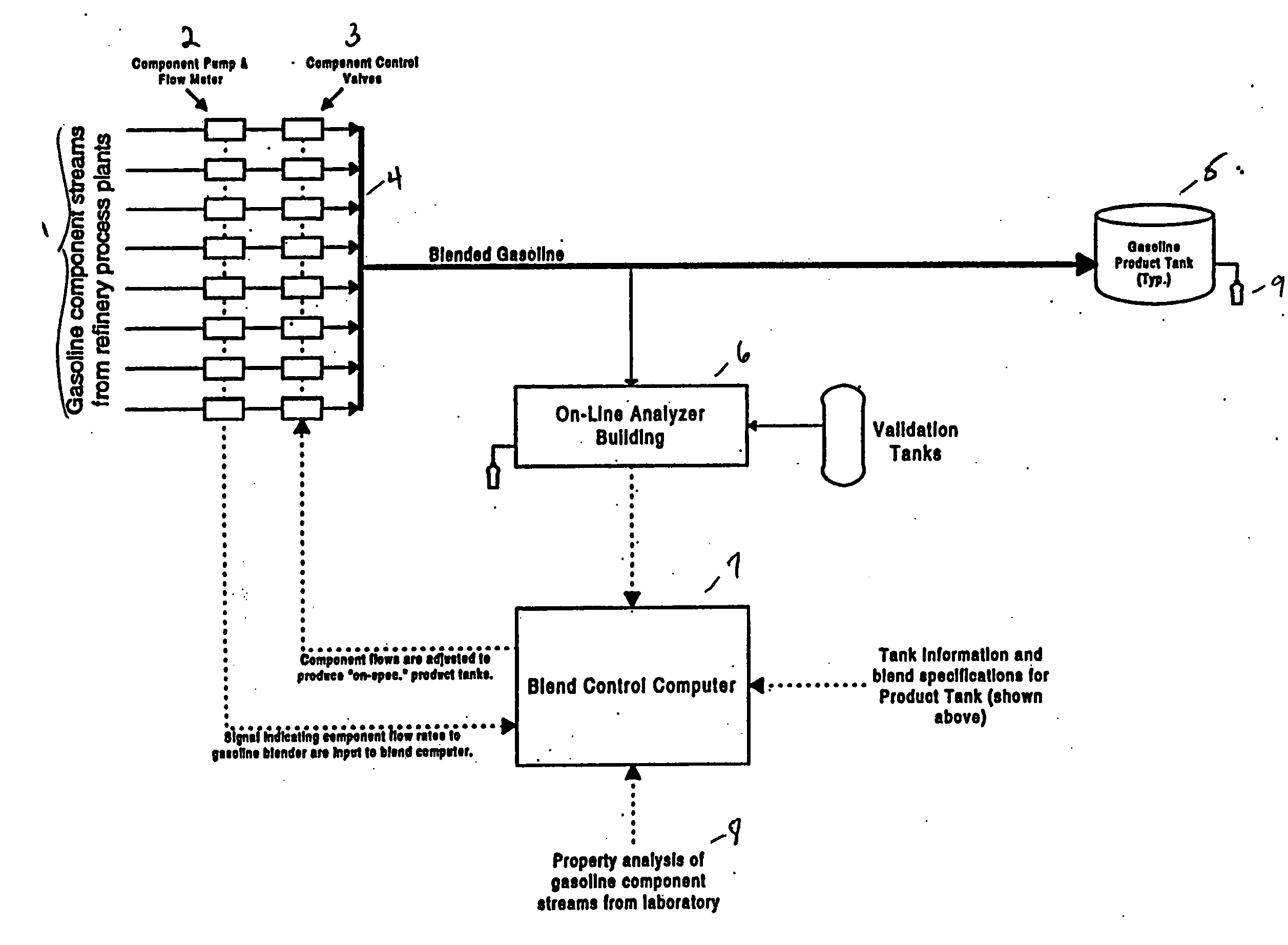

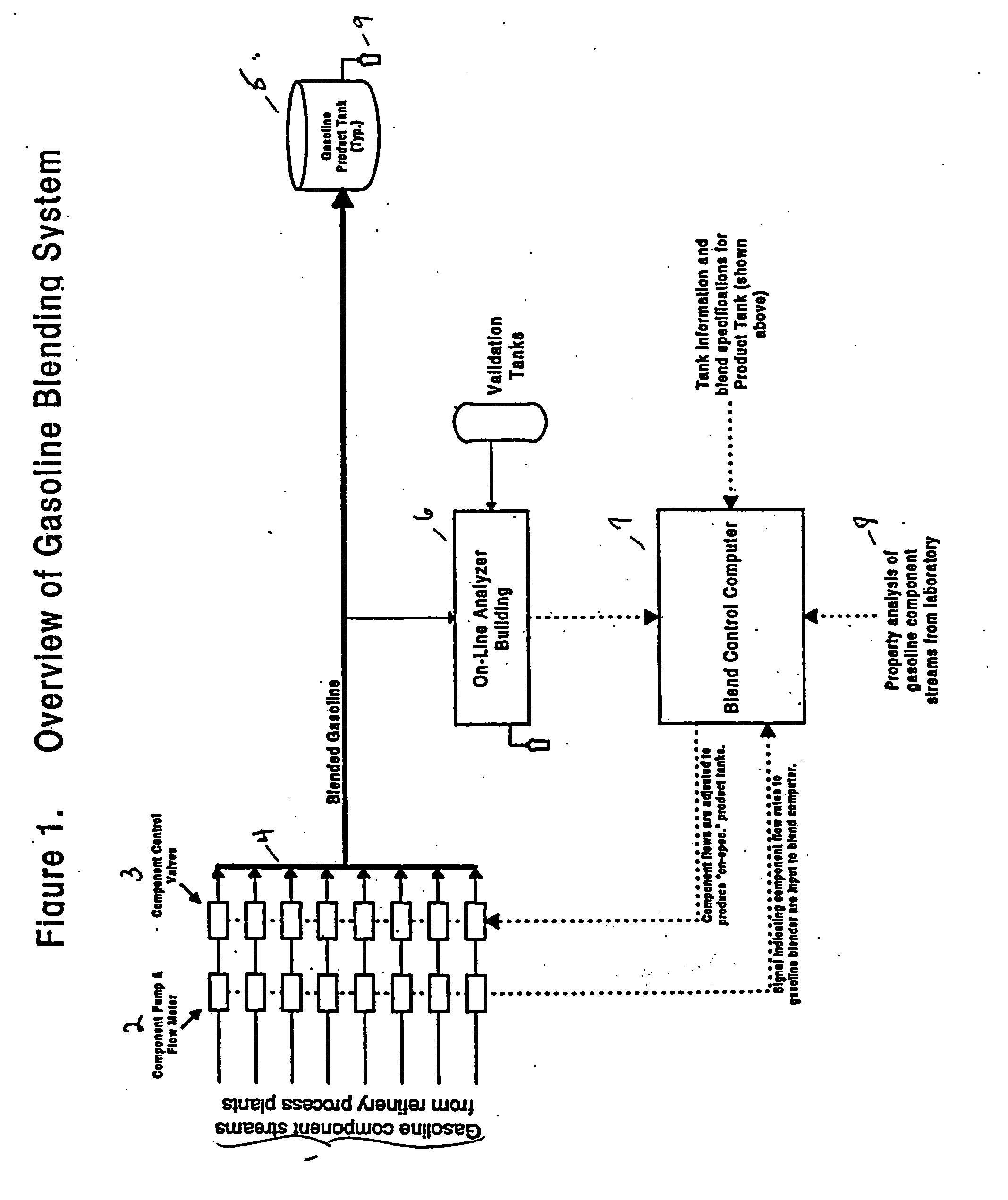

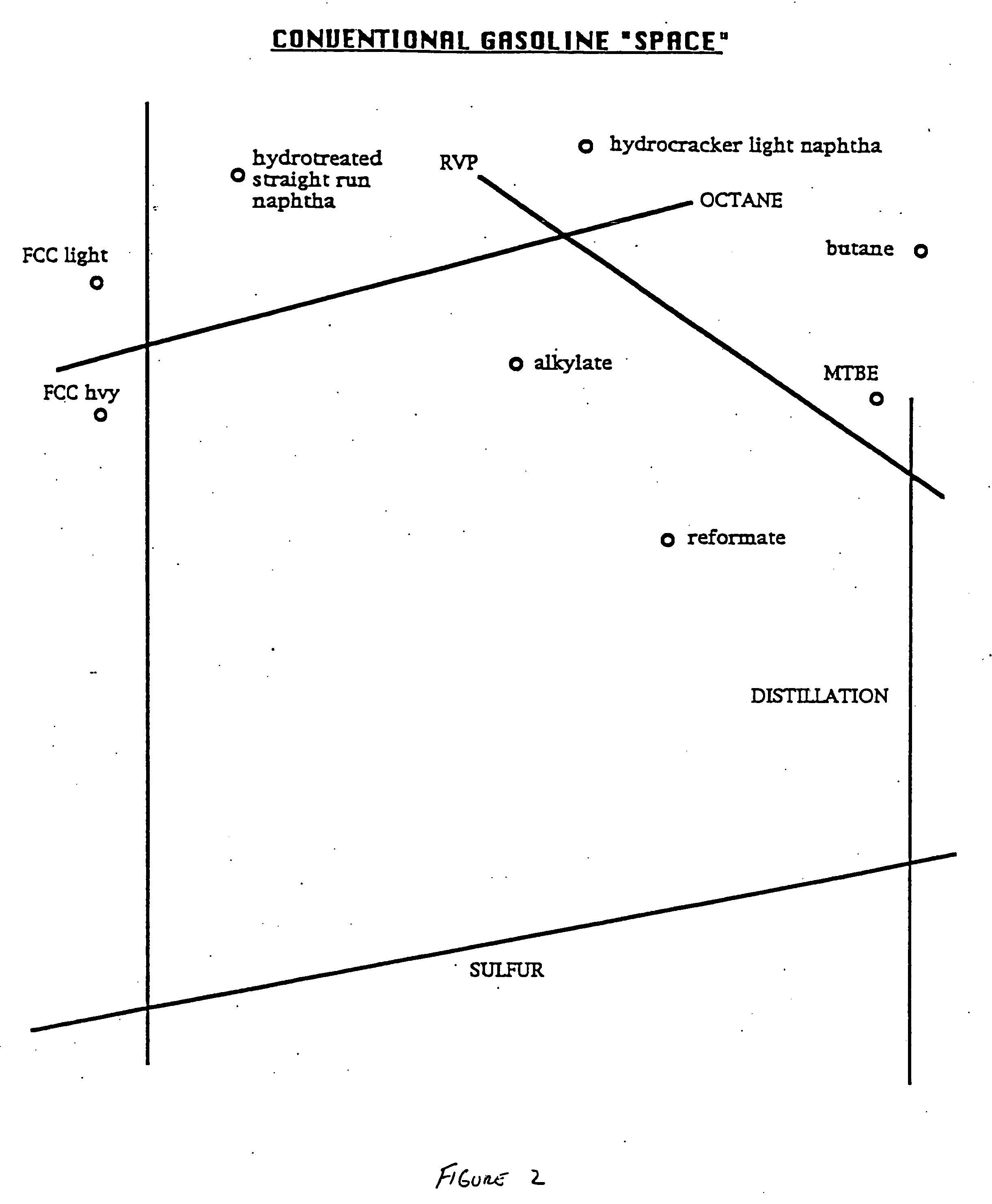

Provided is a novel gasoline composition which is substantially free of ether compounds and is in compliance with a California Predictive Model. The gasoline composition is suitable for use in the winter months, i.e., having a Reid vapor pressure in the range of greater than 7.0 to about 15.0 psi. The method for blending the gasoline comprises blending streams from a refinery in a controlled manner to maintain compliance with the California Predictive Model.

Owner:CHEVROU USA INC

Mixed alcohol fuels for internal combustion engines, furnaces, boilers, kilns and gasifiers

Mixed alcohol formulas can be used as a fuel additive in gasoline, diesel, jet fuel, aviation gasoline, heating oil, bunker oil, coal, petroleum coke or as a neat fuel in and of itself. The mixed alcohols formulations can contain C1-C5 alcohols, or in the alternative, C1-C8 alcohols or higher C1-C10 alcohols in order to boost energy content. The C1-C5 mixed alcohols contain more ethanol than methanol with declining amounts of propanol, butanol and pentanol. C1-C8 mixed alcohols contain the same, with declining amounts of hexanol, heptanol and octanol. C1-C10 mixed alcohols contain the same, with declining amounts of nananol and decanol. Synthetically produced mixed alcohol formulas feature higher octane and energy densities than either MTBE or fermented grain ethanol; more stable Reid Vapor Pressure blending characteristics; and increased soluablizing effects on condensate water. The primary benefits of mixed alcohols are increased combustion efficiencies, reduced emissions profiles and low production costs.

Owner:STANDARD ALCOHOL COMPANY OF AMERICA

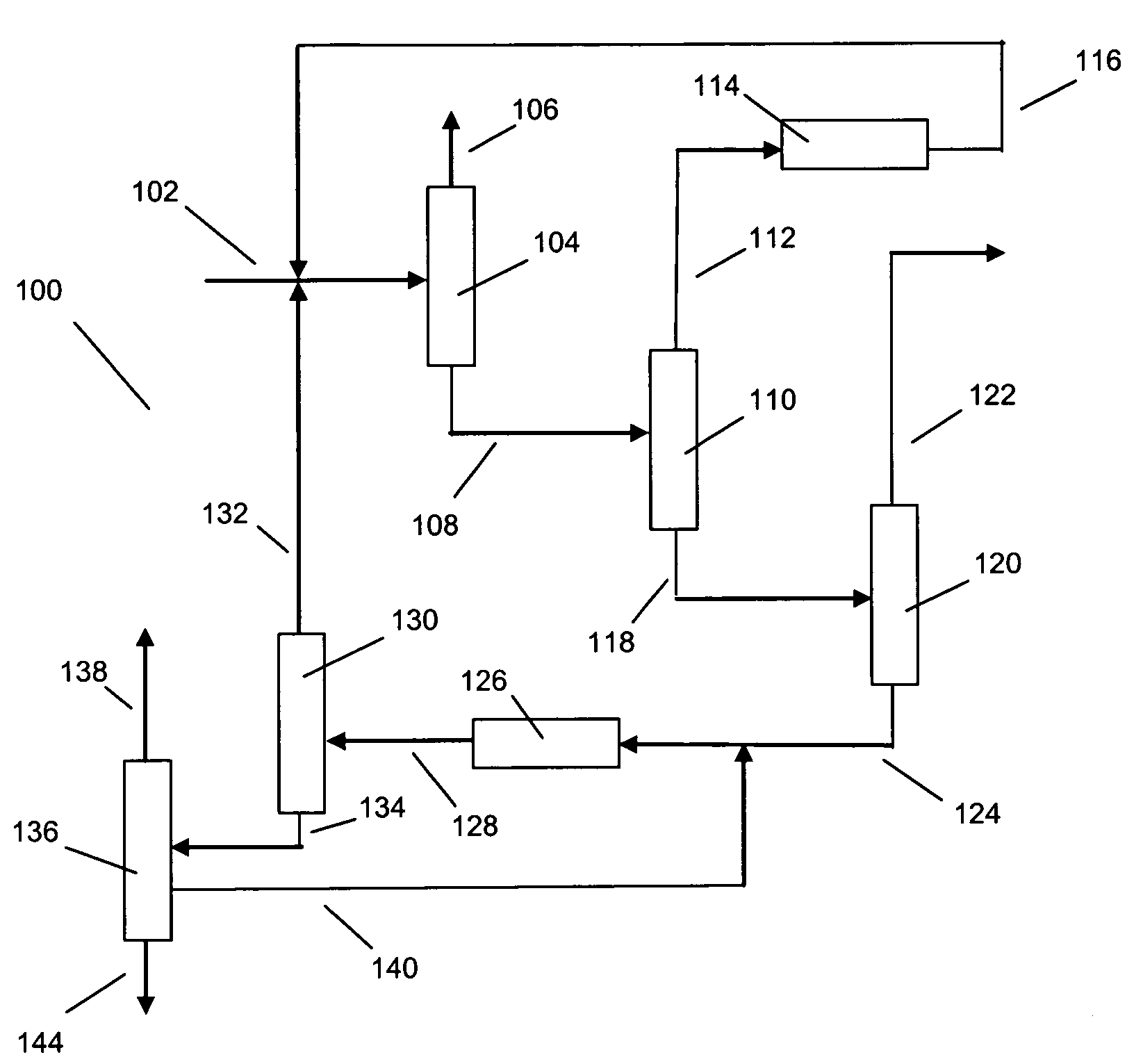

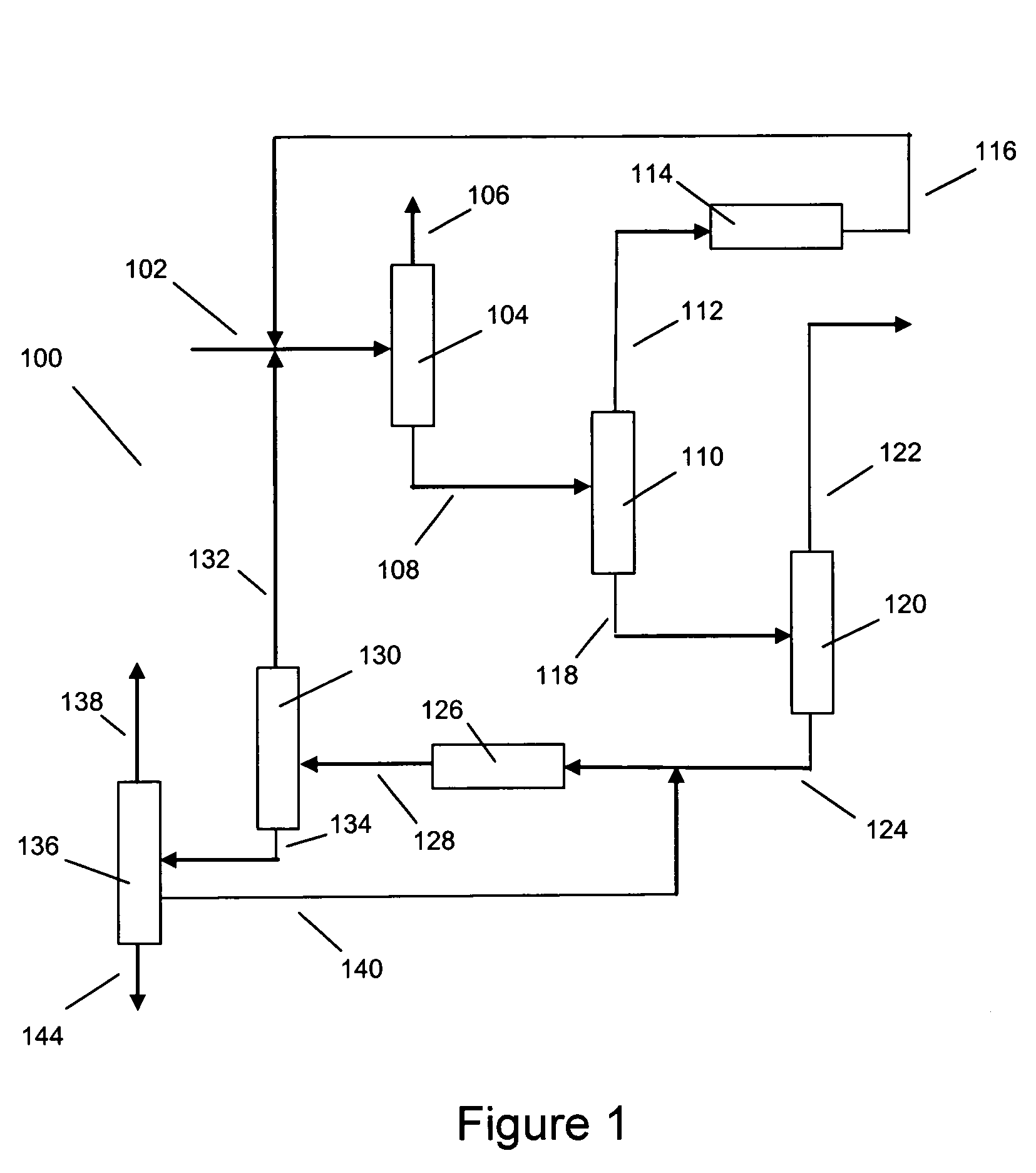

Process For Recovering Hydrocarbons From Crude Carbon Dioxide Fluid

ActiveUS20150184932A1Improved heat integrationReduce heat duty requirementSolidificationLiquefactionWorking fluidAPI gravity

The power required to recover C3+ hydrocarbons from crude carbon dioxide comprising C1+ hydrocarbons and hydrogen sulfide may be reduced by distilling the crude carbon dioxide to produce carbon dioxide-enriched overhead vapor and C3+ hydrocarbon-enriched bottoms liquid such that the hydrogen sulfide is rejected with the overhead vapor. Power consumption reductions may be achieved by incorporating a heat pump cycle using carbon dioxide vapor as working fluid to provide at least a part of the refrigeration duty and using a side reboiler to reduce the bottom reboiler duty. Where the bottoms liquid is further processed to produce “lighter” and “heavier” hydrocarbon fractions, the process enables optimization of upgrading crude oil on the basis of API gravity, Reid Vapor pressure and / or viscosity.

Owner:AIR PROD & CHEM INC

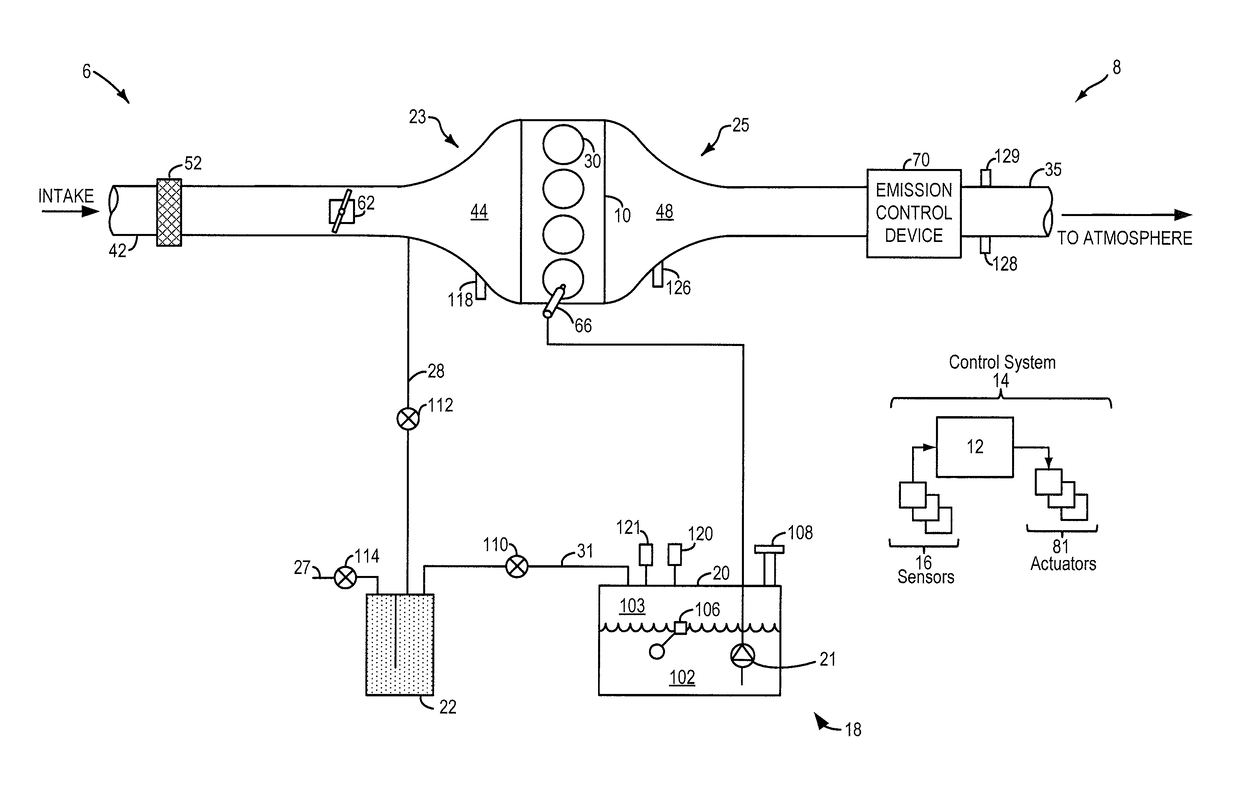

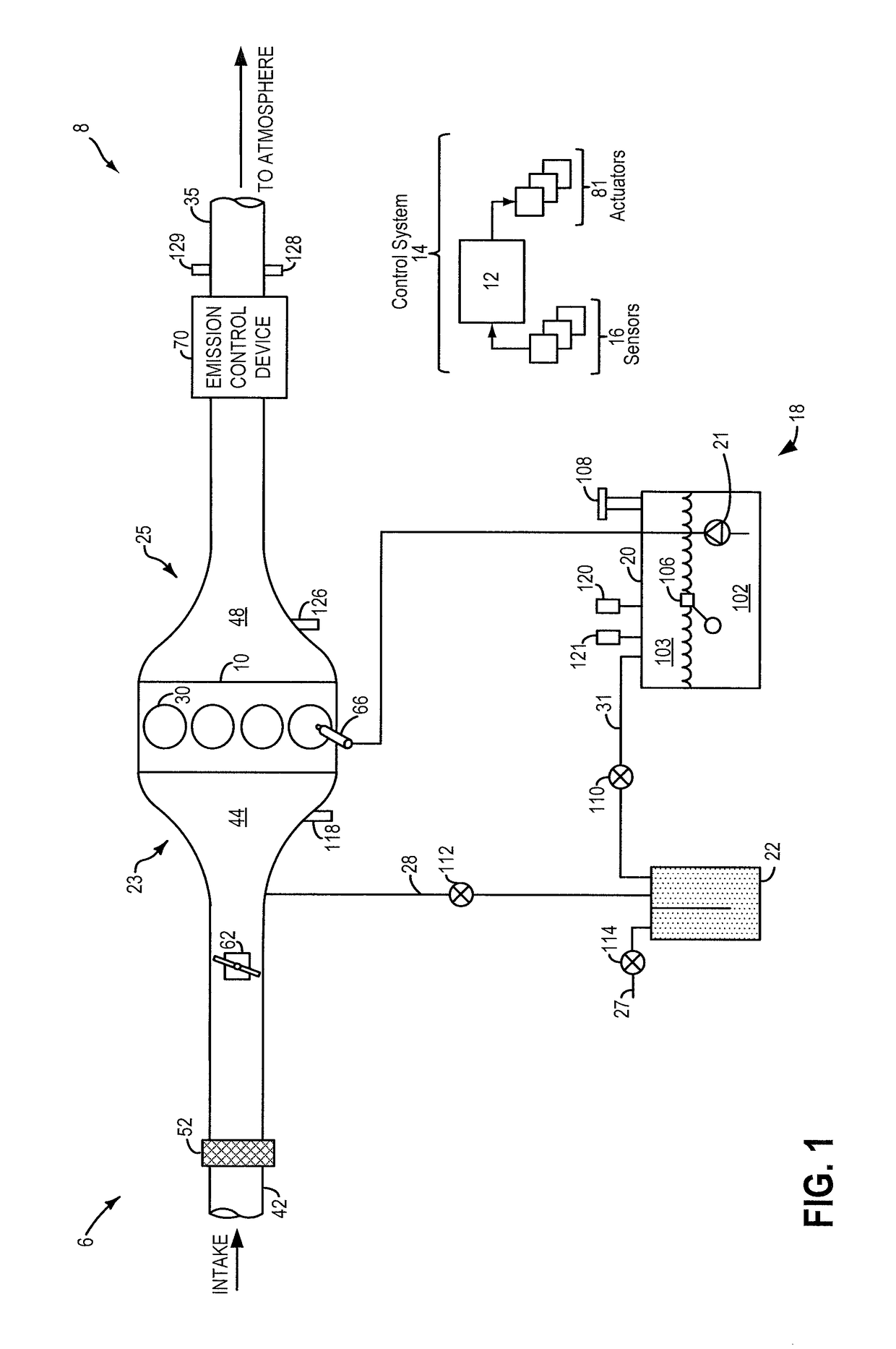

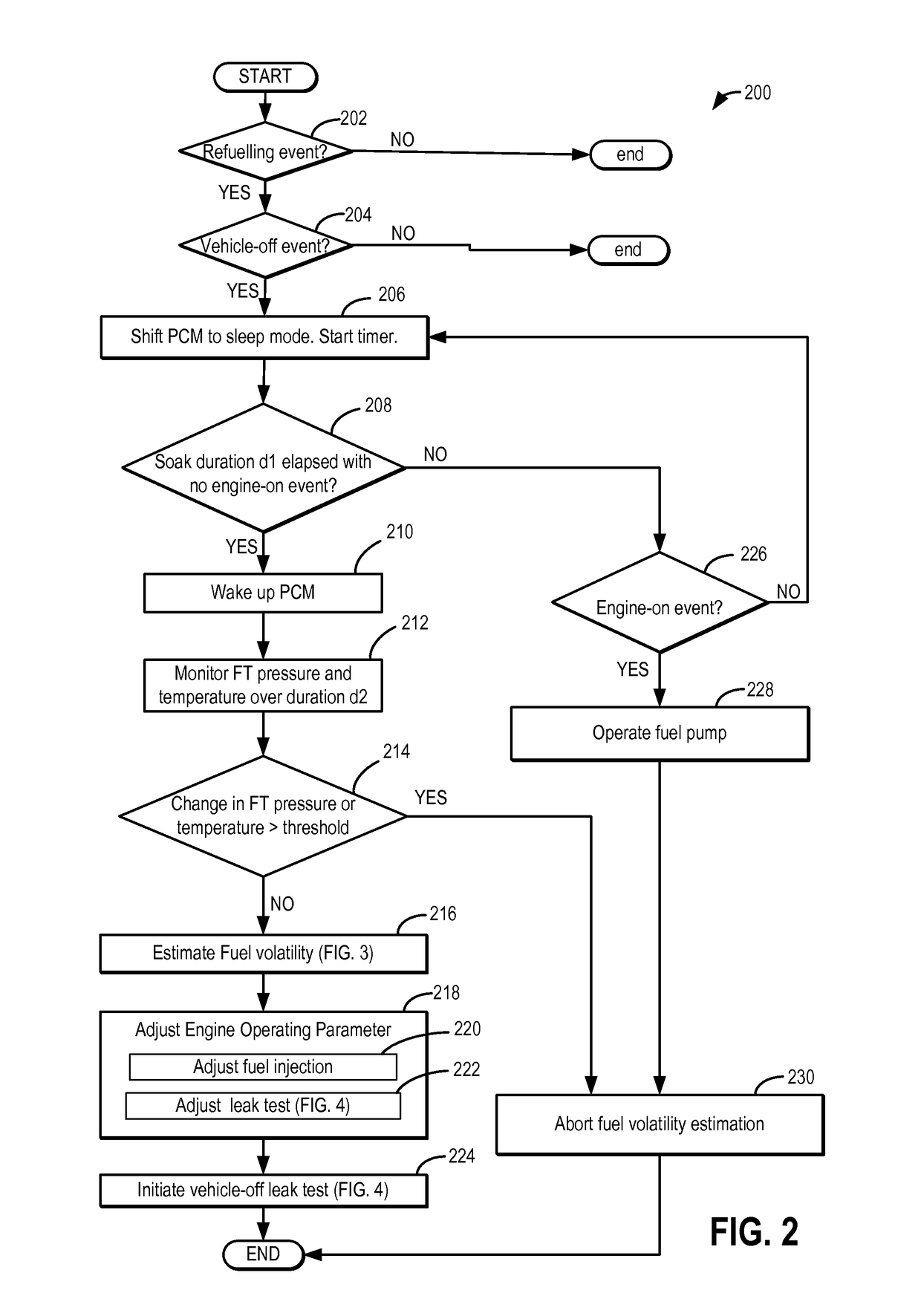

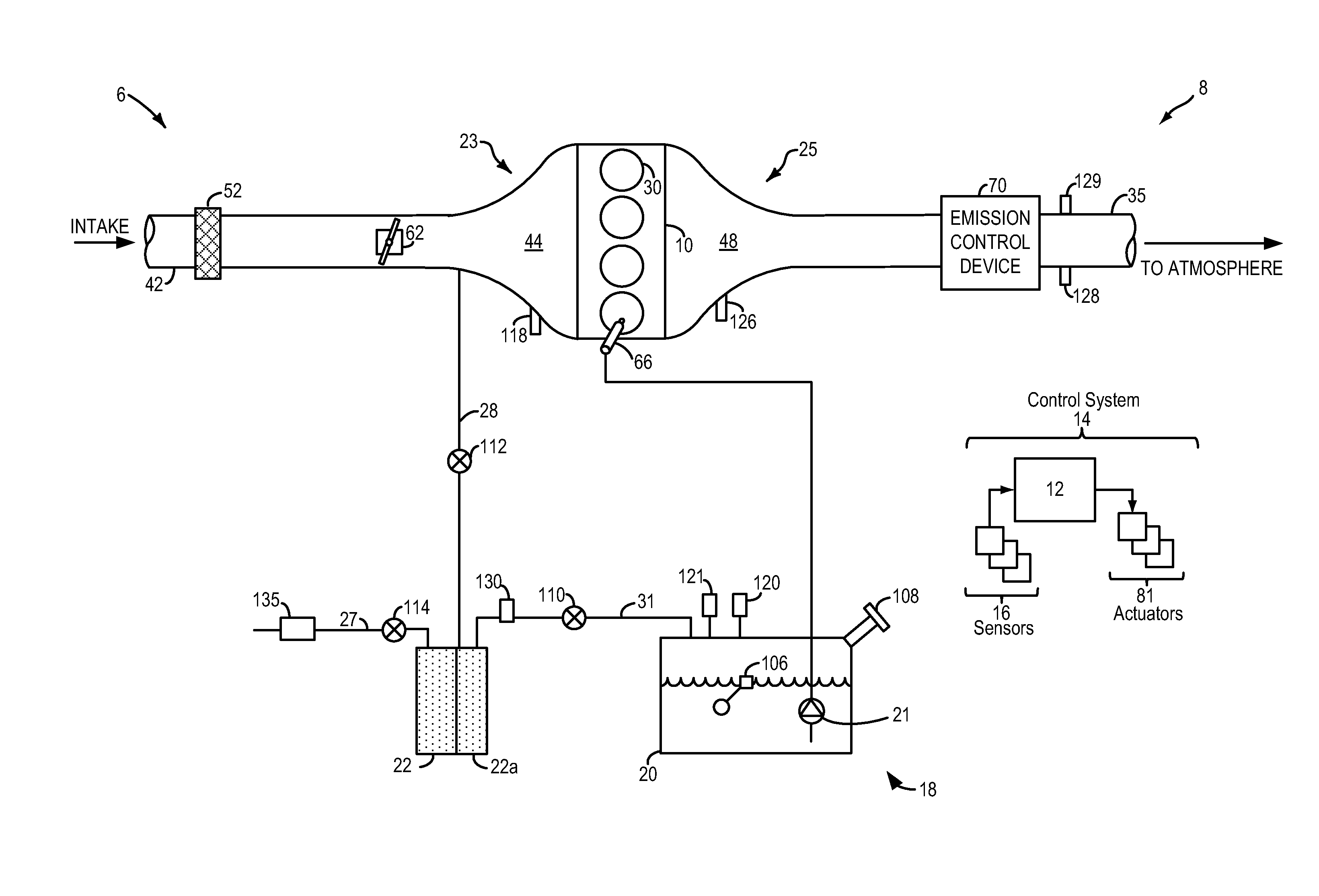

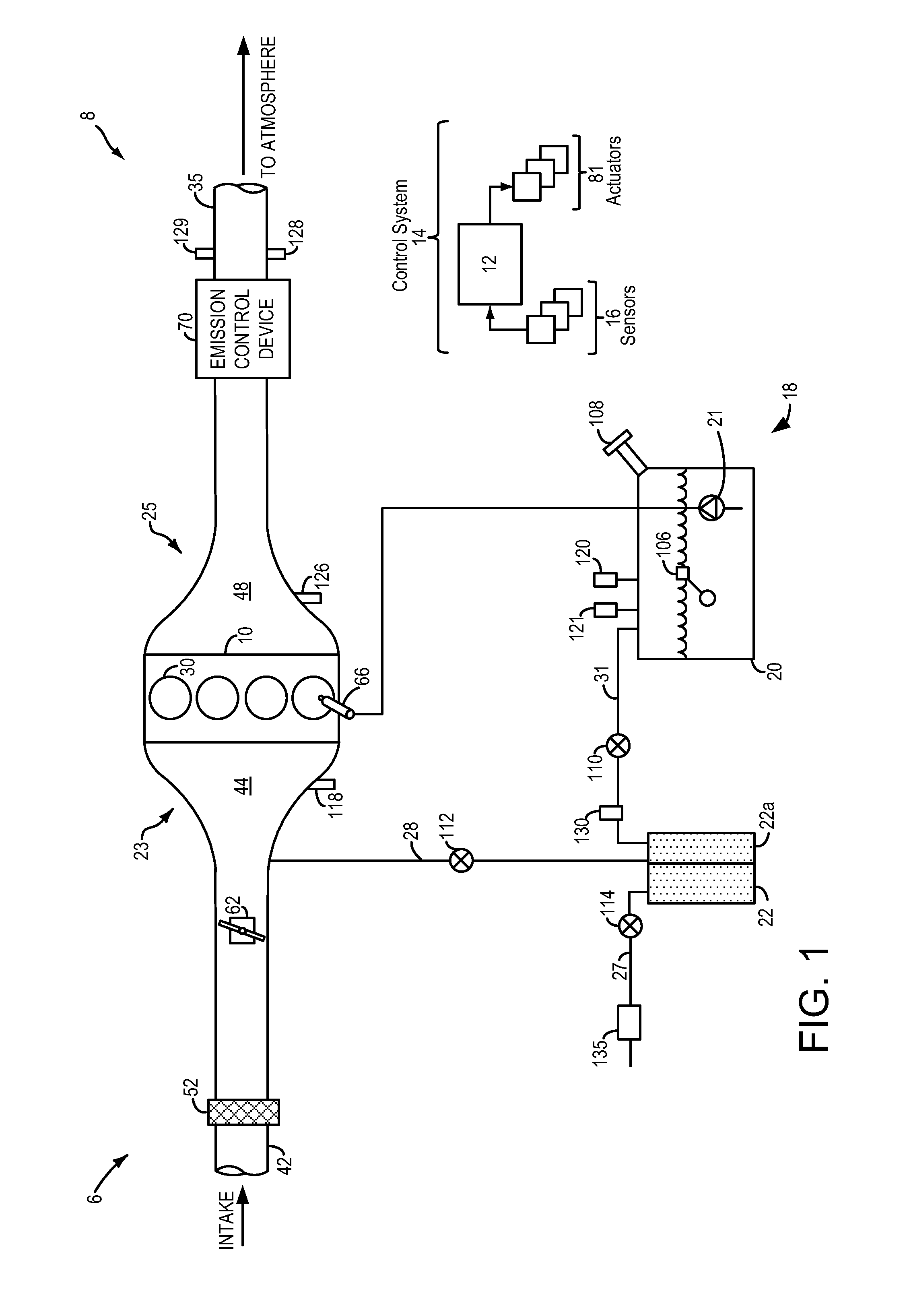

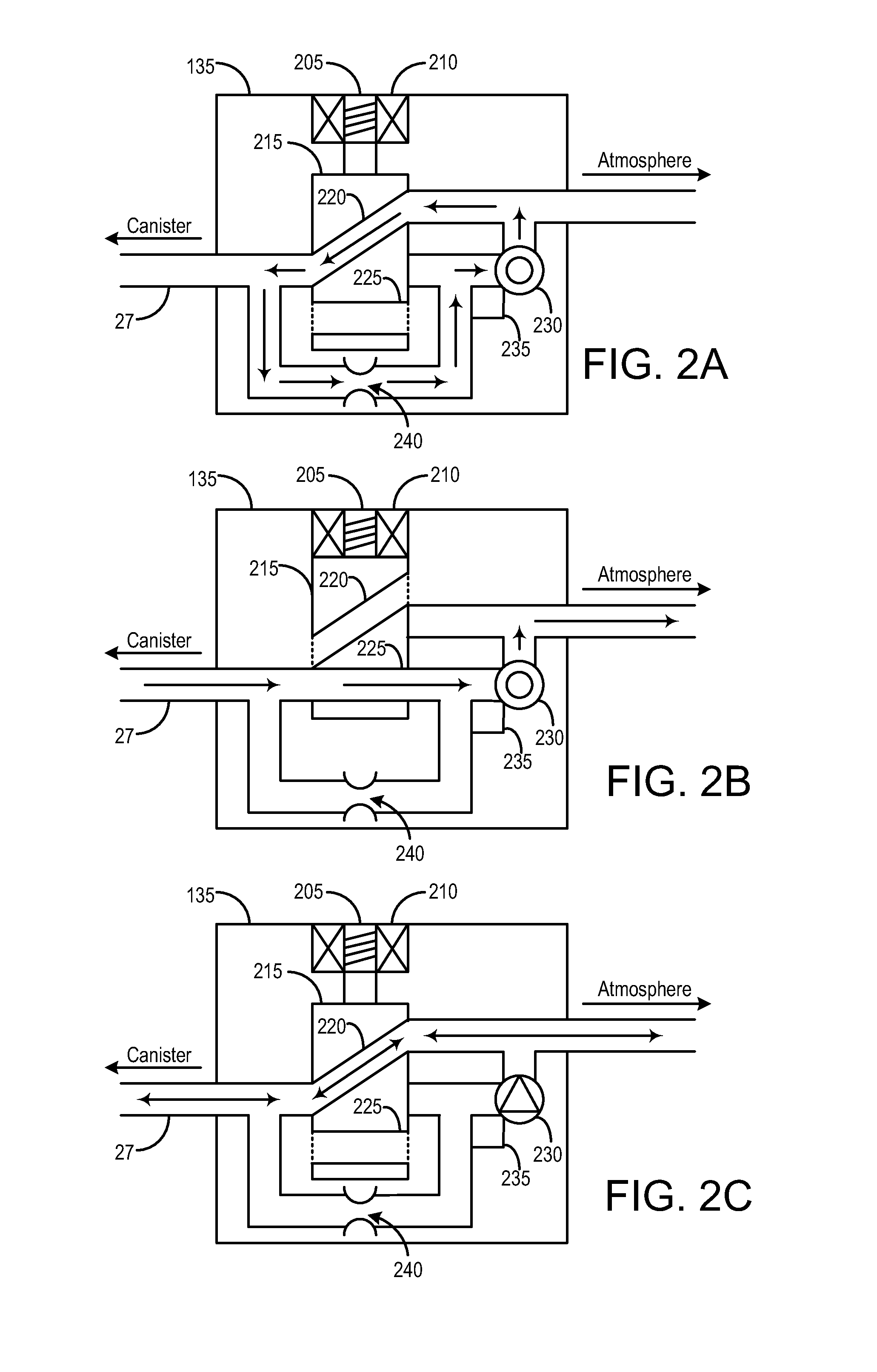

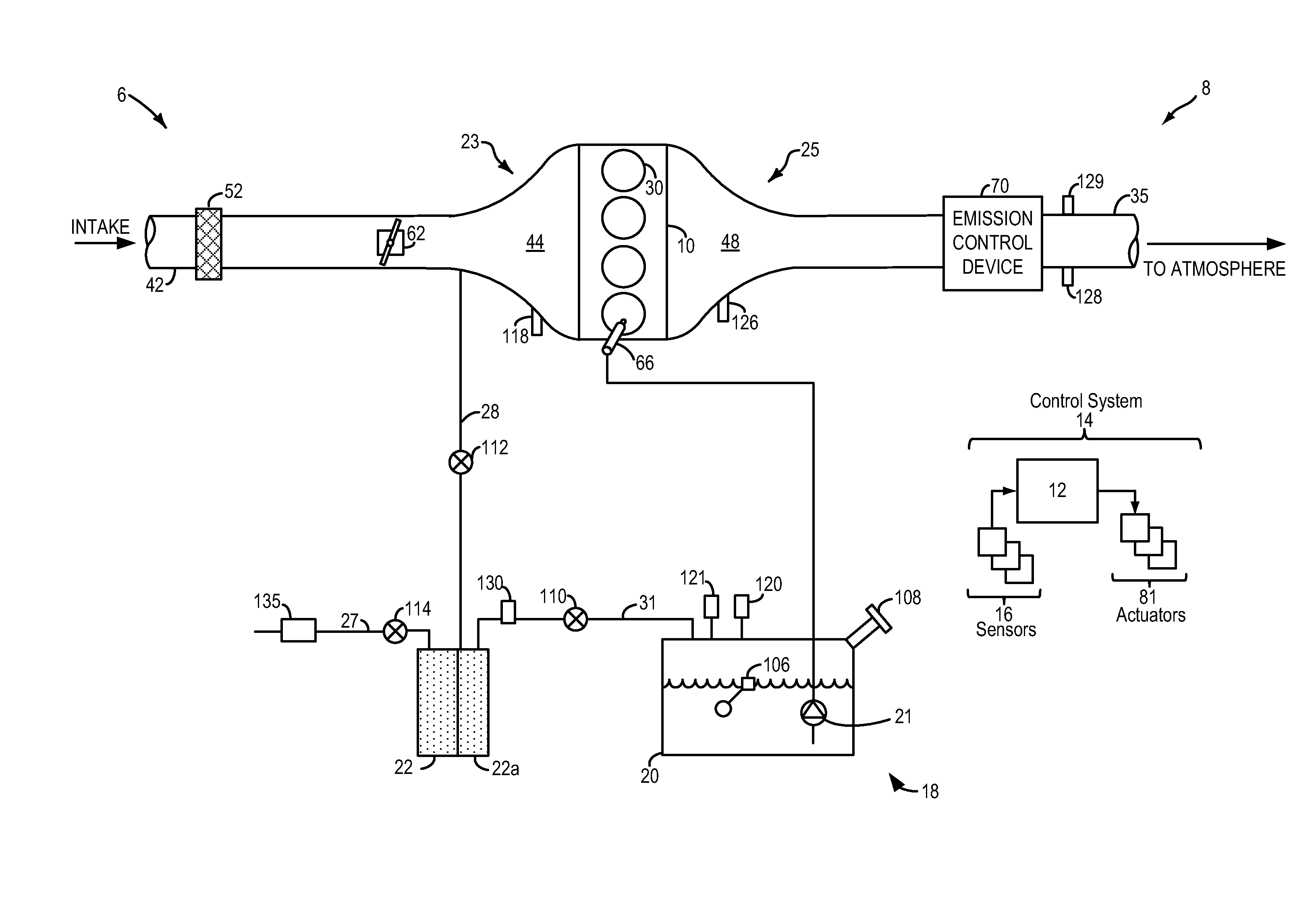

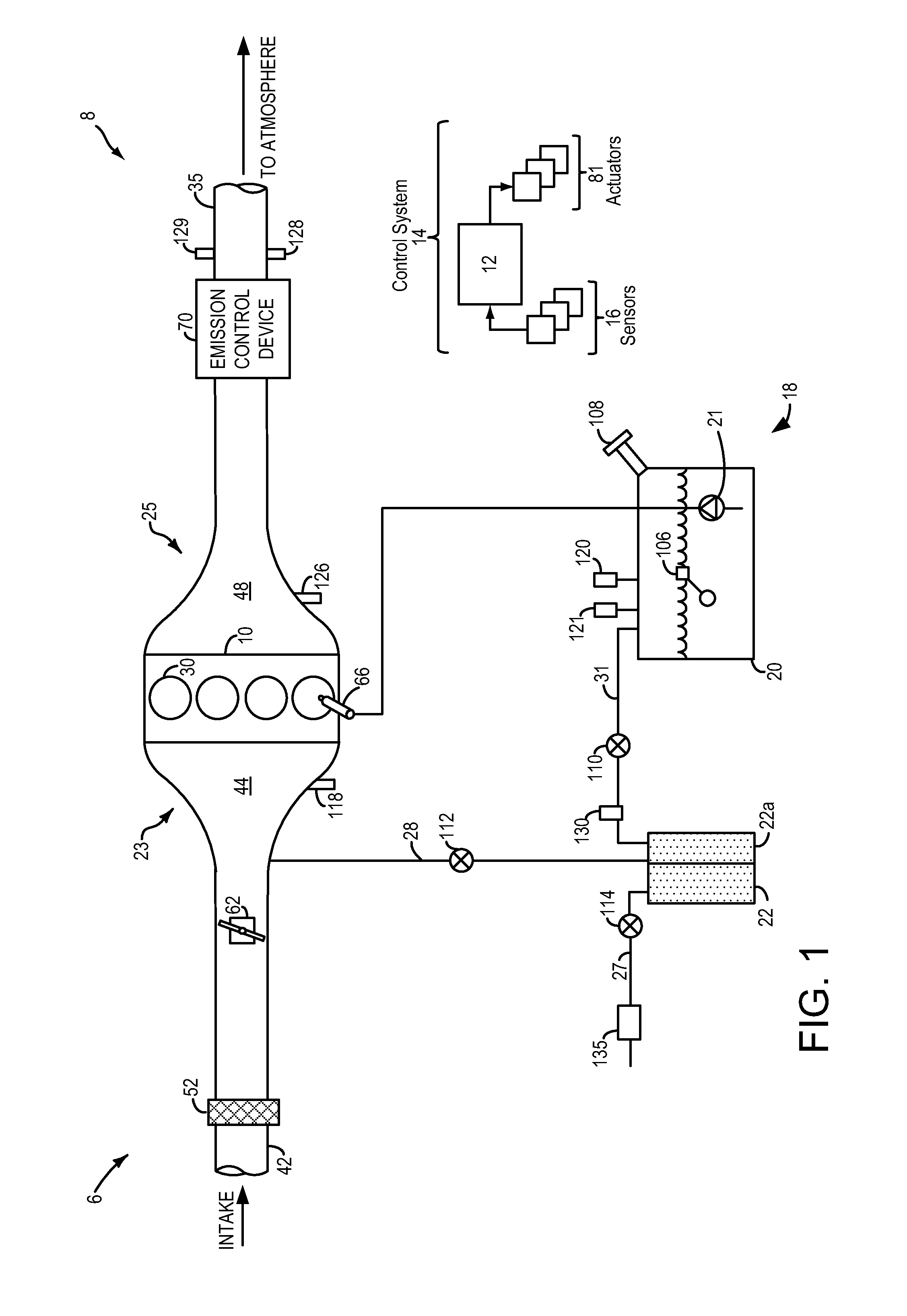

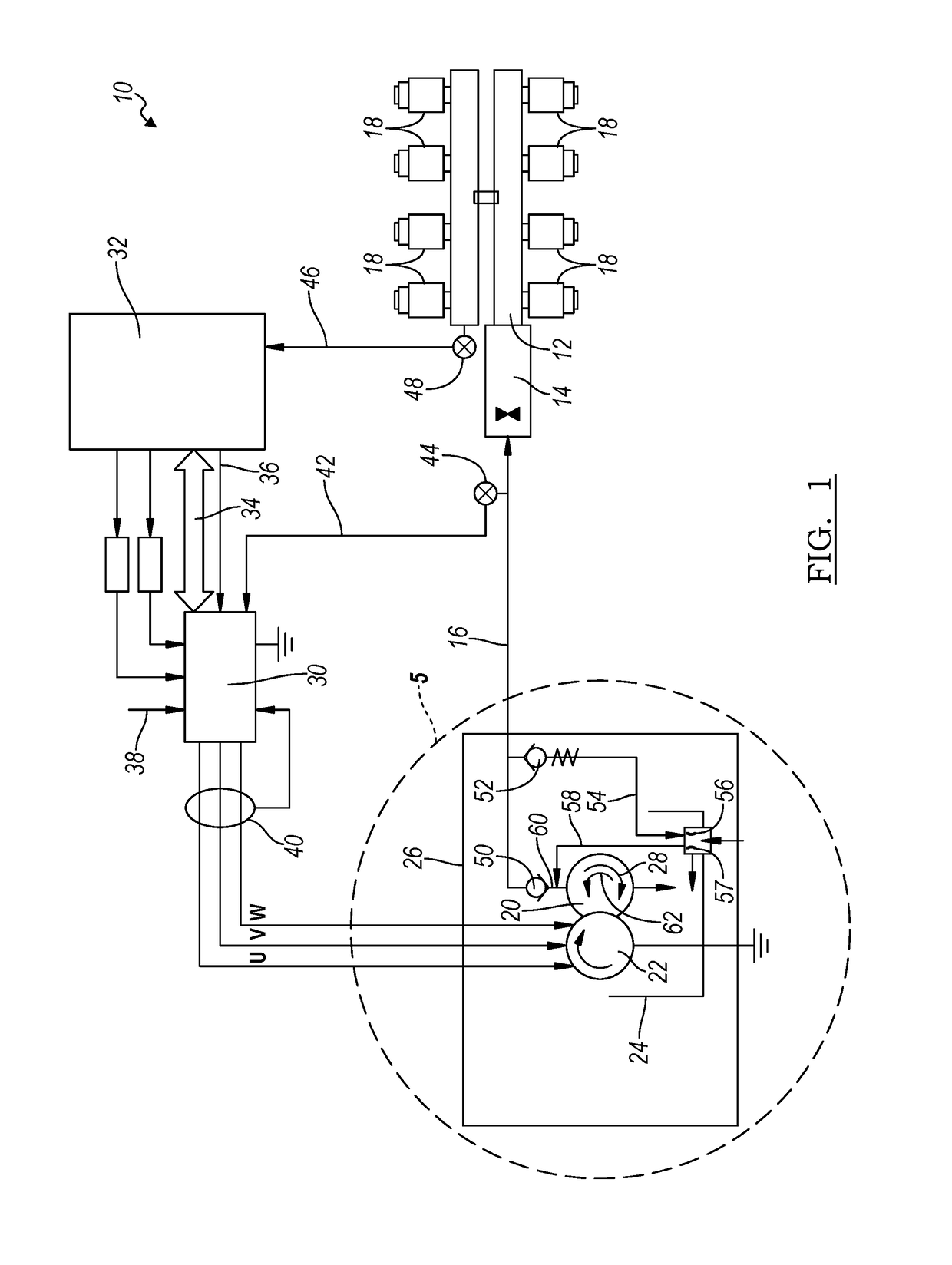

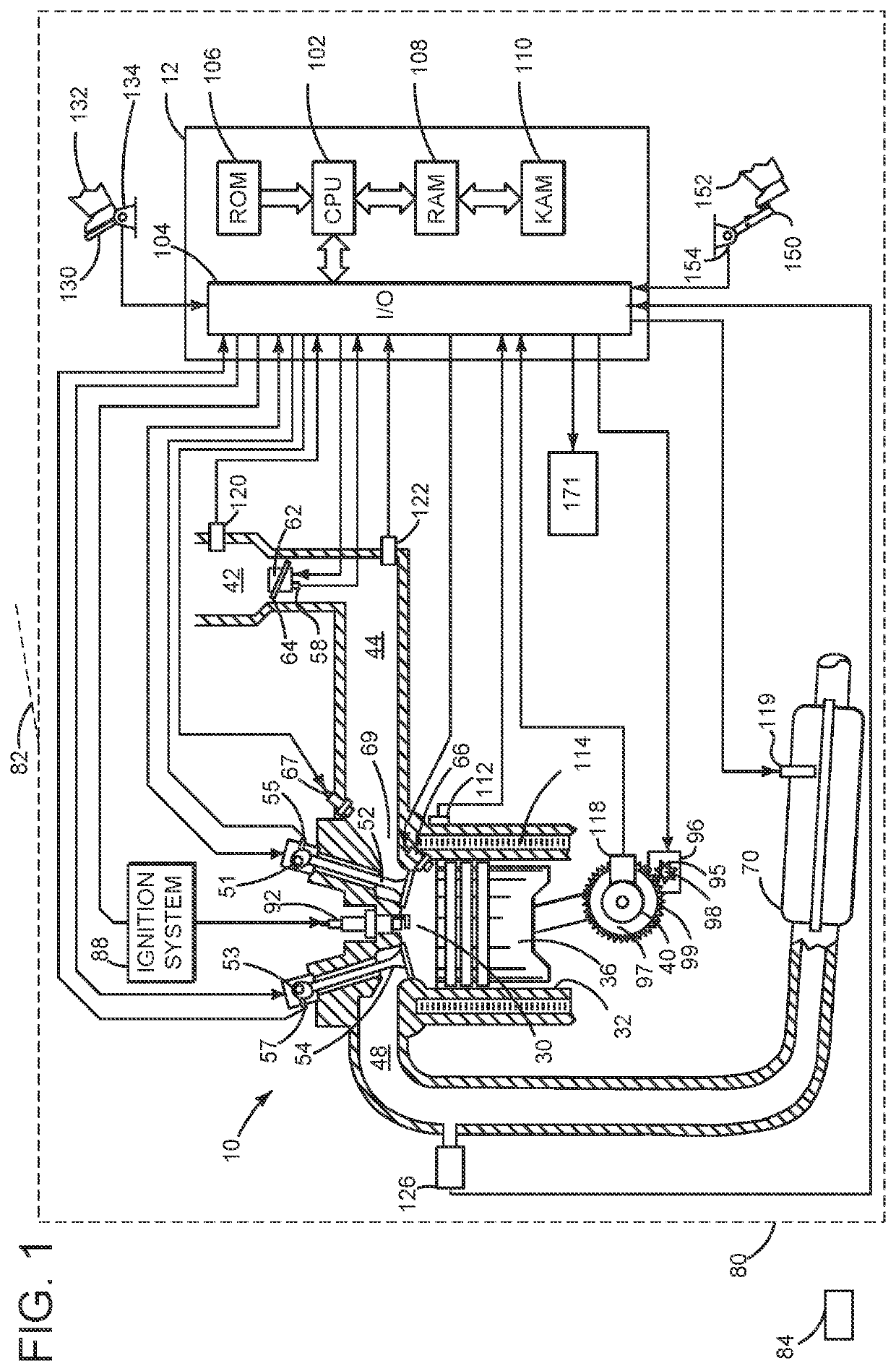

Estimating vehicle fuel Reid vapor pressure

InactiveUS9850853B2Accurately estimating fuel volatilityMore robust and accurate leak diagnostic resultsHybrid vehiclesElectrical controlFuel tankReid vapor pressure

Methods and systems are provided for estimating fuel volatility. During a vehicle-off condition following a refueling event, fuel volatility may be estimated by operating a fuel pump of a fuel system immediately after the refueling event while a fuel tank temperature is stable. Based on estimated fuel volatility, fuel injection amount and leak test thresholds may be adjusted.

Owner:FORD GLOBAL TECH LLC

Mixed alcohol fuels for internal combustion engines, furnaces, boilers, kilns and gasifiers

Mixed alcohol formulas can be used as a fuel additive in gasoline, diesel, jet fuel, aviation gasoline, heating oil, bunker oil, coal, petroleum coke or as a neat fuel in and of itself. The mixed alcohols formulations can contain C1-C5 alcohols, or in the alternative, C1-C8 alcohols or higher C1-C10 alcohols in order to boost energy content. The C1-C5 mixed alcohols contain more ethanol than methanol with declining amounts of propanol, butanol and pentanol. C1-C8 mixed alcohols contain the same, with declining amounts of hexanol, heptanol and octanol. C1-C10 mixed alcohols contain the same, with declining amounts of nananol and decanol. Synthetically produced mixed alcohol formulas feature higher octane and energy densities than either MTBE or fermented grain ethanol; more stable Reid Vapor Pressure blending characteristics; and increased soluablizing effects on condensate water. The primary benefits of mixed alcohols are increased combustion efficiencies, reduced emissions profiles and low production costs.

Owner:STANDARD ALCOHOL COMPANY OF AMERICA

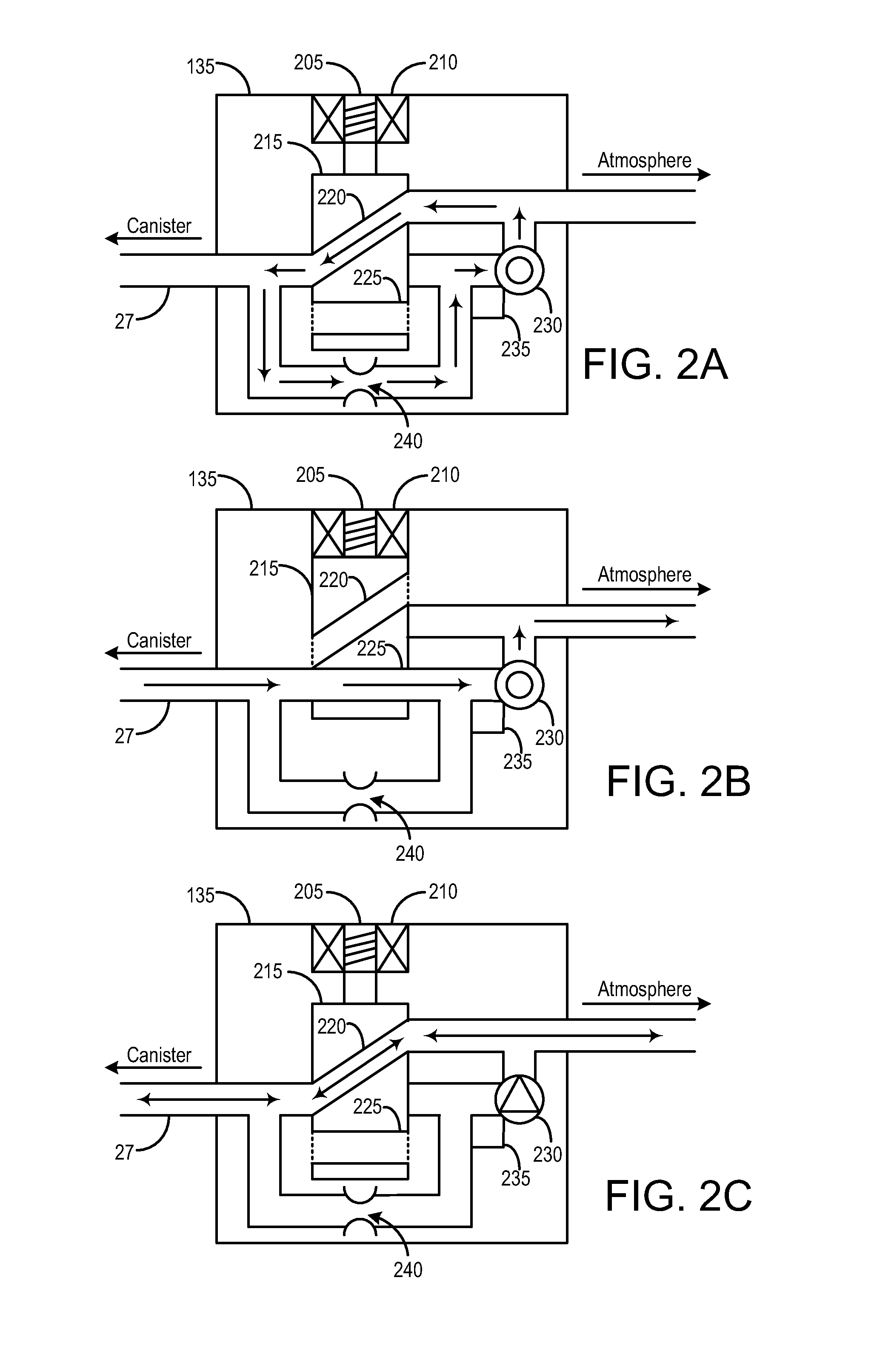

Fuel system leak check based on fuel reid vapor pressure

ActiveUS20150114089A1Detection of fluid at leakage pointMeasurement of fluid loss/gain rateSteam pressureFuel tank

A method for an evaporative emissions leak test, comprising: adjusting a pressure threshold based on a fuel volatility of a fuel contained in a fuel tank; and performing the evaporative emissions leak test based on the adjusted pressure threshold. By determining fuel volatility and adjusting a pressure threshold based on the fuel volatility, a more robust and accurate evaporative emissions leak test may be employed without adding additional components to a fuel system.

Owner:FORD GLOBAL TECH LLC

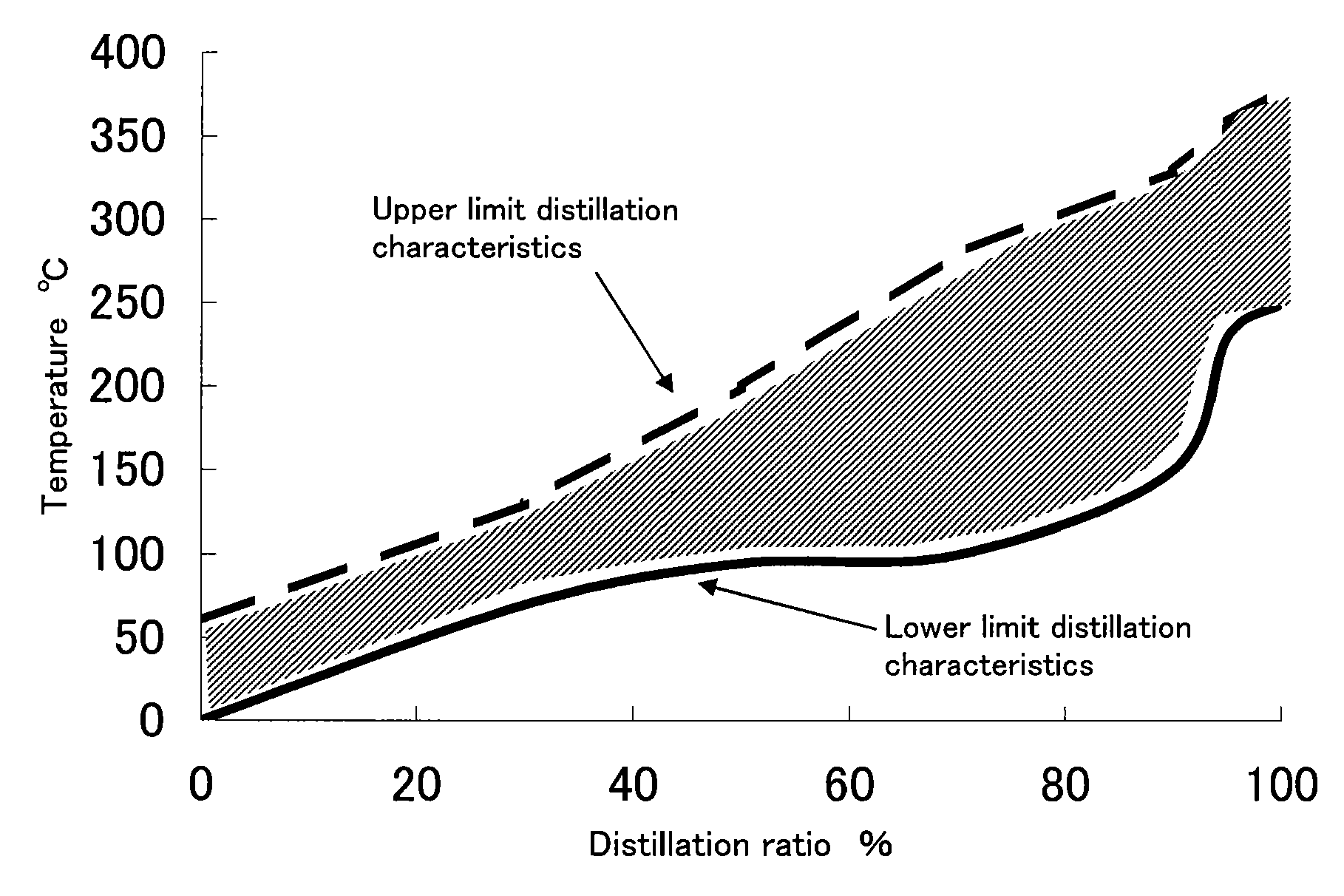

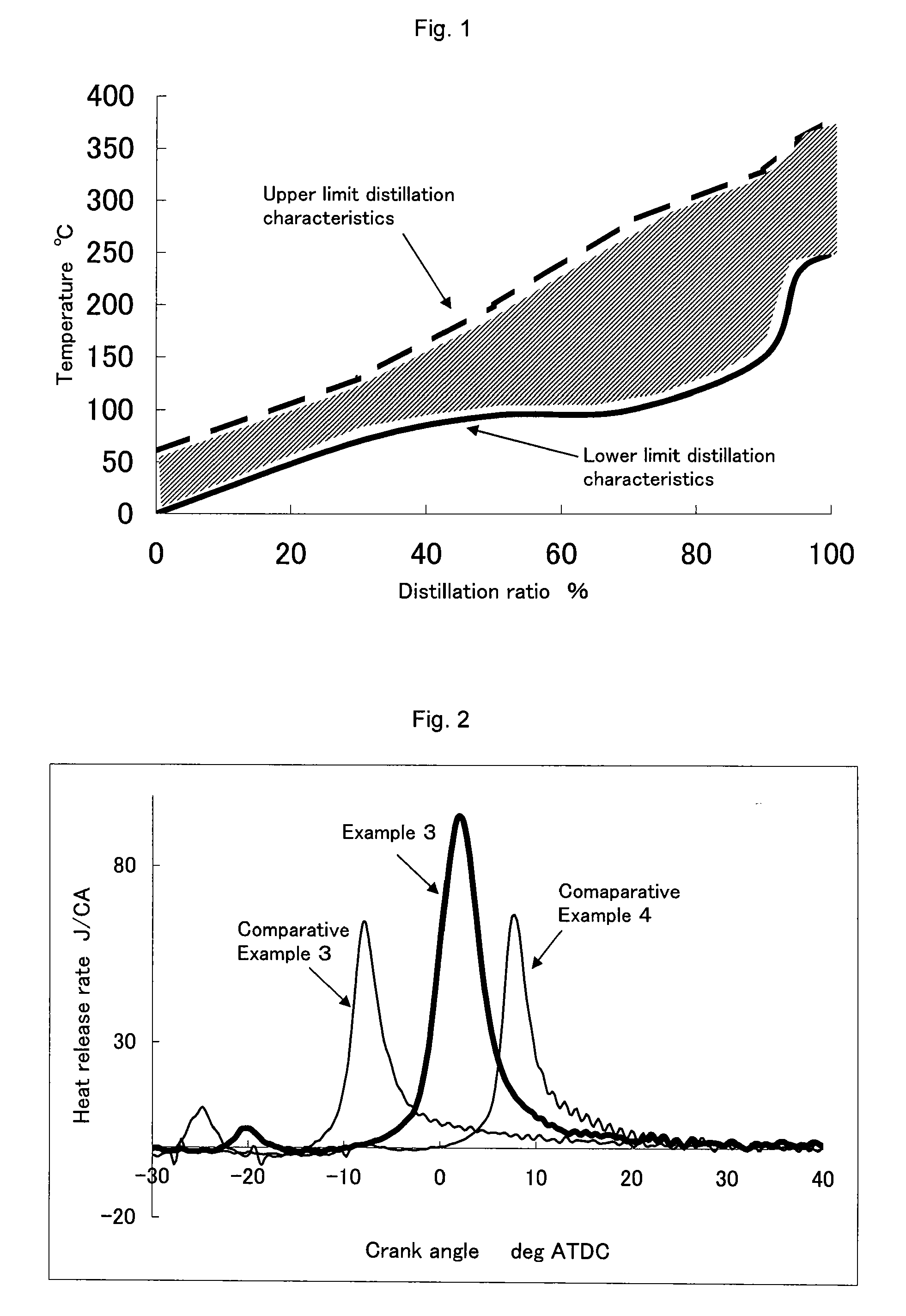

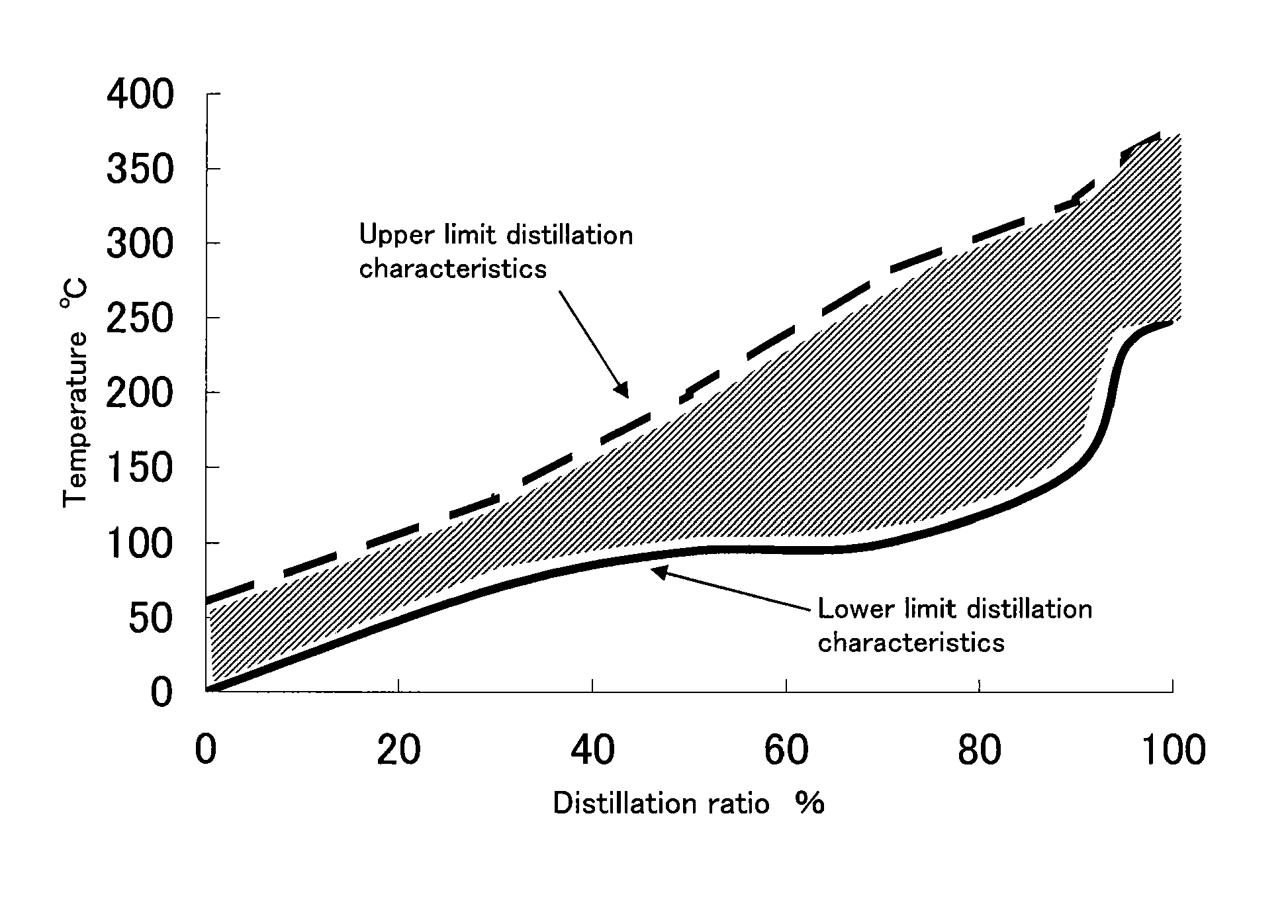

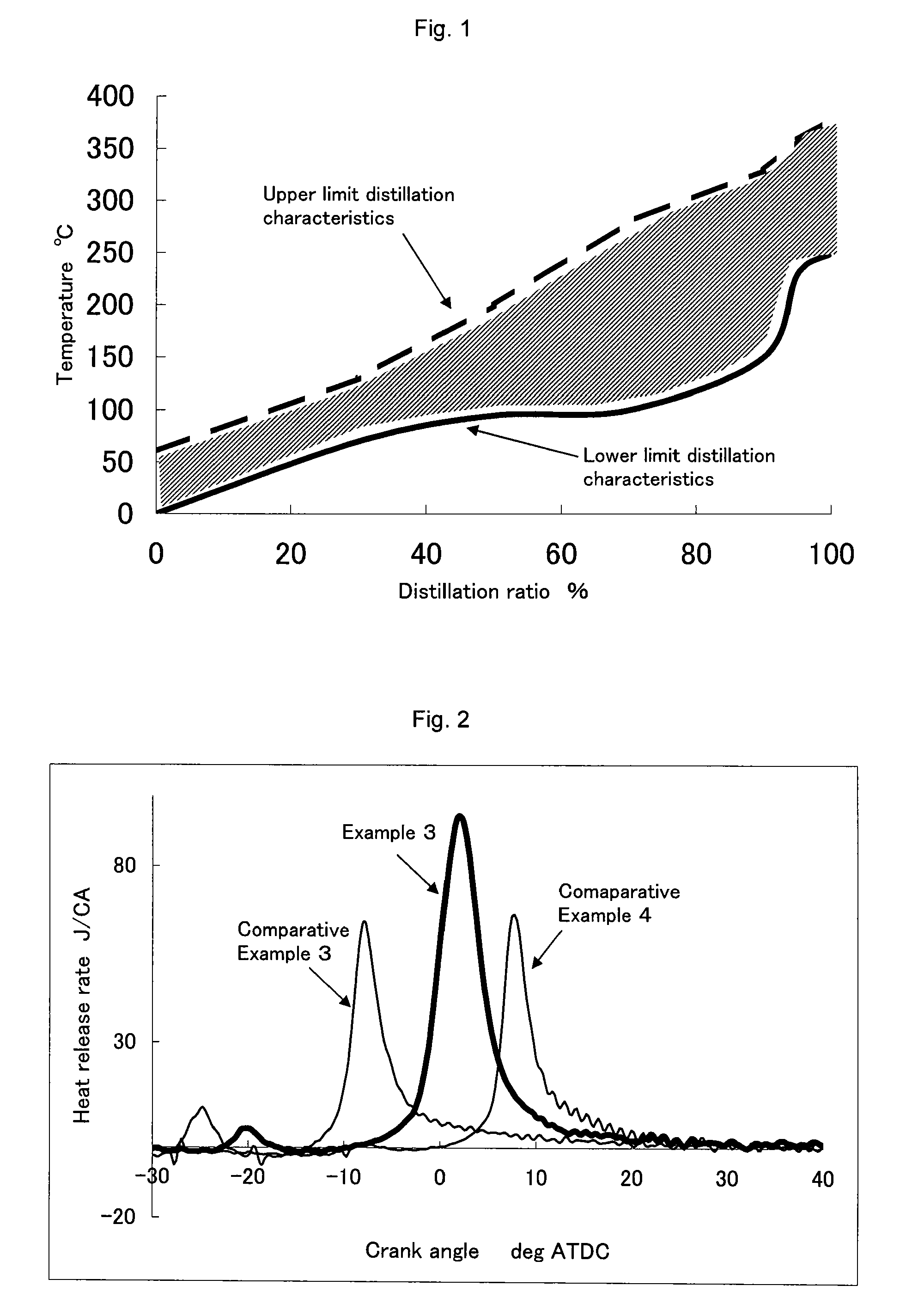

Fuel for homogeneous charge compression ignition engine

ActiveUS20090229175A1Stable HCCI combustionIncrease productionSolid fuelsLiquid carbonaceous fuelsHomogeneous charge compression ignitionBoiling point

The present invention provides a fuel for homogeneous charge compression ignition engines, which can achieve a stable homogeneous charge compression ignition at a higher output. The fuel satisfies the following requirements (1), (2), (3), and (4):(1) distillation characteristics:initial boiling point (IBP): 0° C. or higher and 60° C. or lower;30 volume percent distillation temperature (T30): 70° C. or higher and 130° C. or lower;50 volume percent distillation temperature (T50): 95° C. or higher and 200° C. or lower;70 volume percent distillation temperature (T70): 100° C. or higher and 280° C. or lower;90 volume percent distillation temperature (T90): 150° C. or higher and 330° C. or lower;95 volume percent distillation temperature (T95): 230° C. or higher and 360° C. or lower; andend point (EP): 250° C. or higher and 380° C. or lower;(2) research octane number: 62 or greater and 85 or less(3) density at 15° C.: 0.700 g / cm3 or higher and lower than 0.800 g / cm3; and(4) Reid vapor pressure at 37.8° C.: 30 kPa or greater and lower than 65 kPa.

Owner:NIPPON OIL CORP

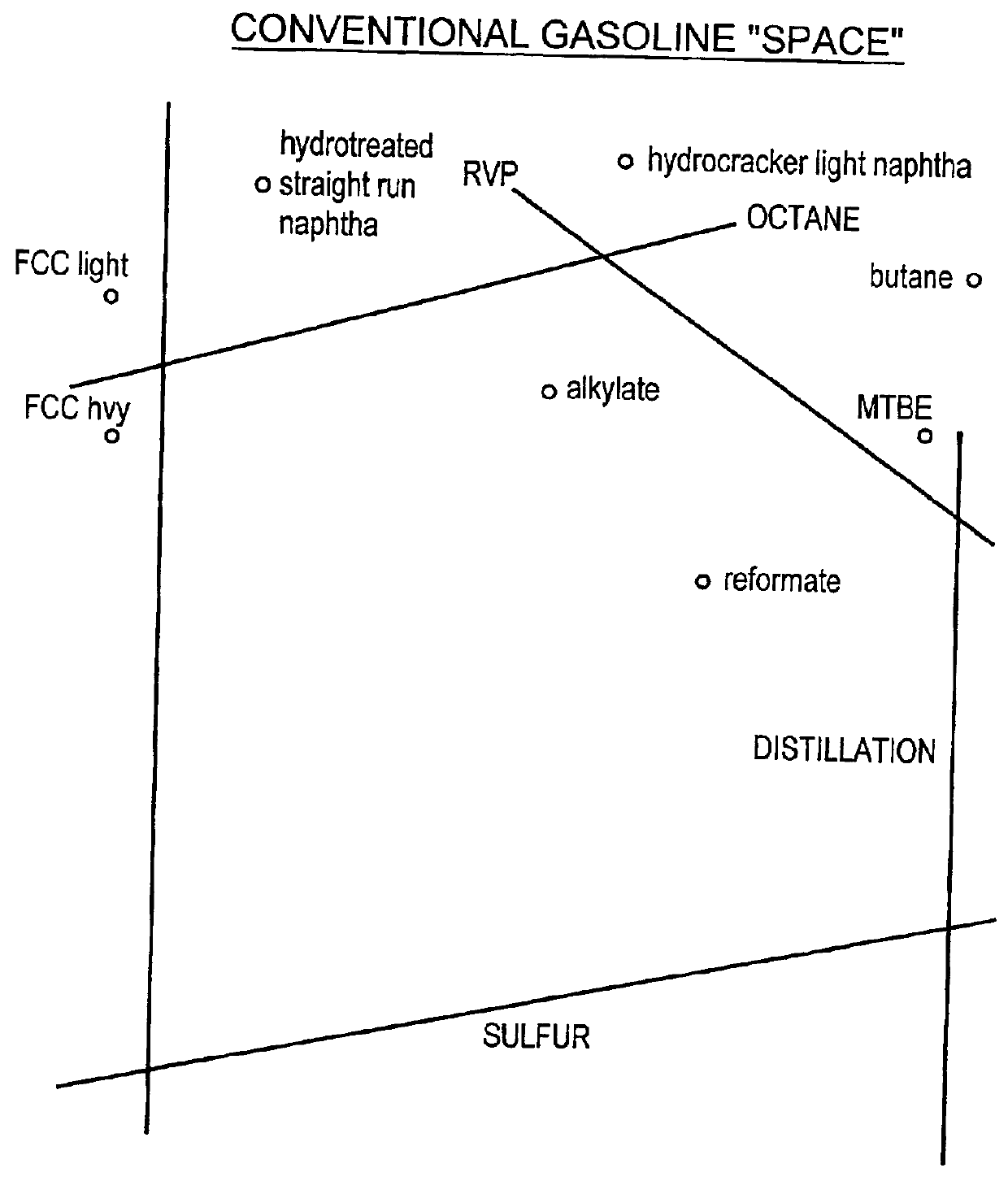

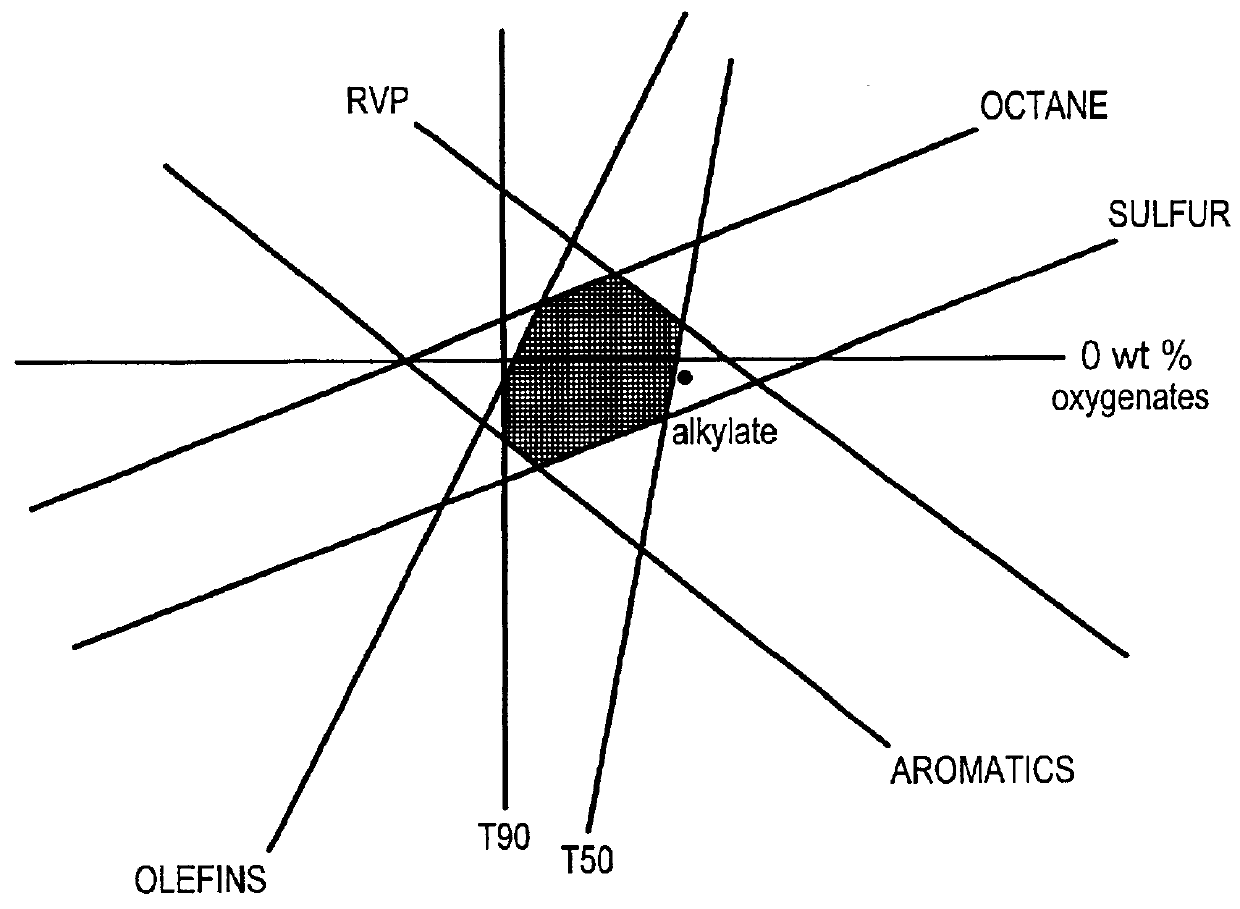

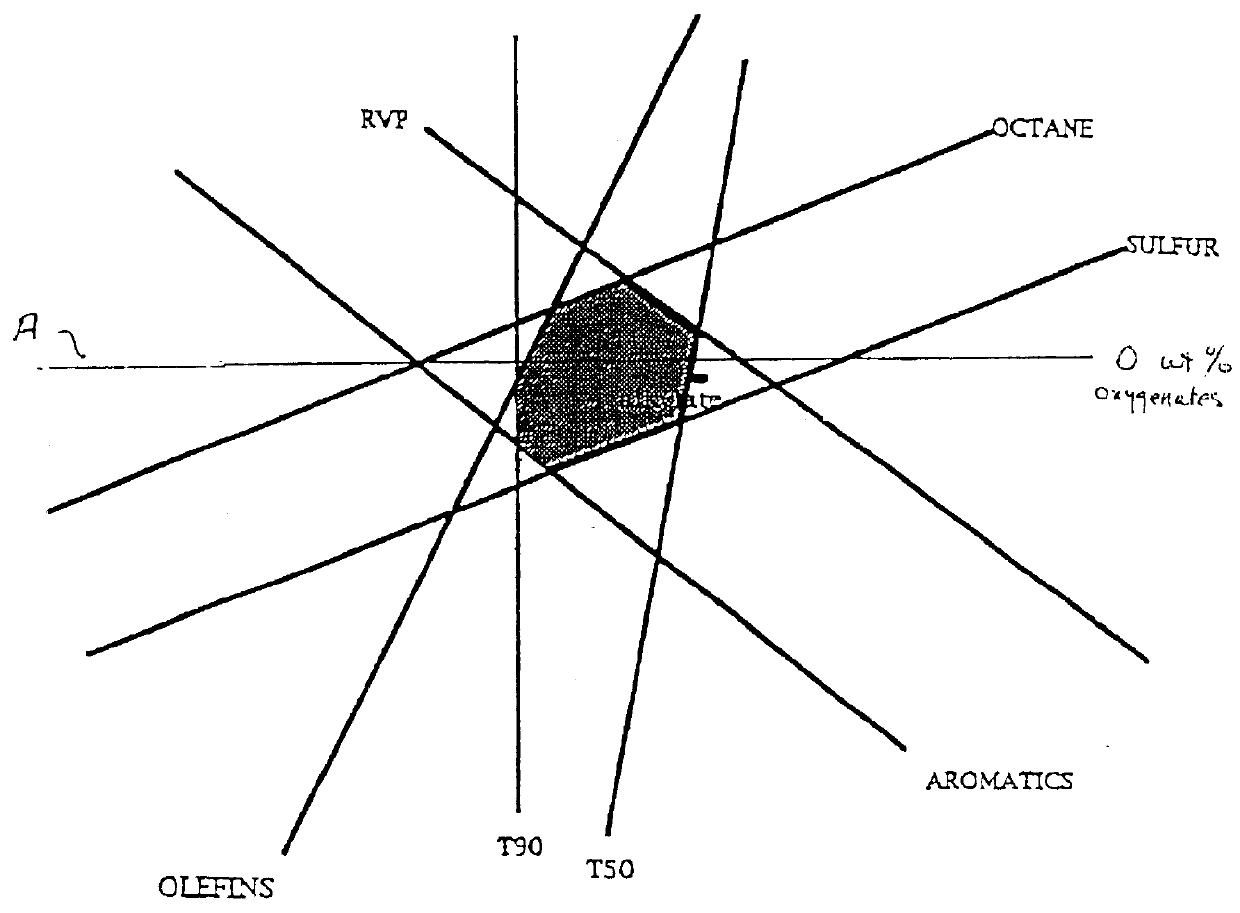

Blending of economic, reduced oxygen, summer gasoline

Provided is a novel high octane summer gasoline composition which is substantially free of oxygenates, and is in compliance with the California Predictive Model. The gasoline composition is suitable for use in the summer, i.e., having a Reid vapor pressure of 7.0 or less. The method for blending the gasoline comprises blending streams from a refinery in a controlled manner to maintain compliance with the California Predictive Model.

Owner:CHEVROU USA INC

Fuel system leak check based on fuel reid vapor pressure

Owner:FORD GLOBAL TECH LLC

Fuel for homogeneous charge compression ignition engine

ActiveUS8038742B2Stable combustionIncrease productionSolid fuelsLiquid carbonaceous fuelsHomogeneous charge compression ignitionBoiling point

The present invention provides a fuel for homogeneous charge compression ignition engines, which can achieve a stable homogeneous charge compression ignition at a higher output. The fuel satisfies the following requirements (1), (2), (3), and (4):(1) certain distillation characteristics between an initial boiling point (IBP): 0° C. or higher and 60° C. or lower; and an end point (EP): 250° C. or higher and 380° C. or lower;(2) research octane number: 62 or greater and 85 or less;(3) density at 15° C.: 0.700 g / cm3 or higher and lower than 0.800 g / cm3; and(4) Reid vapor pressure at 37.8° C.: 30 kPa or greater and lower than 65 kPa.

Owner:NIPPON OIL CORP

High-proportion methanol gasoline for vehicle and preparation method thereof

InactiveCN101892094ASave resourcesImprove cold start performanceLiquid carbonaceous fuelsOxygenReid vapor pressure

The invention discloses high-proportion methanol gasoline for a vehicle. The methanol gasoline comprises the following components in percentage by weight: 74 to 88.5 percent of methanol, 5 to 10 percent of low-carbon oxygen-containing component oil, 1 to 3 percent of mixed C5, 2 to 6 percent of mixed ether, 2 to 3 percent of C4 hydrocarbon, 1 to 2 percent of mixed alcohol and 0.5 to 2 percent of liquefied petroleum gas, wherein the low-carbon oxygen-containing component oil consists of 70 percent of dimethoxymethane and 30 percent of gasoline hydrocarbon with final boiling point less than 200DEG C; the mixed C5 consists of 80 percent of C5 alkane and 20 percent of C5 alkene; the C4 hydrocarbon is butane; and the mixed alcohol consists of ethanol, n-propanol and iso-propanol in the weight ratio of 4 to 3 to 3. In the preparation method, the high-proportion methanol gasoline product with reid vapor pressure (RVP) value ranging from 82 to 101kpa is prepared at the temperature of between-30 and 15 DEG C; and the method comprises the following steps of: uniformly mixing the components in weight percentage in the claim 1; and filling a preparation tank with the C4 hydrocarbon and the liquefied petroleum gas by using a dispenser to prepare the methanol gasoline. The methanol gasoline and the method have the advantages of making full use of the excess methanol resource, saving the petroleum resource, improving the cold start performance and solving the problem that high-proportion methanol gasoline can not be used in cold area.

Owner:山西新源煤化燃料有限公司

Gasoline Reid Vapor Pressure detection with brushless fuel pump

InactiveUS10094305B1Vaporize more readilyEasier engine startElectrical controlInternal combustion piston enginesCounter rotationReid vapor pressure

A gasoline Reid vapor pressure (RVP) detection system includes a fuel pump and a motor operating the fuel pump in a forward direction of rotation to feed a gasoline fuel to a vehicle engine. A control device is in communication with the motor selectively directing change from the forward direction of rotation to a reverse direction of rotation opposite to the forward direction of rotation. A pressure reduction device receives flow of the fuel during operation in the reverse direction of rotation and reduces a pressure of the fuel until fuel vaporization occurs. A pump speed at which vaporization of the fuel occurs at the pressure reduction device when a motor speed and a motor current change non-linearly is correlated to a fuel RVP.

Owner:GM GLOBAL TECH OPERATIONS LLC

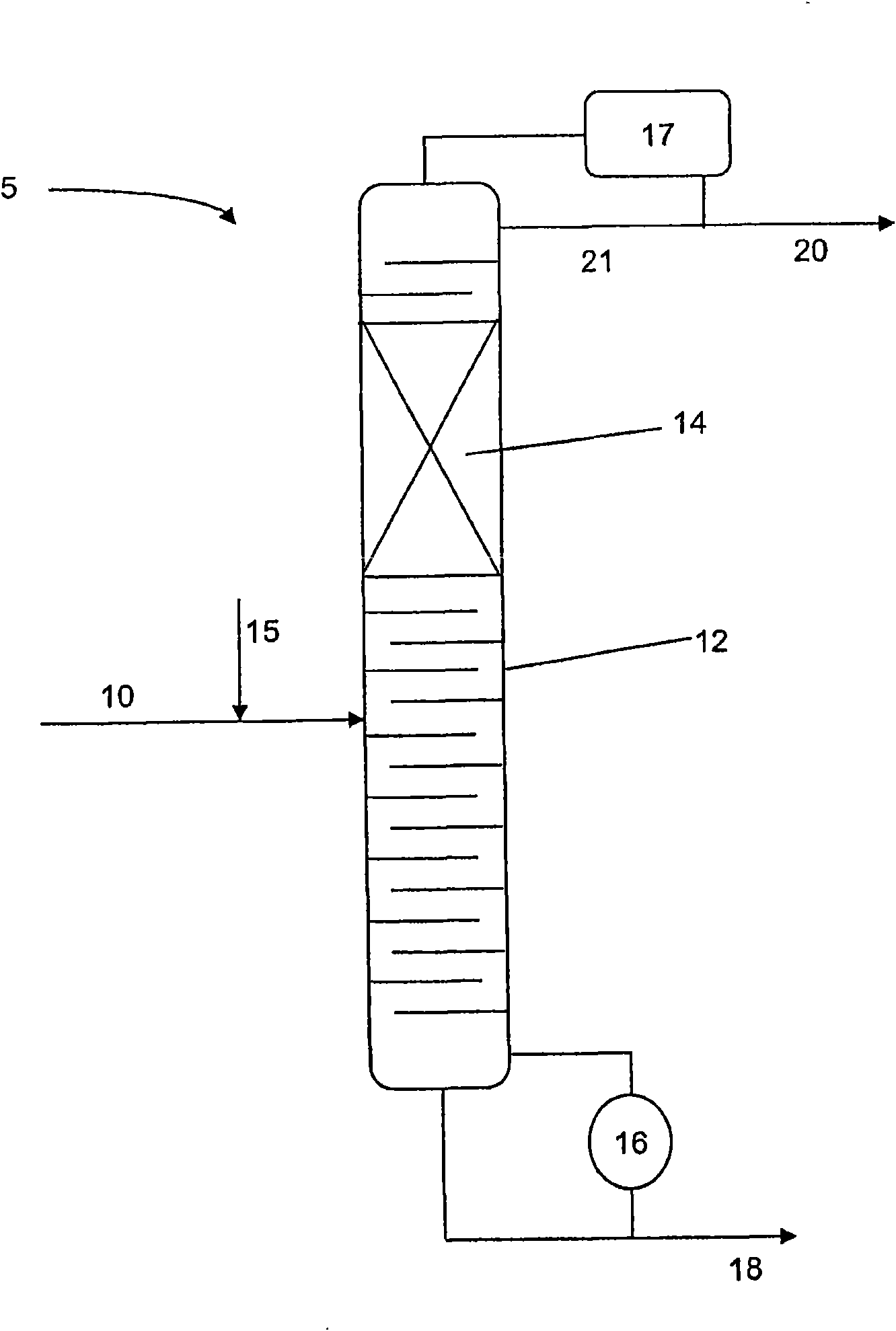

Method for processing natural gasoline

A method for rendering a high Reid Vapor Pressure natural gasoline feed suitable for addition to the gasoline pool by using steam stripping conditions that provide an overhead fraction that is suitable for thermal cracking, and a bottoms product that has a substantially reduced Reid Vapor Pressure as compared to the natural gasoline feed.

Owner:EQUSR CHEM LP

Process to produce clean gasoline/bio-ethers using ethanol

A fuel or fuel blendstock comprising ethanol, ethyl ethers, olefins, and alkanes. In some embodiments, the fuel or fuel blendstock of claim 1, wherein the fuel or fuel blendstock may have an octane number greater than 92 (RON+MON) / 2). In other embodiments, the fuel or fuel blendstock may have a Reid vapor pressure less than 7.2 psi. Also disclosed is a process for the production of a fuel, the process including: contacting ethanol and at least one gasoline fraction including alkanes and olefins in the presence of a catalyst to form a fuel mixture including ethyl ethers, alkanes, unreacted olefins, and unreacted ethanol; and recovering the fuel mixture for use as a gasoline or gasoline blendstock without separation of the ethanol from the fuel mixture.

Owner:CHEM RES & LICENSING CO

Reduced vapor pressure gelled fuels and solvents

InactiveUS20080263941A1High viscosityReduce the amount requiredSolid fuelsLiquid carbonaceous fuelsHydrocarbon solventsGasoline

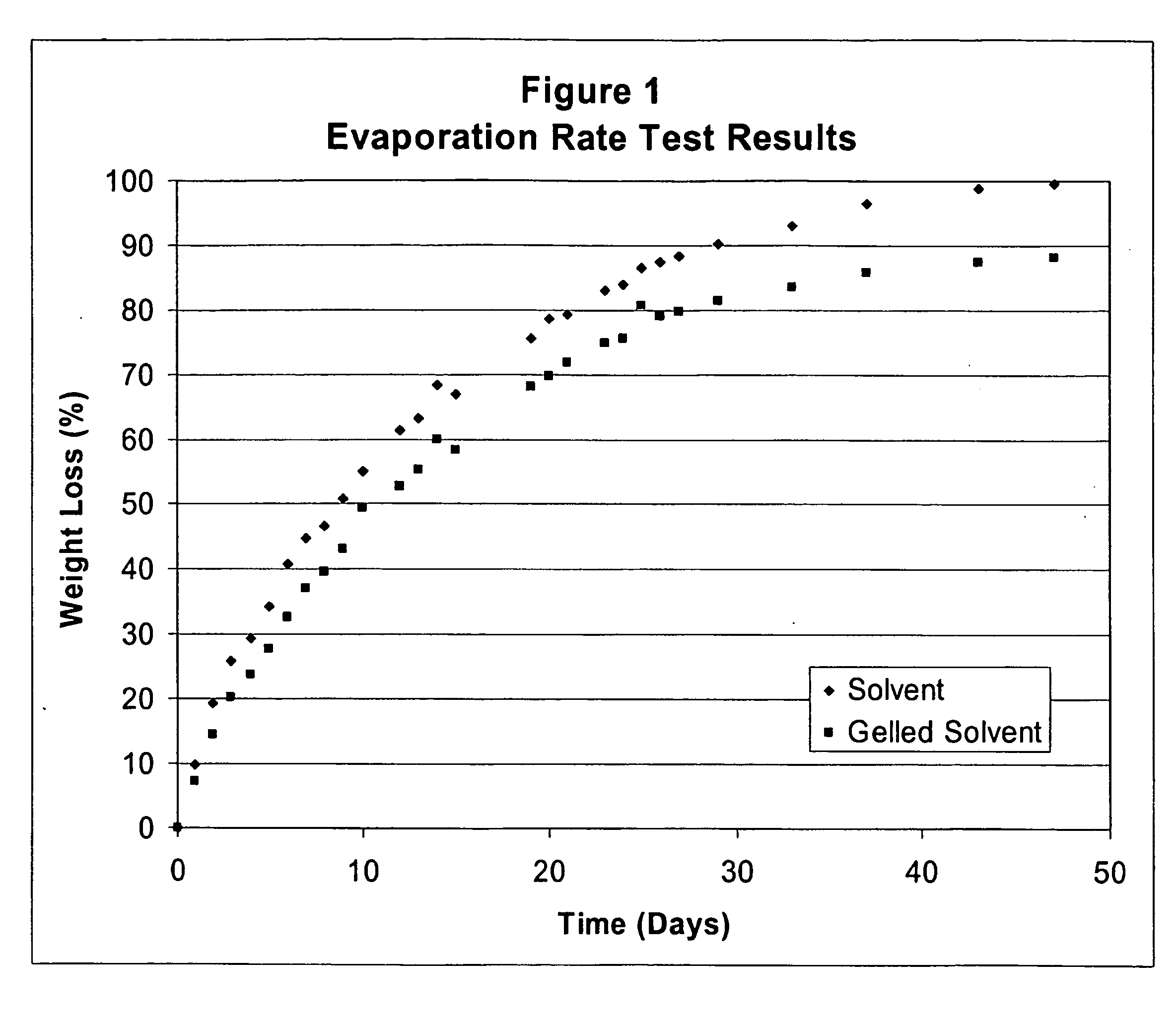

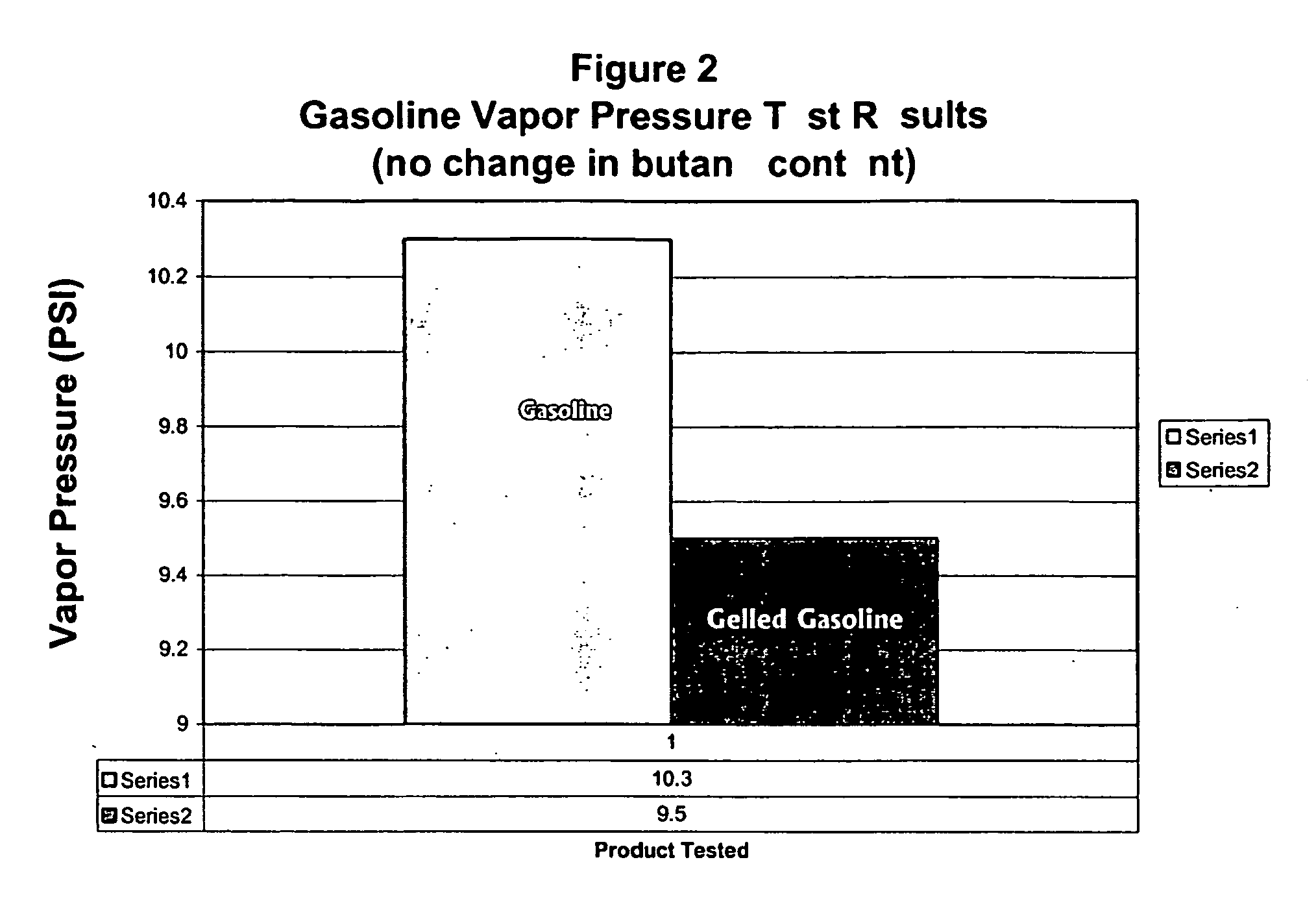

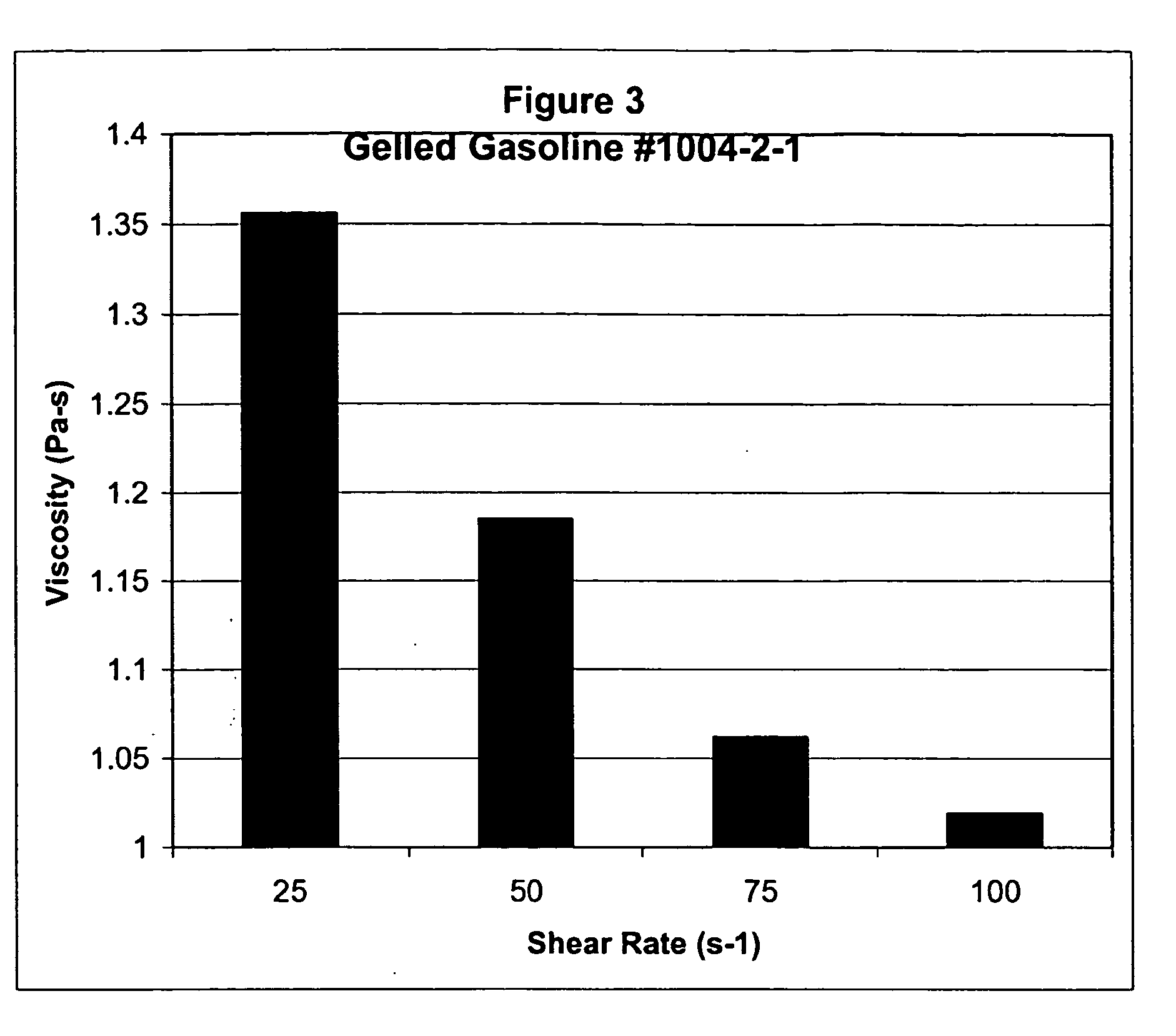

The present invention relates generally to gelled fuels and solvents. Specifically the invention relates to gel thickeners that reduce vapor pressure in fuels and solvents and are shear thinning (pseudoplastic or thixotropic) or are shear thickening and remain pourable and flowable. Still more specifically, the invention relates to nonaqueous gels made with diblock copolymers that reduce the Reid Vapor Pressure of gelled gasoline and lower the total volatility of gelled hydrocarbon solvents. These gels may contain secondary amino acid or triblock polymer gelling agents. The invention includes gel compositions and methods of making gels.

Owner:BUTUC STELUTA GINA

Blending of economic, reduced oxygen, summer gasoline

Provided is a novel high octane summer gasoline composition which is substantially free of oxygenates, and is in compliance with the California Predictive Model. The gasoline composition is suitable for use in the summer, i.e., having a Reid vapor pressure of 7.0 or less. The method for blending the gasoline comprises blending streams from a refinery in a controlled manner to maintain compliance with the California Predictive Model.

Owner:CHEVROU USA INC

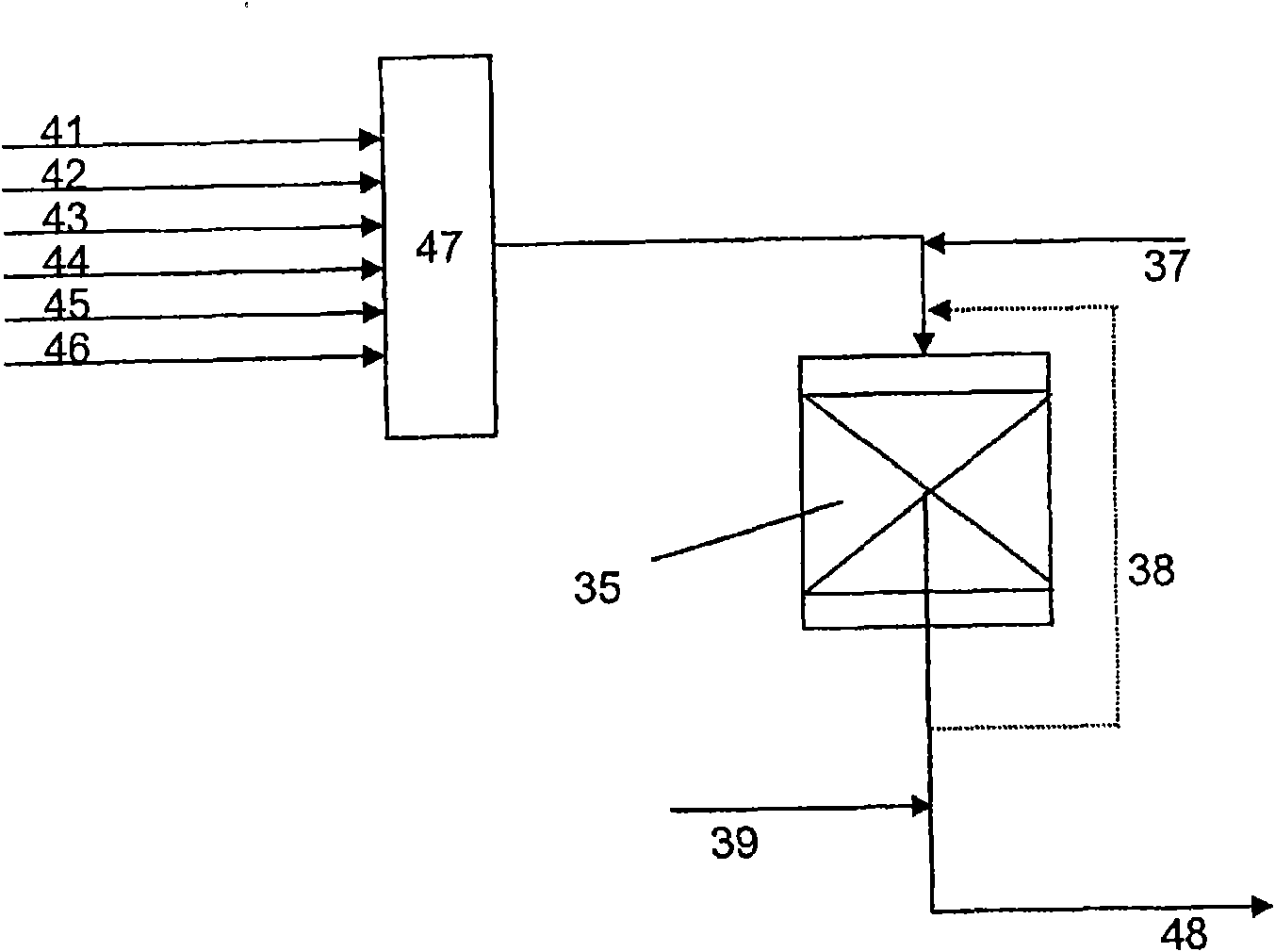

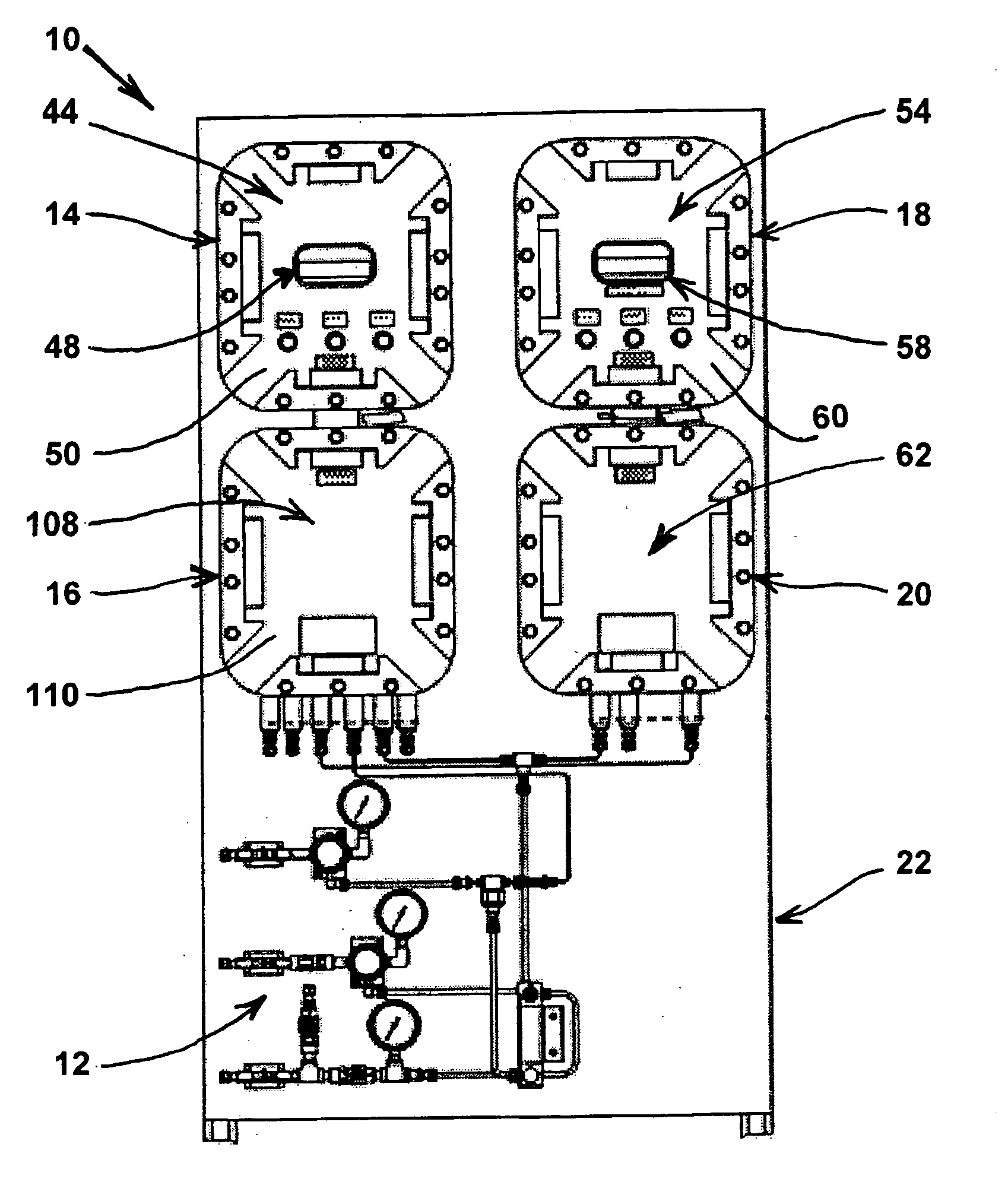

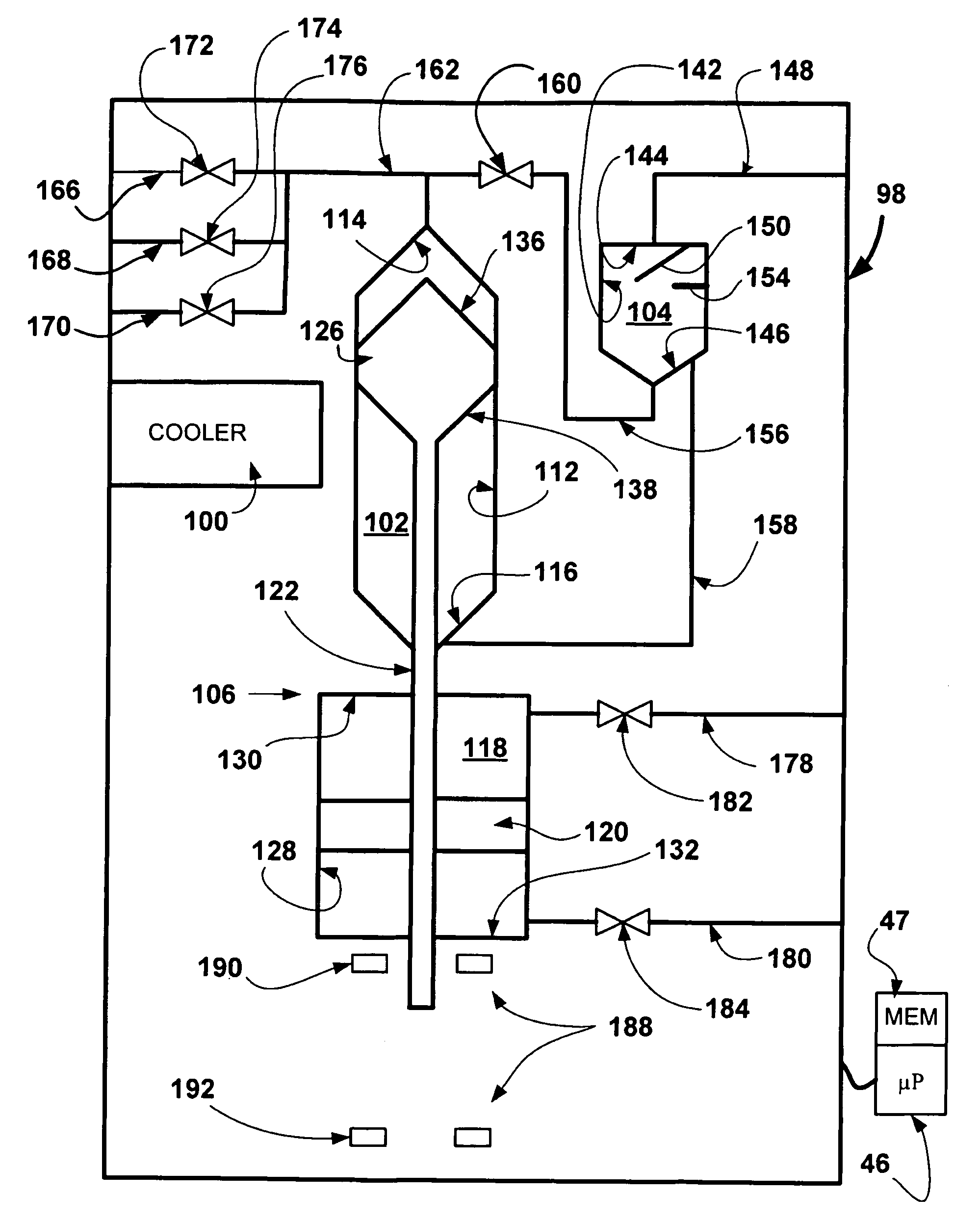

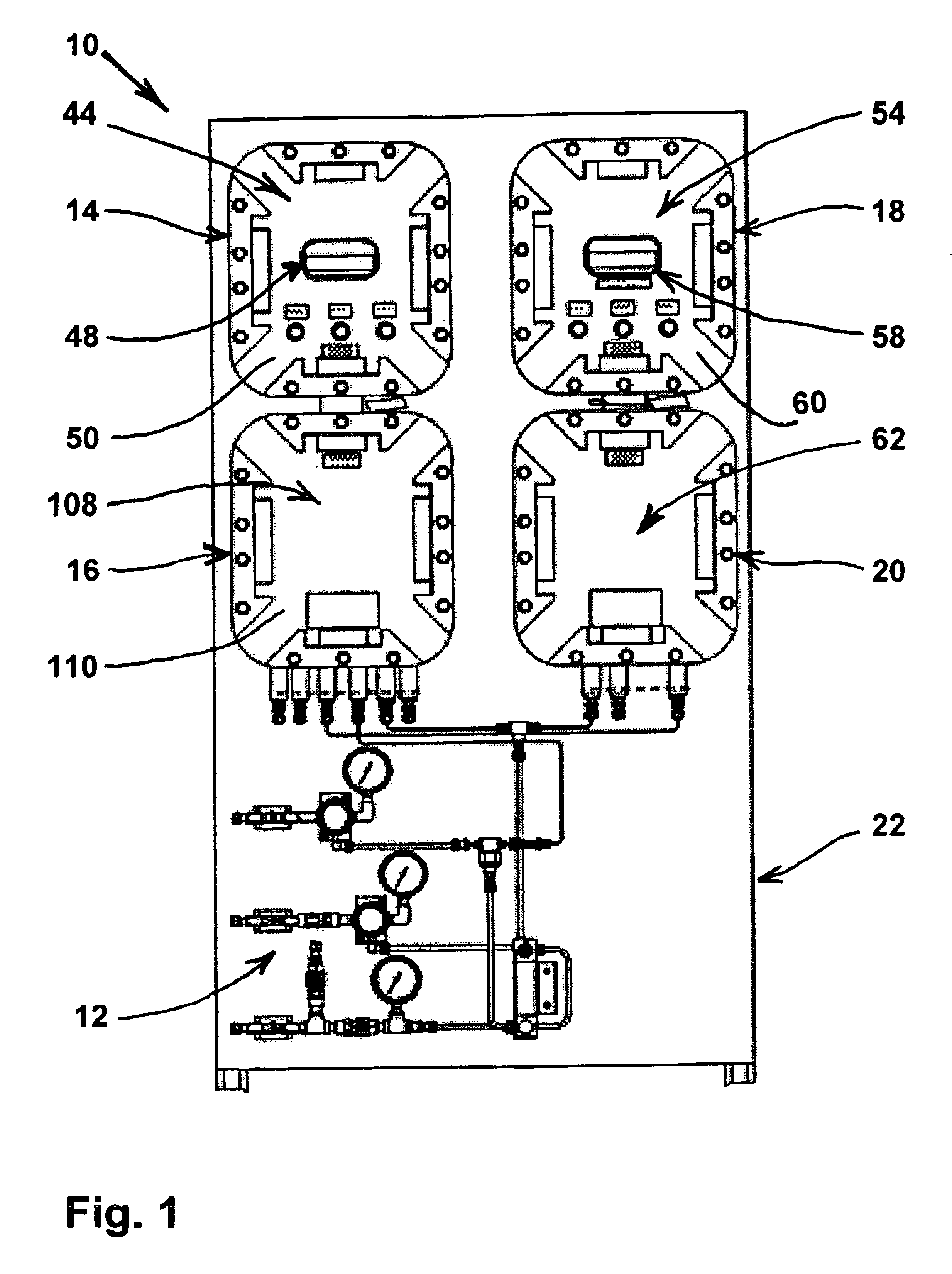

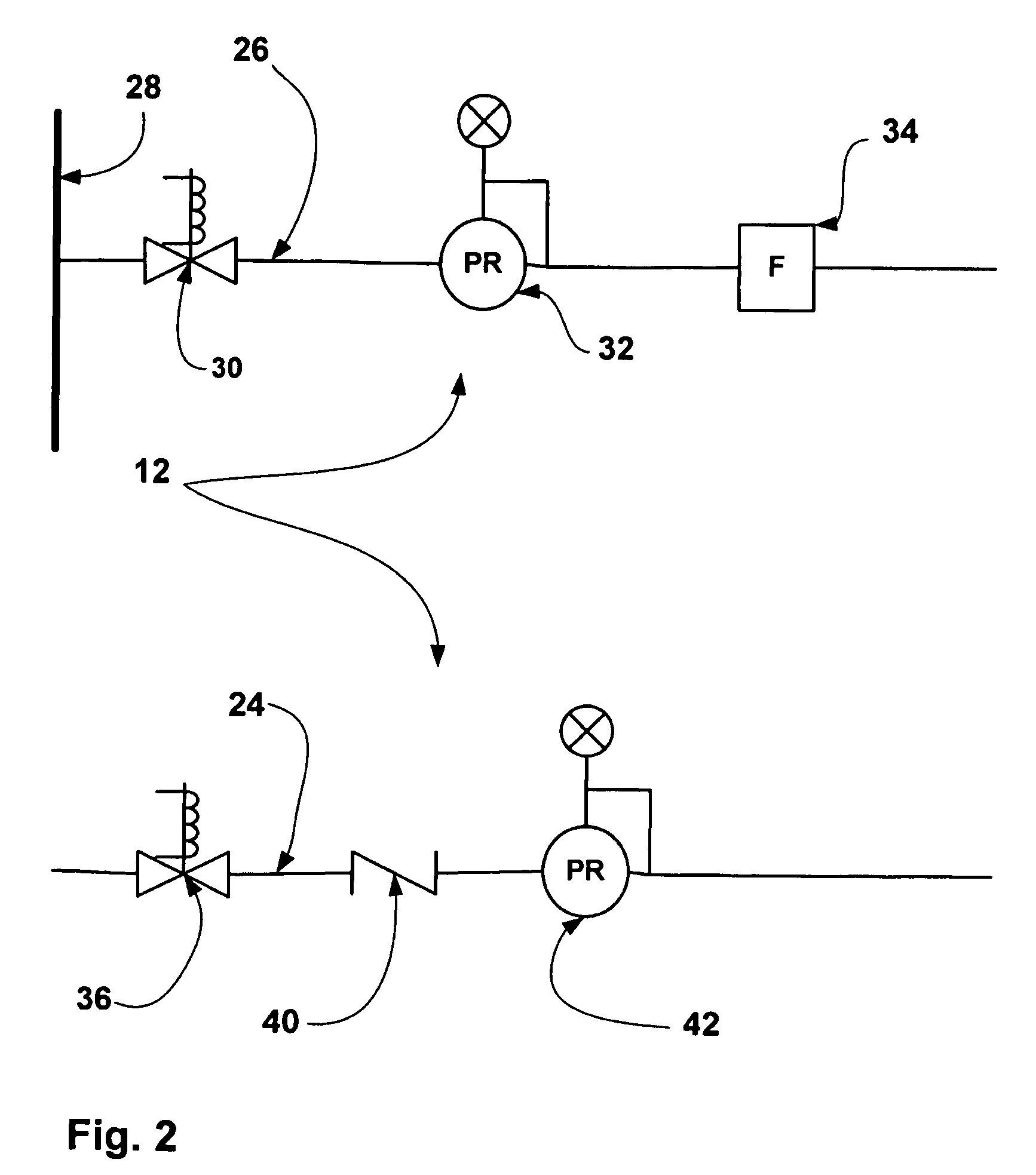

Reid vapor pressure analyzer with an air saturator

The present invention is directed to an analyzer for measuring the vapor pressure of a hydrocarbon liquid. The analyzer includes a pressure measuring system connected to an air saturation system having a circulation chamber with opposing first and second ends. A first opening is disposed toward the first end and a second opening is disposed toward the second end. A plumbing system connects the first and second openings. A pump moves the hydrocarbon liquid through the plumbing system from the first opening to the second opening so as to saturate the hydrocarbon liquid with air. The air saturation system has a cooler for cooling the hydrocarbon liquid and the pressure measuring system has a heater for heating the hydrocarbon liquid. The pump may be a piston actuated pump or a motor-driven pump and the plumbing system may include an aeration chamber.

Owner:ABB INC

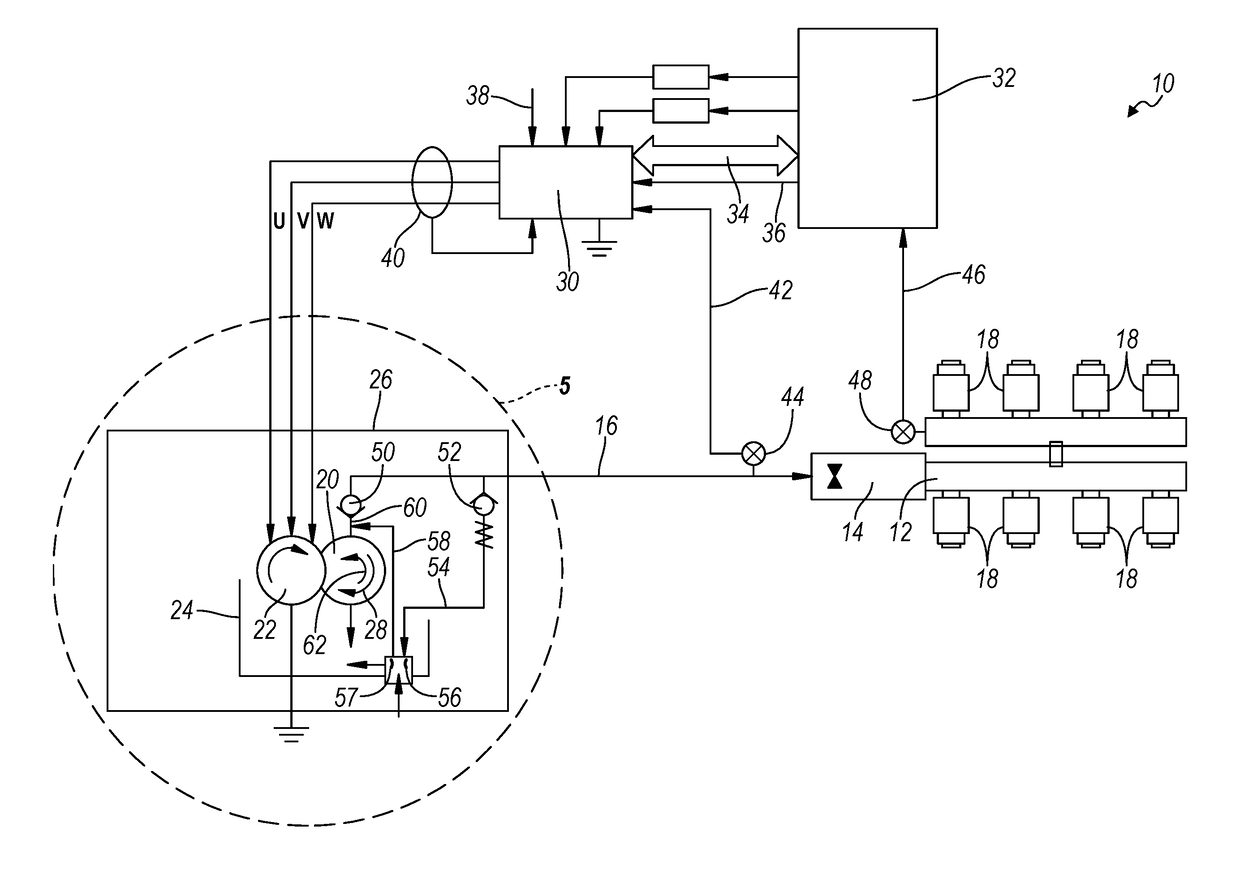

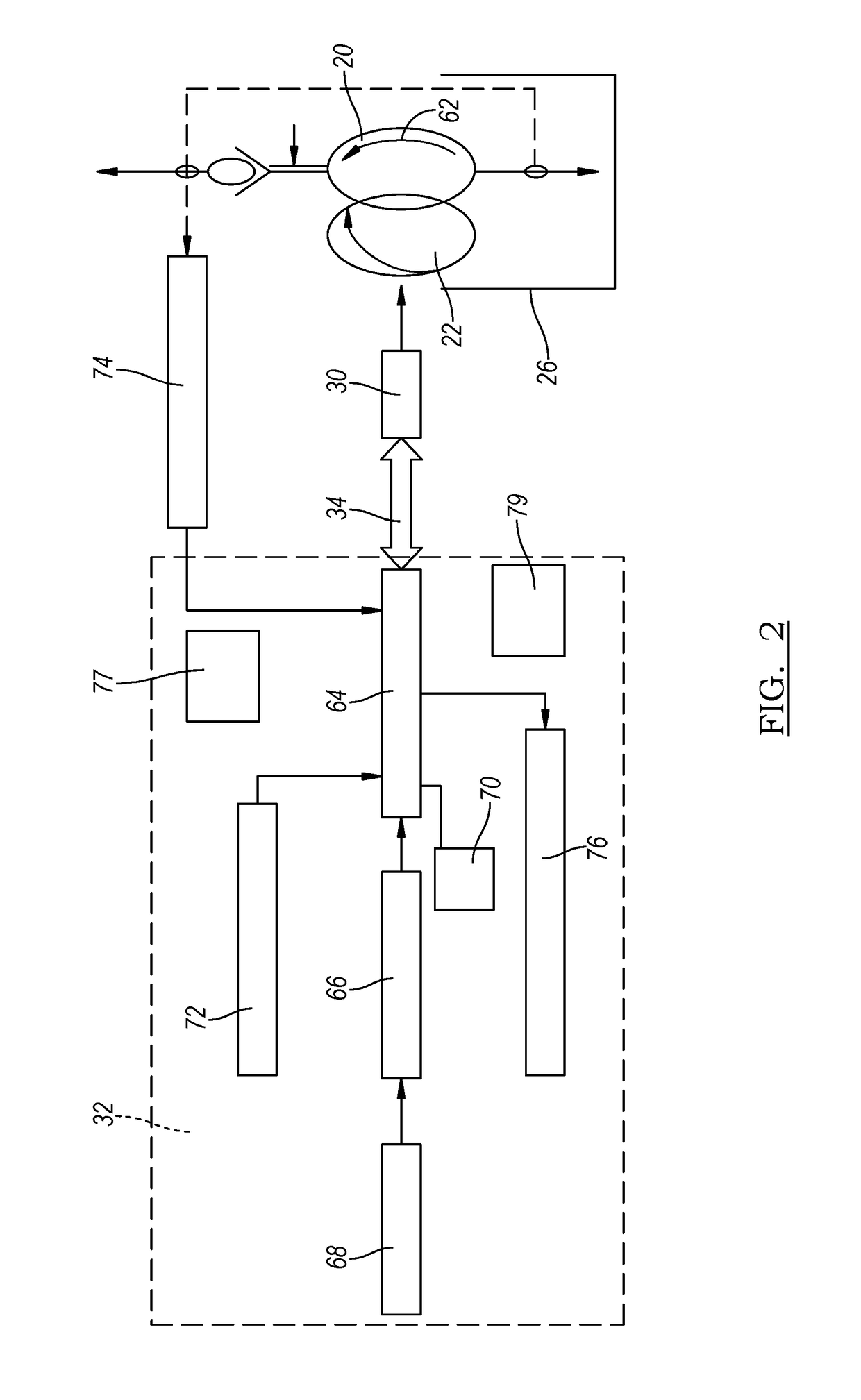

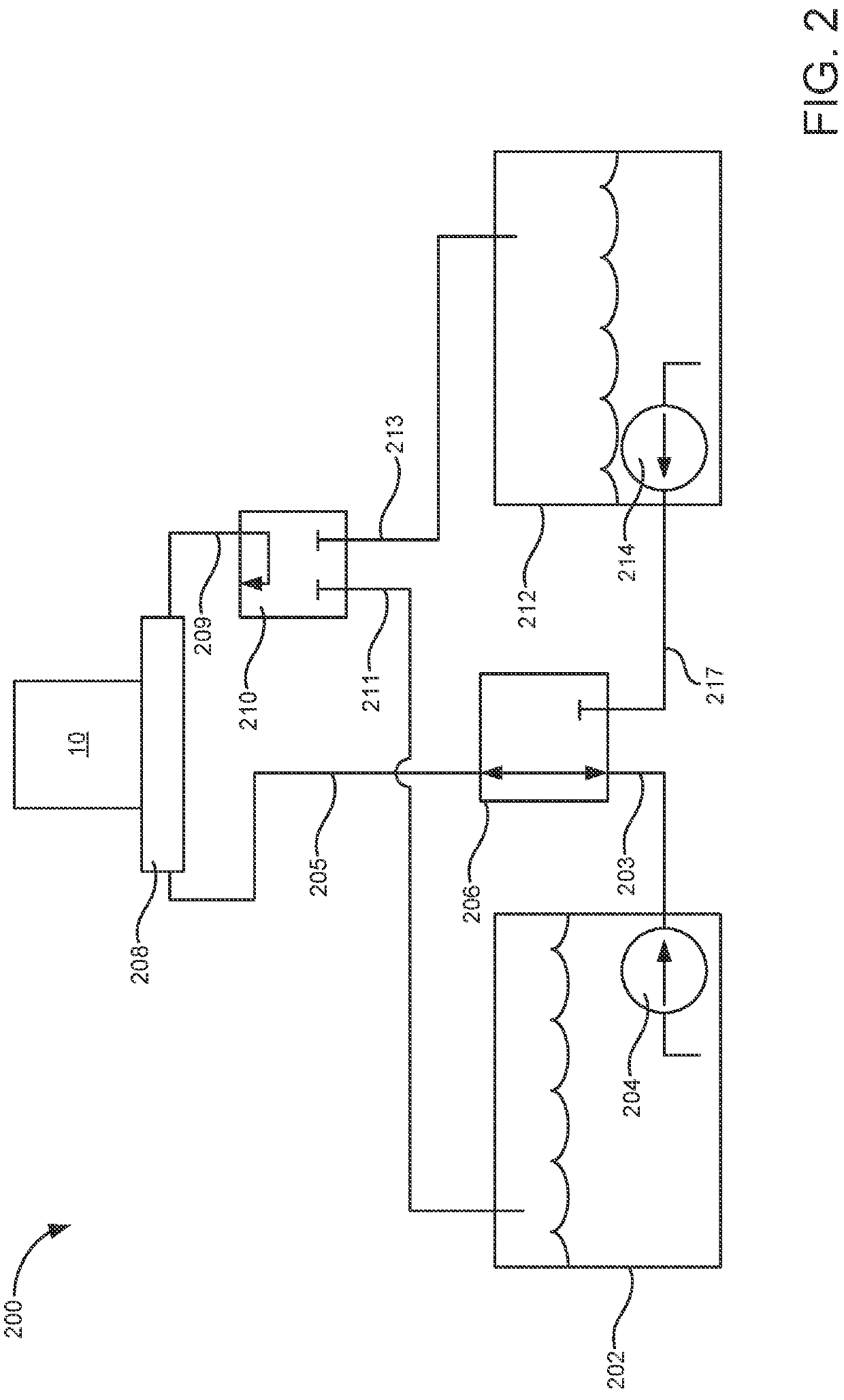

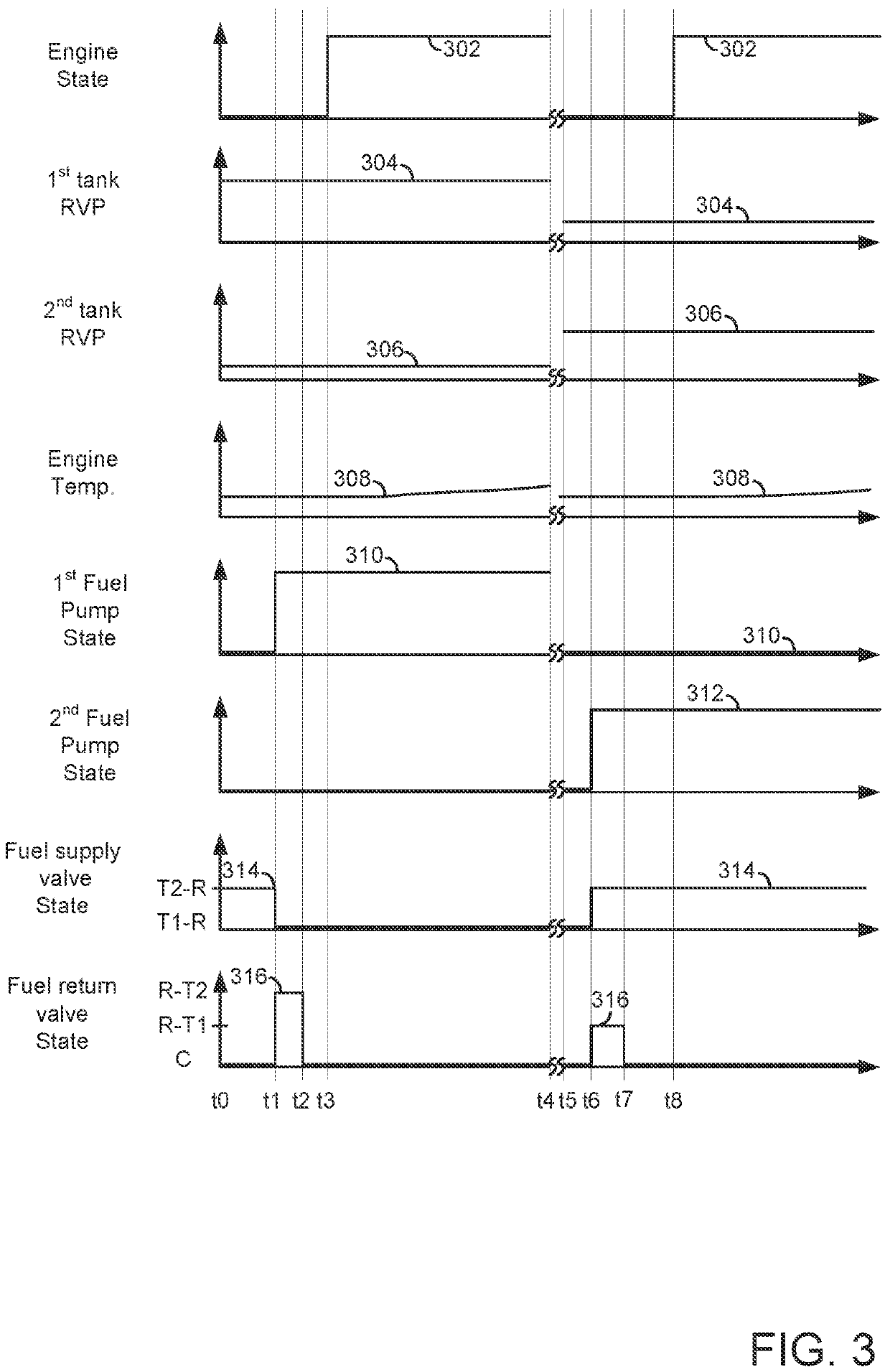

Methods and systems for operating a vehicle with two fuel tanks

ActiveUS11300083B1Improve engine startingAccelerate emissionsElectrical controlInternal combustion piston enginesThermodynamicsFuel tank

Systems and methods for operating a fuel system that includes two separate fuel tanks are disclosed. In one example, fuel may be purged from a fuel rail in response to Reid vapor pressure of a fuel so that engine starting may be improved. A fuel with a higher Reid vapor pressure may be pumped into the fuel rail when the engine is expected to be cold started.

Owner:FORD GLOBAL TECH LLC

Reid vapor pressure analyzer with an air saturator

Owner:ABB INC

Firefighting training fluid and method for making same

InactiveUS7341112B2Maintain normal dischargeReduce smoke emissionsSolid fuelsFire rescueAlkaneParticulates

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

High-proportion methanol gasoline for vehicle and preparation method thereof

InactiveCN101892094BSave resourcesImprove cold start performanceLiquid carbonaceous fuelsAlkaneOxygen

The invention discloses high-proportion methanol gasoline for a vehicle. The methanol gasoline comprises the following components in percentage by weight: 74 to 88.5 percent of methanol, 5 to 10 percent of low-carbon oxygen-containing component oil, 1 to 3 percent of mixed C5, 2 to 6 percent of mixed ether, 2 to 3 percent of C4 hydrocarbon, 1 to 2 percent of mixed alcohol and 0.5 to 2 percent of liquefied petroleum gas, wherein the low-carbon oxygen-containing component oil consists of 70 percent of dimethoxymethane and 30 percent of gasoline hydrocarbon with final boiling point less than 200DEG C; the mixed C5 consists of 80 percent of C5 alkane and 20 percent of C5 alkene; the C4 hydrocarbon is butane; and the mixed alcohol consists of ethanol, n-propanol and iso-propanol in the weight ratio of 4 to 3 to 3. In the preparation method, the high-proportion methanol gasoline product with reid vapor pressure (RVP) value ranging from 82 to 101kpa is prepared at the temperature of between-30 and 15 DEG C; and the method comprises the following steps of: uniformly mixing the components in weight percentage in the claim 1; and filling a preparation tank with the C4 hydrocarbon and the liquefied petroleum gas by using a dispenser to prepare the methanol gasoline. The methanol gasoline and the method have the advantages of making full use of the excess methanol resource, saving the petroleum resource, improving the cold start performance and solving the problem that high-proportion methanol gasoline can not be used in cold area.

Owner:山西新源煤化燃料有限公司

Blending of economic, reduced oxygen, winter gasoline

Provide is a novel gasoline composition which is substantially free of oxygenates and is in compliance with the California Phase 3 Predictive Model. The gasoline composition is suitable for use in the winter months, i.e., having a Reid vapor pressure in the range of greater than 7.0 to about 15.0 psi. The method for blending the gasoline comprises blending streams from a refinery in a controlled manner to maintain compliance with the California Phase 3 Predictive Model.

Owner:CHEVROU USA INC

Blending of economic, ether free summer gasoline

Provided is a novel summer gasoline composition which is substantially free of ethers, contains less than 20 ppm sulfur, and is in compliance with the California Predictive Model. The gasoline composition is suitable for use in the summer, i.e., having a Reid vapor pressure of 7.2, and more preferably 7.0 or less, but also offers the advantages of low-emissions while being substantially free of ethers. The method for blending the gasoline comprises blending streams from a refinery in a controlled manner to maintain compliance with the California Predictive Model.

Owner:CHEVROU USA INC

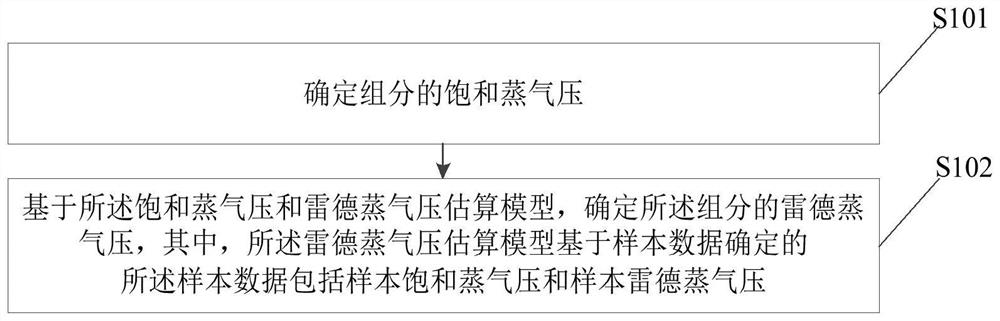

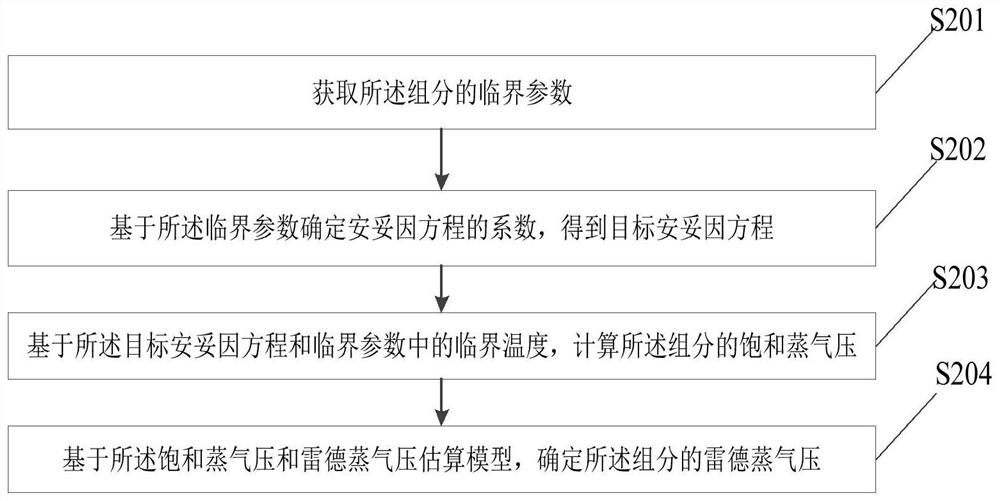

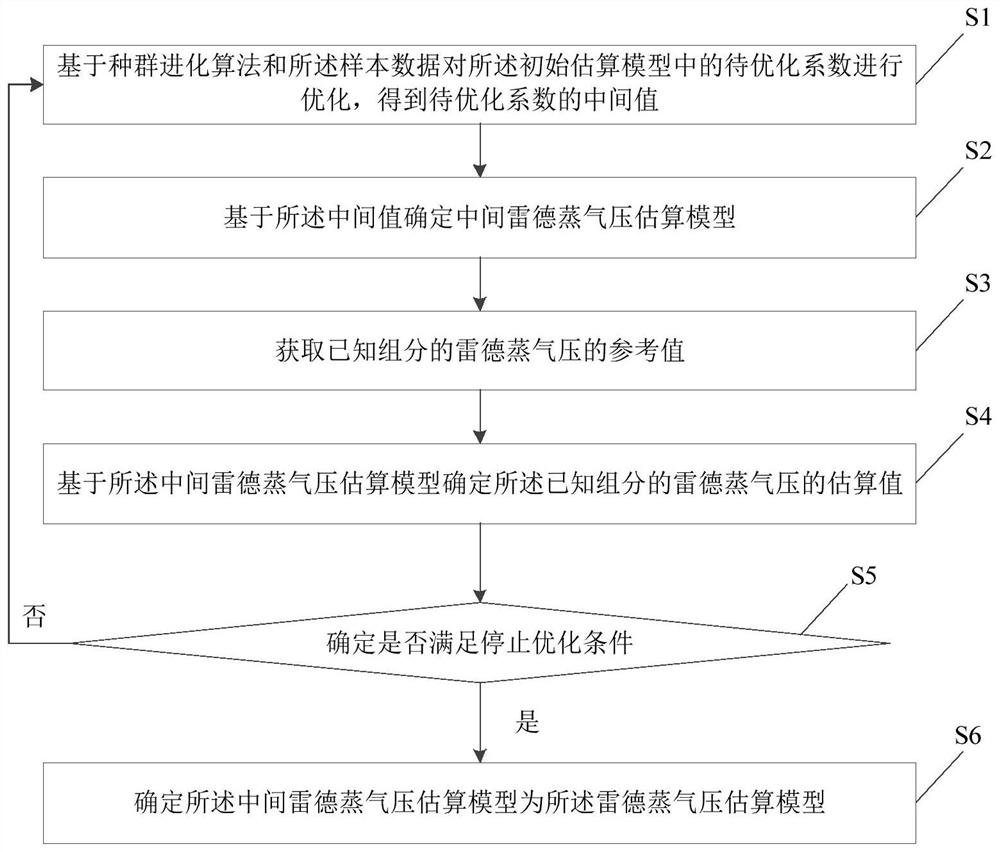

Reid vapor pressure estimation method and device, electronic equipment and storage medium

PendingCN114818244AReduce mistakesSimple calculationDesign optimisation/simulationSpecial data processing applicationsThermodynamicsReid vapor pressure

Owner:CHINA PETROLEUM & CHEM CORP +1

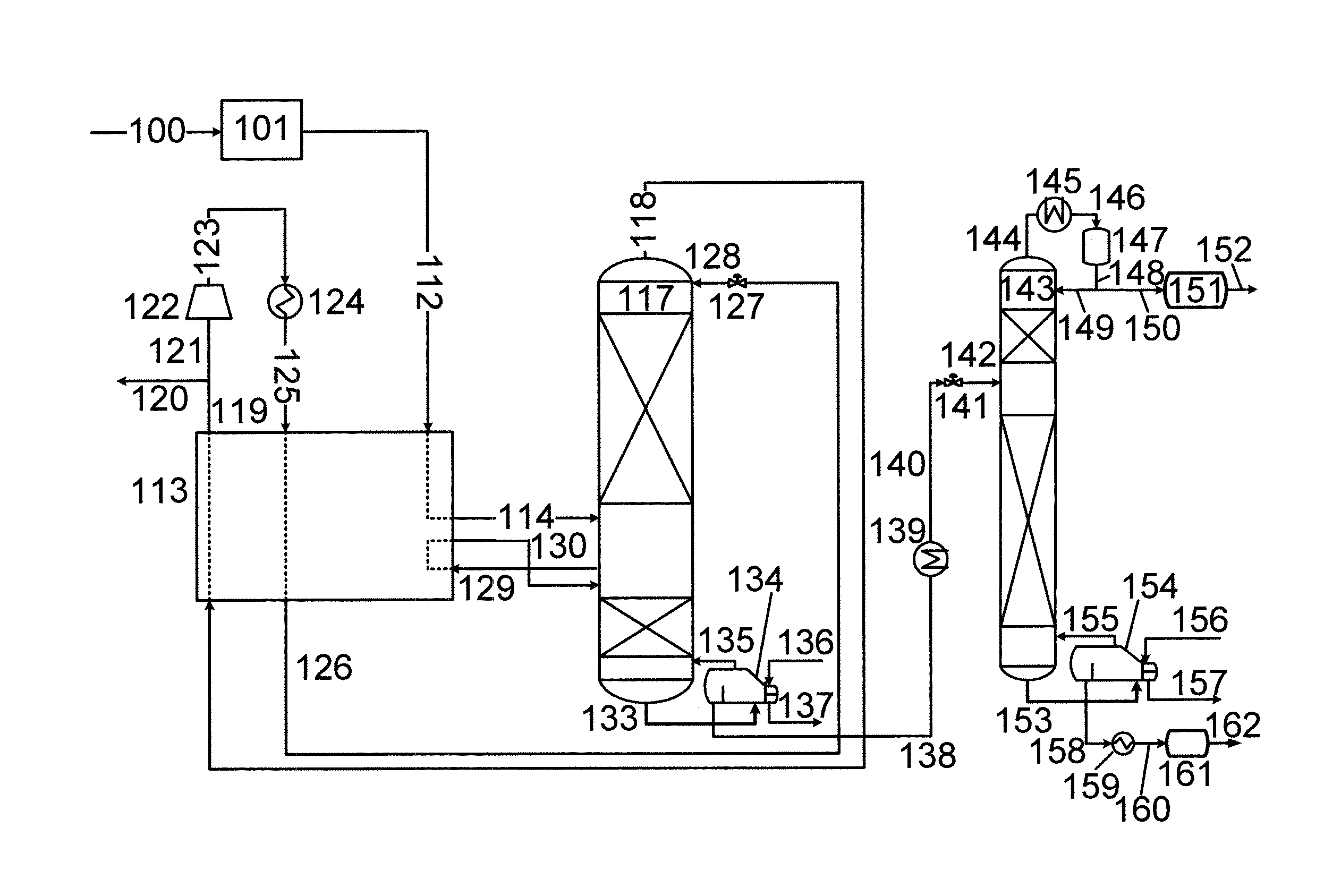

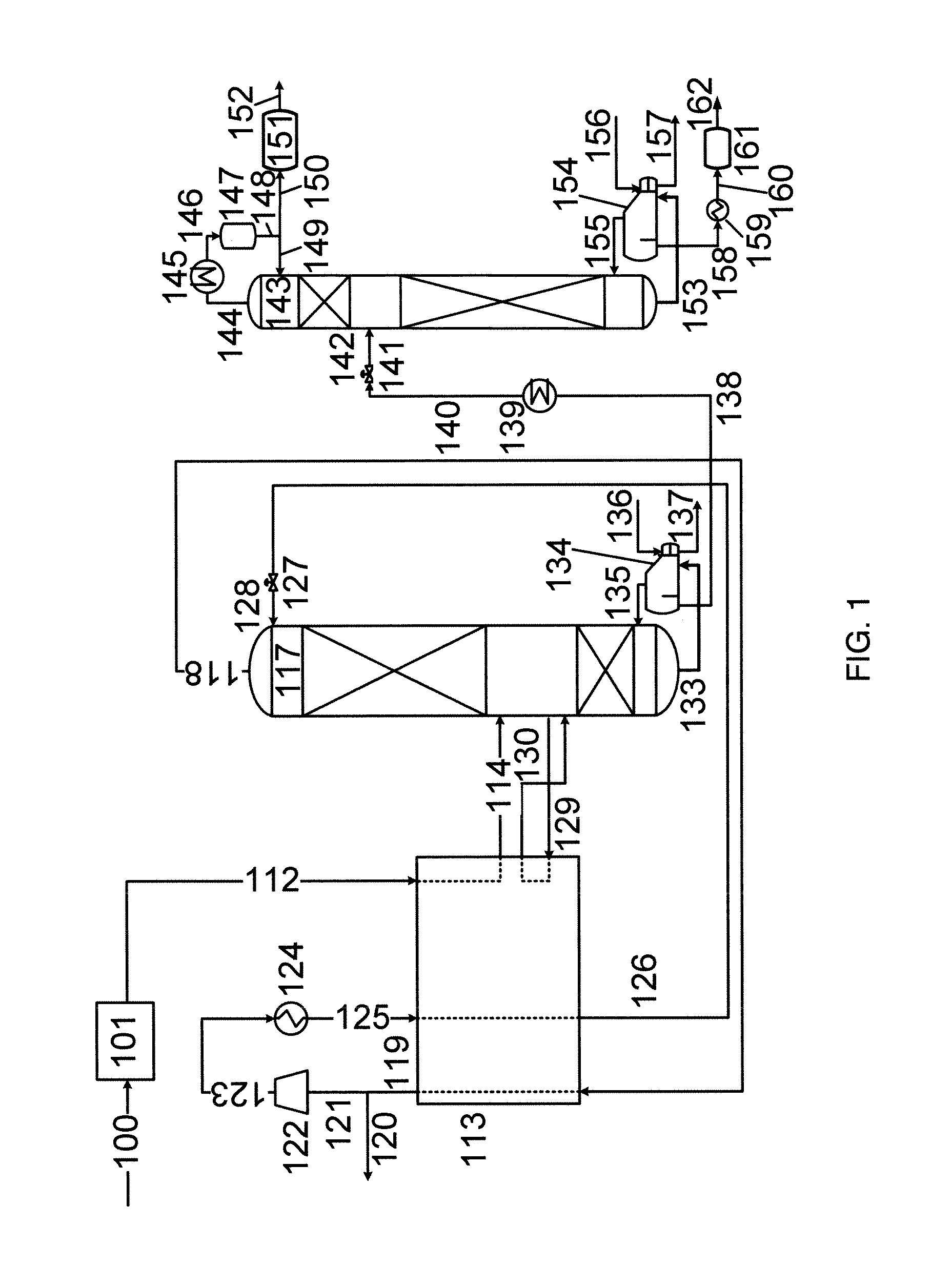

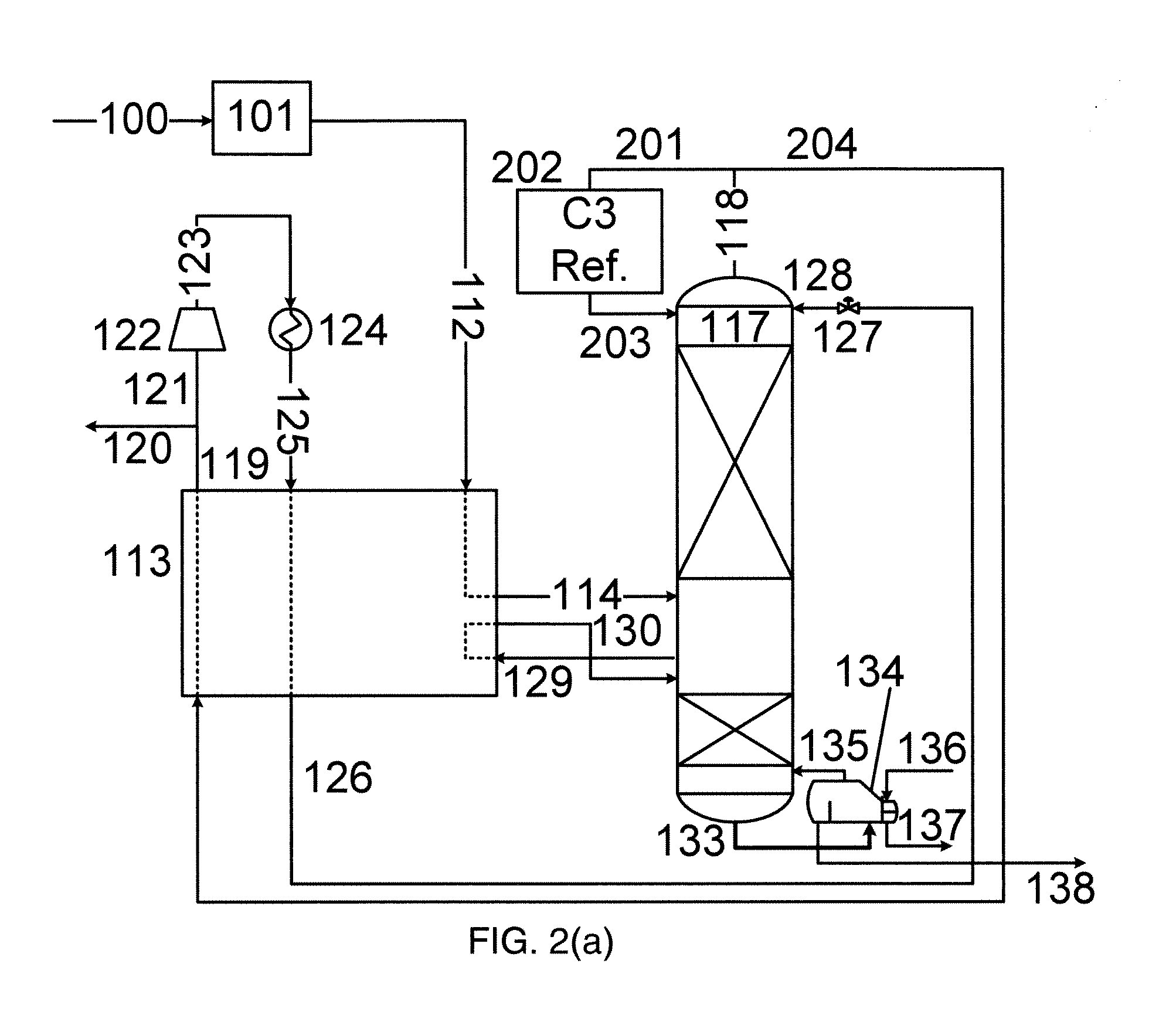

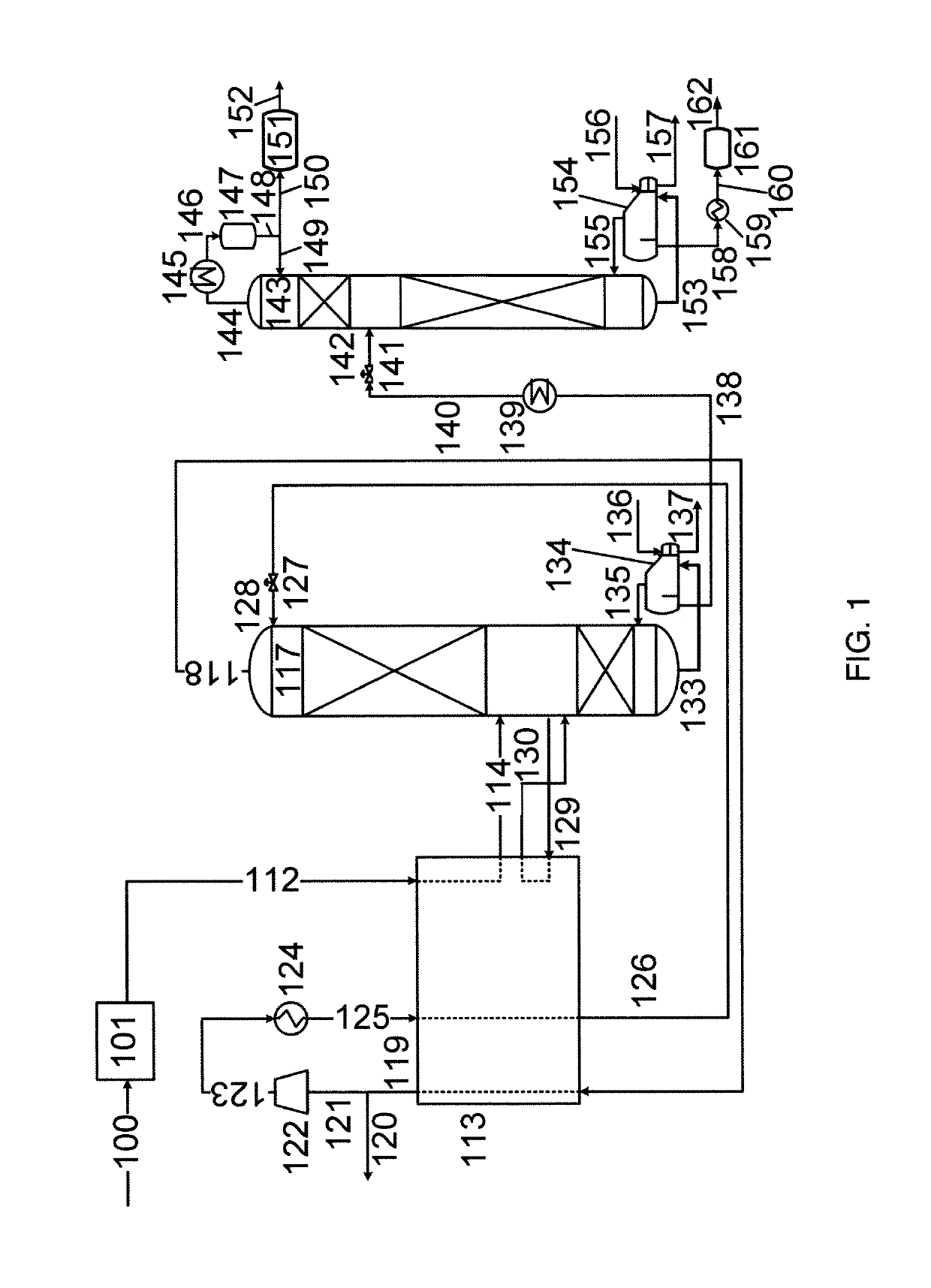

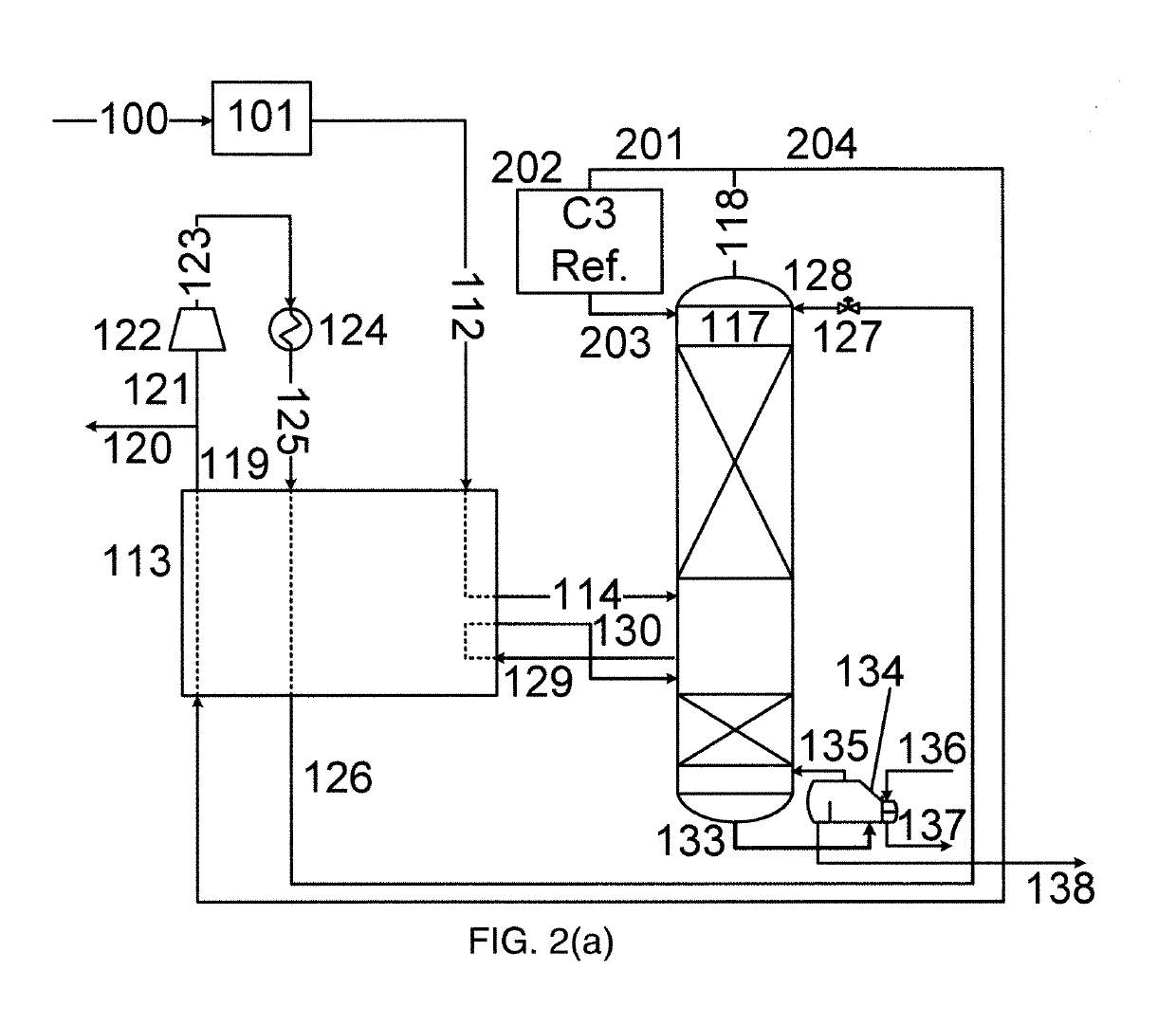

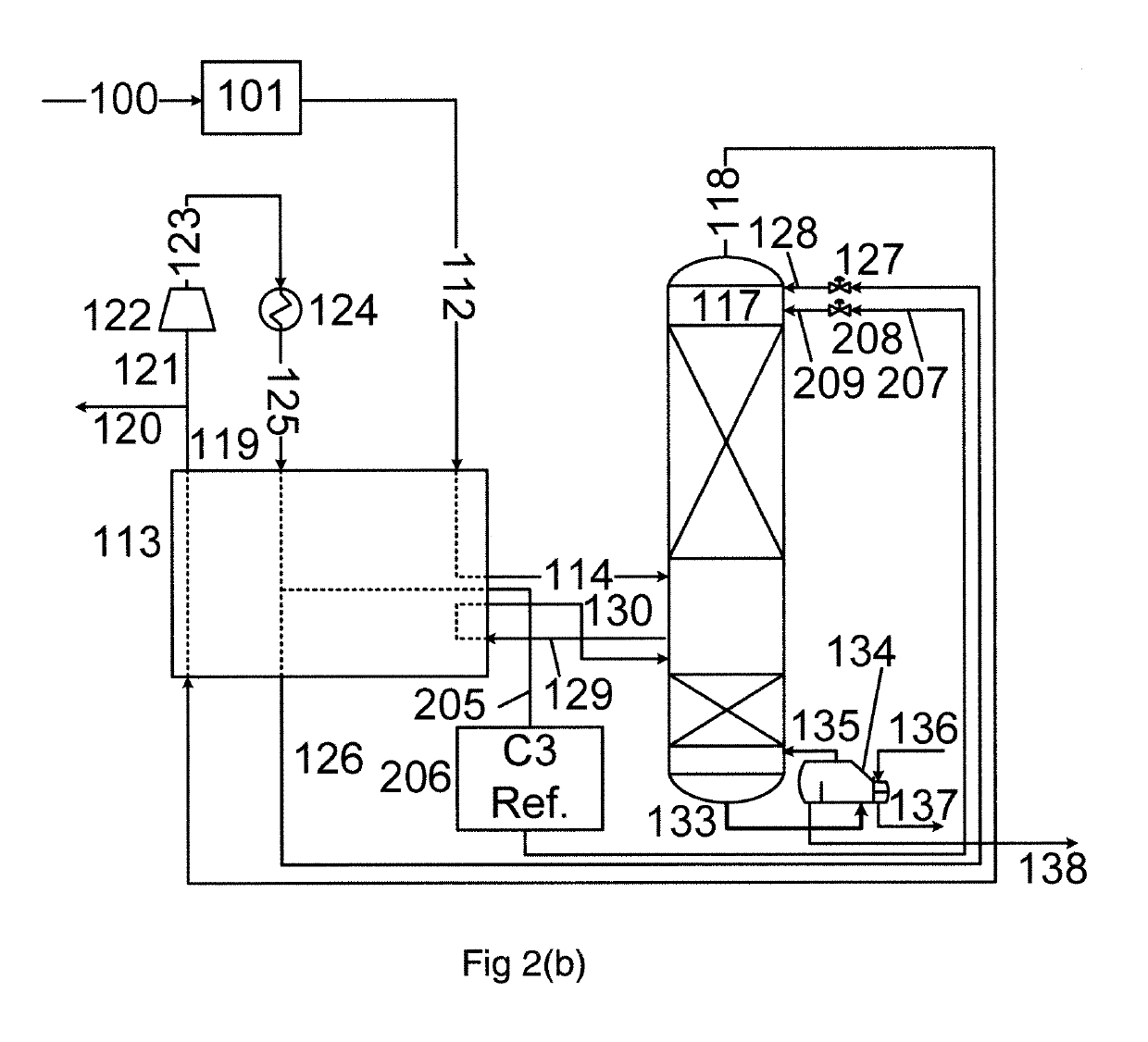

Process for recovering hydrocarbons from crude carbon dioxide fluid

The power required to recover C3+ hydrocarbons from crude carbon dioxide comprising C1+ hydrocarbons and hydrogen sulfide may be reduced by distilling the crude carbon dioxide to produce carbon dioxide-enriched overhead vapor and C3+ hydrocarbon-enriched bottoms liquid such that the hydrogen sulfide is rejected with the overhead vapor. Power consumption reductions may be achieved by incorporating a heat pump cycle using carbon dioxide vapor as working fluid to provide at least a part of the refrigeration duty and using a side reboiler to reduce the bottom reboiler duty. Where the bottoms liquid is further processed to produce “lighter” and “heavier” hydrocarbon fractions, the process enables optimization of upgrading crude oil on the basis of API gravity, Reid Vapor pressure and / or viscosity.

Owner:AIR PROD & CHEM INC

Rejuvenation of stored gasoline

The method of adding to gasoline which has been stored in a container, of relatively small size for a substantial period of time to cause substantial loss of the more volatile gasoline components, an additive composition which comprises a flammable organic liquid having a Reid vapor pressure of 2 to 18 psig, to improve starting capacity of a motor fueled by said gasoline.

Owner:GOLD EAGLE

Rejuvenation of stored gasoline

The method of adding to gasoline which has been stored in a container, of relatively small size for a substantial period of time to cause substantial loss of the more volatile gasoline components, an additive composition which comprises a flammable organic liquid having a Reid vapor pressure of 2 to 18 psig, to improve starting capacity of a motor fueled by said gasoline.

Owner:GOLD EAGLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com