Reduced vapor pressure gelled fuels and solvents

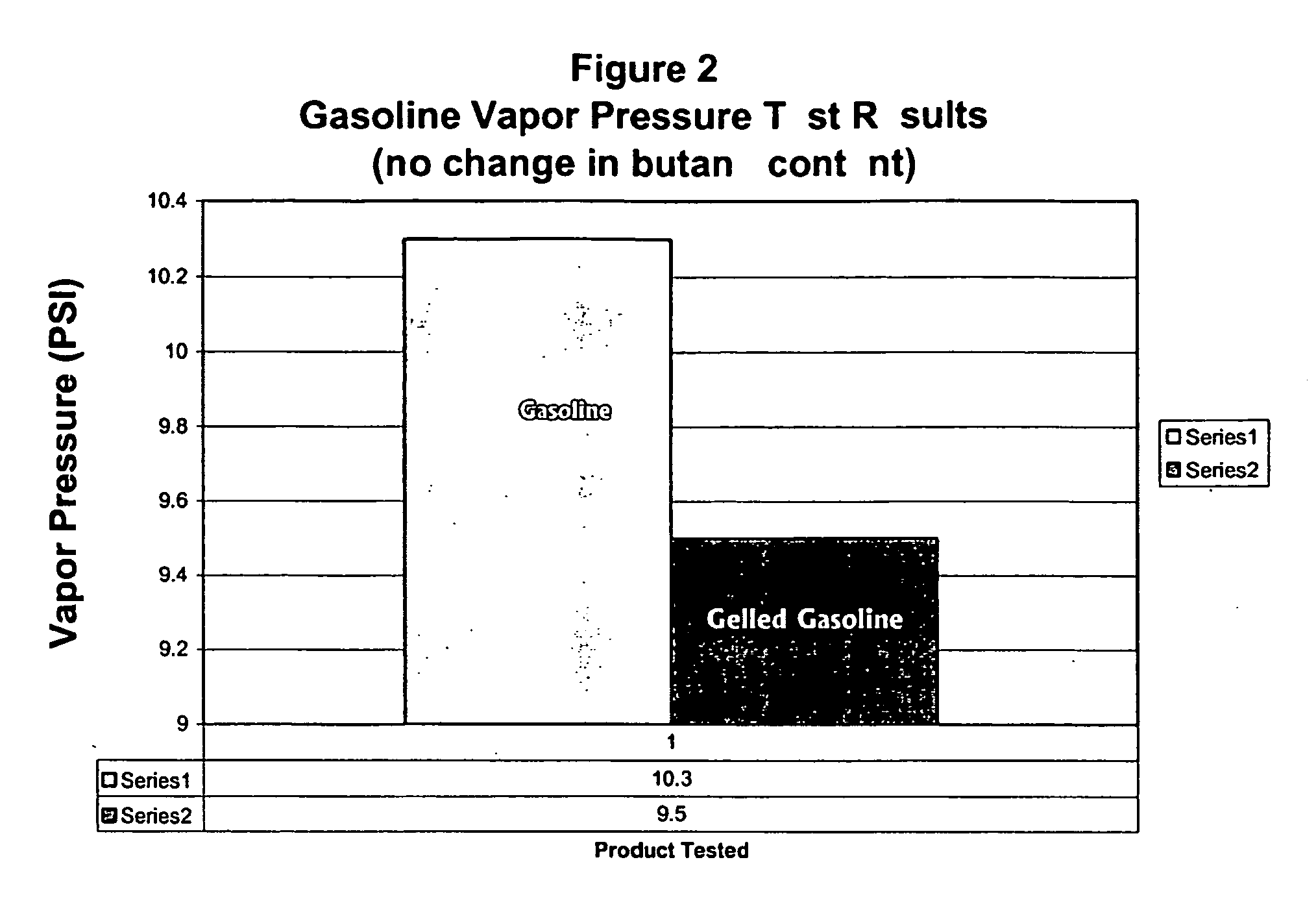

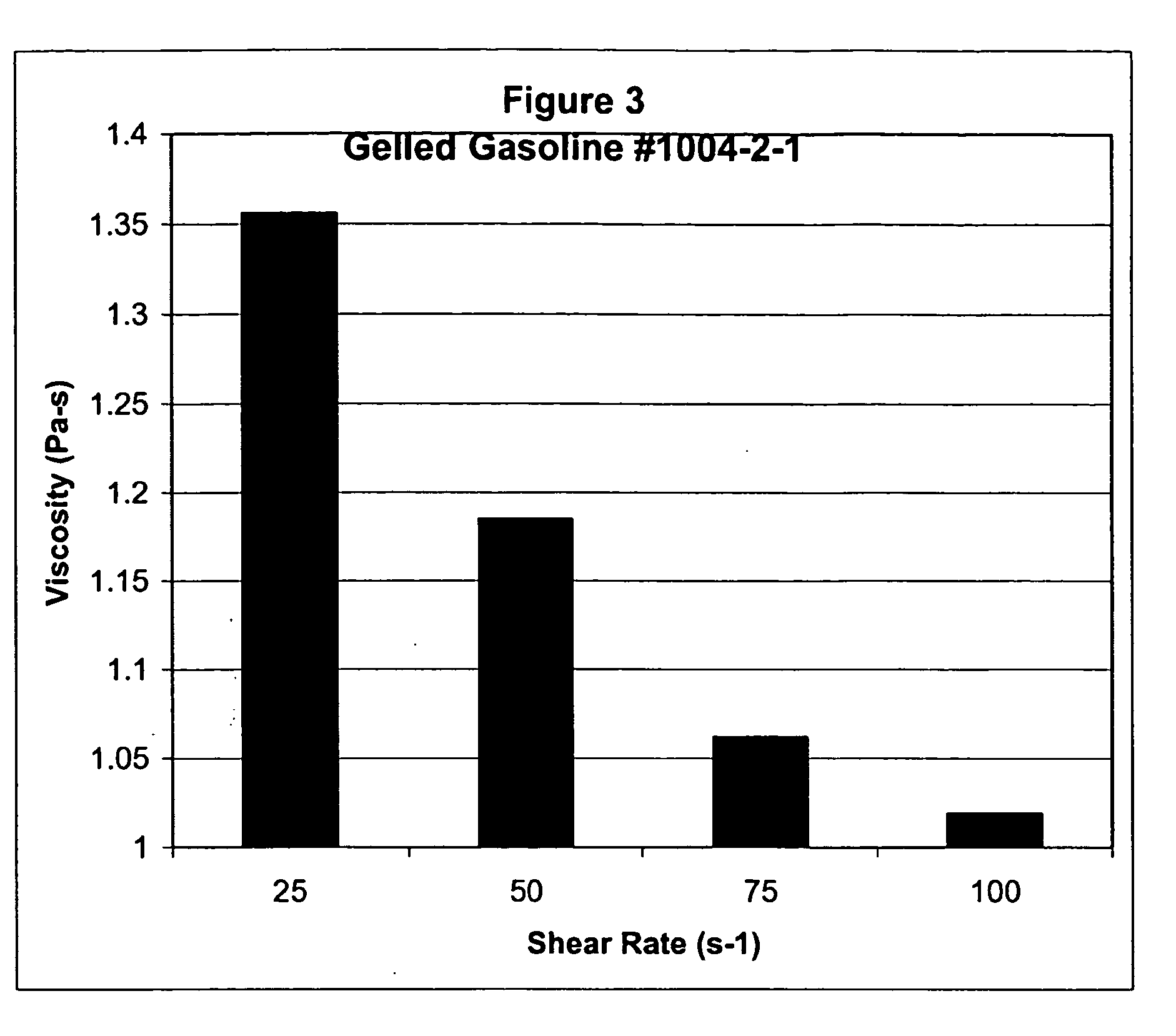

a gelled fuel and solvent technology, applied in the petroleum industry, liquid carbonaceous fuels, solid fuels, etc., can solve the problems of engine knocking and hard starting, low vapor pressure of gasoline, and high cost of oxygenates, so as to reduce the total amount of volatile organic compounds (voc), increase the viscosity of gelled solvent, and reduce the vapor pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0046]The following are examples of gelled fuel and solvent made according to an embodiment of the present invention. These examples should be taken as illustrative of the invention and not as limiting its scope. All values are in weight percent.

[0047]Gelled Hydrocarbon Solvent

[0048]The first example is a gelled solvent. The base hydrocarbon solvent is Penreco Conosol C-145. This solvent is made and sold by Penreco of Houston, Tex. Conosol C-145 is a high-purity, low-odor aliphatic solvent composed primarily of C10-C13 cycloparaffinic and isoparaffinic hydrocarbons. It is a low-toxicity product that contains less than 0.5% aromatics, and it has a higher solvent strength than competitive 140+ flash aliphatic solvents.

[0049]The Conosol solvent is gelled by the addition of 9.5 weight percent of Kraton 1702 diblock copolymer and 0.5 Kraton 1650 triblock copolymer. These polymers are produced and sold by Kraton Polymers of Houston, Tex.

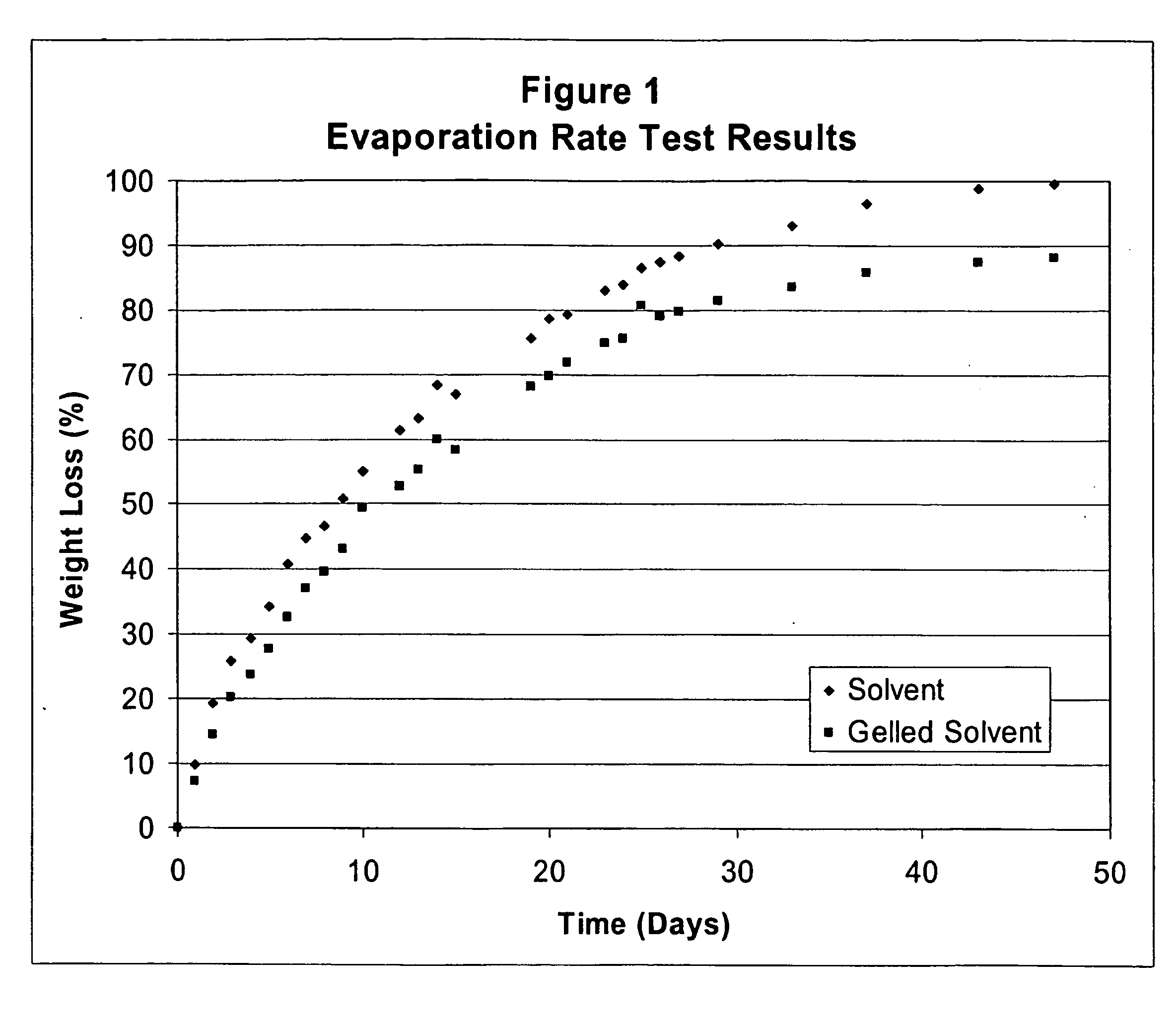

[0050]The control solvent and the gelled solvent wer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com