Patents

Literature

80 results about "Ion calcium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Be the first to review this product. Ionic Calcium is made from Calcium Chloride and is 27% Calcium, highly soluble in an acid PH solution and as a liquid with readily dissociated Calcium ions, highly bioavailable and are already in a suitable size and form to be transported to where they are required in the cells.

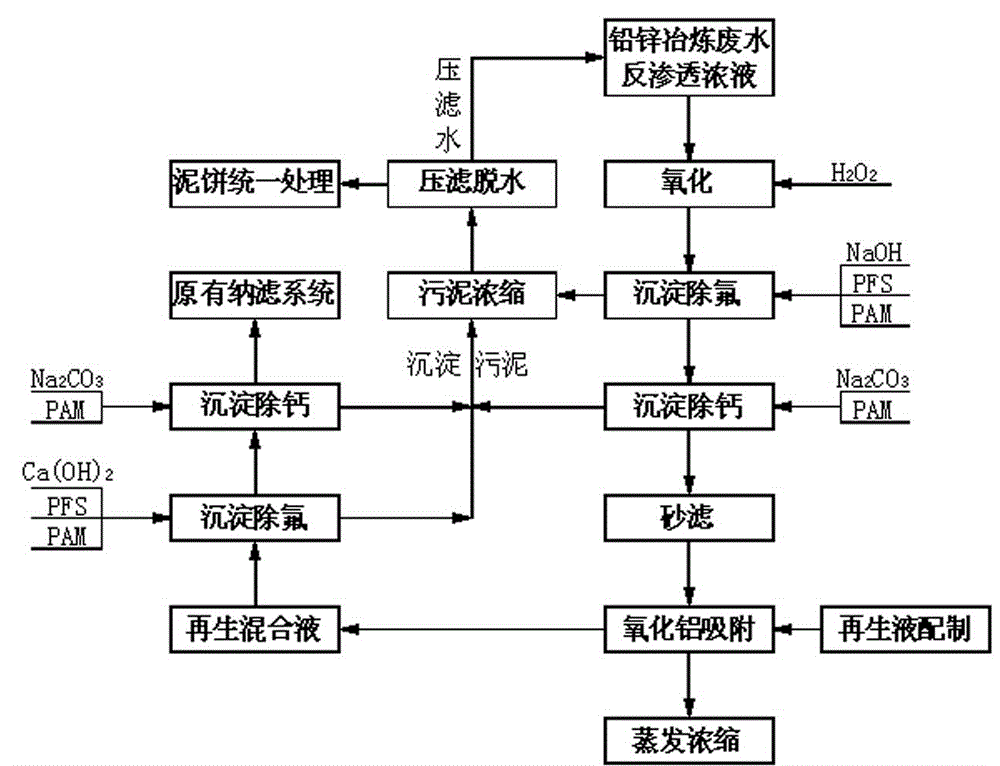

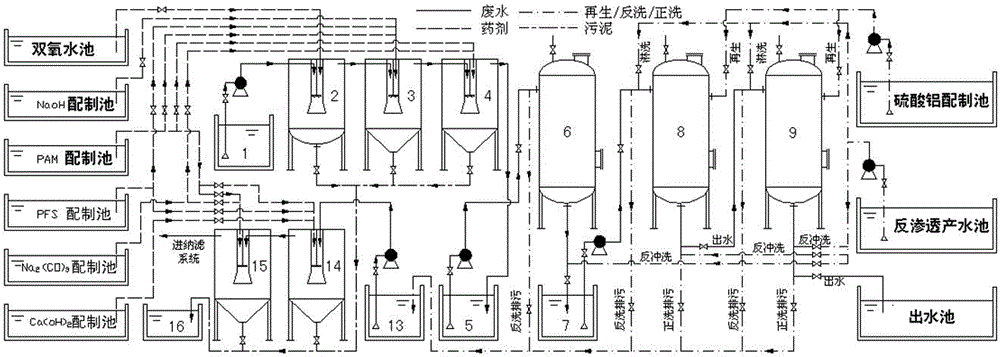

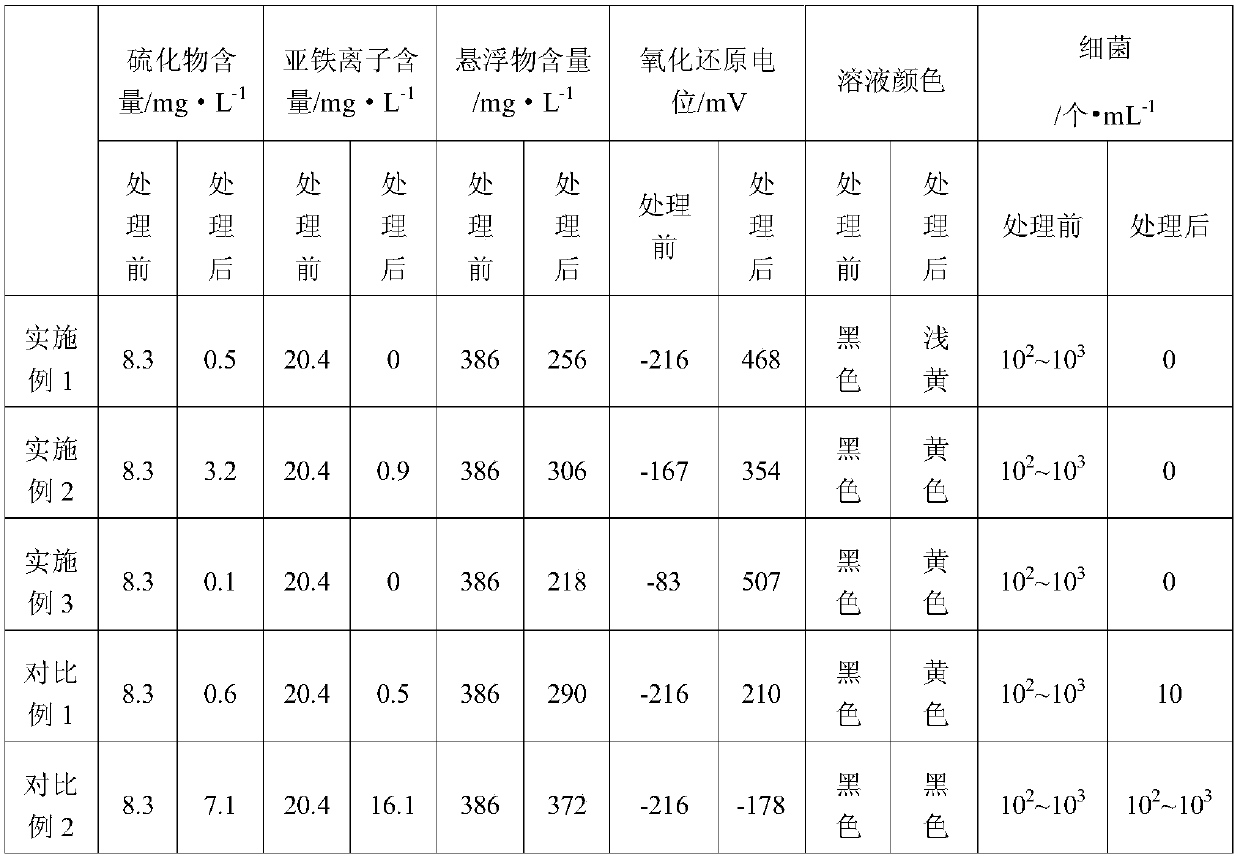

Synchronous fluorine-calcium removal treatment process for reverse osmosis concentrated liquor of waste water from lead-zinc smelting

ActiveCN104445717ADestroy scale inhibitionEnsure reaction precipitation effectWater contaminantsWaste water treatment from metallurgical processCalcium handlingReverse osmosis

The invention relates to a synchronous fluorine-calcium removal treatment process for the reverse osmosis concentrated liquor of waste water from lead-zinc smelting. The process comprises the following steps: firstly, removing fluorine by virtue of oxidation and precipitation, secondly, removing calcium by precipitating, thirdly, removing fluorine by virtue of adsorption, next, sequentially regenerating activated aluminum oxide, removing fluorine from the generated mixed liquor, removing calcium from the generated mixed liquor and treating the generated mixed liquor, and finally, removing fluorine by precipitating, wherein the precipitation sludge generated in the calcium removal process is gathered and dehydrated by virtue of filter pressing, the water obtained by filter pressing is returned to a reverse osmosis concentrated liquor collecting tank for circular treatment, and the mud cake is subjected to unified disposal. After the oxidization, precipitation and adsorption treatment processes are adopted, the fluorine content and the calcium content of the reverse osmosis concentrated liquor are lower than 3mg / L and 50mg / L, respectively, and the problems of scaling and blockage caused by fluorine ions and calcium ions in the subsequent evaporation and concentration process of the reverse osmosis concentrated liquor are solved.

Owner:SHENZHEN ZHONGJIN LINGNAN NONFEMET COMPANY +1

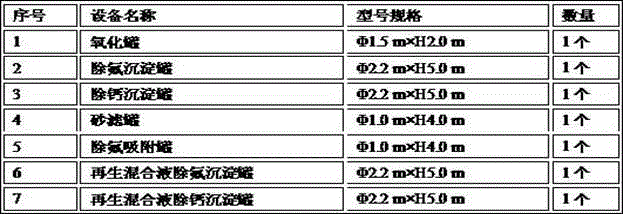

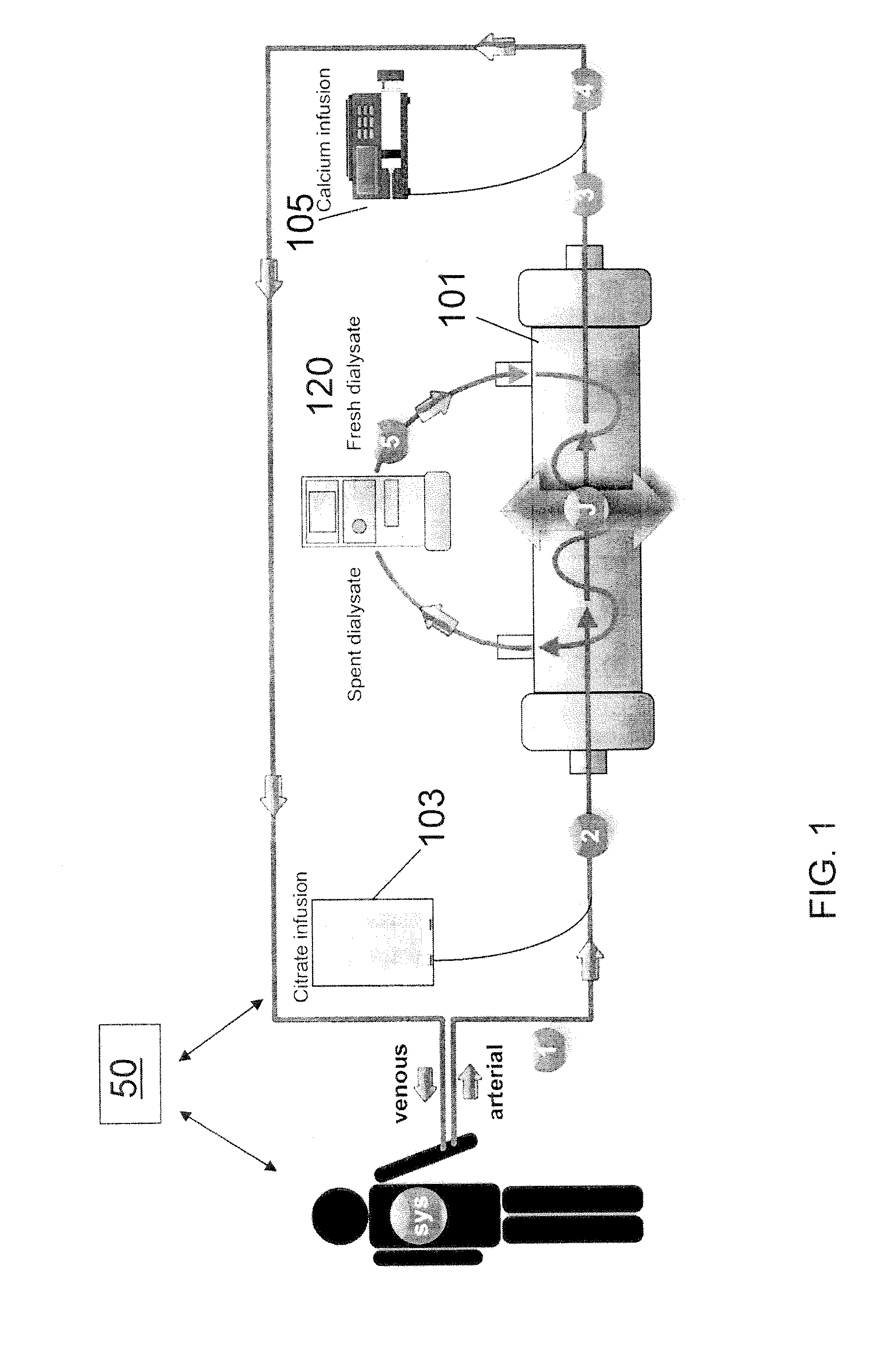

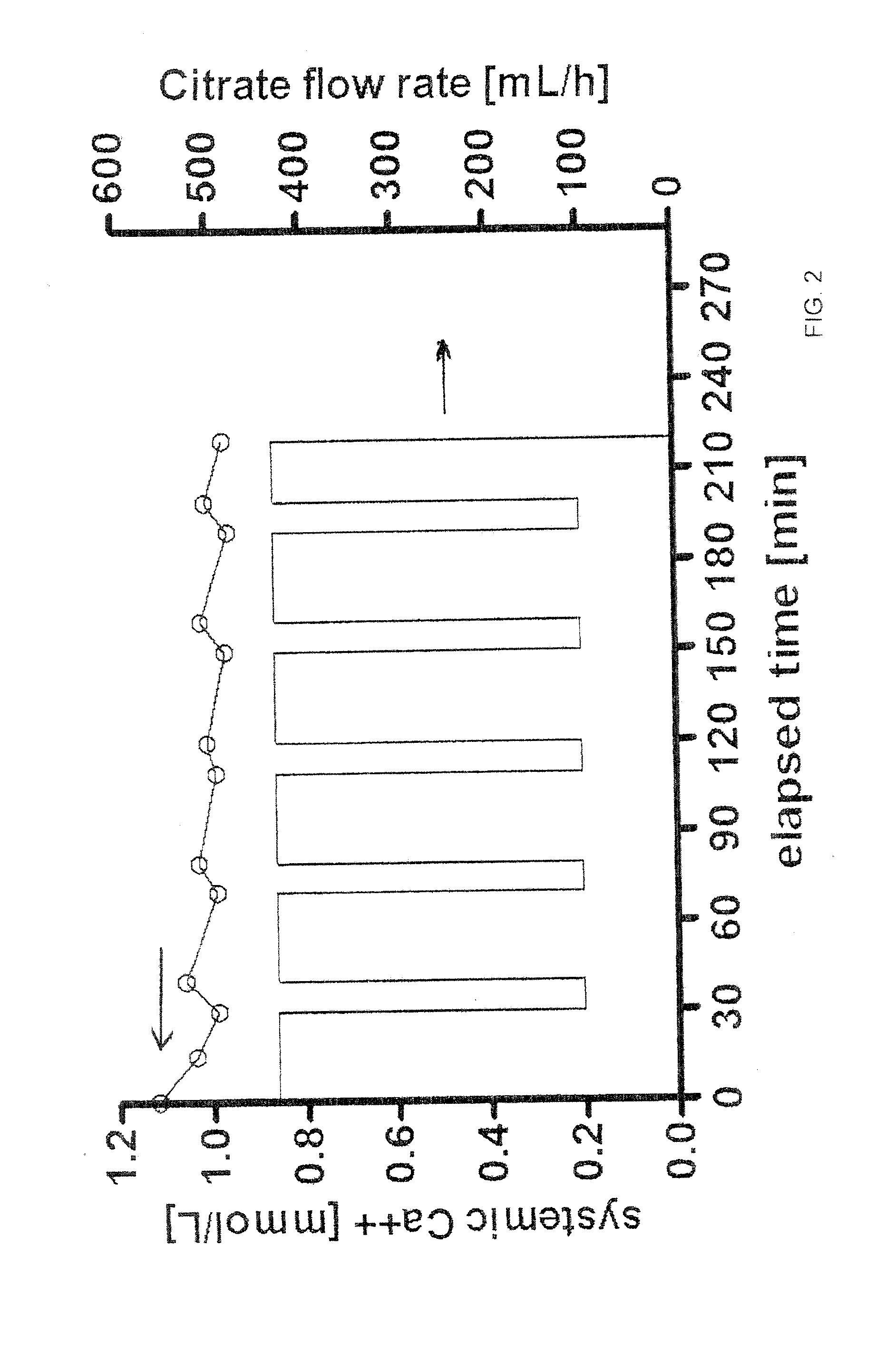

Methods of Regional Citrate Anticoagulation Dialysis

ActiveUS20110237996A1Eliminating well-known downsideEliminates potentialDialysis systemsMedical devicesDialysis membranesCITRATE ESTER

A method of performing regional citrate anticoagulant dialysis of a patient's blood includes flowing blood from and back to the patient through an extracorporeal circuit including a dialyzer having semi-permeable dialysis membranes and a dialysate chamber surrounding the membranes. The method further includes flowing a dialysate containing calcium and citrate through the dialysate chamber of the dialyzer and introducing citrate into the patient's blood upstream of the dialyzer, whereby the patient's blood is dialyzed. The method can further include predicting the concentration of systemic ionized calcium in the blood of the patient at any point in the dialysis treatment or post-dialysis, such as by a mathematical model. The method can further include statistically correcting the preliminary predicted post-dialysis concentration of systemic ionized calcium in the patient's blood to provide a final predicted post-dialysis systemic ionized calcium concentration. The method can further include statistically correcting the preliminary predicted systemic ionized calcium concentration for any time point during the dialysis treatment to provide a final predicted systemic ionized calcium concentration for that time point.

Owner:FRESENIUS MEDICAL CARE HLDG INC

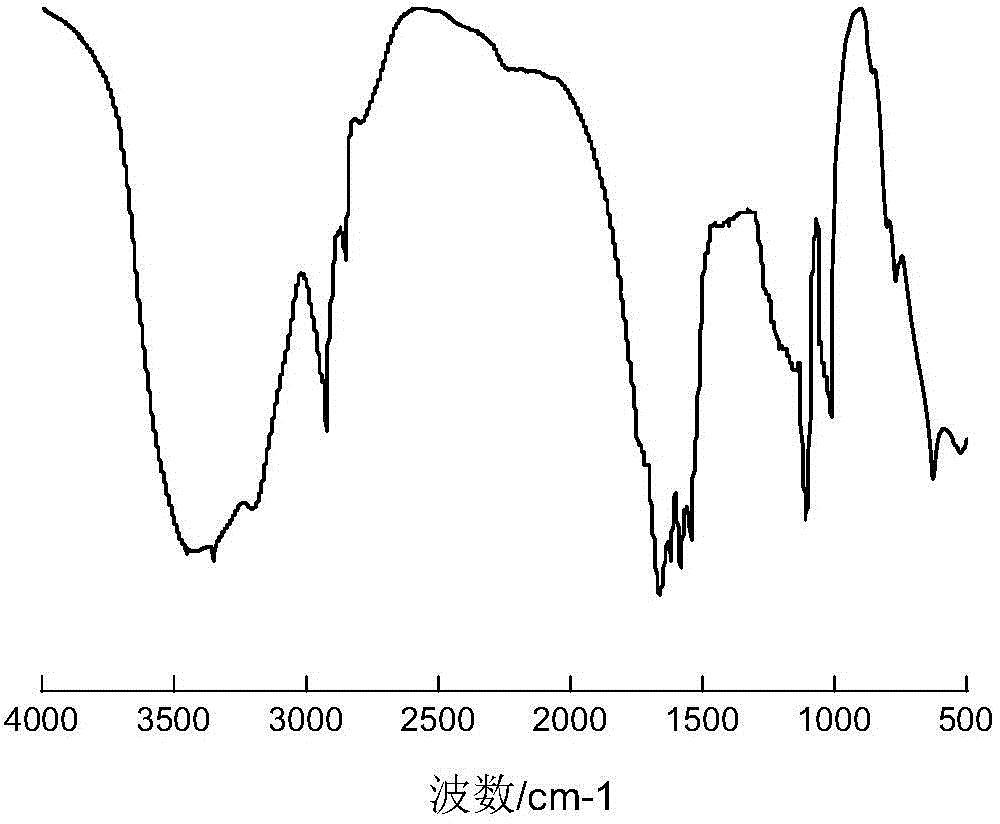

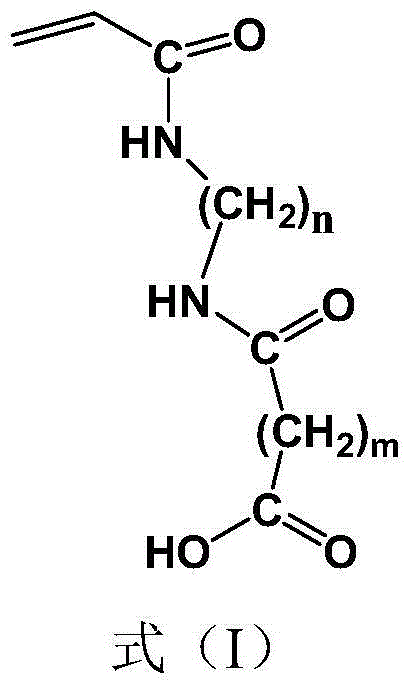

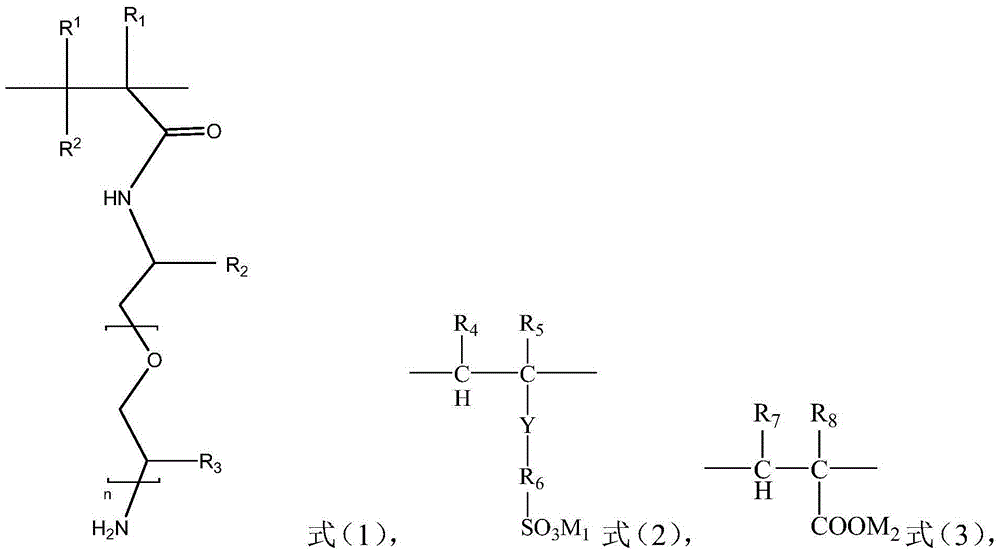

Acrylamide type polymer, preparation method and applications thereof

ActiveCN104926989AGood inhibition of hydration swellingInhibits hydration swellingDrilling compositionPolymer scienceStructural unit

The invention provides an acrylamide type polymer, a preparation method and applications thereof. The acrylamide type polymer comprises a structural unit represented by the formula (1), a structural unit represented by the formula (2), a structural unit represented by the formula (3), and a structural unit composed of nonionic monomers; wherein the mole ratio of the structural unit represented by the formula (1) to structural unit represented by the formula (2) to structural unit represented by the formula (3) to structural unit composed of nonionic monomers is (0.05-0.5):(0.1-0.4):(0.01-0.2):(0.1-0.5). The acrylamide type polymer has a strong performance on resisting temperature and salts and a strong inhibiting performance. The operation of the adopted preparation method is simple, the product quality is stable, and the polymer is pollution-free to the environment, has a good fluid loss reducing characteristic under the conditions of high temperature (180 DEG C), high salt content, and existence of high-valent ions (calcium and magnesium), and has a good tackifying effect in clay-free saltwater drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing porous carbon material from aluminum electrolysis waste cathode carbon

InactiveCN111792644AEasy to separateImprove etchabilityCarbon compoundsAluminium electrolysisEtching

The invention discloses a method for preparing a porous carbon material from aluminum electrolysis waste cathode carbon, wherein aluminum electrolysis waste cathode carbon is used as a raw material, and the purposes of fluorine fixation and etching are mainly realized through auxiliary treatment and reactant reaction, so that easy-to-separate porous carbon is obtained. According to the invention,soluble fluorine ions in waste cathode carbon are cured by utilizing calcium ions or magnesium ions in a calcium agent or a magnesium agent, oxygen ions and hydroxyl ions in the calcium agent or the magnesium agent are combined with sodium ions, potassium ions and lithium ions to form oxides and hydroxides with high etching property, so that in-situ hole etching is realized; water vapor generatedby auxiliary treatment or high-temperature decomposition of the calcium agent and the magnesium agent can react with insoluble aluminum fluoride and cryolite to generate hydrogen fluoride and aluminumoxide, so that the content of insoluble fluoride in the carbon is reduced; and air in auxiliary treatment can improve the etching property of a carbon skeleton, increase the wettability of a carbon interface and improve the separability of impurities, so that the content of the impurities in the carbon material is reduced.

Owner:ZHENGZHOU UNIV

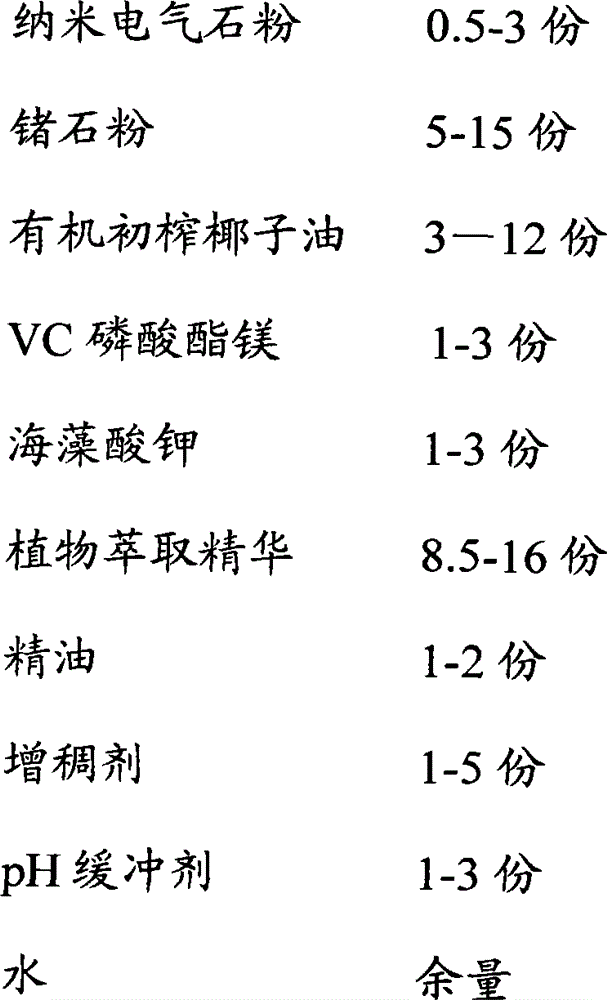

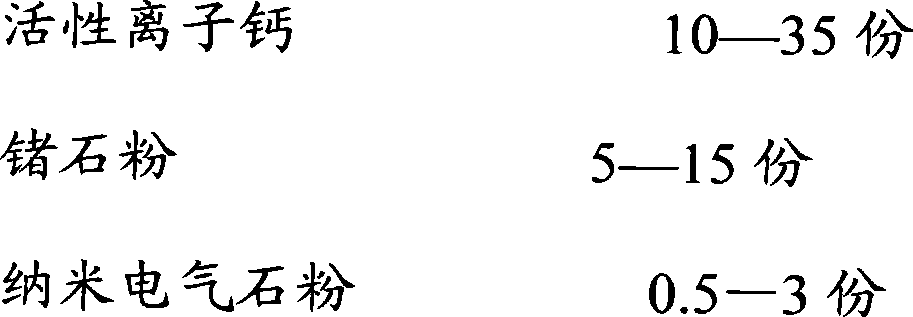

Mineral ion facial cleanser and preparation method thereof

ActiveCN103054786APromote absorptionBalance oil secretionCosmetic preparationsToilet preparationsCleansers skinFully developed

The invention provides a mineral ion facial cleanser which is mainly based on reasonable compatibility of activated ion calcium, germanium powder, nano tourmaline powder and plant extract essence, fully develops high ion activation energy contained in the activated ion calcium, is good in biodegradability, and meets the using requirements on health, maintenance and environment-friendliness. The selected activated ion calcium and the auxiliary ingredients are good in compatibility, do not generate any toxic and side effect, and can interact with one another to stabilize acid-base equilibrium.

Owner:青岛深海蓝金生物技术有限公司

Preparation method of lithium fluorosulfonate

ActiveCN112739652AIncrease optionalitySimple and safe operationSecondary cellsLithium halidesFluorosulfonateIon calcium

The invention discloses a preparation method of lithium fluorosulfonate, which comprises the following steps: (1) taking metal fluorosulfonate (MFSO3) with the purity of >=98.5% as a raw material, and carrying out metathesis exchange reaction with organic lithium salt in an ester, alcohol, nitrile or amide solvent; (2) generating insoluble organic metal salt precipitate, pumping in vacuum, extracting by using a poor solvent of an organic metal salt, filtering, separating, concentrating under reduced pressure, adding a low-polarity aprotic solvent into the concentrated solution, standing, crystallizing, and carrying out vacuum drying to obtain the high-purity lithium fluorosulfonate product. The preparation method of the high-purity lithium fluorosulfonate is simple in post-reaction treatment method, high in product yield, high in purity and capable of effectively reducing the content of impurities such as potassium ions, sodium ions, calcium ions, chloride ions and moisture in the product. The preparation method provided by the invention has the characteristics of simple operation steps, reasonable production cost, high safety, wide substrate selection range, low cost and high product purity.

Owner:ZHUHAI LEE & MAN MATERIALS SCI CO LTD +1

Silkworm nutrient solution

InactiveCN101116483AReduced food intakeReduce silkworm diseaseAnimal feeding stuffAccessory food factorsChelated calciumBombyx mori

A mulberry-silkworm nutrition liquid is provided, which is a novel product of nutrition liquid integrated with the alimentations respectively needed by the growth of the mulberry and the growth and silk-production of silkworm. The product is provided based on the research proving the actual effects. The product comprises the percentage by weight compositions of the components: 30 percent of amino acids (including amino acids from animal proteins and amino acids from vegetable proteins), 1percent of calcium (including chelated calcium, complexation calcium, and ion calcium), 0.5 percent of trace elements, 6*10-4 sodium selenite or sodium selenic, and 68.44 percent of water. The product is used to be sprayed on the mulberry leaves to increase the production volume, and is characterized in that the un-sprayed leaves can be sprayed indoors after picked to breed the silkworm and achieve the same effect as above.

Owner:林炳营

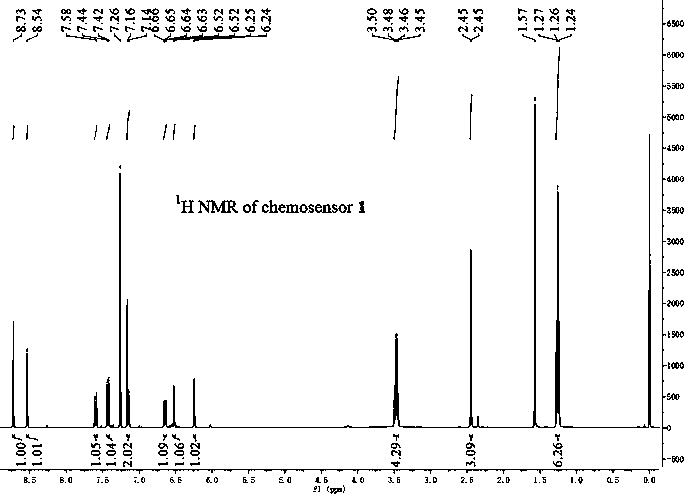

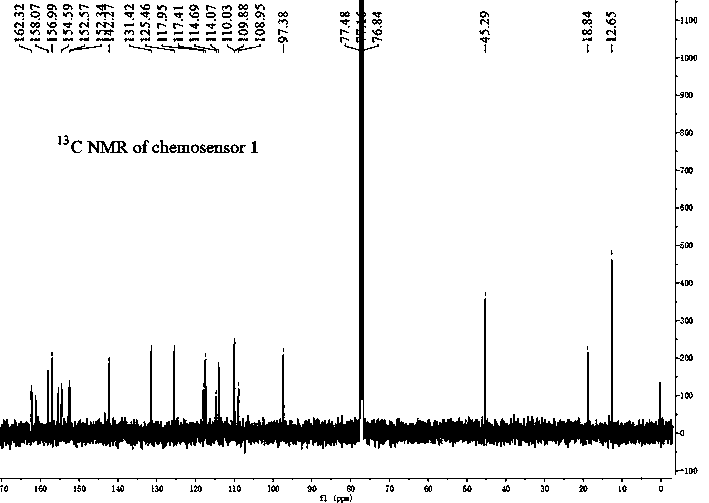

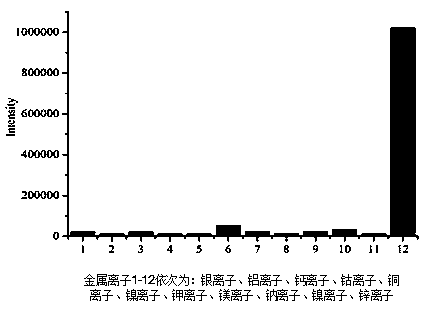

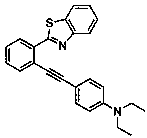

Novel iron ion fluorescence probe and preparation method thereof

ActiveCN108129435AHigh selectivityEnhancement phenomenonOrganic chemistryFluorescence/phosphorescenceAluminum IonMolecular Probe Techniques

The invention discloses a Nnovel iron ion fluorescence probe and a preparation method thereof, and belongs to the technical field of molecular probes. The structural formula of the probe is as follows: the preparation method of the iron ion fluorescence probe is simple. The probe detects iron ions by a mode of enhancing fluorescence and obviously changing color, the iron ions can be identified ina water system highly selectively, and other metal ions (silver ions, aluminum ions, calcium ions, cobalt ions, copper ions, nickel ions, potassium ions, magnesium ions, sodium ions, nickel ions and zinc ions) are not responded. The solution obtained by adding the probe in the water system is orange; after action of the solution and the iron ions, the fluorescence of the solution is obviously enhanced, the color is changed into yellow, the selectivity on the iron ions is high, the phenomenon is obvious and identification is facilitated.

Owner:UNIV OF JINAN

Low-yield paddy field plow layer soil-modifying fertilizer

InactiveCN101139230ABio-organic fraction processingOrganic fertiliser preparationPotassiumIon calcium

The present invention discloses a modified soil organic fertilizer, which is developed for overcoming the low output because of the lacked nutrient in the cultivated crops. After being test in the fields such as rice, vegetable and watermelon, the effect for increasing the output is greater. The organic substance material prepared in the product is organic substance of regenerated castoff in the city and town environment; the utilization cost for the castoff is much lower that is good for environment protection. The weight ratio in the product is that: 30 percent of organic substance in the soil, 6 percent of inorganic nutrient (wherein 2.5 percent of nitrogen, 1.5 percent of phosphor and 2 percent of kalium), 5 percent of calcium (including chelated calcium, complexing calcium and ion calcium), 10 percent of silicon and 0.5 percent of magnesium, zinc, manganese, molybdenum and selenium and so on. The weight ratio of the other filling materials is 48.5 percent (used for cultivated level soil or coated soil).

Owner:林炳营

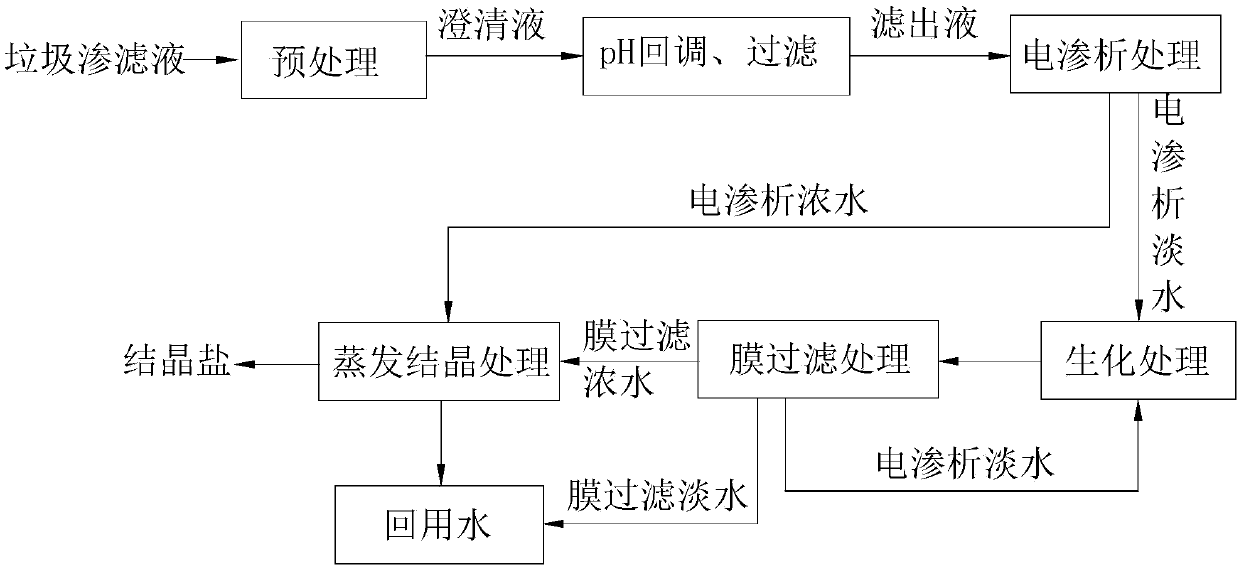

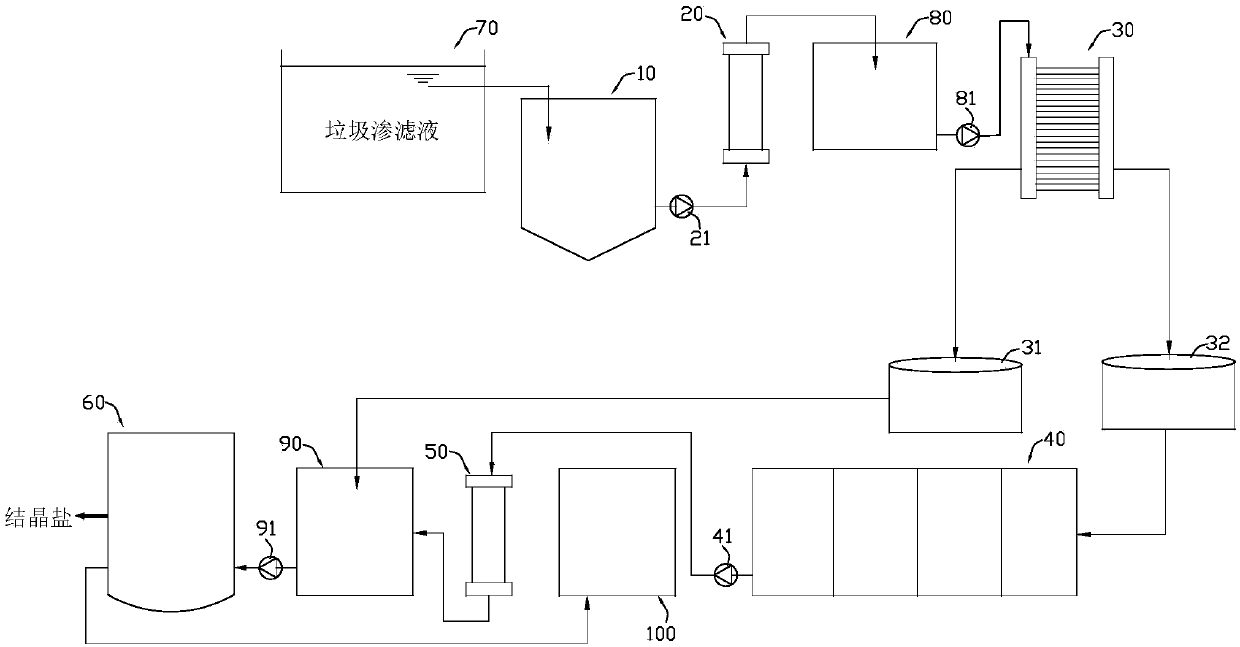

Landfill leachate treatment method and system

PendingCN107840537AReduce loadImprove stabilityWater treatment parameter controlWater contaminantsWater useSulfate radicals

The invention discloses a landfill leachate treatment method and system. The landfill leachate treatment method comprises the following steps: S1, pretreating landfill leachate to remove suspended solids, heavy metals, sulfate ions, calcium ions and magnesium ions so as to obtain clarified liquor; S2, performing pH regulation and filtration on the clarified liquor, and removing the residual suspended solids so as to obtain filtrate with SDI less than 3; S3, performing electrodialytic treatment on the filtrate so as to obtain electrodialytic concentrated water and electrodialytic fresh water; S4, performing biochemical and membrane filtration treatment on the electrodialytic fresh water so as to obtain membrane filtration concentrated water and membrane filtration produced water; and S5, performing evaporative crystallization treatment on the electrodialytic concentrated water and membrane filtration concentrated water, thereby obtaining crystalline salt and recycled water. According tothe method disclosed by the invention, the landfill leachate is subjected to treatments such as concentration and solid-liquid separation by virtue of a process combining pretreatment, filtration, electrodialysis, biochemical treatment and evaporative crystallization, so as to obtain the recyclable crystalline salt and the recycled water, zero wastewater emission and resource reutilization are realized, and the landfill leachate treatment method is environmental-friendly and has wide application prospects.

Owner:深圳能源资源综合开发有限公司

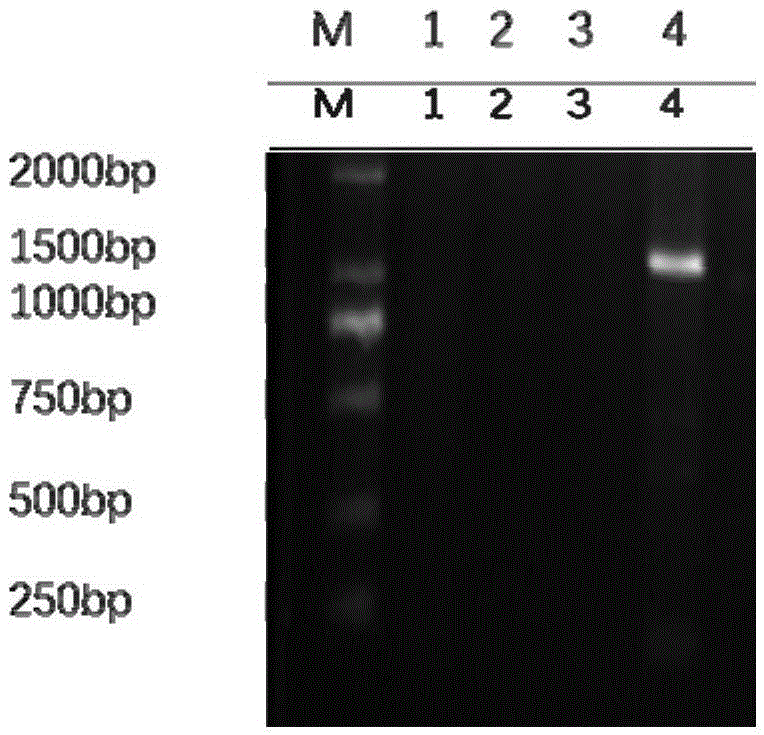

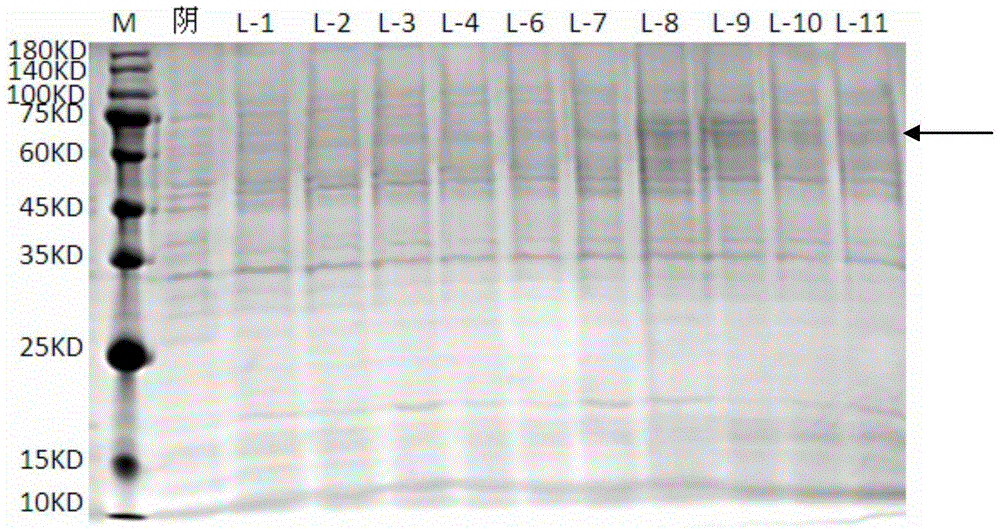

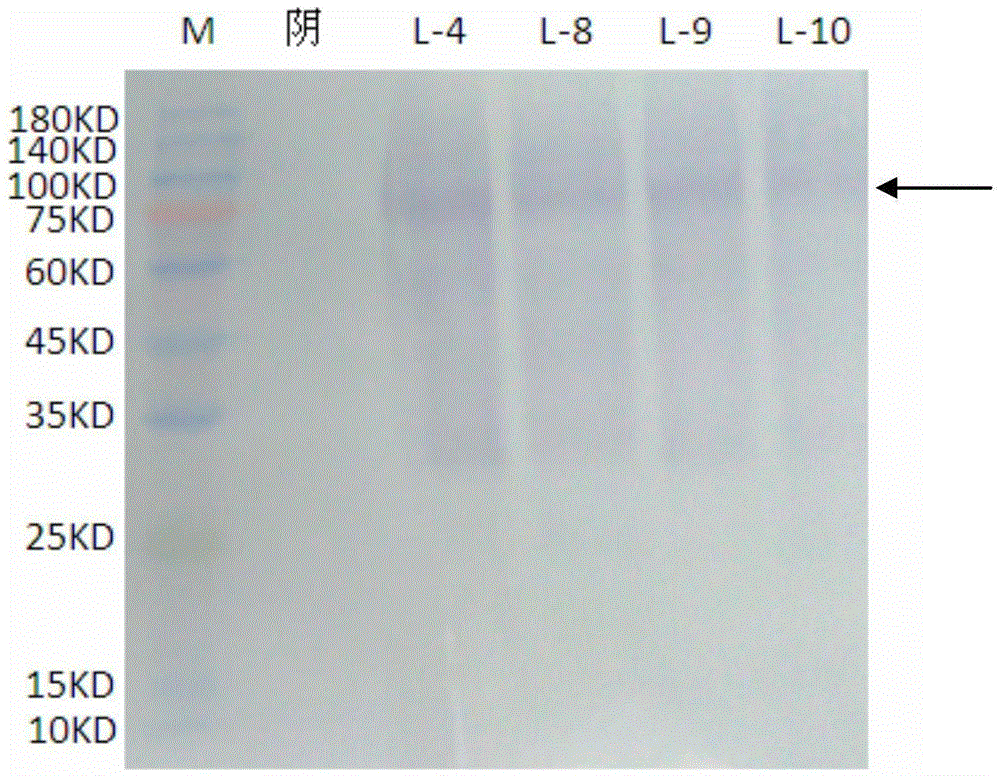

Armillariella tabescens laccase gene, recombined pichia pastoris engineering bacteria thereof and application

The invention discloses armillariella tabescens laccase and a gene thereof. The inventor constructs recombined pichia pastoris engineering bacteria according to armillariella tabescens laccase and the gene thereof. By using the engineering bacteria, efficient fermentation can be achieved for obtaining recombined armillariella tabescens laccase. On the basis of pichia pastoris heterologous expression, the inventor carries out purification and enzymology activity study on zymoprotein. The result shows that laccase has laccase activity, armillariella tabescens laccase or recombined armillariella tabescens laccase can catalyze 2,4-dichlorophenol degradation effectively, metallic copper ions have a function of promoting laccase activity, while manganese ions, zinc ions, magnesium ions, calcium ions, silver ions and SDS have a function of inhibiting activity. Stability analysis of prepared recombined laccase shows that stability of recombined laccase is good, acid environment tolerance is high, and application value is high.

Owner:GUANGXI UNIV

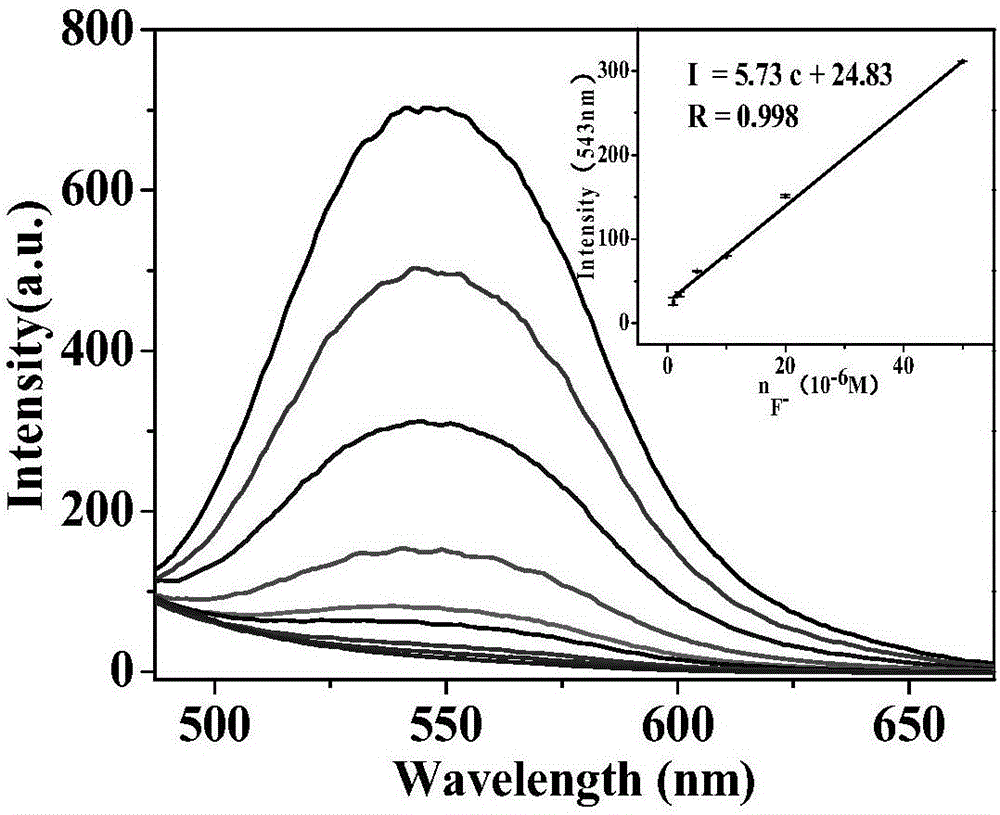

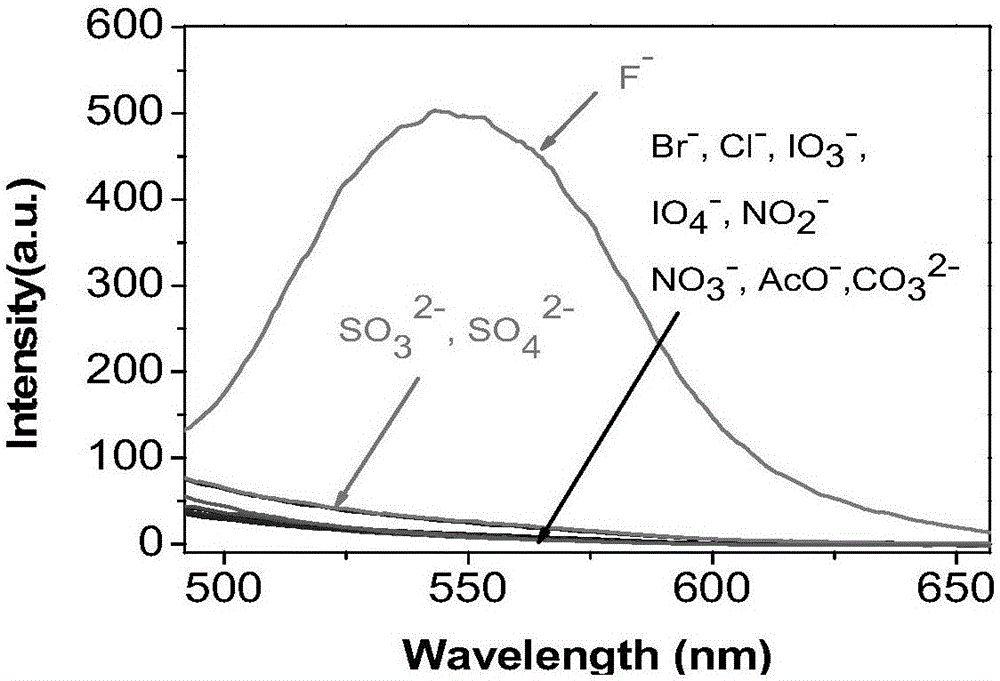

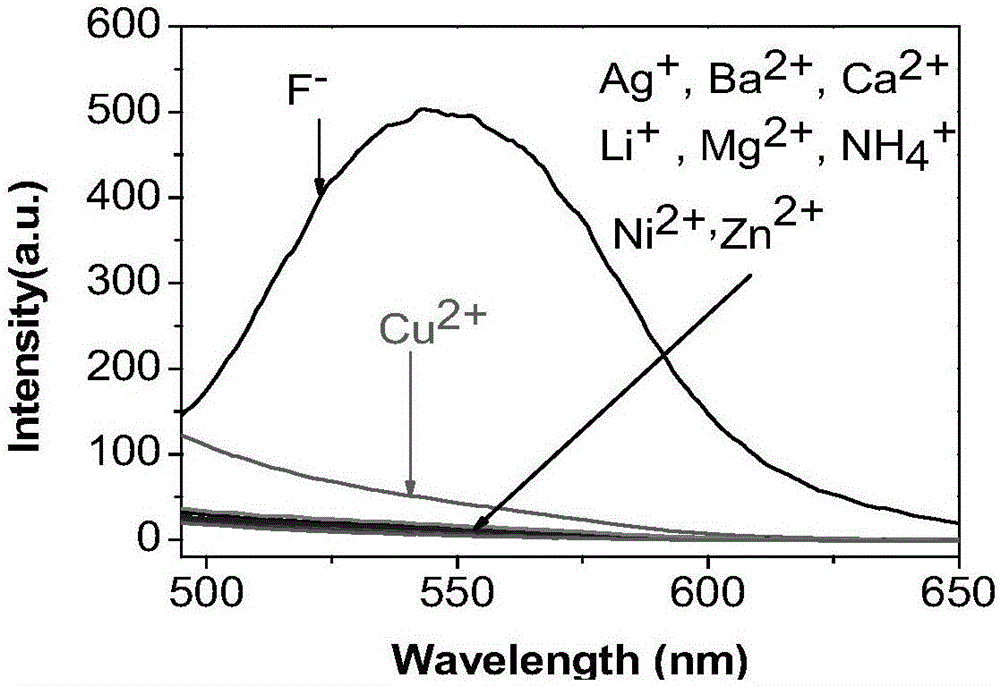

Fluorine ion detection probe based on aggregation-induced emission as well as preparation method and application of fluorine ion detection probe

ActiveCN106632450ASensitive recognitionStrong specificityGroup 4/14 element organic compoundsFluorescence/phosphorescenceFluoProbesFluorescence

The invention discloses a fluorine ion detection probe based on aggregation-induced emission as well as a preparation method and application of the fluorine ion detection probe. The structure of a fluorescent probe is shown as a formula (I); the fluorescent probe is formed by taking salicylic aldehyde as a raw material, forming salicylic aldehyde azine through the raw material and hydrazine hydrate and carrying out silicon protection. The probe disclosed by the invention has stable optical performances, high fluorine ion detection sensitivity and low detection lower limit; the detection limit is 1mu.M and a response range is 1mu.M to 50mu.M. The fluorine ion detection probe has good selectivity and no response on negative and positive ions including chlorine ions, bromine ions, iodate ions, periodate ions, nitrate ions, nitrite ions, acetate ions, carbonate ions, sulfate ions, sulfite ions, silver ions, barium ions, calcium ions, lithium ions, magnesium ions, ammonium ions, nickel ions, zinc ions and the like. The fluorine ion detection probe has the advantages of simple synthesis, moderate conditions and high yield. The fluorescent molecular probe has an actual application value in the fields of biochemistry and environmental chemistry, especially detection of fluorine ions in water and the like. (The formula (I) is shown as the description.).

Owner:HUNAN UNIV OF SCI & TECH

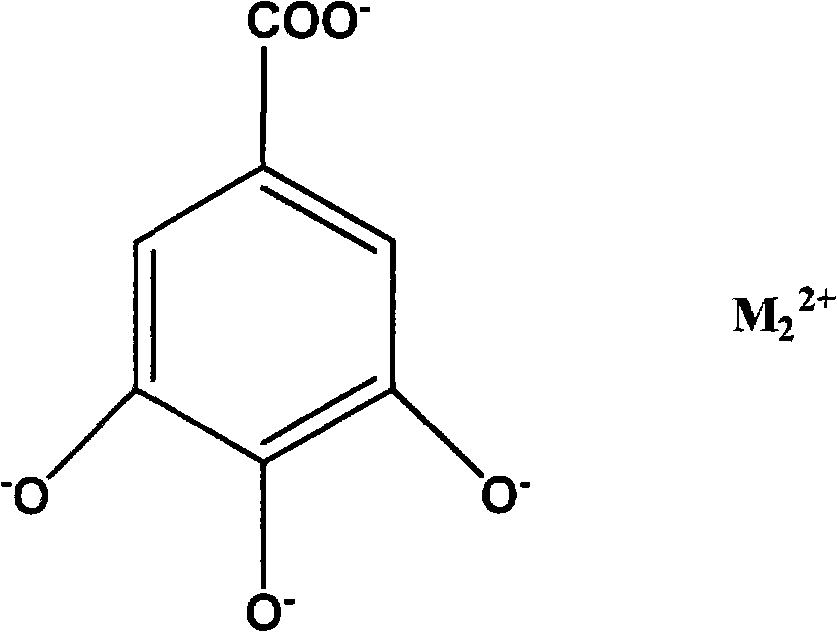

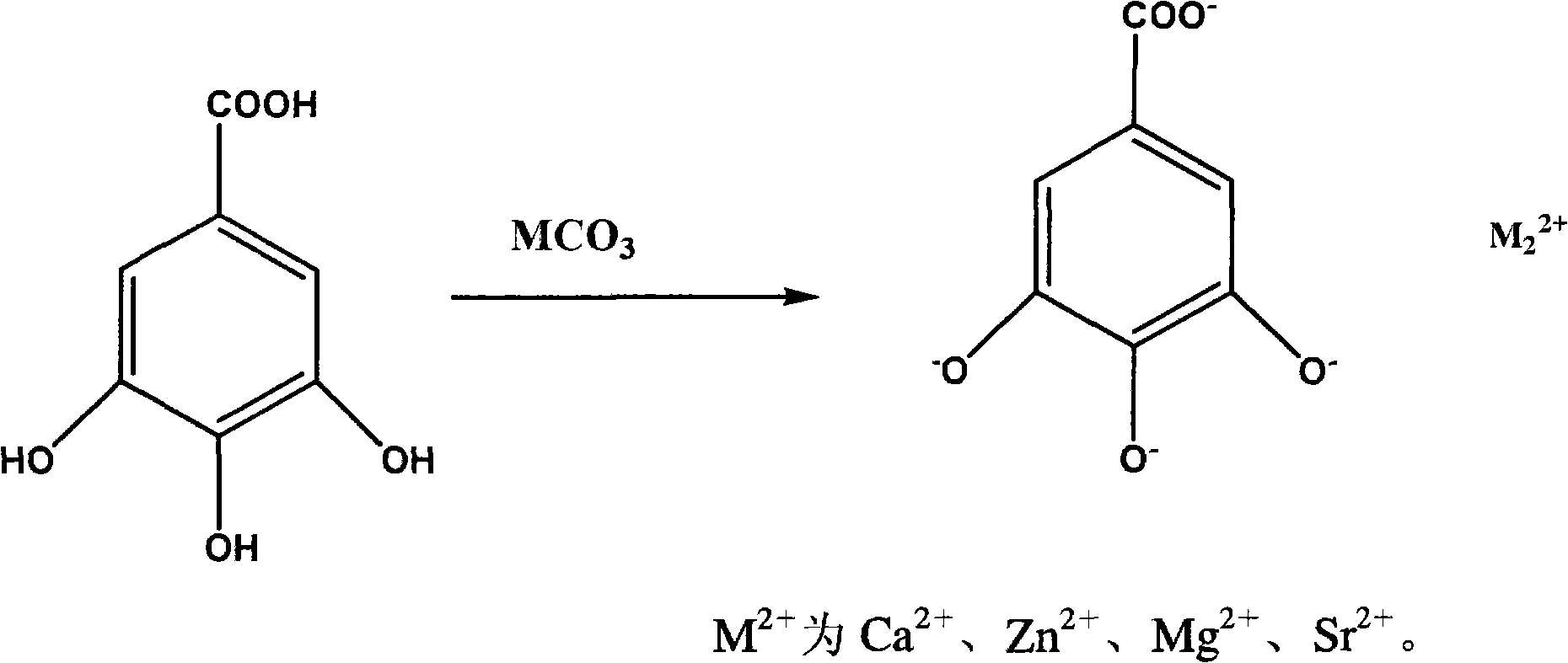

Gallic acid chelates composition and uses thereof

InactiveCN101327203AMutagenicImprove absorption rateOrganic active ingredientsMetabolism disorderGallic acid esterHigh absorption

The invention discloses a gallic acid chelate compound and an application thereof. The gallic acid chelate compound comprises 70 percent to 95 percent of calcium gallic acid chelate, 0 percent to 8 percent of zinc gallic acid chelate, 0 percent to 2 percent of magnesium gallic acid chelate, 0 percent to 2 percent of strontium gallic acid chelate and 5 percent to 18 percent of inulin. In the invention, the gallic acid chelate is in chelation reaction with the bivalent metallic ion calcium, zinc, magnesium and strontium to prepare the calcium gallic acid chelate, zinc gallic acid chelate, magnesium gallic acid chelate and strontium gallic acid chelate. The gallic acid chelate compound which is prepared through the mixing of the four chelates with the inulin according to a certain proportion can be used for treating and preventing acalcerosis or chlasma. The gallic acid chelate compound has the advantages of high absorption efficiency, low toxicity and cheapness, and meanwhile has the characteristics of antivirus, anti-tumor, anti-mutation and oxidation-resistant activities and a plurality of other physiological and pharmacological activities.

Owner:惠州市昆泰精细化工有限公司

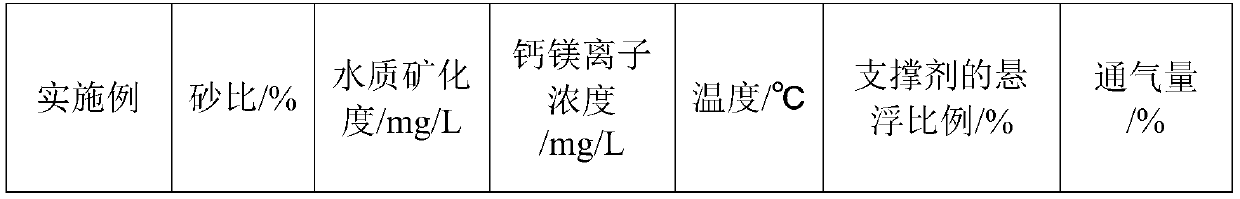

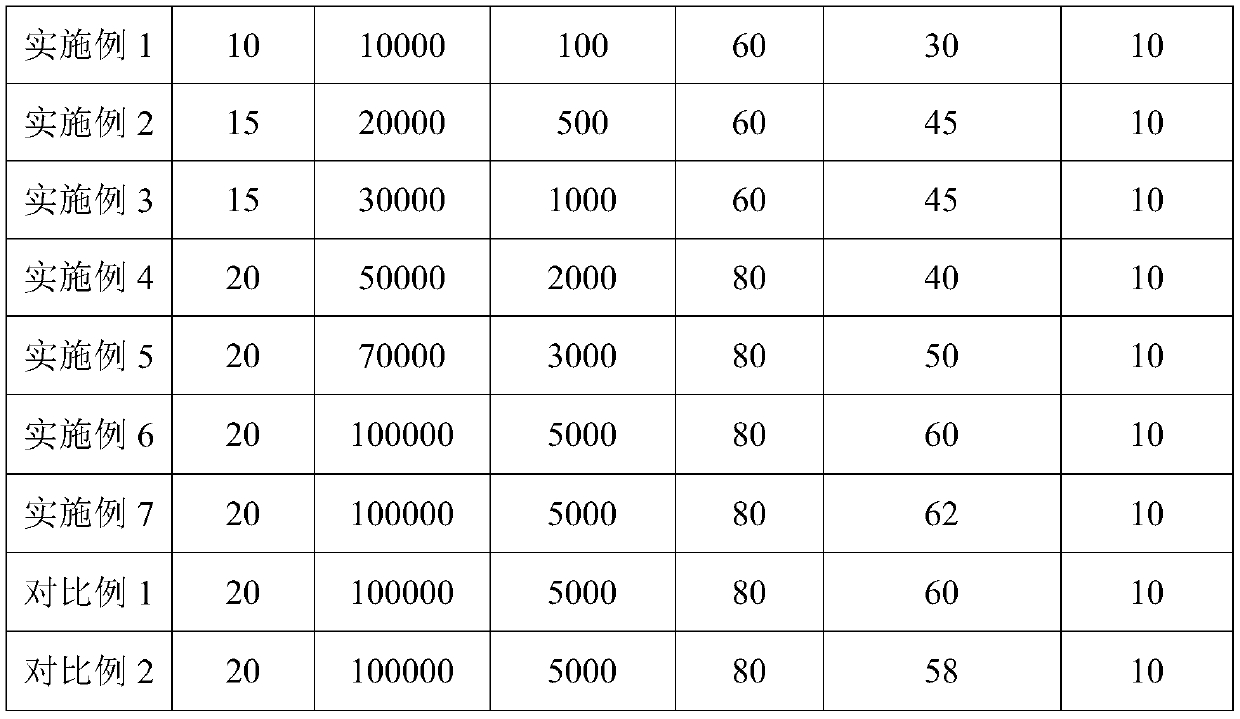

Salt-resistant suspending agent as well as preparation method and application thereof

InactiveCN111548783AStrong salt resistanceSimple preparation processFluid removalDrilling compositionSalt resistanceFoaming agent

The invention relates to a salt-resistant suspending agent as well as a preparation method and application thereof. The salt-resistant suspending agent is prepared from the following components in parts by volume: 0.01-2 parts of a surfactant; 0.01 to 0.5 part of a silane coupling agent; 0.05 to 0.5 part of a foaming agent; 0.1 to 3 parts of a foam stabilizer; 0.4-4 parts of a dispersing agent; 0.5 to 3 parts of a hydrophobic agent; 0.01 to 0.1 part of a pH adjusting agent; and 15-20 parts of water. The salt-resistant suspending agent provided by the invention has good salt resistance, is relatively low in viscosity (less than 5mPa. S), and can be used for realizing a relatively good suspending effect under the conditions that the mineralization degree is 300-100000mg / L, the concentrationof divalent cations (calcium and magnesium) is 10-5000mg / L and nitrogen is introduced.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

Method for treating wastewater after ore leaching and ore closing of ionic rare earth ore

InactiveCN112456620ARealize harmless dischargeEnable recyclingCalcium/strontium/barium chloridesWater contaminantsAluminium chlorideMining engineering

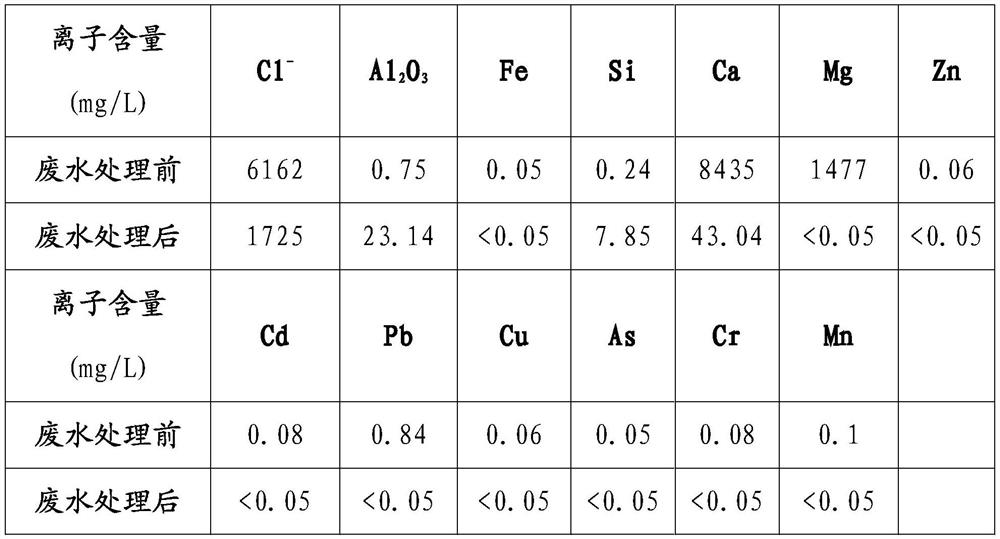

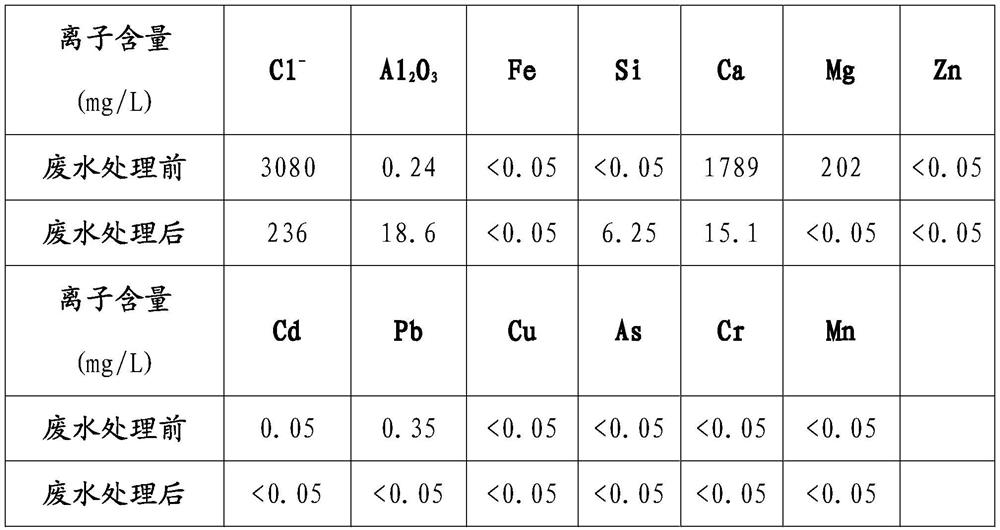

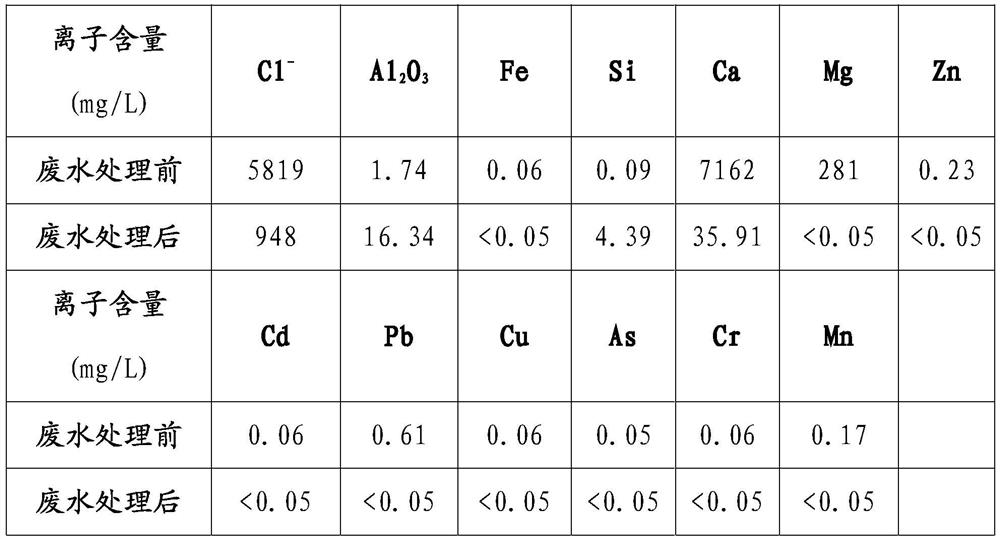

The invention discloses a method for treating wastewater after ore leaching and ore closing of ionic rare earth ores. The method comprises the following steps: S1, taking ore leaching tail liquid, precipitation supernatant and product water washing liquid generated in an ore leaching process of ionic rare earth ores as raw materials, and determining the concentrations of rare earth ions, chlorineions, calcium ions and aluminum ions and the concentrations of other non-rare earth ions and heavy metal ions in the wastewater; S2, adding lime and sodium metaaluminate into the wastewater until themass ratio of Ca<2+> to Al<3+> to Cl<-> in the wastewater is (9-12):(1.5-2):1, stirring for reaction, and filtering; and S3, filtering to obtain a Fremys salt precipitate, and decomposing with hydrochloric acid to obtain a solution containing calcium chloride and aluminum chloride. According to the method, calcium salt, aluminum salt and chlorine ions in closed ore waste water are converted into Fremys salts to achieve recycling of an ore leaching agent while the content of the chlorine ions and the content of heavy metal Zn, Cd, Pb, Cu, As, Cr and Mn in the wastewater are reduced to achieve the harmless discharge of the wastewater, and the mining area environment influence after ore closing is small, so that efficient and environment-friendly extraction of ionic rare earth can be achieved.

Owner:LONGNAN COUNTY NANYU RARE EARTH RESOURCES COMPREHENSIVE UTILIZATION CO LTD +2

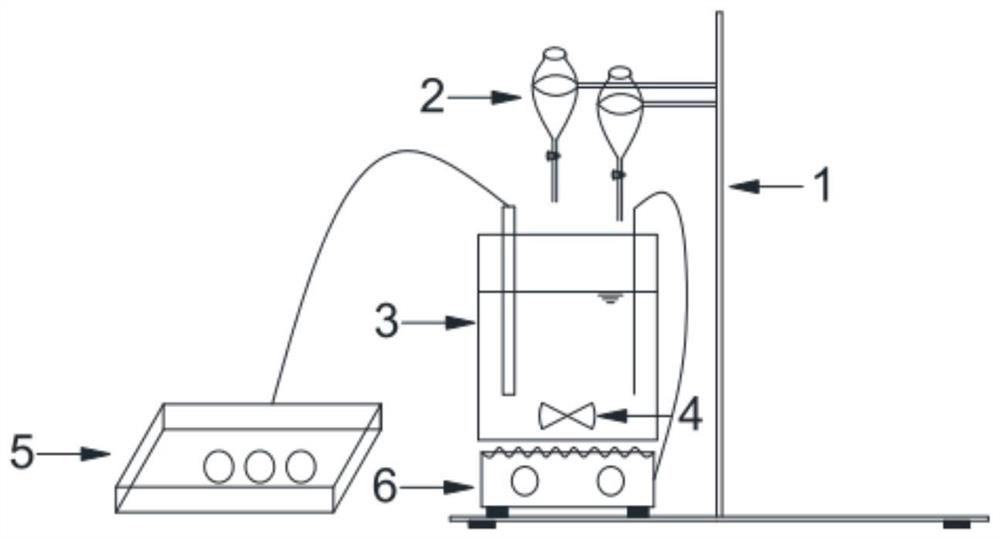

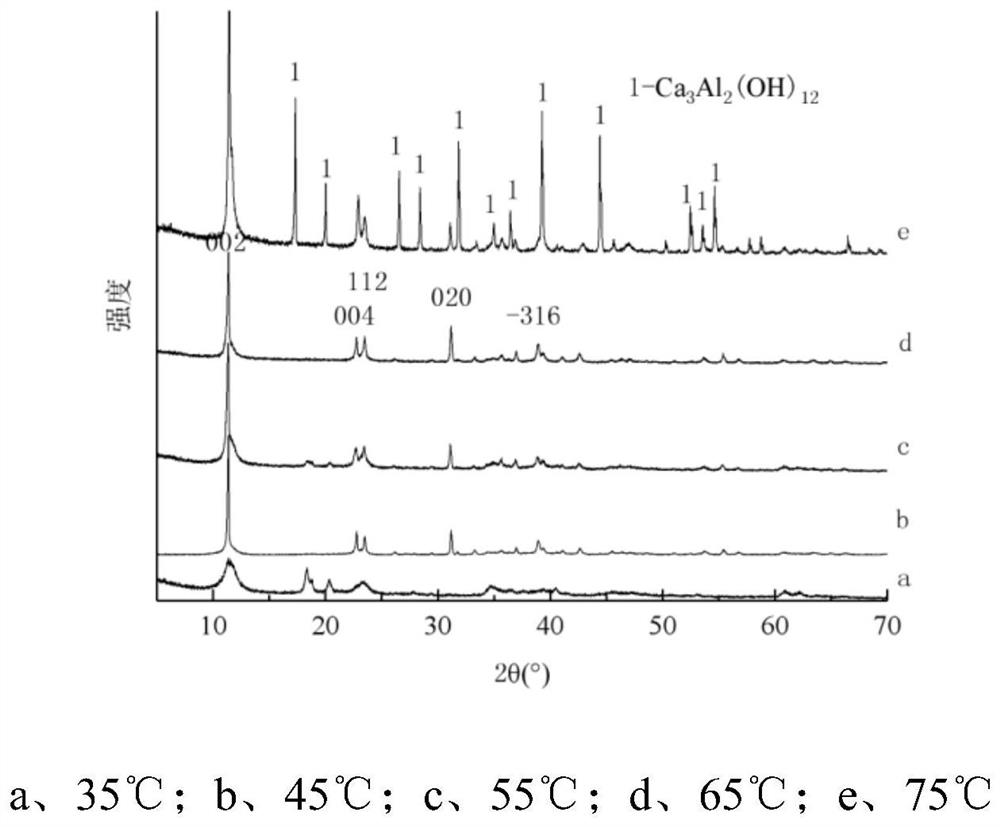

Preparation method of roasted calcium-magnesium-aluminum-based LDHs and application of roasted calcium-magnesium-aluminum-based LDHs in phosphorus removal

PendingCN112108106AImprove adsorption capacitySolve pollutionOther chemical processesWater contaminantsIon calciumDivalent

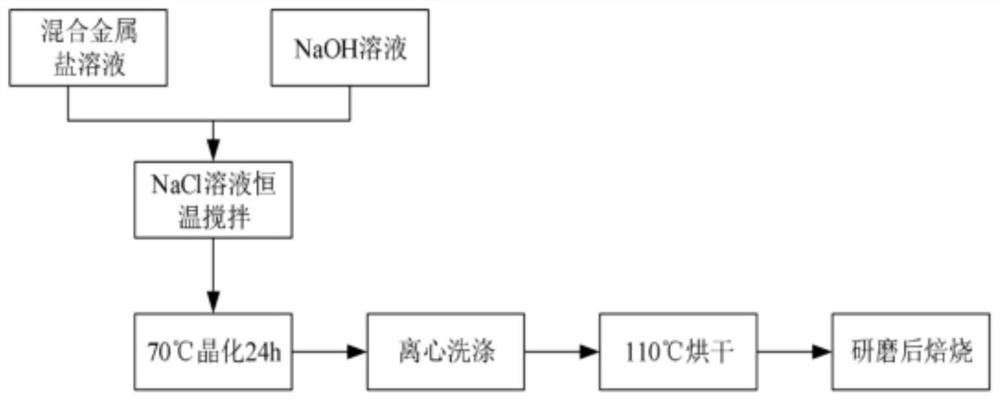

The invention discloses a preparation method of roasted calcium-magnesium-aluminum-based LDHs and application of the roasted calcium-magnesium-aluminum-based LDHs in phosphorus removal. The preparation method comprises the following steps: (a) preparing a mixed metal salt solution according to a certain molar ratio of divalent metal cations to trivalent metal cations, namely calcium, magnesium andaluminum, wherein a NaOH solution is used as a precipitant; (b) dropwise adding the mixed metal salt solution and the NaOH solution into a beaker containing a NaCl solution together, conducting stirring at a constant temperature within a set certain temperature range, controlling the titration speed of the mixed metal salt solution, stopping titration after the mixed metal salt solution is titrated, and continuing stirring at a constant temperature; and (c) carrying out water-bath crystallization for a period of time at a certain temperature, then centrifugally washing an obtained material with distilled water until no Cl is detected in a supernate, carrying out forced air drying,conducting grinding, and performing roasting at a certain temperature to obtain the roasted calcium-magnesium-aluminum-based LDHs. The preparation method is relatively simple, the phosphorus adsorption capacity of the obtained adsorbent is huge, and the adsorbent has good adsorption kinetics performance and can be applied to treatment of industrial and agricultural phosphorus-containing wastewater and emergency pollution treatment of phosphorus in ecological environment protection.

Owner:LIAONING TECHNICAL UNIVERSITY +2

Method for preparing D-arabinose

InactiveCN101845065ANo pollution in the processReduce labor intensitySugar derivativesSugar derivatives preparationArabinoseGluconates

The invention provides a method for preparing D-arabinose, which mainly comprises the following steps of: (1) preparing an iron-containing ion-calcium ion zeolite oxidation catalyst; (2) catalyzing hydrogen peroxide by using the prepared catalyst to oxidize gluconate so as to prepare the D-arabinose; and (3) reclaiming the catalyst, and removing the leaked iron ions and calcium ions. The method does not produce pollution on the environment, prepares product with good and stable quality, and is suitable for large-scale industrialized production.

Owner:YICHANG TIANCHU CHEM

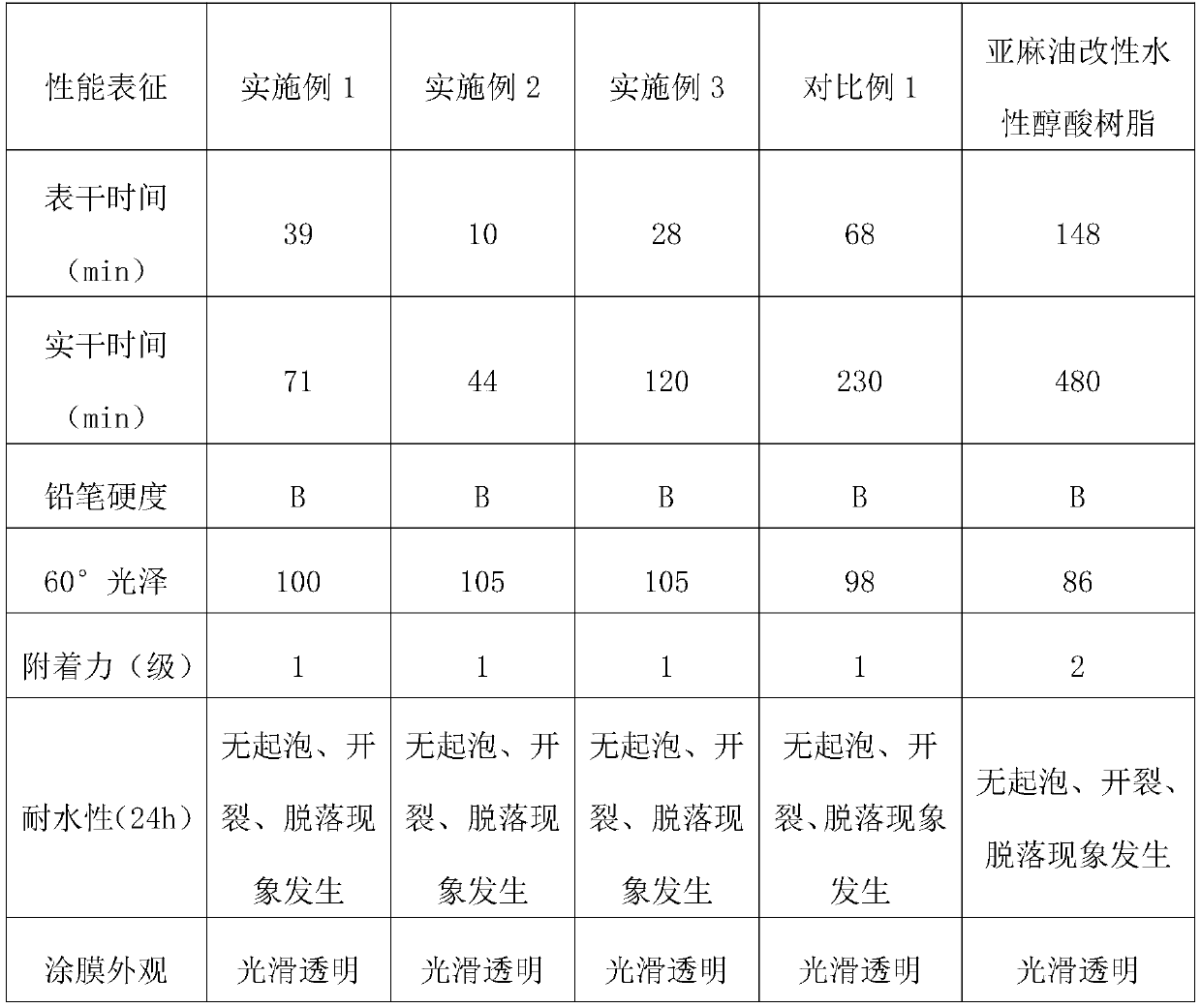

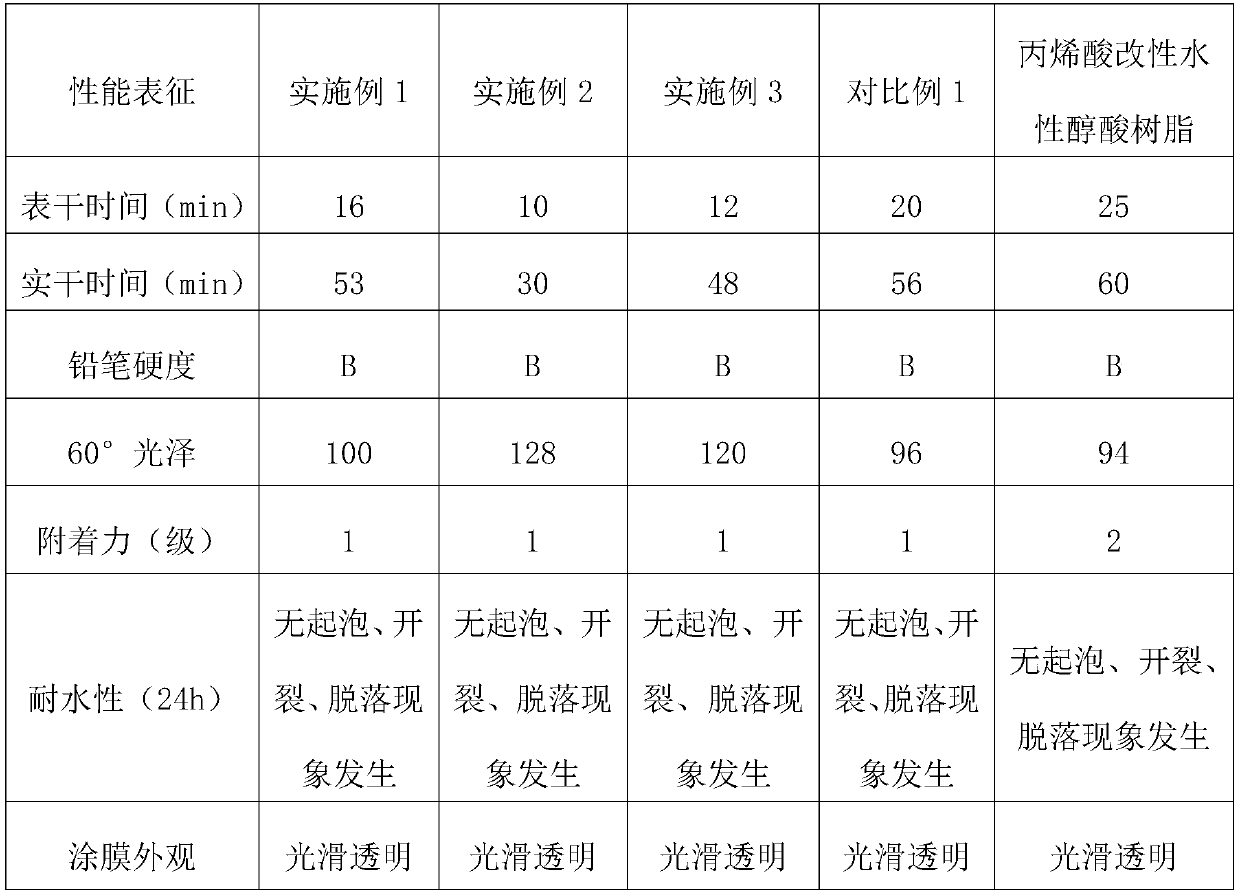

Aqueous composite drier and preparation method thereof

InactiveCN110760213AGood water solubilityImprove solubilitySiccativesEpoxy resin coatingsPhysical chemistryAqueous solubility

The invention belongs to the technical field of driers, and particularly relates to an aqueous composite drier and a preparation method thereof. In the composition provided by the invention, metal salts have a certain promotion effect with each other, so that an intermolecular structure tends to be developed towards a direction of water solubility, then a stable state structure with good water solubility is formed, and dissolution in water is facilitated. According to the invention, cobalt ions, zirconium ions and calcium ions are added into the composition, and uniformity of surface drying and interior drying is established in a paint film through a synergistic effect among different metals, so that stability of paint storage is improved, and leveling property, gloss property and hardnessof the paint film are improved. According to the invention, activity of the cobalt ions can be increased through existence of a zirconium salt drier and a calcium salt drier, drying ability of the composition is improved, and thus the paint film can be quickly dried; and through addition of a calcium salt, the composition is not easily oxidized or reduced, and can be adsorbed on the surface of apigment filler, so that the drying speed of the whole system is slowed down after the drier is adsorbed by the pigment filler.

Owner:沈阳澳宇化工有限公司

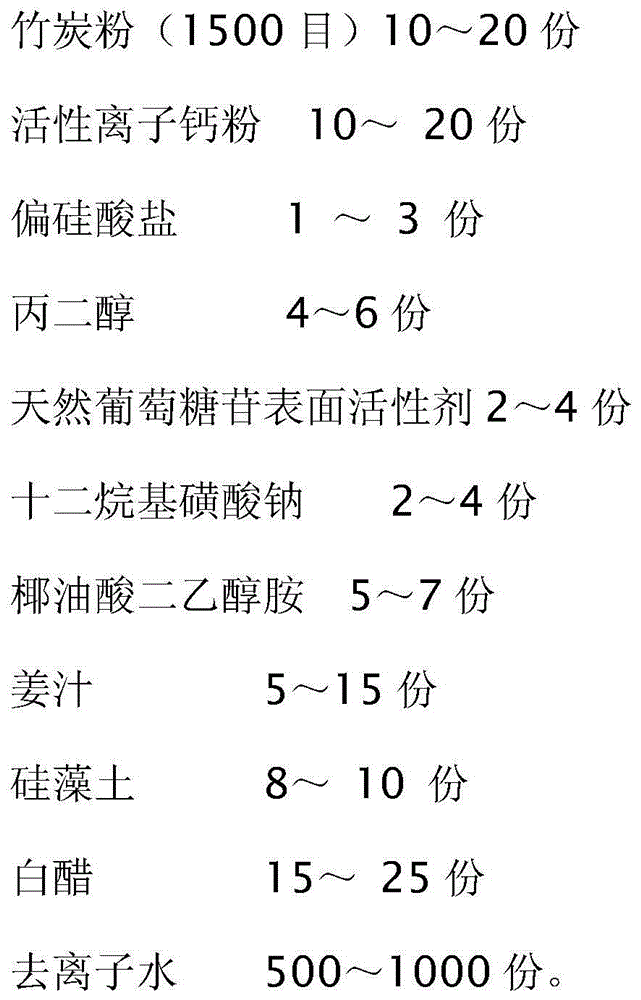

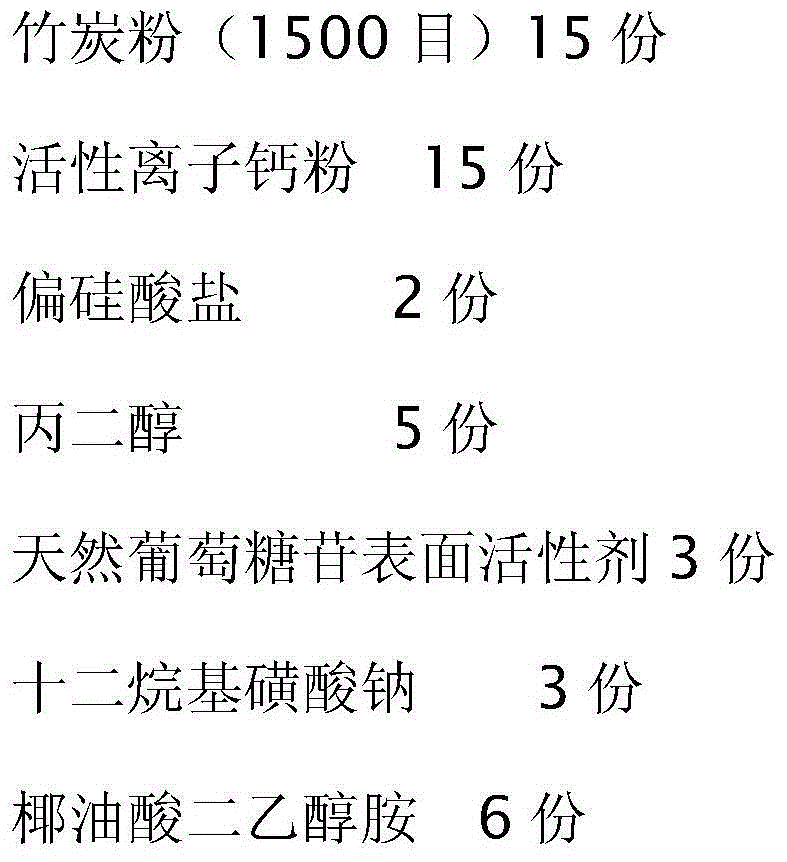

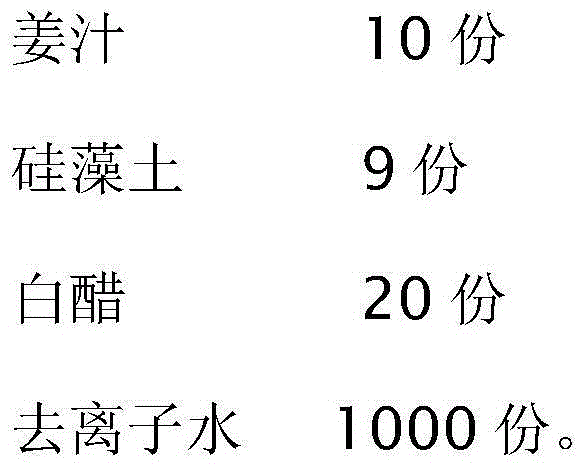

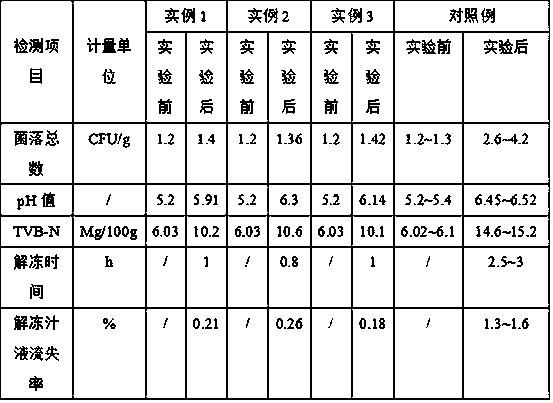

Fruit surface cleaning agent and preparation method thereof

InactiveCN104479930AGood removal effectQuick and effective removalSurface-active non-soap compounds and soap mixture detergentsPesticide residueSurface cleaning

The invention relates to a fruit surface cleaning agent consisting of the following components in parts by weight: bamboo charcoal powder (1500 meshes), active ion calcium powder, metasilicate, propylene glycol, a natural glucoside surfactant, dodecyl sodium sulfate, coconut oleic acid diethanolamine, a ginger juice, diatomite, white vinegar and deionized water. The fruit surface cleaning agent provided by the invention has the following beneficial effects that the components of the cleaning agent are nontoxic and harmless to human bodies, and the cleaning agent does not have residues, has a good removal effect, and can quickly and effectively remove wax on fruit surfaces. When the cleaning agent is used for cleaning wax layers, pesticide residues on the fruit surfaces can also be cleaned, so that the fruit can be cleaned up. The fruit surface cleaning agent provided by the invention is low in cost, convenient to popularize and use and easy to decompose after being used, and cannot generate secondary pollution.

Owner:青岛市市南区隆德中医药研究所

Nutrient salt balancing method for low-salinity circulating water used for penaeus vannamei culture

InactiveCN110839574AGood experimental foundationGood scientific basisClimate change adaptationPisciculture and aquariaSulfate radicalsBorate ion

The invention discloses a nutrient salt balancing method for low-salinity circulating water used for penaeus vannamei culture. The nutrient salt balancing method is realized by adjusting the concentration of main ions. The main ion concentrations of the water body are: 0.2-0.4g / L of calcium ion, 0.6-1.5g / L of magnesium ion, 0.07-0.15g / L of potassium ion, 3-5g / L of sodium ion, 2-5g / L of chloride ion, 0.5-1g / L of sulfate ion, 0.02-0.04g / L of carbonate ion, 0.2-0.5g / L of bicarbonate ion, 0.02-0.04g / L of bromide ion and 0.05-0.1g / L of borate ion; and the ratio of the calcium ion to magnesium ion is 1: 3-5. The nutrient salt balancing method of the low-salinity circulating water is used for penaeus vannamei culture, the yield of the penaeus vannamei reaches 6-7kg / m3, the survival rate of the penaeus vannamei is high, the growth is fast, and the culture range of the penaeus vannamei is effectively widened, so that the method plays a greater role in promoting the development of the culture ofthe penaeus vannamei.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Unfreezing method of frozen meat

InactiveCN107624861AImprove electrolysis efficiencyInhibition of fat activityMeat/fish preservation by freezing/coolingElectrolysisAmmonium nitrate

The invention belongs to the technical field of unfreezing of meat products, and particularly relates to an unfreezing method of frozen meat. According to the unfreezing method disclosed by the invention, cactuses are subjected to extraction so that a soaking solution is obtained, the frozen meat is protected with the soaking solution, the fat activity is restrained, and running off is avoided; inaddition, an antibacterial film is formed on the surface of the frozen meat to protect the frozen meat, so that bacterium resistance is improved, and infection is avoided; in addition, calcium oxideis made into calcium hydroxide for heat release, so that the frozen meat is preliminarily unfrozen, then an acid is used, calcium chloride is formed, and calcium ions are increased and are adhered onto protein to protect the protein; in addition, electrolytic efficiency is improved through adhered calcium ions; and finally, ammonium nitrate is added for electrolysis and heat release, further through the effects of heat release and electricity, crystal water in the frozen meat is destroyed, besides, nutrient substances are protected through ascorbic acid, running off is avoided, and unfreezingis effectively performed.

Owner:薛银福

Treatment agent and treatment method of fracturing flow-back fluid

InactiveCN110937669ARapid sterilizationAchieve reuseWaste water treatment from quariesWater/sewage treatment using germicide/oligodynamic-processOrganic acidPhysical chemistry

The invention provides a treatment agent and a treatment method of a fracturing flow-back fluid. The treatment agent comprises chlorite and organic acid. By adopting the treatment agent provided by the invention, the purposes of rapidly killing bacteria and simultaneously removing sulfide, ferrous ions, iron ions, calcium ions, magnesium ions and suspended solids can be achieved. Meanwhile, the invention further provides a method for treating the fracturing flow-back fluid through the treatment agent. The method is simple in process and low in cost and realizes resource recycling; and the treatment agent does not have adverse effects on the performance of the subsequently-prepared fracturing fluid even if residues exist.

Owner:PETROCHINA CO LTD

Bath cream with purely natural extractives and preparation method thereof

InactiveCN104367520AGood compatibilityReduce pollutionCosmetic preparationsToilet preparationsSodium bicarbonateSide effect

The invention relates to a bath cream with purely natural extractives. The bath cream comprises the following components in parts by weight: active ion calcium powder, germanite powder, nano tourmaline powder, fatty glyceride, potassium alginate, sodium bicarbonate, a red clover extractive, a tribulus terrestris extractive, a natural basil extractive, fennel essential oil, semen armeniacse dalce oil, sodium polyacrylate and deionized water. The bath cream with mineral ions is reasonable in compatibility; the high ion activation energy generated by active ion calcium can be fully exerted; the bath cream is high in biodegradability; the use requirements of health, maintenance and environmental protection can be met; the selected active ion calcium and auxiliary material component are high in compatibility; no toxic or side effect is derived; the interaction is achieved; the acid-base balance is stabilized; the bath cream brings benefits to the health of the personal hygiene and the reduction of environmental pollution of domestic life.

Owner:青岛市市南区隆德中医药研究所

A compound traditional Chinese medicine composition for treating sexually transmitted diseases and its application

ActiveCN103110748BClean up thoroughlyFast effectOrganic active ingredientsAntiviralsAdditive ingredientIrritation

The invention provides a compound traditional Chinese medical composition which comprises the following components: active ion calcium, podophyllotoxin extract, lygodium japonicum extract, macleaya cordata extract, oleuropein, polygonum cuspidatum extract, usnic acid, essential oil of chaste tree, organic tea tree essential oil, Eastern Indian sandalwood essential oil, sea salt and medical citric acid. The compound traditional Chinese medical composition provided by the invention has superior curative effect and generalization performance and is used as an external medicine which is directly effected on sebaceous gland and mucosa, and is not harmful to a body, not irritant and not allergic. The compound traditional Chinese medical composition not only has positive energy formula of mineral components, but also maintains unique effect of Chinese herbal medicines, and the compound traditional Chinese medical composition is free from any irritation and harm. The compound traditional Chinese medical composition is a pure natural green therapy for removing secret sorrow.

Owner:隋丽梅

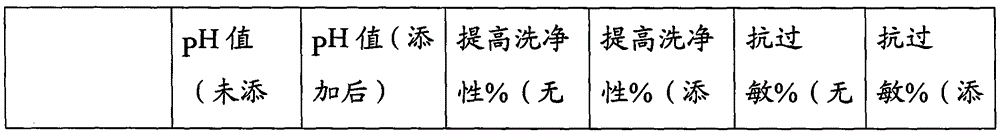

Liquid shampoo and manufacturing method thereof

InactiveCN104983603AReduce the phenomenon of dust absorptionReduce generationCosmetic preparationsHair cosmeticsPolymer scienceActive agent

The invention discloses a liquid shampoo and a manufacturing method thereof. The liquid shampoo comprises, 0.1-0.3 part of cationic guar gum, 100 parts of softened water, 0.2-0.6 part of dodecyl alcohol ether ammonium sulfate, 0.15-0.45 part of natural fat alcohol ether ammonium sulfate, 0.1-0.3 part of docosyl trimethyl ammonium chloride, 1-3 parts of a surface active agent, 2-6 parts of an anti-dandruff agent, 0.5-1.5 parts of pearly lustre thick liquid, 2-6 parts of organic silicon emulsion, 5-8 parts of a nonionic surface active agent, 2-5 parts of protein polymers, 10-12 parts of a softener, 15-20 parts of essence, 0.2-0.3 part of cocinic acid monoethanol amide, 0.15-0.35 part of coco glucoside diacetic acid amide, 10-20 parts of vitamin E, 2-3 parts of an ionized calcium water solubility preparation and 1200 parts of distilled water.

Owner:舒文一

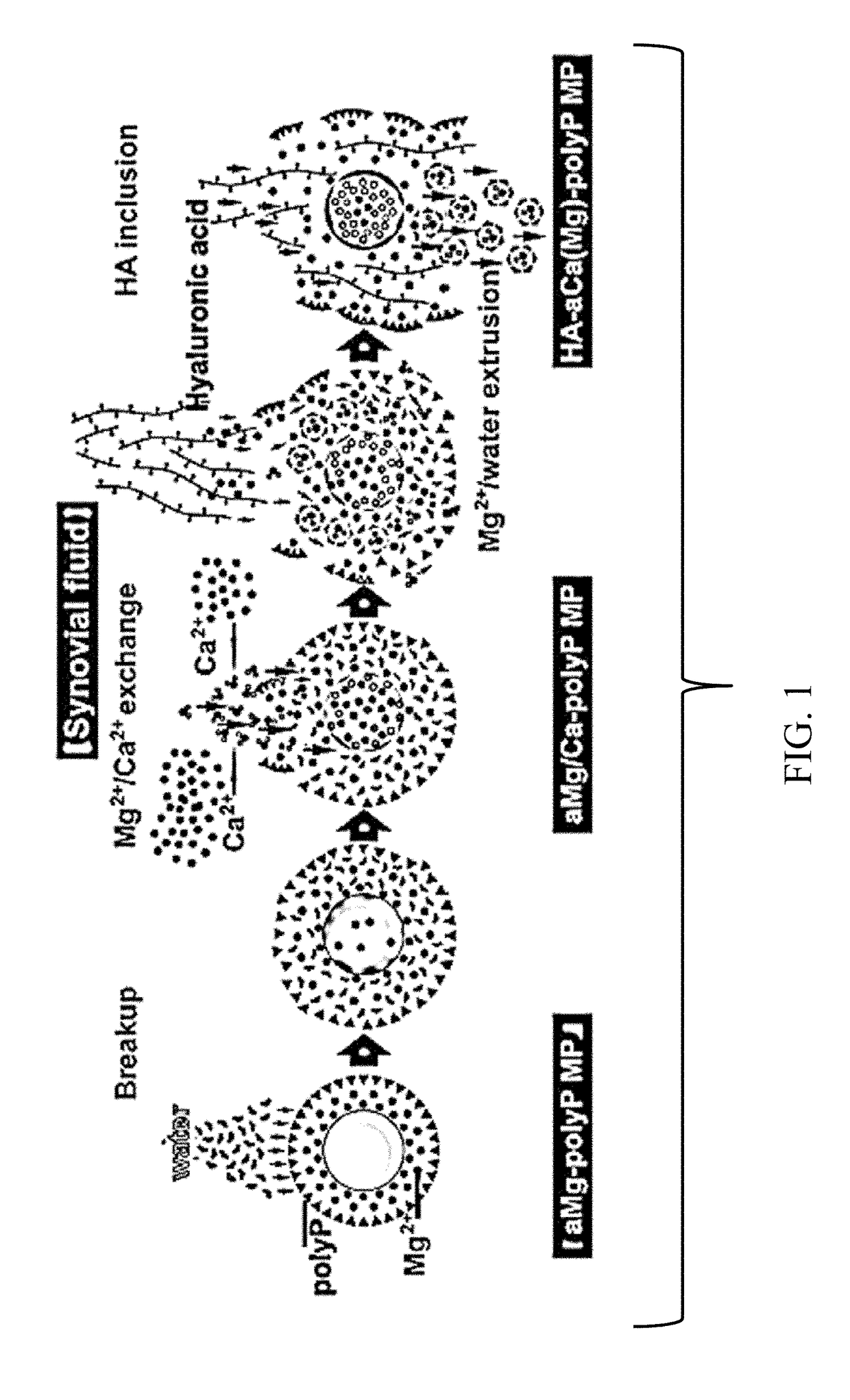

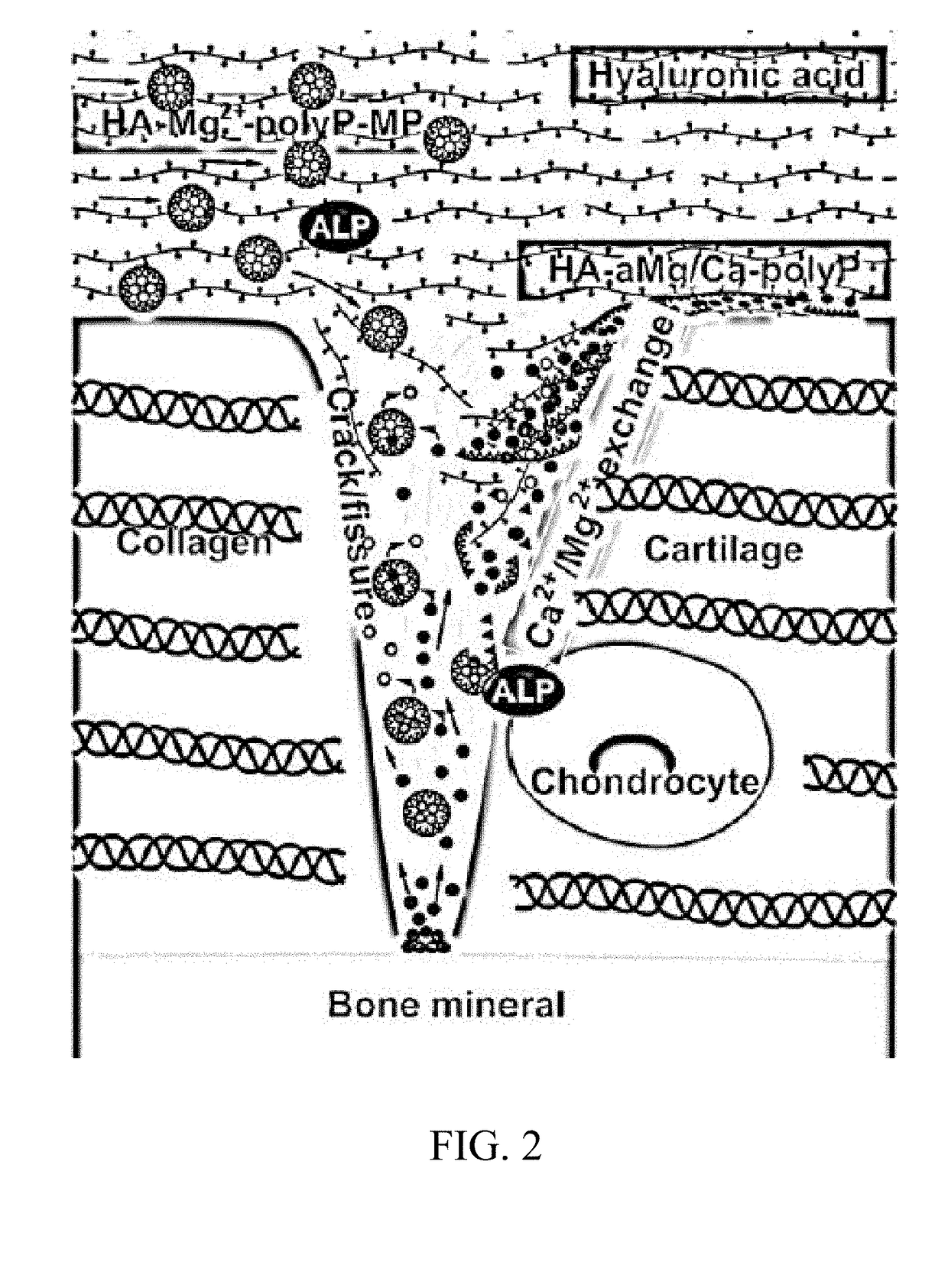

Amorphous hyaluronic acid-magnesium/calcium polyphosphate microparticles for cartilage regeneration and repair

InactiveUS20180015205A1Improve adhesionUpregulates expressionPowder deliveryOrganic active ingredientsBiomechanicsIon calcium

This invention concerns a biomimetic material based on energy-rich amorphous magnesium polyphosphate (Mg-polyP) microparticles that enhance cartilage synthesis and regeneration. One preferred formulation of the inventive material is a hyaluronic acid-Mg / Ca-polyP paste that can be produced from a water-soluble salt of polyP and water-soluble hyaluronic acid in the presence of water-insoluble / nearly insoluble calcium carbonate. Surprisingly, the inventor found that this cartilage-like material comprising amorphous Mg / Ca-polyP microparticles promotes the adhesion of chondrocytes and strongly upregulates the expression of the chondrocyte marker genes encoding alkaline phosphatase, collagen type 3A1, aggrecan and Sox9. The material through scavenging calcium ions (Mg2+ / Ca2+ exchange) and binding of the calcium-polyP to hyaluronic acid shows biomechanical properties, comparable to cartilage and thus can be used for prevention of calcium crystal formation in the synovial fluid and treatment of joint dysfunctions caused by osteoarthritis.

Owner:NANOTECMARIN

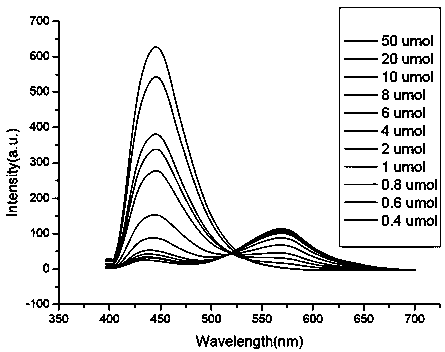

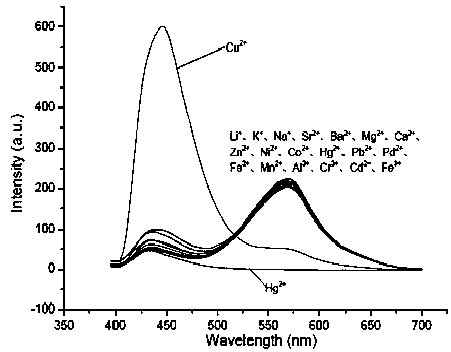

Copper ion detection probe based on o-alkynyl benzoxazole as well as preparation method and application thereof

ActiveCN110713826AChanges in fluorescence intensitySensitive recognitionOrganic chemistryFluorescence/phosphorescenceFluoProbesBenzaldehyde

The invention discloses a copper ion detection probe based on o-alkynyl benzoxazole as well as a preparation method and application thereof. The structure of the fluorescent probe is shown as a formula I, and the fluorescent probe is prepared with 2-(4-ethylenediamine phenylethynyl) benzaldehyde as a raw material by forming a benzothiazole derivative with o-aminothiophenol. The fluorescent probe is stable in optical performance, high in copper ion detection sensitivity and low in detection lower limit, the detection limit is 3.08 nM, and the response range is 0.4-4.0 [mu]M. The selectivity isgood, and no response is made to silver ions, barium ions, calcium ions, lithium ions, sodium ions, potassium ions, magnesium ions, aluminum ions, nickel ions, zinc ions, mercury ions, cobalt ions, lead ions, palladium ions and strontium ions. The synthesis is simple, the conditions are mild, and the yield is high. The fluorescent molecular probe provided by the invention has practical applicationvalue in the fields of copper ion detection in biochemistry and environmental chemistry and the like.

Owner:HUNAN UNIV OF SCI & TECH

Ionized calcium water-soluble mineral fertilizer

InactiveCN110590413ARegulate pHPassivation and mitigation of pollutionCalcareous fertilisersAnimal corpse fertilisersKeelDecomposition

The invention provides ionized calcium water-soluble mineral fertilizer. A processing method of the ionized calcium water-soluble mineral fertilizer comprises the steps that in parts by weight, 100 parts of oyster shells, 70 parts of shells of pearl oyster, 5 parts of pearl powder, 20 parts of calcium carbonate, and 5 parts of keels are prepared; raw materials are crushed; the raw materials exceptfor the calcium carbonate are subjected to high-temperature calcination and made into ultrafine particles through a technology of preparing ultrafine nanoparticles through a high-frequency plasma; then distilled water is added for heating reflux; full drying is conducted after cooling; storage is conducted for two weeks at the dark place under the constant temperature and saturation humidity; ultrafine particles are obtained through a technology of preparing the ultrafine particles with a high-frequency plasma generator; the raw materials, the calcium carbonate, and the distilled water are mixed and stirred into paste and stored for 48 hours; and then high-temperature calcination, decomposition in a plasma reaction furnace, and the like are conducted, and thus the ultrafine particles, namely the ionized calcium water-soluble mineral fertilizer are prepared. The ionized calcium water-soluble mineral fertilizer is small in using amount, convenient to use, low in cost, easily soluble inwater and extremely high in nutritional ingredient utilization rate.

Owner:舒文一

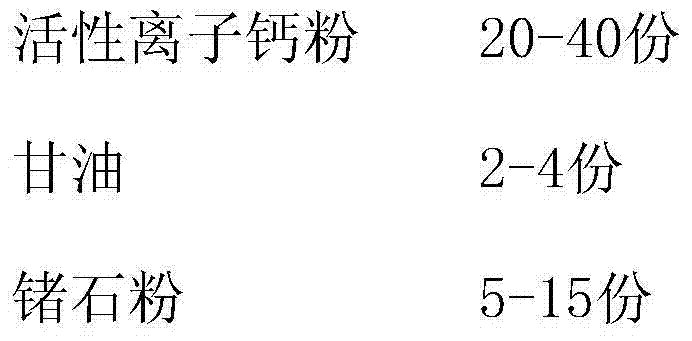

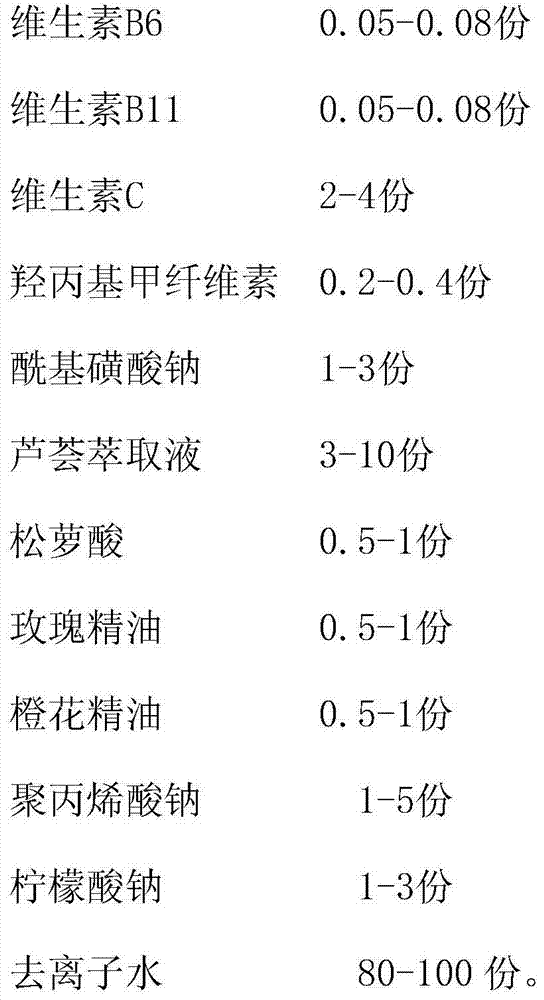

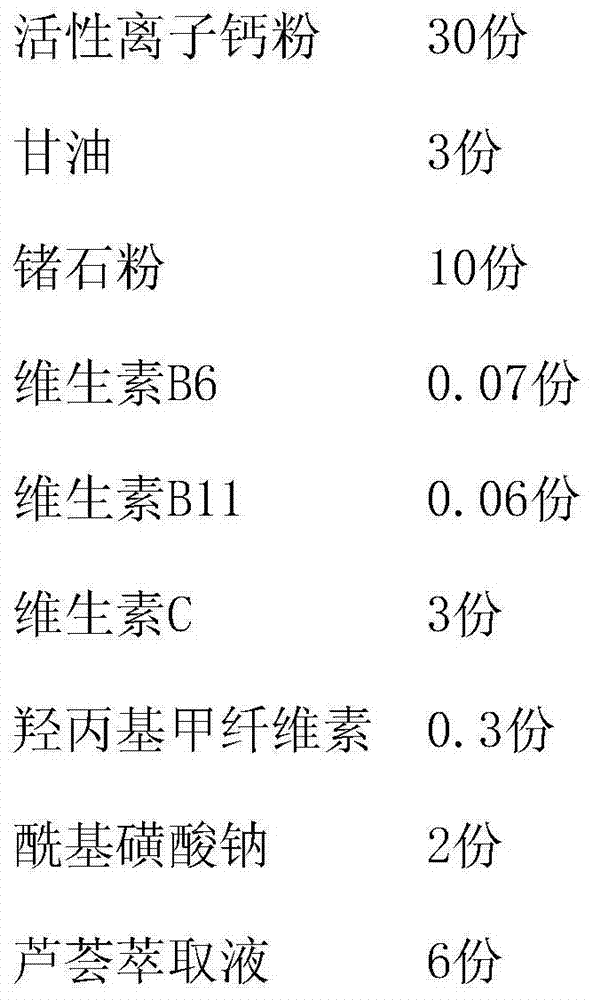

Face cleansing cream and preparation method thereof

InactiveCN104490653AEasy to cleanGood moisturizing effectCosmetic preparationsToilet preparationsVitamin CAdditive ingredient

The invention relates to a face cleansing cream, comprising the following components in parts by weight: reactive ion calcium powder, glycerinum, germanite power, vitamin B6, vitamin B11, vitamin C, hydroxypropyl cellulose, sodium cocoyl isethionate, an aloe extract liquid, usnic acid, rose essential oil, neroli essential oil, sodium polyacrylate, sodium citrate and deionized water. The face cleansing cream disclosed by the invention adopts a surfactant with mild property as a main ingredient, and is matched with ingredients of the aloe extract liquid, so that the face cleansing cream has the advantages of being high in cleaning ability, mild in face cleaning property, relatively good in moisturizing effect, and suitable for women. No toxic and side effects are derived; and the face cleansing cream can work together, and can maintain a relatively stable weak acid environment.

Owner:青岛市市南区隆德中医药研究所

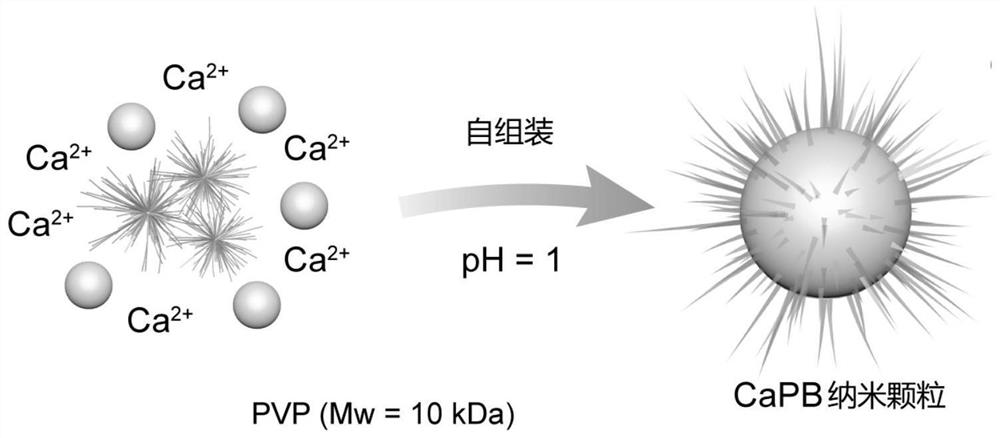

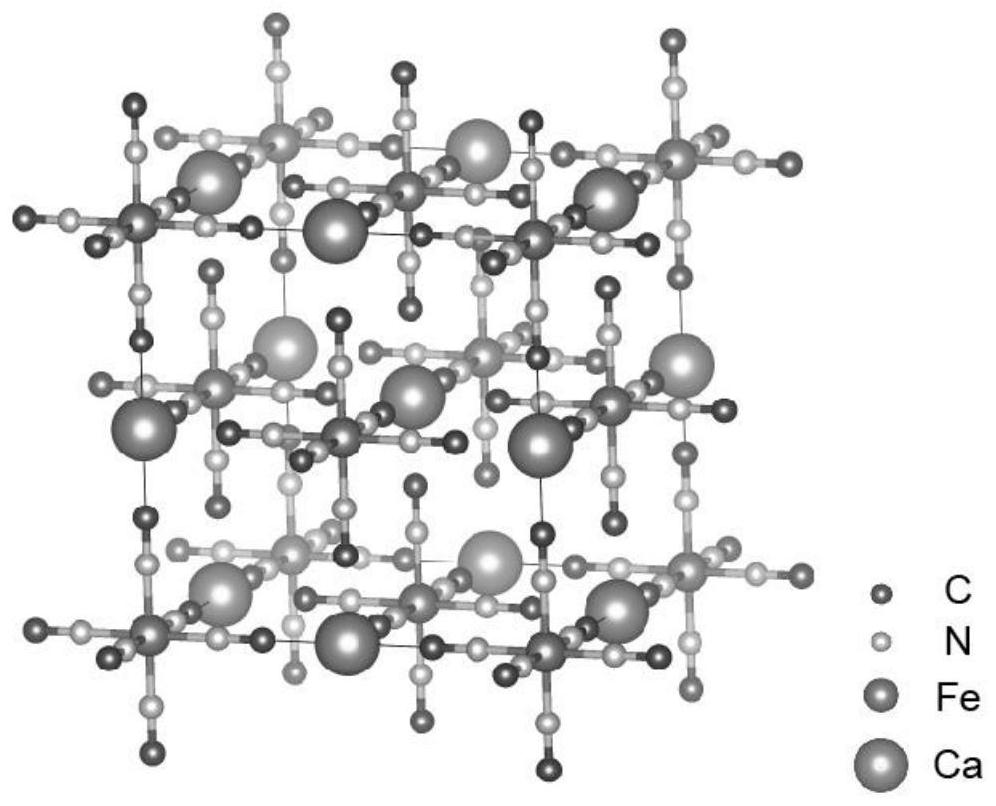

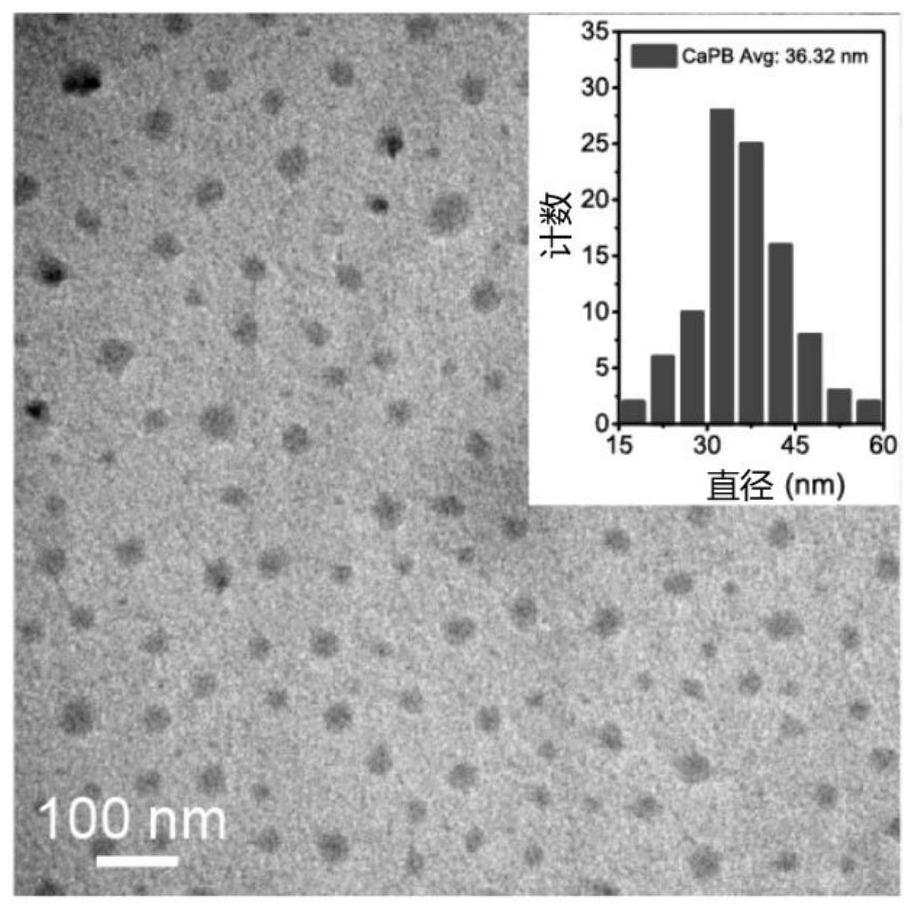

Application of CaPB nanoparticles in preparation of drugs for treating retinal degenerative diseases

PendingCN113876718ALong effective timeEffective time is excellentHeavy metal active ingredientsSenses disorderPyrrolidinonesIon exchange

The invention discloses an application of calcium-substituted prussian blue analogue (CaPB) nanoparticles in preparation of a medicine for treating a retinal degenerative disease. The inner core of the nano-particle is of a calcium ion uniformly doped Prussian blue skeleton structure, the surface of the nano-particle is modified with polyvinylpyrrolidone with biocompatibility, and the nano-particle can be formed by self-assembling ferricyanide ions, calcium ions and polyvinylpyrrolidone. The nanoparticles can enter cells and can be selectively combined with iron in the cells through a simple ion exchange method, so that diseases related to retinal pigment epithelial cell degeneration caused by ferrous ions serving as oxidative stress sources are prevented; and the application is a promising alternative scheme for treating oxidative stress mediated retinal cell injury diseases.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com