Acrylamide type polymer, preparation method and applications thereof

An acrylamide-type, polymer technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of poor emulsification and dispersion performance, lack of polymerizable properties, and disappearance of polymerizable parts, etc., to achieve good reduction Filtration characteristics, good viscosity increasing effect, low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] According to the preparation method provided by the present invention, preferably, the double-terminal amino polyether represented by formula (I-1) and the acrylic halide represented by formula (I-2) are contacted in an organic solvent and / or It is carried out in the presence of a binding acid agent. More preferably, the double-terminal amino polyether represented by formula (I-1) and the acrylic halide represented by formula (I-2) are contacted in an organic solvent and a binding acid agent. It is carried out in the presence of moles, and the double-terminal amino polyether: organic solvent: acid binding agent is preferably 1:15-25:1.0-1.05, more preferably 1:18-22:1.0-1.02.

[0063] The organic solvent may be various organic solvents that can be used for the condensation reaction of amino groups and acid halides, as long as they do not adversely affect the reaction. Preferably, the organic solvent is one or more of dichloromethane, dichloroethane and trichloromethane.

[...

Embodiment approach

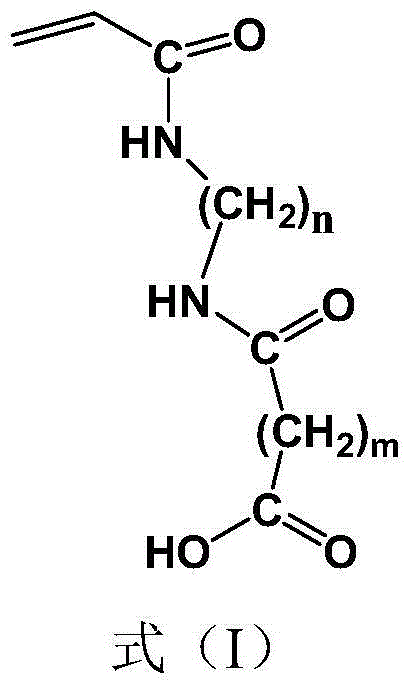

[0065] According to a preferred embodiment of the present invention, the preparation method of the polyoxyethylene ether monomer represented by formula (I) includes the following steps:

[0066] (1) Add double-end amino polyether, organic solvent and 20-50% by weight of acid binding agent solution into a reaction flask equipped with a cooling device, lower the temperature to below 5°C, and then slowly add acrylic halide, During the addition, the temperature should not exceed 15°C. After the addition of acryloyl halide, react at a temperature below 10-20°C for 0.5-4h;

[0067] (2) Let the reactant obtained in step (1) stand still, separate the organic phase, wash it several times with an aqueous sodium chloride solution (preferably with a concentration of about 10% by weight) to remove water-soluble substances, and then use anhydrous sulfuric acid Dry the sodium and evaporate the organic solvent to obtain an orange-red viscous liquid—the crude product of N-terminal amino polyether a...

Embodiment 1

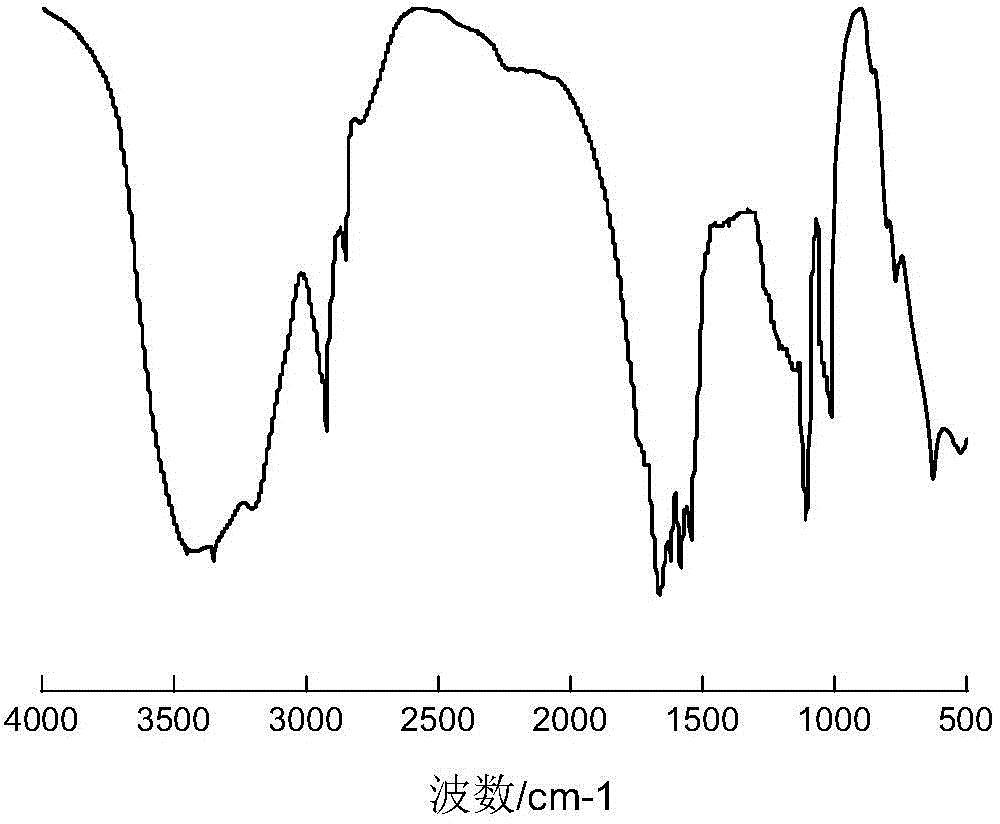

[0099] Put 1 mole of double-end amino polyether (structure like formula (I-1), R 2 =R 3 =H, n=2), 15 moles of dichloromethane and 1 mole of sodium hydroxide (made into an aqueous solution with a concentration of 40% by weight) are added to a reaction flask equipped with a cooling device, the temperature is reduced to 5°C, and then 1 Molar of acryloyl chloride, the temperature does not exceed 15°C during the addition, after the addition of acryloyl chloride, react at below 15°C for 0.5h; the resulting reactant is allowed to stand, the organic phase is separated, and washed with a NaCl aqueous solution with a concentration of 10% by weight 3 times, dry with anhydrous sodium sulfate, distill off the organic solvent to obtain an orange-red viscous liquid-crude product, and wash the crude product with acetone to obtain a polymer grade product. The product was subjected to infrared spectroscopy. by figure 1 It can be clearly seen that the primary amine group peaks in the polymer gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com