Treatment agent and treatment method of fracturing flow-back fluid

A technology for fracturing flowback fluid and treatment methods, which is applied in the fields of mining wastewater treatment, oxidized water/sewage treatment, sterilization/microdynamic water/sewage treatment, etc., and can solve high cost, waste of resources, and performance impact of fracturing fluid and other problems, to achieve the effect of simple method, realization of reuse and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

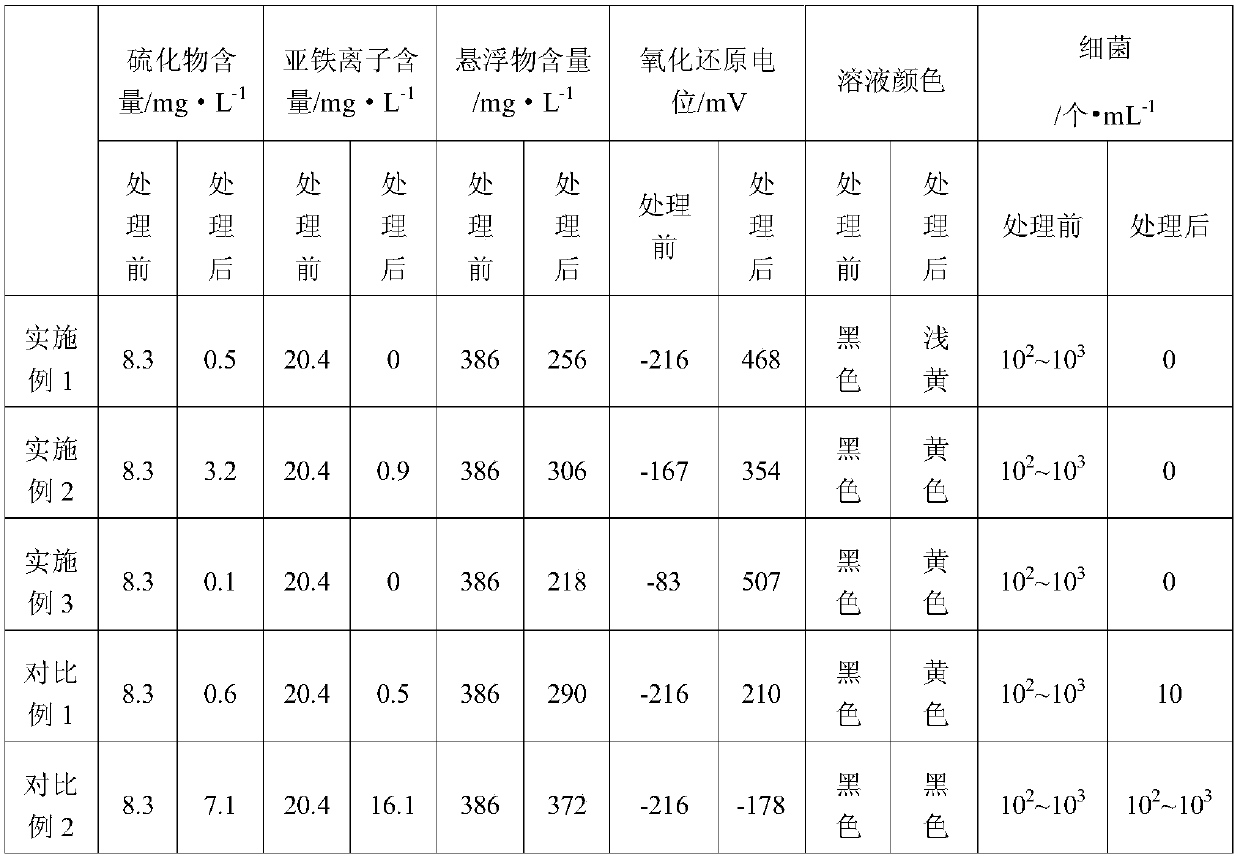

[0035] Take a certain amount of flowback fluid of hydroxypropyl guaridine fracturing fluid from Xinjiang Oilfield, adjust the pH value of the fracturing flowback fluid to 6.5 with a pH regulator, and add a treatment agent accounting for 0.15% of the weight of the fracturing flowback fluid. The treating agent includes sodium chlorite and citric acid, wherein the added amount of sodium chlorite is 0.1%, and the added amount of citric acid is 0.05% (the weight ratio of the two is 10:5). After stirring and filtering, the changes of various indicators of the fracturing flowback fluid before and after the measurement and treatment are shown in Table 1.

Embodiment 2

[0037]The difference from Example 1 is that for the treating agent accounting for 0.0145% of the fracturing flowback fluid, the added amount of sodium chlorite is 0.01%, and the added amount of citric acid is 0.0025% (the weight ratio of the two is 10:2.5) .

Embodiment 3

[0039] The difference from Example 1 is that a treatment agent accounting for 0.112% of the fracturing flowback fluid is added, wherein the added amount of sodium chlorite accounts for 0.1%, and the added amount of citric acid accounts for 0.01% (the weight ratio of the two is 10:1 ), and add partially hydrolyzed polyacrylamide accounting for 0.002% of the fracturing flowback fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com