Helical-ribbon sterilization-fermentation-mixing all-in-one machine and method for treating agricultural and sideline dregs by using machine

A technology of agricultural and sideline residues and an integrated machine, which is applied in the field of bioengineering, can solve problems such as difficult large-scale industrial production, small equipment processing capacity, and difficult temperature control, and achieve the effects of reliable equipment, improved production efficiency, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

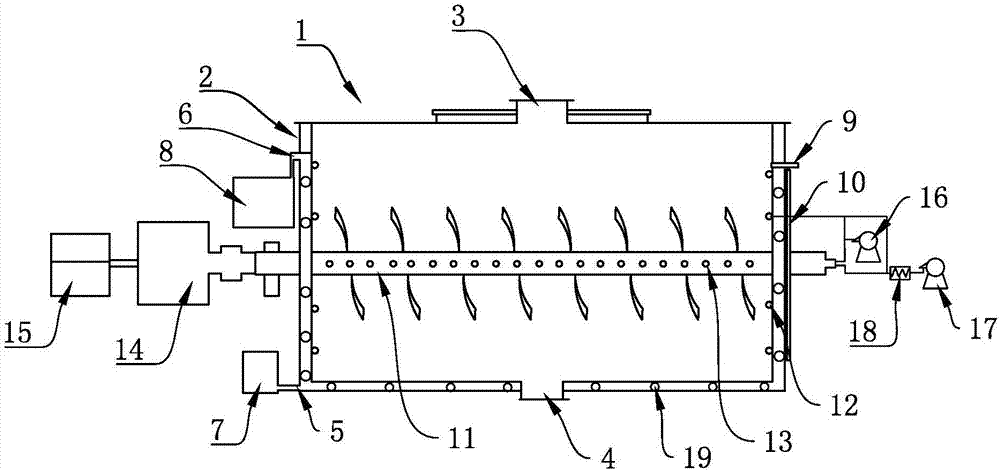

[0042] Such as figure 1 As shown, the screw-belt type sterilization and fermentation mixing machine includes a whole mixing machine 1, and the mixing machine whole 1 includes a shell 2 provided with an interlayer, a top cover is set on the shell 2, and a feeding Port 3, a liquid level gauge 10 and a temperature sensor 9 are provided on the side wall of the housing 2, and a discharge port 4 is provided at the bottom of the housing 2;

[0043] A water circulation coil 19 is arranged in the interlayer of the housing 2, and the water inlet port 5 of the water circulation coil 19 located at the lower part of the housing 2 is connected to the external water pump 7, and the water outlet port 6 located at the upper part of the housing 2 is connected to the external collector. Water container 8;

[0044]A stirring device is arranged inside the housing 2, and the stirring device includes a hollow stirring main shaft 11, the stirring main shaft 11 is provided with a plurality of ventila...

Embodiment 2

[0049] Embodiment two: Specific fermentation example one:

[0050] a. Feeding and mixing: start the stirring device, set the rotating speed to 1 rev / min, set the temperature to 40°C, open the water circulation system in the interlayer for preheating; : 1:4:1 mixture) and materials to be treated (cassava residue, fruit residue, livestock and poultry manure, straw mixture) are put into the mixer at a ratio of 1:3, and mixed for 20 minutes;

[0051] b. Bacteria inoculation: Activate the fermented bacteria (the mixture of Enterococcus faecalis, Saccharomyces cerevisiae, Bacillus subtilis, protease and cellulase in a weight ratio of 1:2:1:0.1:0.2) and an equal amount of glucose with warm water 30min, then add 0.1% of the weight of the material described in step a into the material, and mix;

[0052] c. Rapid activation: close the feed inlet, continue to stir and mix, turn on the water circulation system or the second Roots blower to control the temperature and ventilation as nee...

Embodiment 3

[0056] Embodiment three: Concrete fermentation example two:

[0057] a. Feeding and mixing: start stirring, the rotating speed is set to 1 rev / min, the temperature of the interlayer is set to 20°C, and the water circulation system in the interlayer is opened to preheat; at the same time, the auxiliary materials (bran, cornmeal, rice husk powder and peanut powder with a weight ratio of 5 : 1:2:3 mixture) and the materials to be treated (sugar residue, starch residue, cassava residue, fruit residue, livestock and poultry manure mixture) are put into the mixing machine according to 2:4, and mixed for 20 minutes;

[0058] b. Bacteria inoculation: Activate the fermented bacteria (the mixture of Enterococcus faecalis, Saccharomyces cerevisiae, Bacillus subtilis, protease and cellulase in a weight ratio of 1:2:1:0.1:0.2) and an equal amount of glucose with warm water 30min, then add 0.15% of the weight of the material described in step a into the material, and mix well;

[0059] c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com