Patents

Literature

30results about How to "No corrosive effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polythene physics foaming material and preparing method thereof

The invention discloses a physical polyethylene foaming material and making method, which comprises the following steps: adopting low-density polyethylene and high-density polyethylene as raw material; adding foamer and adjuvant; blending in the single-screw / double-squeezer to grain; obtaining the product.

Owner:徐晓冰

Method for low temperature brazing aluminium alloy to obtain brazed joint with high temperature use performance

ActiveCN101088690AHigh strengthSmall amount of deformationWelding/cutting media/materialsWelding/soldering/cutting articlesEtchingUltimate tensile strength

The method for low temperature brazed aluminum alloy to obtain brazed joint with high temperature use performance includes the following steps: 1. setting the brazing alloy inside the brazed gap; 2. primary brazing; and 3. ultrasonic treatment. The said brazing process has no any etching on the aluminum alloy workpiece, short brazing period, low brazing temperature, low operation cost, and capacity of obtaining brazed joint with high strength and high temperature use performance.

Owner:哈尔滨工大光电科技有限公司

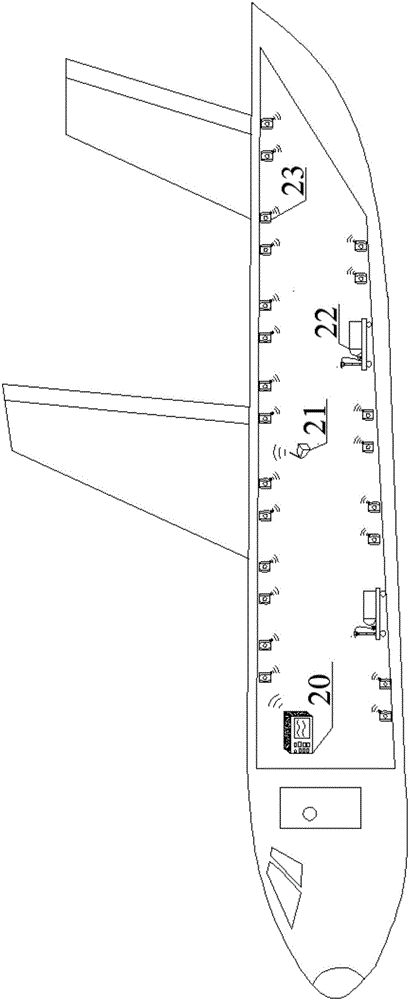

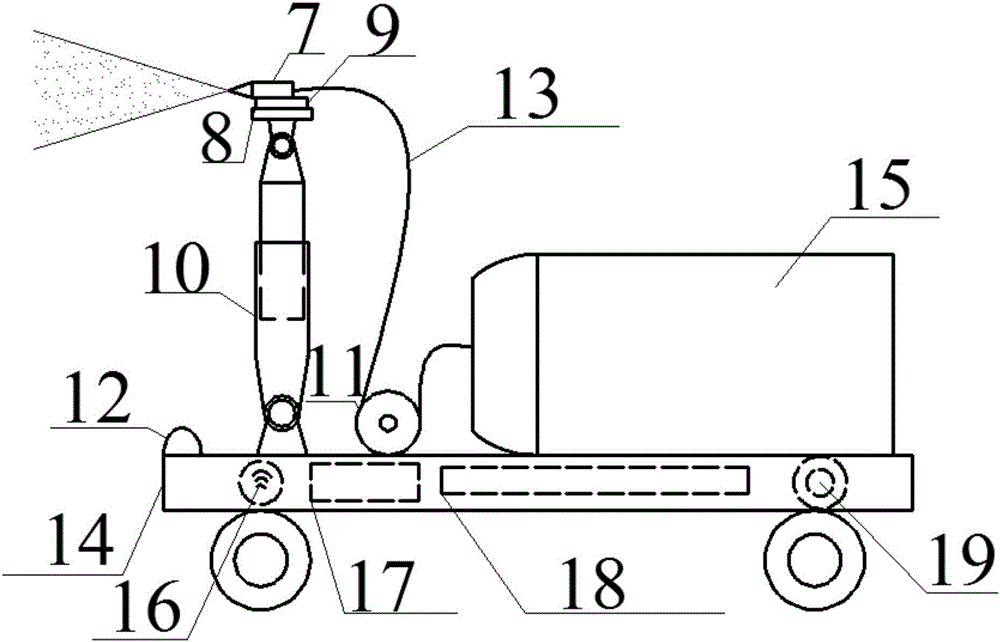

Real-time monitoring and active fire extinguishing method and device

InactiveCN105999590AImprove forecast sensitivityHazard reductionFire rescueJet aeroplaneWireless transmission

The invention discloses a real-time monitoring and active fire extinguishing method and device. The device mainly comprises a TMS (Temperature Management System) series wireless temperature on-line monitoring system and fire extinguishing mobile trolleys; the TMS series wireless temperature on-line monitoring system comprises temperature sensors, a collector, a data storage device and a CPU, wherein the temperature sensors are distributed at various parts of an airplane for collecting the temperature information of the airplane and provide position information through the distribution positions, the CPU analyzes fire disasters and fire risks, and a wireless transmission module transmits signals to the fire extinguishing mobile trolleys when the fire disasters and the fire risks exist; wireless receivers in the fire extinguishing mobile trolleys receive the information, the fire extinguishing mobile trolleys move to the positions and further accurately determine the positions of the fire disasters and the fire risks, telescopic arms of the fire extinguishing mobile trolleys are adjusted so that spraying heads can spray ultrafine water mist towards the positions with the fire disasters and the fire risks for fire extinguishment, the fire extinguishing mobile trolleys return to the initial positions after the fire disasters and the fire risks are eliminated, and then the fire extinguishment task is completed. The TMS series wireless temperature on-line monitoring system continues monitoring the temperature of various parts of an airplane compartment in real time.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Refrigerator sterilization deodorant

The invention discloses a refrigerator sterilization deodorant and belongs to the technical field of daily-use chemical industry. The defect that the conventional sterilization deodorant is incomplete in sterilization or the refrigerator is corroded is overcome. The preparation method comprises the following steps: respectively adding aloe, fresh lemon, ginger, mint, clove, honeysuckle, coptis chinensis and fructus forsythiae into deionized water, soaking, boiling, cooling, filtering and retaining the filtrate; adding the filter residues into the deionized water again, boiling, cooling, filtering, merging the filtrate twice, concentrating the filtrate to the concentration of 1.3-1.4g / cm<3,> and obtaining the plant extract; taking 20-40 percent of the plant exact, adding 45-70 percent of deionized water for diluting, uniformly stirring, sequentially adding 2-8 percent of triethanolamine N-coco acyl-glutamate and 5-10 percent of lauramidopropyl betaine, uniformly mixing, so as to obtain the refrigerator sterilization deodorant.

Owner:樊继绪

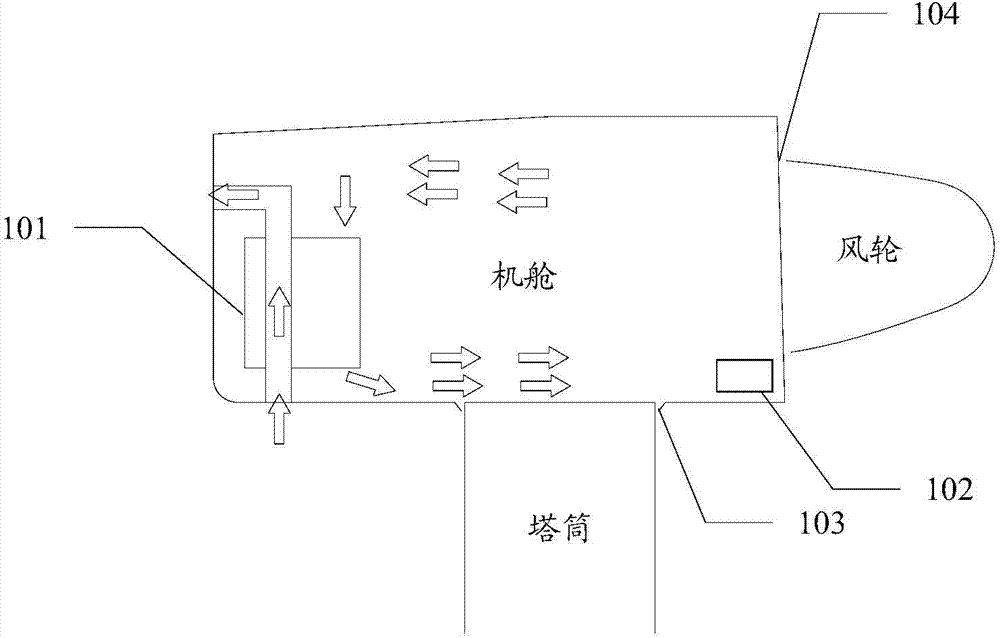

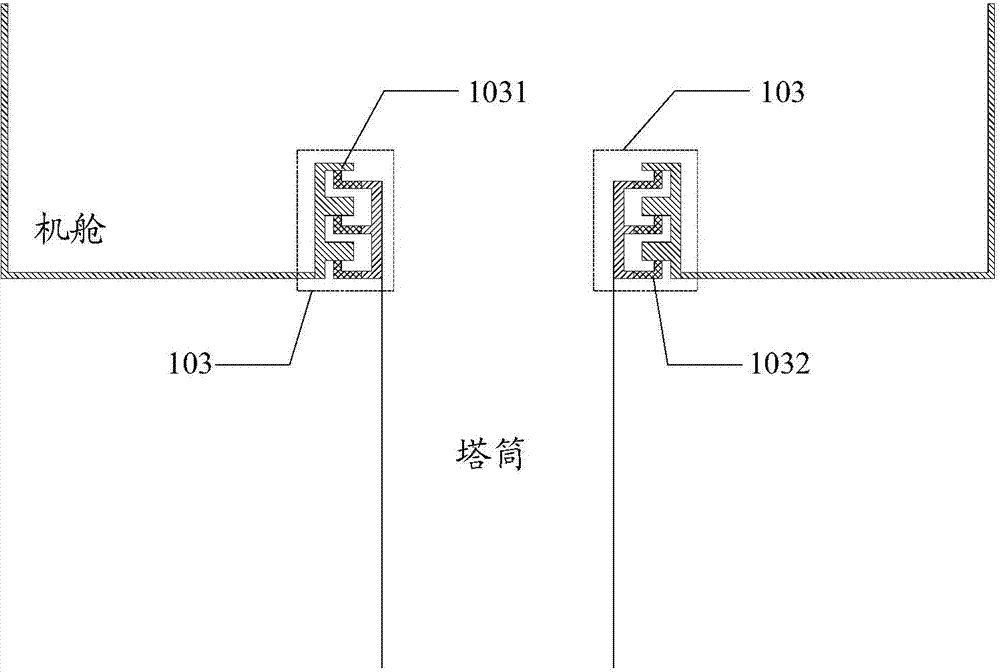

Cabin environment control device of offshore wind generating set

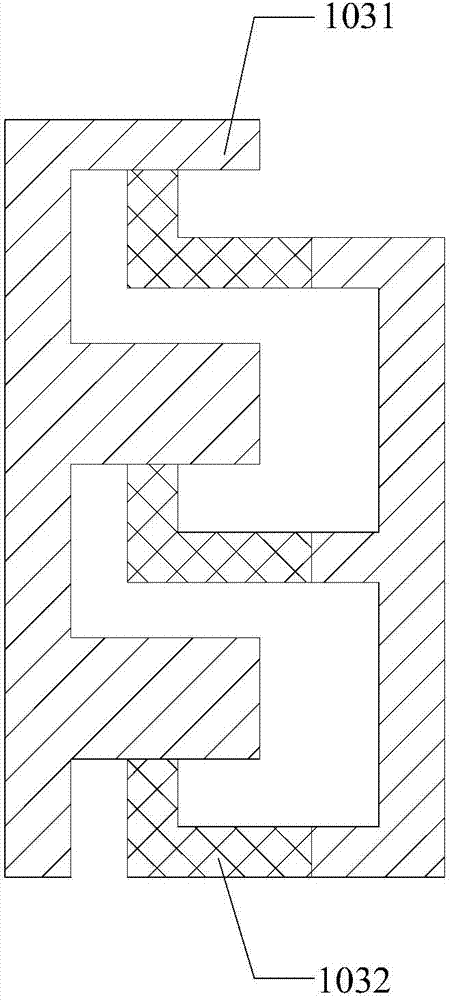

The invention discloses a cabin environment control device of an offshore wind generating set. The device comprises a cooling system, a dehumidification system, a first sealing structure and a second sealing structure. The cooling system is arranged inside or outside a cabin to adjust the temperature of air in the cabin. The dehumidification system is arranged in the cabin to adjust the humidity of the air in the cabin. The first sealing structure is arranged in a gap between the cabin and a tower drum. The second sealing structure is arranged in a gap between the cabin and a wind wheel. According to the cabin environment control device of the offshore wind generating set, cabin parts of the offshore wind generating set can be prevented from being corroded well.

Owner:CSIC CHONGQING HAIZHUANG WINDPOWER EQUIP

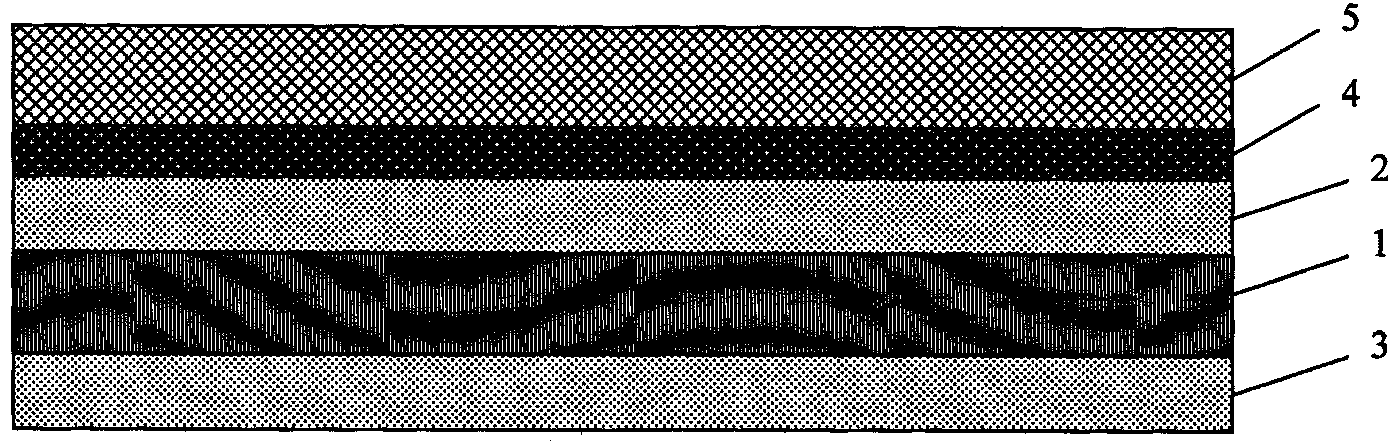

High temperature resistant anti-corrosion Al-Zn alloy coated steel sheet and preparation method thereof

InactiveCN103350539ANo corrosive effectThere will be no cracking or crackingLaminationLamination apparatusSheet steelAlloy

A high temperature resistant anti-corrosion Al-Zn alloy coated steel sheet and a preparation method thereof belong to the technical field of coating steel sheets. The steel sheet comprises a baseplate, a first structural layer combined with one side surface of the baseplate, a second structural layer combined with the other side surface of the baseplate, and a passivation layer combined with the surface of the first structural layer, and is characterized in that the surface of the passivation layer is combined with a high temperature resistant anti-corrosion layer. The preparation method comprises the following steps: selecting a cold-roll steel sheet with a flawless surface, cleaning and drying the surface of the cold-roll steel sheet to obtain the baseplate; coating structural layer material on one side surface of the baseplate to form the first structural layer, while coating the structural layer material on the other side surface of the baseplate to form the second structural layer; performing passivation and drying treatment to the surface of the first structural layer by adopting a passivator; coating high temperature resistant anti-corrosion paint on the surface of the passivation layer by adopting a roller painting manner, and performing calcination and solidification to obtain a finished product. According to the invention, the high temperature resistant anti-corrosion Al-Zn alloy coated steel sheet cannot be eroded while being continuously used for a long time in a high-temperature environment, and cracking, fracture and the like are avoided.

Owner:江苏克罗德科技有限公司

HFC-245fa refining method

ActiveCN101768046AHigh purityNo increase in acidityHalogenated hydrocarbon separation/purificationActivated carbonNon toxicity

The invention relates to a 1,1,1,3,3-pentafluoropropane (HFC-234fa) refining method. In the method, treatment by activated carbon adsorbent treated by an acid and / alkali is performed to effectively remove unsaturated impurities such as 1-chloro-3,3,3-trifluoropropene (R1233zd), 1-chloro-3,3,3-tetrafluoropropene (R1224zd) and 2-chloro-3,3,3-tetrafluoropropene (R1224xe) in the crude product of HFC-245 fa. The HFC-245fa refining method has the advantages of readily available raw materials, low cost, non-toxicity, environmental friendliness, simple treatment method and the like. The product HFC-245 fa is mainly used to replace HCFC-141b in polyurethane foaming.

Owner:ZHEJIANG LANTIAN ENVIRONMENTAL PROTECTION HI TECH +1

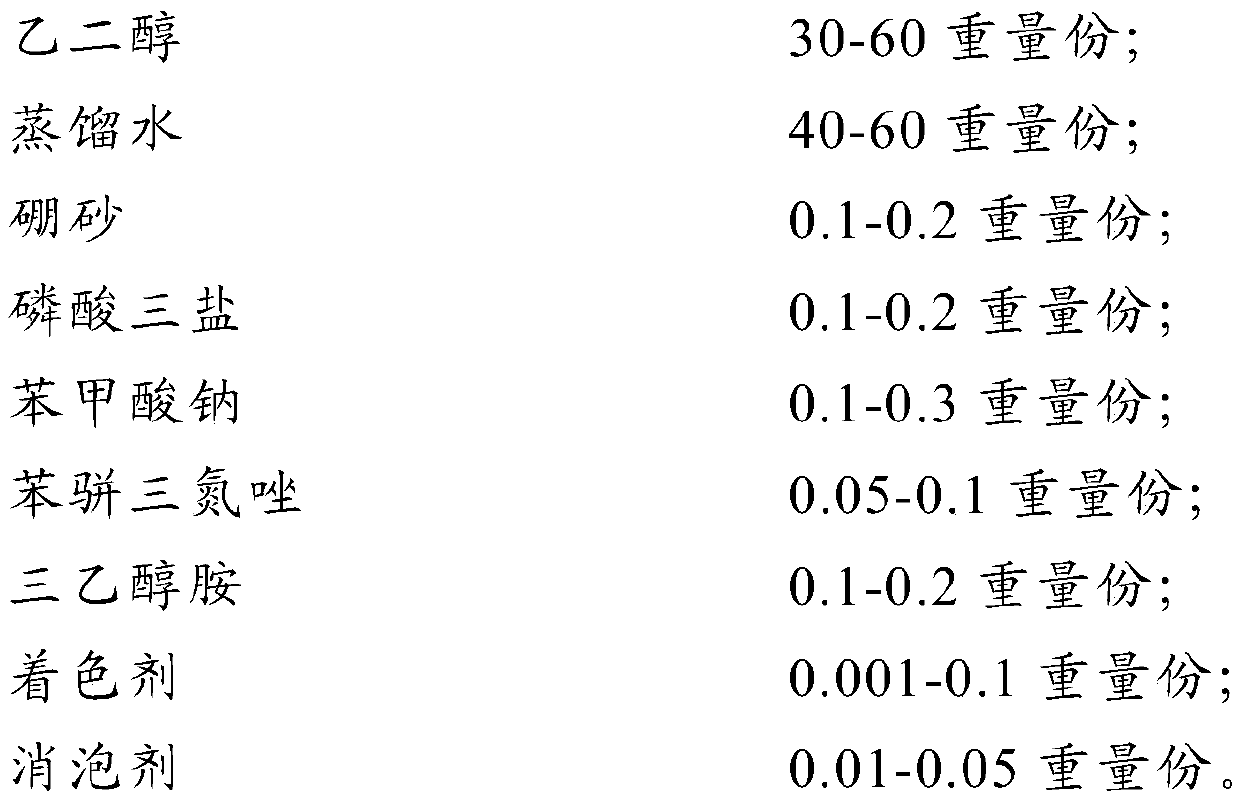

Long-acting antifreezing solution for automobile

InactiveCN105505335ALowering the freezing pointAccelerated corrosionHeat-exchange elementsPhosphateCast iron

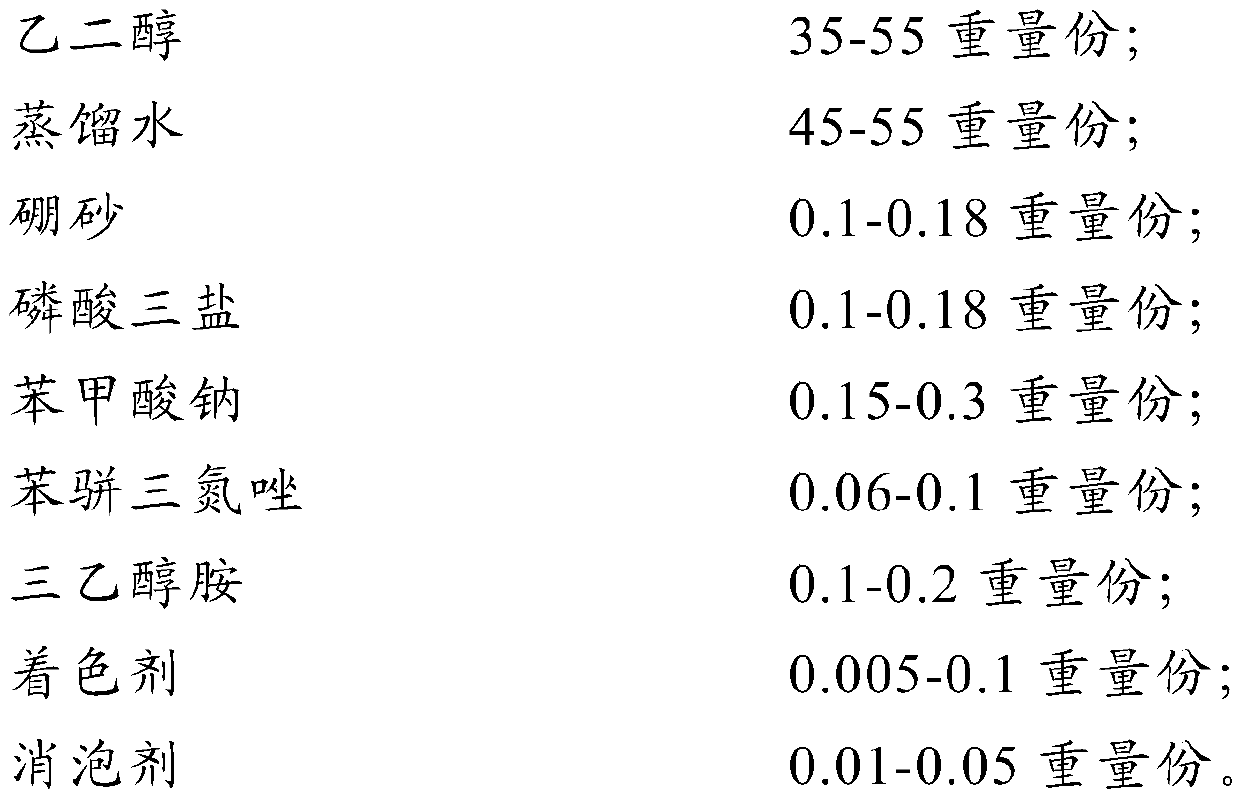

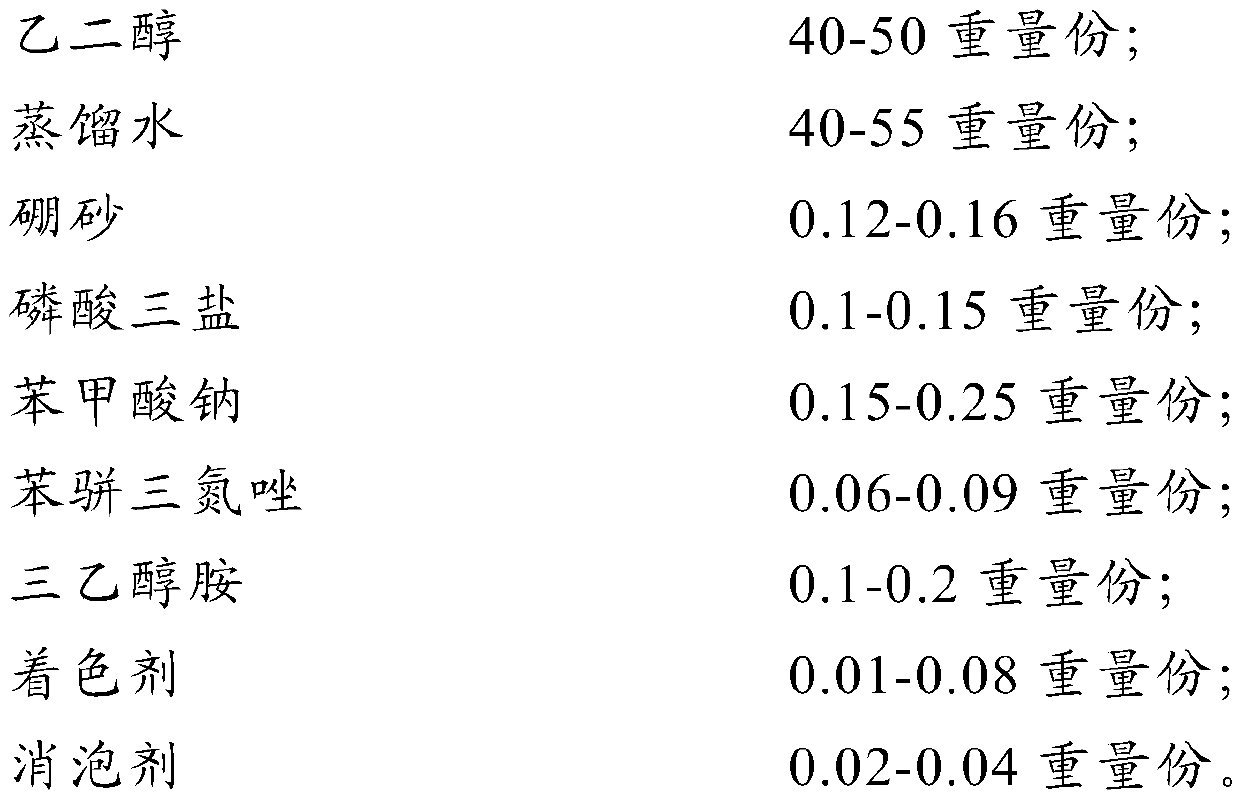

The invention provides a long-acting antifreezing solution for an automobile. The long-acting antifreezing solution is prepared from, by weight, 30-60 parts of ethylene glycol, 40-60 parts of distilled water, 0.1-0.2 part of borax, 0.1-0.2 part of trivalent phosphate, 0.1-0.3 part of sodium benzoate, 0.05-0.1 part of benzotriazole, 0.1-0.2 part of triethanolamine, 0.001-0.1 part of a coloring agent and 0.01-0.05 part of an antifoaming agent. Ethylene glycol is adopted as a raw material, and the high stability of the long-acting antifreezing solution for the automobile is guaranteed. A preservative, a rust remover, the antifoaming agent, a pH value adjusting agent and the like are reasonably matched, and the corrosivity of the long-acting antifreezing solution to automobile metal is effectively relieved. Compared with the prior art, the long-acting antifreezing solution has multifunctional purposes, is lower in freezing point and more stable, and cannot corrode copper, iron, aluminum, tin, cast iron and other automobile metal accessories.

Owner:BAODING JINYUEMEI IND & TRADE CO LTD

Antifogging and antifreezing agent for automotive glass and preparation method of anti-fog antifreezing agent

InactiveCN107083234ASimple preparation processPlay the role of cleaning and decontaminationNon-ionic surface-active compoundsOther chemical processesAntibacterial agentSodium succinate

The invention discloses an antifogging and antifreezing agent for automotive glass. The antifogging and antifreezing agent is prepared by the steps of sequentially adding water, an antifreezing agent, an antifogging agent, sulphur sodium succinate and alkyl glycoside to a stirrer and stirring until the raw materials are completely dissolved; adding sulfamic acid, zinc oxide, an antistatic agent, a dispersing agent and sorbic acid, stirring, mixing, dissolving, standing for 1-5min, and filtering; and adding an essence to the obtained filtrate for mixing evenly to obtain the finished product. The antifogging and antifreezing agent for automotive glass is simple in preparation technology; environment-friendly raw materials are adopted; and the antifogging and antifreezing agent has the functions as follows: the surfactants, namely sulphur sodium succinate and alkyl glycoside, play cleaning and decontaminating roles, the composite antifreezing agent and the antifogging agent are used for ensuring that windshield glass is clear, transparent and clear in view; charges on the surface of the glass can be eliminated through the antistatic agent; and an anti-corrosive and antibacterial agent does not have any corrosive effect on various metals, and an automotive topcoat and rubber are absolutely safe.

Owner:句容耀皮节能玻璃科技发展有限公司

Anticorrosive windshield water

InactiveCN104893839AEasy to cleanNot corrosiveInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsXylylenePolymer science

The invention relates to anticorrosive windshield water. The anticorrosive windshield water is prepared by adopting the following raw materials: 4 to 7 parts of neoprene, 12 to 18 parts of oleyl-alcohol polyoxyethylene, 10 to 24 parts of emulsion polymerized butadiene styrene rubber, 2 to 4 parts of dodecyl diethanolamide, 3 to 4 parts of sodium phosphate, 2.5 to 3.6 parts of sodium xylene sulfonate, 2 to 6 parts of alcohol ether, 3 to 7 parts of nonylphenol polyoxyethylene ether, 5 to 8 parts of sodium diethylhexyl sulfosuccinate, 6 to 10 parts of silicate stabilizer, 3 to 6 parts of borax, 6 to 12 parts of liquid paraffin, 4 to 5 parts of propanediol, 10 to 18 parts of corrosion inhibitor and 5 to 9 parts of surface active agent. The anticorrosive windshield water has beneficial effects of good cleanness, no corrosion for various metals, absolute safety for automotive topcoat and rubber and long service life.

Owner:QINGDAO DEXITUOCHUANG HIGH TECH CO LTD

Metal restoration additive for engine

The invention discloses a metal restoration additive for lubricating oil of an engine. The metal restoration additive is characterized by consisting of the following components in percentage by weight: 3 to 5 percent of polyisobutene, 5 to 8 percent of dialkyl dithiophosphate, 4 to 6 percent of phosphite ester, 8 to 10 percent of tert-butyl phenyl phosphate, 5 to 7 percent of alkyl methacrylate copolymer, 3 percent of sulfurized calcium alkyl phenolate, 3 to 5 percent of nanometer copper oxide powder, 2 to 4 percent of nanometer magnesium powder and the balance of base oil. A method is simple and practicable; and the prepared restoration additive for the engine powerfully functions in the restoration of various engines, has low cost and the good effects of wear resistance and fuel saving, can prolong the service life of the engine and a drain period, is safe to use and does not have any corrosion action on the engine.

Owner:TIANJIN GONGBO SCI TECH DEV

Nano titanium dioxide photocatalyst

InactiveCN110152742AWide variety of sourcesImprove catalytic performanceGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic effectChloride

The invention discloses a nano titanium dioxide photocatalyst. The photocatalyst comprises the following components in parts by weight: 10-20 parts of nano titanium dioxide, 1-3 parts of a dispersingagent, 2-4 parts of nano-silver, 3-6 parts of nano-silica, 3-9 parts of nano zirconia, 4-10 parts of nano-zinc oxide, 12-22 parts of deionized water, 4-10 parts of ferric chloride and 5-12 parts of polyvinylpyrrolidone. The preparation method is simple, the raw material source is wide, and the prepared photocatalyst is excellent in catalytic effect, does not produce corrosion, and is high in oxidizing ability, high in bactericidal ability and long in preservation time.

Owner:四川净入环境工程有限公司

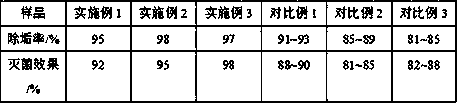

Antibacterial deodorizing agent for refrigerator and preparation method thereof

The invention discloses an antibacterial deodorizing agent for a refrigerator and a preparation method thereof and relates to the technical field of the deodorizing agents. The antibacterial deodorizing agent is prepared from the following raw materials in parts by weight: 24-26 parts of herba lythri salicariae extract, 20-22 parts of honeysuckle flower extract, 13-16 parts of eucalyptus leaves oil, 4-6 parts of lauramidopropyl betaine, 4-6 parts of modified shell powder, 1-2 parts of potassium sorbate, 1-2 parts of humectant, 0.2-0.5 part of preservative, 45-50 parts of porous-type carrier and deionized water. The preparation method comprises the steps of preparing solvent components and the like. The antibacterial deodorizing agent disclosed by the invention is environment-friendly and safe, has no irritation, is fresh in odor, can realize lasting bacteriostasis and has a certain cleaning action.

Owner:HEFEI HUAGAI BIOTECH CO LTD

Engine repairing additive

The invention relates to an engine repairing additive. The engine repairing additive is basically characterized by consisting of the following components in percentage by weight: 3 to 6 percent of polyisobutene, 6 to 8 percent of dialkyl dithiophosphate, 4 to 6 percent of phosphite ester, 10 to 12 percent of tertiary butyl phenyl phosphate, 4 to 5 percent of methacrylic alkyl ester copolymer, 2 percent of thioalkyl calcium powder and the balance of base oil. A preparation method of the engine repairing additive is simple and practical. The prepared engine repairing additive has strong repair effects on various engines. The prepared product has low cost, high efficiency and wear-resistant and fuel oil-saving effects, can prolong the service life of the engine and the fuel oil changing period, is safe to use, and has no corrosion effect on the engine.

Owner:TIANJIN GONGBO SCI TECH DEV

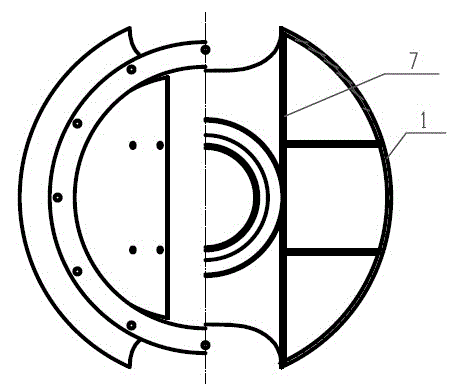

Novel axial flow fan for ship

InactiveCN103334939ASimple structureEasy to operatePump installationsNon-positive displacement fluid enginesImpellerCoupling

The invention relates to a novel axial flow fan for a ship, which comprises a housing, a motor, an impeller, a transmission group, a tire coupler, an anti-explosion ring, an inner interlayer cylinder, water distribution plates, drainage pipes, partition plates and a protecting net, wherein the motor is mounted in the inner interlayer cylinder, and connected with the impeller by the tire coupler and the transmission group; the water distribution plates are mounted on the partition plates at the top of the inner interlayer cylinder; and the anti-explosion ring is made of a brass plate. The axial flow fan is simple in structure, simple to operate, long in service life and high in safety performance, and the motor cannot be subject to corrosion of a sea breeze.

Owner:QINGDAO HAISHUNFENG SHIP EQUIP

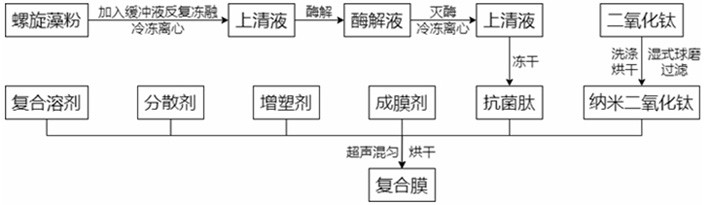

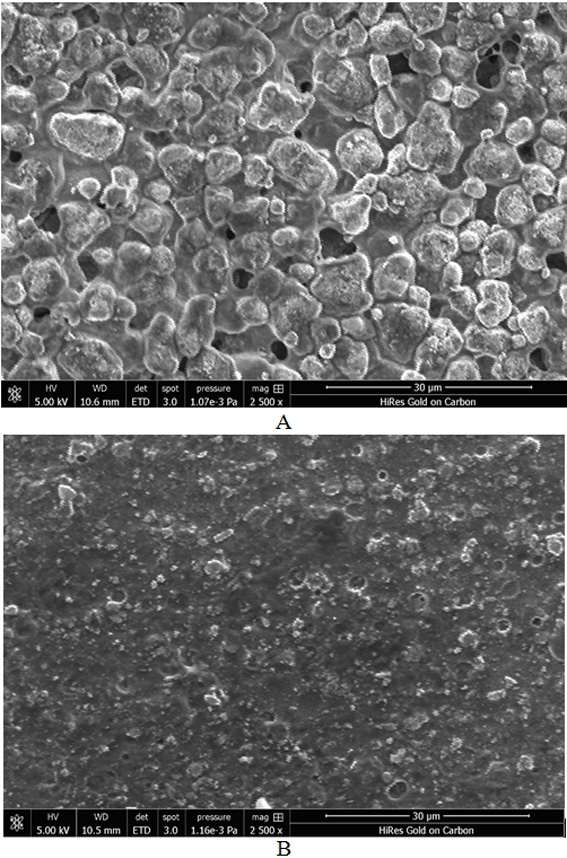

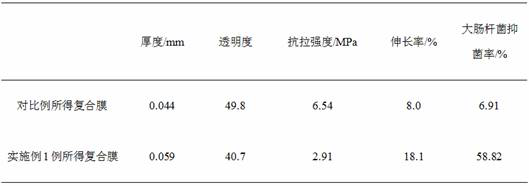

Preparation method of spirulina antibacterial peptide composite membrane

ActiveCN111808307AIncrease productionLow costPeptide preparation methodsFermentationSpirulina sp.Chemistry

The invention discloses a preparation method of a spirulina antibacterial peptide composite membrane. The preparation method comprises the following steps: carrying out enzymolysis on spirulina powderby neutral protease to obtain spirulina antibacterial peptide, carrying out low-vacuum variable-frequency ultrasonic mixing on the spirulina antibacterial peptide, nano titanium dioxide, sodium alginate and the like, and drying to obtain the spirulina antibacterial peptide composite membrane. The prepared composite membrane is uniform in thickness, smooth in surface, free of obvious bubbles and good in antibacterial property, the tensile property of the composite membrane is greatly improved, and the composite membrane can be used as a packaging material.

Owner:FUQING BRANCH OF FUJIAN NORMAL UNIV

Method for low temperature brazing aluminium alloy to obtain brazed joint with high temperature use performance

ActiveCN100519032CHigh strengthSmall amount of deformationWelding/cutting media/materialsWelding/soldering/cutting articlesBraze alloySoldering

Owner:哈尔滨工大光电科技有限公司

Method for preparing pure octadecylamine emulsion

The invention relates to a method for preparing pure octadecylamine emulsion. The method comprises the following steps: (1) preparing a hydrotropy system in sufficient stirring, wherein the hydrotropy system comprises a dispersing agent, a cosolvent and a solvent; (2) slowly adding octadecylamine solid into the hydrotropy system in stirring at constant temperature, and additionally adding the solvent to dissolve the octadecylamine solid; (3) stirring for 2 hours at constant temperature, thereby obtaining the stable octadecylamine emulsion. Due to addition of the dispersing agent, the cosolvent and the solvent into the octadecylamine solid, the octadecylamine solid can be converted into a liquid, and the octadecylamine emulsion is relatively high in low-temperature stability and is applicable to maintenance of heat supply equipment in the heat supply stopping process.

Owner:天津百伦斯生物技术有限公司

Method for removing thin polymer film on the surface of old organic photoconductive drum

The invention provides a novel remover. By using the remover and a cleaning method in the invention, thin polymer film adhered on the surface of the organic photoconductive drum can be effectively removed in a short time and the organic photoconductive drum drum-based aluminum is avoided from being corroded. In addition, the film removing method has simple operation, small time consumption and good film removing effect, and the aluminum base after being removed film can be used in reproducing of the organic photoconductive drums.

Owner:FOREVER TECH

Preparation method of titanium oxide and its application

InactiveCN1326777CNo need for high temperature sinteringStrong adhesionPigmenting treatmentTitanium dioxideTitanium hydroxideAqueous solution

A process for preparing titanium oxide includes such steps as converting the Ti-contained aqueous solution to titanium hydroxide, adding hydrogen peroxide and generating thermal reaction to obtain the solution of anatase-type titanium oxide solution with complex group, and drying. It can be used to prepare coating solution, while has high adhesion and no corrosion to substrate.

Owner:广东奥因环保科技有限公司

Composite additive special for compressor oil

The invention relates to a composite additive special for compressor oil. The composite additive is basically characterized by comprising, by weight, 5% of polyisobutylene dibutyl imide, 4.5% of sterically hindered phenol, 3.5% of ethoxy phenol, 3.5% of a toluyl triazole derivative, 12% of a dialkyl dithiocarbamic acid metal salt, 3.5% of polyalkoxy phenol, 4% of a styrene propylene copolymer, 4% of polyacrylic ester, and the balance base oil. The making method of the composite additive is simple, feasible, economical and practical, and the prepared compressor lubricating oil additive is low in cost, and has corrosion resistance, oxidation resistance and strong thermal stability to various compressor lubricating oil. The viscosity index can be maintained for a long time, the wear resistance is obviously enhanced, and gas sealing and long-term lubrication of the compressor can be provided, the composite additive has no corrosion to the inside of the compressor and can maintain the clean effect of the compressor lubricating oil for a long time. The waste oil is degradable, thus improving the environmental protection requirements.

Owner:TIANJIN ZEYA TECH

False tooth cleaning agent and preparation method thereof

InactiveCN108434073AAvoid stickingInhibitionCosmetic preparationsToilet preparationsCleansing AgentsPharmaceutical formulation

The invention discloses a false tooth cleaning agent and a preparation method thereof, and belongs to the field of medicinal preparations. The method is characterized in that enteromorpha, sea mud, marine fish and the like are used as raw materials; dextran 20000 is added to a screening culture medium; a marine strain with enzyme generation function is screened and is subjected to fermenting culture, and thus the enzyme generation activity is improved; the dextran enzyme substances are screened; ad meanwhile, the dextran enzyme substances are capable of desorbing some substances such as tartarattached to false teeth during preventing and treating; the dextran enzyme acts on water soluble glucan in dental plaque biological membrane exopolysaccharides, thus dental plaques on the surfaces ofthe false teeth can be separated, and as a result, the washing and sterilizing effects are achieved; and meanwhile, the adsorbing and corrosion of the dental plaques to the false teeth can be effectively prevented; a false tooth support cannot be corroded during use; the tartar is removed by a natural degrading process; and the problem of low tartar removing capacity and low sterilizing capacityof a current false tooth cleaning agent can be solved.

Owner:CHANGZHOU AMANTE CHEM CO LTD

Cleaning agent for LX type industrial equipment

PendingCN112410137ANo pollution in the processEasy to useInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsLiquid productMetallurgy

The invention discloses a cleaning agent for LX type industrial equipment. The cleaning agent comprises the following raw materials in parts by weight: 80-100 parts of water, 5-10 parts of a cosolvent, 5-10 parts of an organic solvent, 5-10 parts of an antioxidant, 3-8 parts of a surfactant, 3-8 parts of sulfonated coal, 2-4 parts of sodium octadecanoate, 2-4 parts of a defoaming agent, 5-10 partsof a grinding agent and 2-4 parts of a dispersing agent. Water serves as a medium of heat exchange equipment, calcium and magnesium ions are contained in the water, the higher the temperature is, theheavier the scaling is, the cleaning agent is formed by compounding multiple agents such as an organic solvent, a surfactant, a corrosion inhibitor, a penetrating agent and a grinding agent, the product can remove multiple kinds of water scale, is non-toxic, colorless and safe to use, improves the heat efficiency, and by adding the antirust agent and the surfactant, a passivation protective filmis formed on the surface of the heat exchanger equipment after the cleaning agent is used, rust on the surface is removed, alkalinity and acidity in the cleaning agent are weak, no corrosion effect iscaused to the equipment after neutralization, operation is safe, and the product is colorless and odorless.

Owner:辽宁蓝欣环保科技有限公司

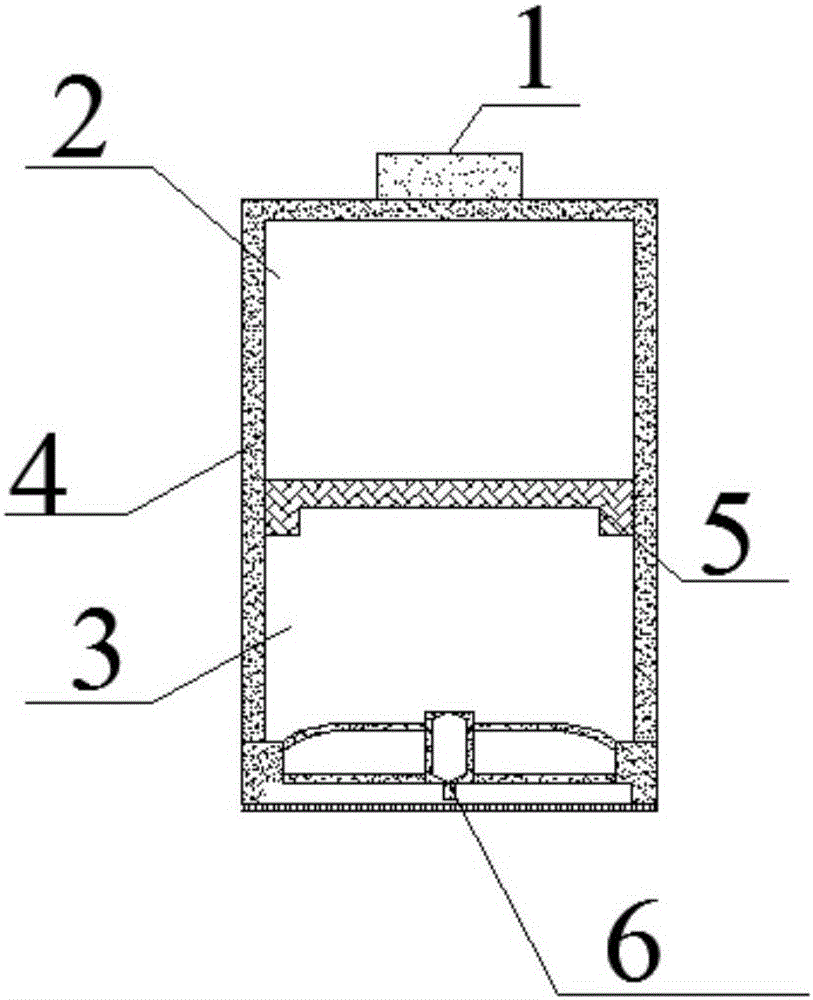

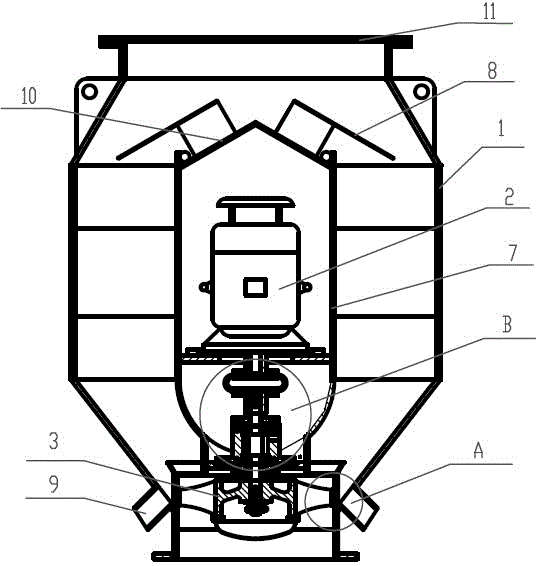

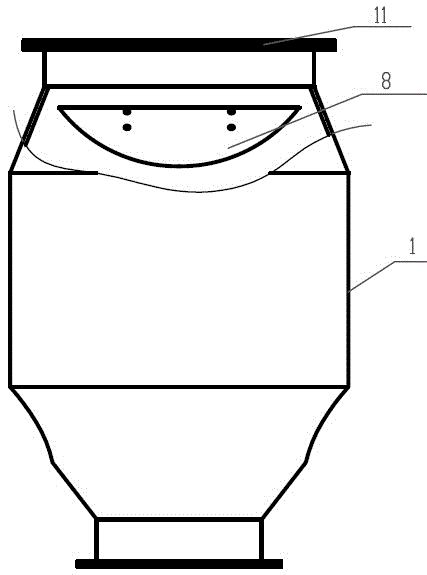

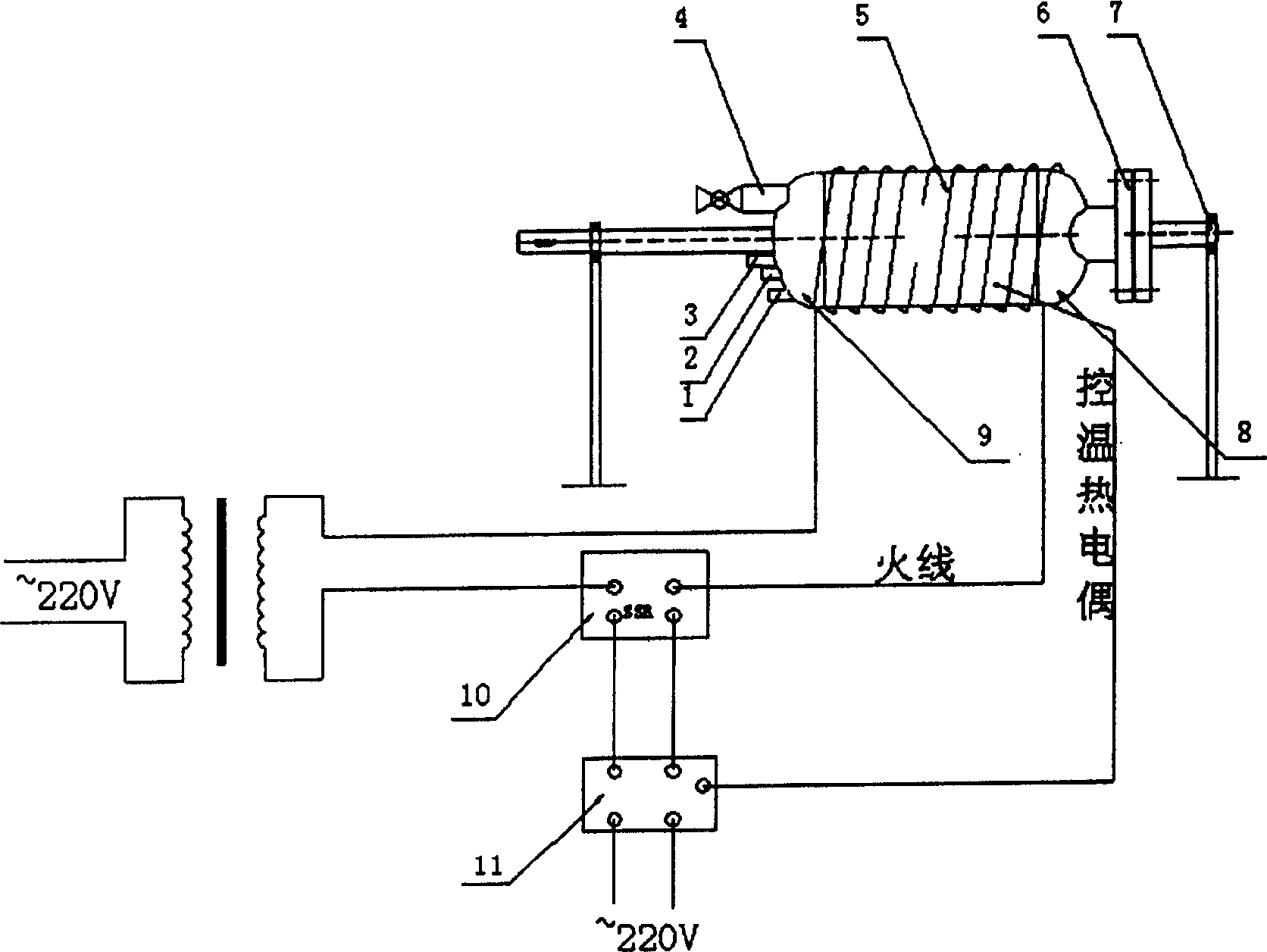

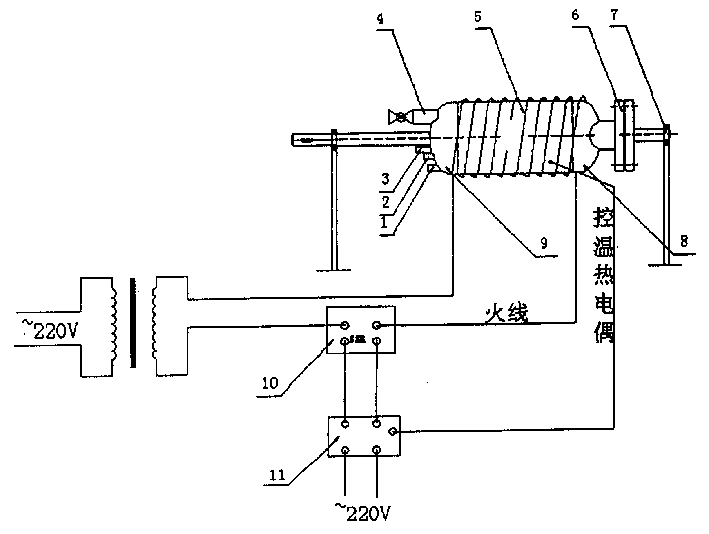

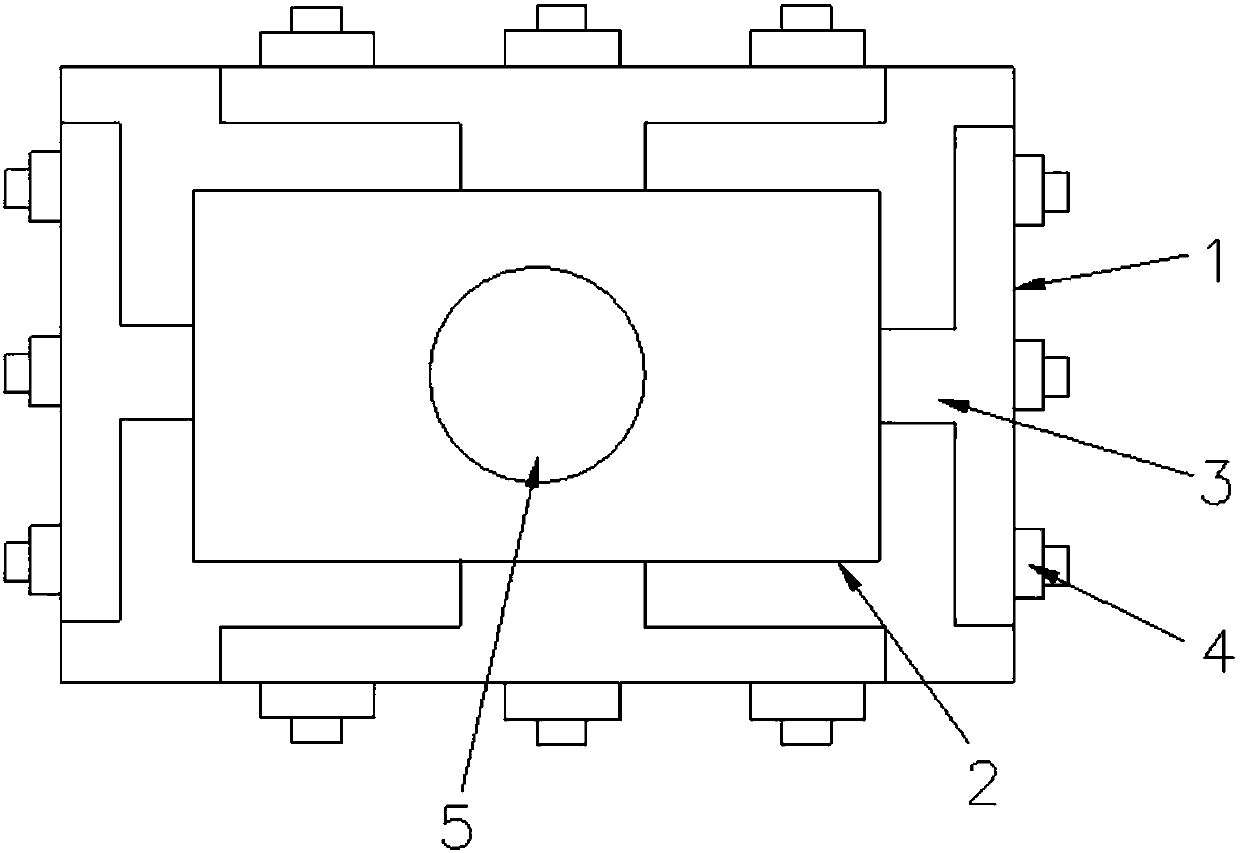

Modification apparatus and method for calcium-base desulfurizer

The present invention is the modification of calcium-base desulfurizer to raise its desulfurizing efficiency and belongs to the field of fume purifying technology. The modification apparatus consists of safety valve joint, thermocouple joint, pressure gauge joint, discharge valve, main body, heater and flange. The main body is one cylindrical container, there are flange at its one end; safety valve joint, thermocouple joint, pressure gauge joint and discharge valve at its other end; and heater on its outer surface. The modification method includes setting calcium-base desulfurizer and water in some container, sealing, introducing nitrogen at 2-10 MPa, heating to 200-320 deg.c to make high pressure water penetrate into pores of the calcium-base desulfurizer, relieving pressure suddenly to expand the pores and alter the porosity characteristic of the desulfurizer via the flash evaporation of the pressurized and saturated water.

Owner:SOUTHEAST UNIV

Water sterilization method and system for embedded intelligent household electrical appliance

InactiveCN107715150ARapid and comprehensive disinfection and sterilization treatmentSimple structure and principleBiocideFungicidesWater storageDisinfectant

The invention discloses a water sterilization method and system for an embedded intelligent household electrical appliance. The water sterilization system comprises a water sterilization device body,wherein the water sterilization device body comprises an outer shell, a water storage bin is arranged in an inner cavity of the outer shell, a refrigerator disinfectant is stored in the water storagebin, water outlet pipes are respectively connected to four side surfaces and bottom end surface of the water storage bin, atomization heads are fixedly mounted on four side surfaces and bottom end surface of the outer shell and are communicated with the water outlet pipes, and a micro-pump is further mounted in the water storage bin. The water sterilization system is simple in structure principleand high in sterilization efficiency and can be used for carrying out rapid and all-directional disinfection and sterilization in refrigerating chambers of a refrigerator.

Owner:魔水科技(北京)有限公司

HFC-245fa refining method

ActiveCN101768046BHigh purityNo increase in acidityHalogenated hydrocarbon separation/purificationActivated carbonNon toxicity

The invention relates to a 1,1,1,3,3-pentafluoropropane (HFC-234fa) refining method. In the method, treatment by activated carbon adsorbent treated by an acid and / alkali is performed to effectively remove unsaturated impurities such as 1-chloro-3,3,3-trifluoropropene (R1233zd), 1-chloro-3,3,3-tetrafluoropropene (R1224zd) and 2-chloro-3,3,3-tetrafluoropropene (R1224xe) in the crude product of HFC-245 fa. The HFC-245fa refining method has the advantages of readily available raw materials, low cost, non-toxicity, environmental friendliness, simple treatment method and the like. The product HFC-245 fa is mainly used to replace HCFC-141b in polyurethane foaming.

Owner:ZHEJIANG LANTIAN ENVIRONMENTAL PROTECTION HI TECH +1

A kind of solid photocatalyst and preparation method thereof

ActiveCN105363439BImprove photocatalytic performanceSmall particle sizeHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsAlcoholSolvent

The invention discloses a solid photocatalyst and a preparation method thereof. The method specifically includes the steps of mixing and heating ethyl alcohol-water solvent, phosphate buffer and polyhydric alcohols, dropwise adding tetrabutyl titanate at the same time, then adding nano-silver, conducting a hydrolysis reaction, and conducting purifying and drying to obtain a finished product after the reaction ends. The solid photocatalyst is small in titanium dioxide grain size, good in catalysis effect, higher in oxidation capacity and better in sterilization effect, pH is close to neutralism, and no corrosion effect can be generated.

Owner:鹤山市顺鑫实业有限公司

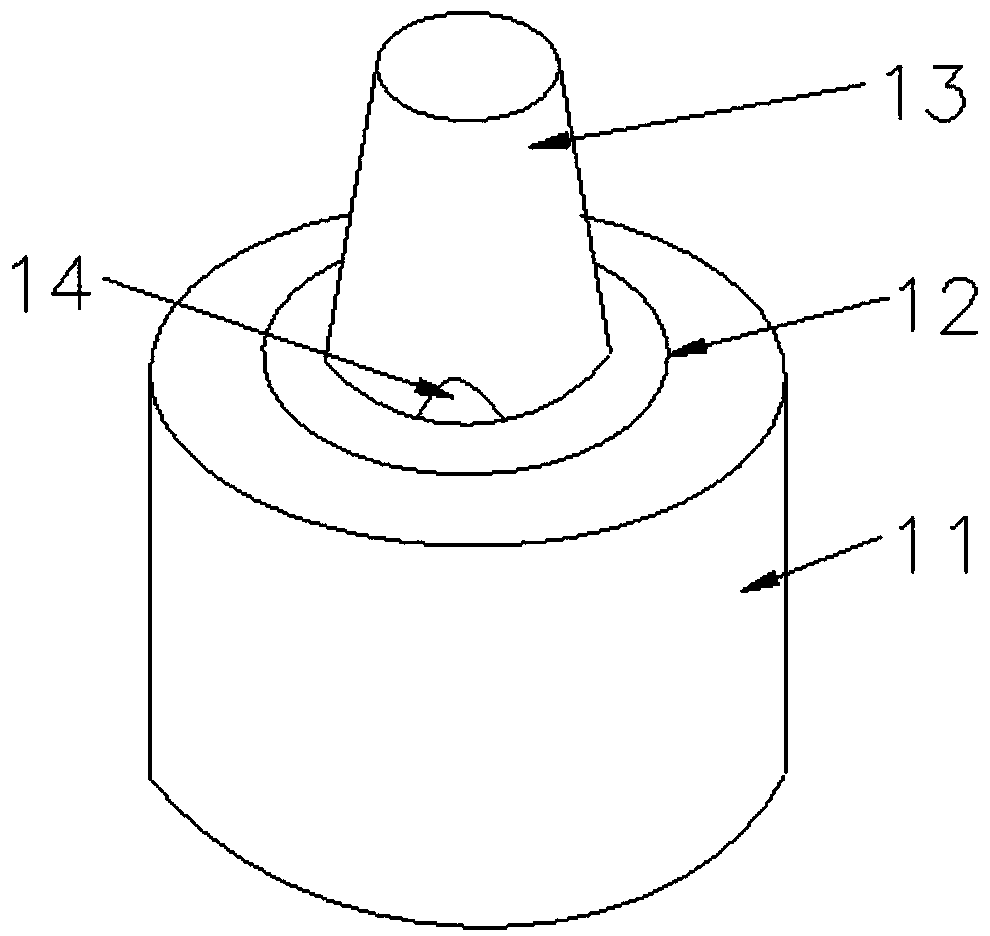

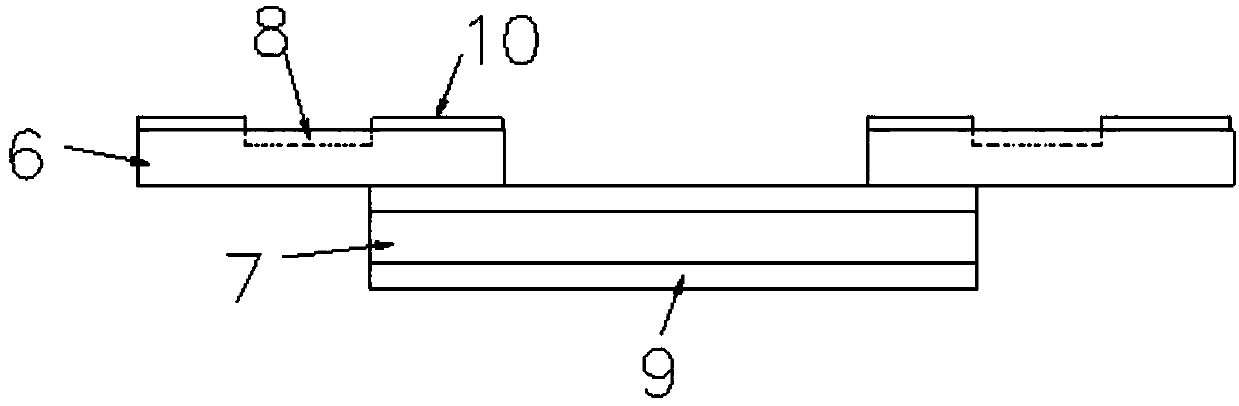

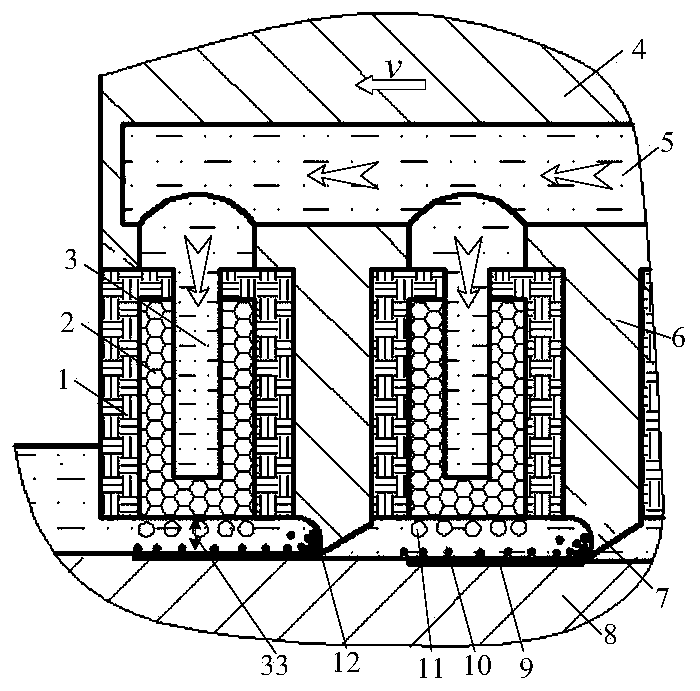

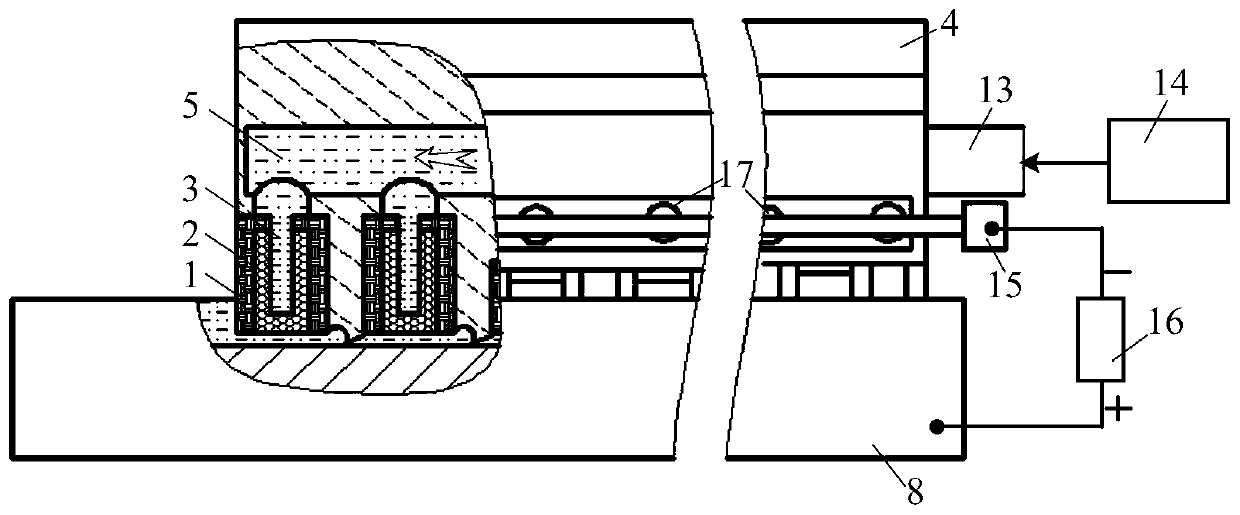

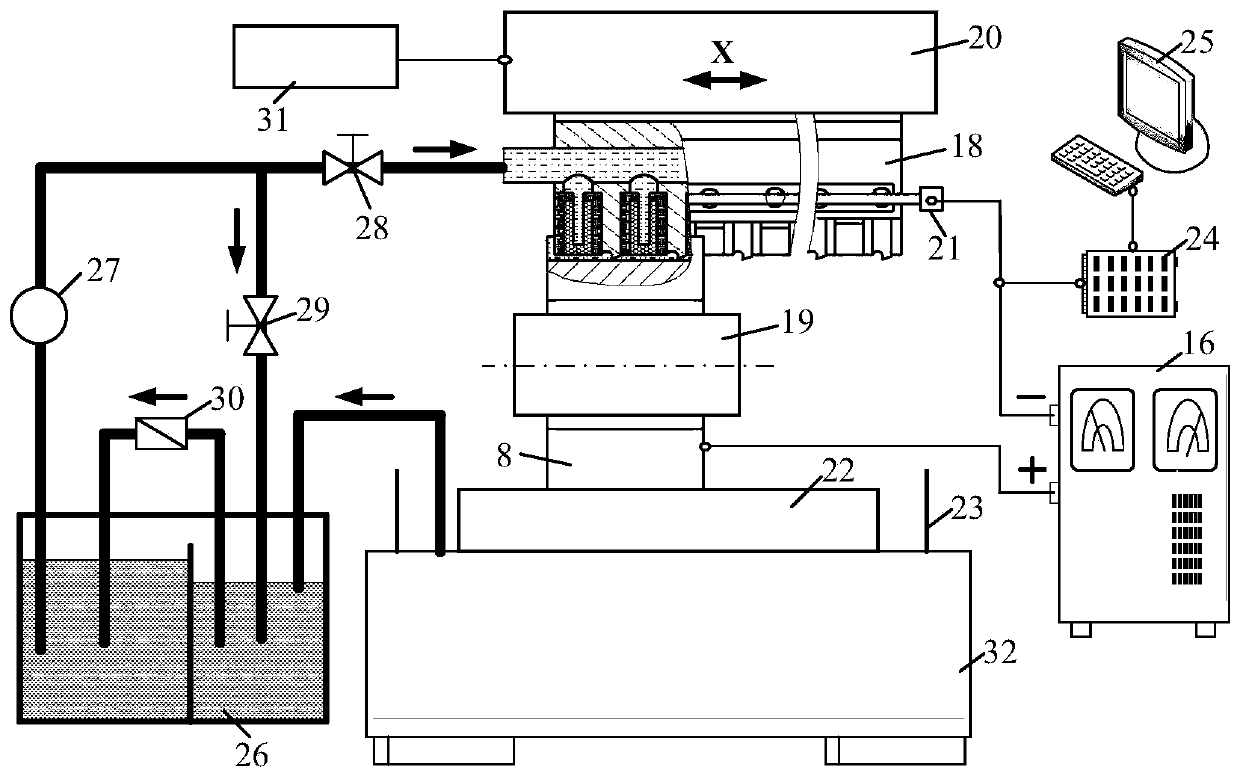

A kind of electrolysis-broaching compound processing method

An electrolysis-broaching composite processing method belongs to the field of special processing technology. The low-concentration neutral salt solution passes through the internal flow channel and is transported from the pores of the porous metal plate to the processing gap; The corresponding area on the surface forms electrochemical corrosion, which reduces the mechanical properties of the matrix material on the surface of the workpiece. The broaching blade cuts into the workpiece, easily removes excess material on the surface, and exposes fresh matrix material; as the tool electrode continues to move forward, the next piece of porous metal plate The electrode performs electrochemical corrosion on the fresh matrix material exposed on the surface of the workpiece again, and the surface corrosion layer is cut off by the next broaching blade, thereby exposing the fresh matrix material again; the invention improves the process performance of broaching and improves the processing quality And tool life, reducing the overall processing costs.

Owner:YANGZHOU UNIV

Paste agent specially for battery and preparation method thereof

ActiveCN101831254BLow costMeet strength requirementsStarch derivtive adhesivesCell component detailsPhospholipidPropanediol

The invention relates to a paste agent especially for a battery and a preparation method thereof. The paste agent is prepared by the following materials by weight ratio: modified starch, pure water, urea, sorbierite or propanediol, phospholipids or glycerel monostearte, sodium dehydroacetate or dimethyl fumarate and defoaming agents. The preparation method of the paste agent comprises the following steps of: placing the modified starch and the pure water into a reaction kettle, and heating and stirring till the modified starch is sufficiently dissolved at heating temperature lower than 65 DEG C; adding the sorbierite or the propanediol and the phospholipids or the glycerel monostearte to the reaction kettle by increasing the temperature to 65-70 DEG C, and preserving the temperature for 0.5-1 hour; adding the urea by increasing the temperature to 85-90 DEG C, and preserving the temperature; adding the sodium dehydroacetate or the dimethyl fumarate by reducing the temperature to 55-70 DEG C after the content of soluble solid state materials reaches 72 percent, and then adding the defoaming agents to stir for 0.5-1 hour; and discharging after the temperature is reduced to 40 DEG C so as to obtain the paste agent specially for the battery. The invention has the advantages of low cost, high product strength, good stickiness, difficult desquamation, durable service, safety and environmental protection without pollution and corrosion and is suitable for popularization and application.

Owner:GUANGZHOU FOOD IND RES INST

Paste agent specially for battery and preparation method thereof

ActiveCN101831254ALow costMeet strength requirementsStarch derivtive adhesivesCell component detailsPhospholipidPropanediol

The invention relates to a paste agent specially for a battery and a preparation method thereof. The paste agent is prepared by the following materials by weight ratio: modified starch, pure water, urea, sorbierite or propanediol, phospholipids or glycerel monostearte, sodium dehydroacetate or dimethyl fumarate and defoaming agents. The preparation method of the paste agent comprises the following steps of: placing the modified starch and the pure water into a reaction kettle, and heating and stirring till the modified starch is sufficiently dissolved at heating temperature lower than 65 DEG C; adding the sorbierite or the propanediol and the phospholipids or the glycerel monostearte to the reaction kettle by increasing the temperature to 65-70 DEG C, and preserving the temperature for 0.5-1 hour; adding the urea by increasing the temperature to 85-90 DEG C, and preserving the temperature; adding the sodium dehydroacetate or the dimethyl fumarate by reducing the temperature to 55-70 DEG C after the content of soluble solid state materials reaches 72 percent, and then adding the defoaming agents to stir for 0.5-1 hour; and discharging after the temperature is reduced to 40 DEG C so as to obtain the paste agent specially for the battery. The invention has the advantages of low cost, high product strength, good stickiness, difficult desquamation, durable service, safety and environmental protection without pollution and corrosion and is suitable for popularization and application.

Owner:GUANGZHOU FOOD IND RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com