Preparation method of spirulina antibacterial peptide composite membrane

A technology of antimicrobial peptides and spirulina, which is applied in the field of preparation of spirulina antimicrobial peptide composite films, can solve the problems of complicated process, unsuitable for large-scale production, inconvenient storage and transportation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

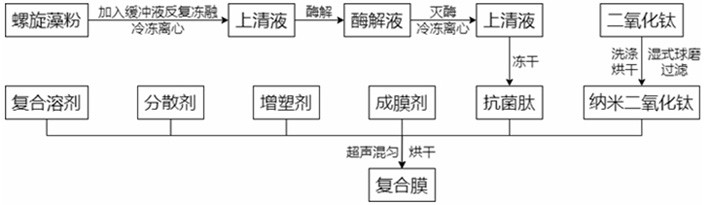

Method used

Image

Examples

Embodiment 1

[0025] 1) Preparation of spirulina antimicrobial peptides: Add 6 g of spirulina powder into 120 mL of sodium phosphate buffer solution with pH=7.0, freeze and thaw three times at -20°C and thaw at room temperature, and centrifuge at 4°C for 30 min , then take the supernatant, add neutral protease in the amount of 0.0125g / 100mL, enzymolyze at 45°C for 4 hours, maintain the pH value at 7.0 during this period, heat the enzymolyzate in a water bath at 95°C for 10 minutes to inactivate the enzyme, and again After refrigerated centrifugation at 4°C for 30 min, the supernatant was vacuum freeze-dried to obtain the spirulina antimicrobial peptide;

[0026] 2) Preparation of nano-titanium dioxide: wash the titanium dioxide with deionized water and dry it, then add absolute ethanol according to the mass volume ratio of 1g:20mL, ball mill for 48 hours, and obtain nano-titanium dioxide after filtration;

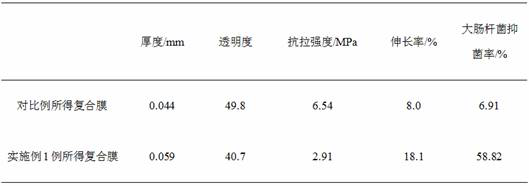

[0027] 3) Preparation of composite membrane: 0.6 g of spirulina antimicrobial peptid...

Embodiment 2

[0029] 1) Preparation of spirulina antimicrobial peptides: Add 6 g of spirulina powder into 120 mL of sodium phosphate buffer solution with pH=7.0, freeze and thaw three times at -20°C and thaw at room temperature, and centrifuge at 4°C for 30 min , then take the supernatant, add neutral protease in the amount of 0.0125g / 100mL, enzymolyze at 30°C for 8 h, maintain the pH value at 7.0 during this period, heat the enzymolyzate in a water bath at 95°C for 10 min to inactivate the enzyme, and again After refrigerated centrifugation at 4°C for 30 min, the supernatant was vacuum freeze-dried to obtain the spirulina antimicrobial peptide;

[0030] 2) Preparation of nano-titanium dioxide: wash the titanium dioxide with deionized water and dry it, then add absolute ethanol according to the mass volume ratio of 1g:20mL, ball mill for 48 hours, and obtain nano-titanium dioxide after filtration;

[0031] 3) Preparation of composite film: Add 1 g of spirulina antimicrobial peptide, 2 g of ...

Embodiment 3

[0033] 1) Preparation of spirulina antimicrobial peptides: Add 6 g of spirulina powder into 120 mL of sodium phosphate buffer solution with pH=7.0, freeze and thaw three times at -20°C and thaw at room temperature, and centrifuge at 4°C for 30 min , then take the supernatant, add neutral protease in the amount of 0.0125g / 100mL, enzymolyze at 70°C for 2 h, maintain the pH value at 7.0 during this period, heat the enzymolyzate in a water bath at 95°C for 10 min to inactivate the enzyme, and again After refrigerated centrifugation at low temperature for 30 min, the supernatant was vacuum freeze-dried to obtain the spirulina antimicrobial peptide;

[0034] 2) Preparation of nano-titanium dioxide: wash the titanium dioxide with deionized water and dry it, then add absolute ethanol according to the mass volume ratio of 1g:20mL, ball mill for 48 hours, and obtain nano-titanium dioxide after filtration;

[0035] 3) Preparation of composite membrane: Add 3 g of spirulina antimicrobial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com