Modification apparatus and method for calcium-base desulfurizer

A desulfurization agent and modified technology, which is applied in the field of flue gas purification, can solve the problems of pore blockage, etc., and achieve the effects of easy vaporization and expansion, small molecular weight, and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

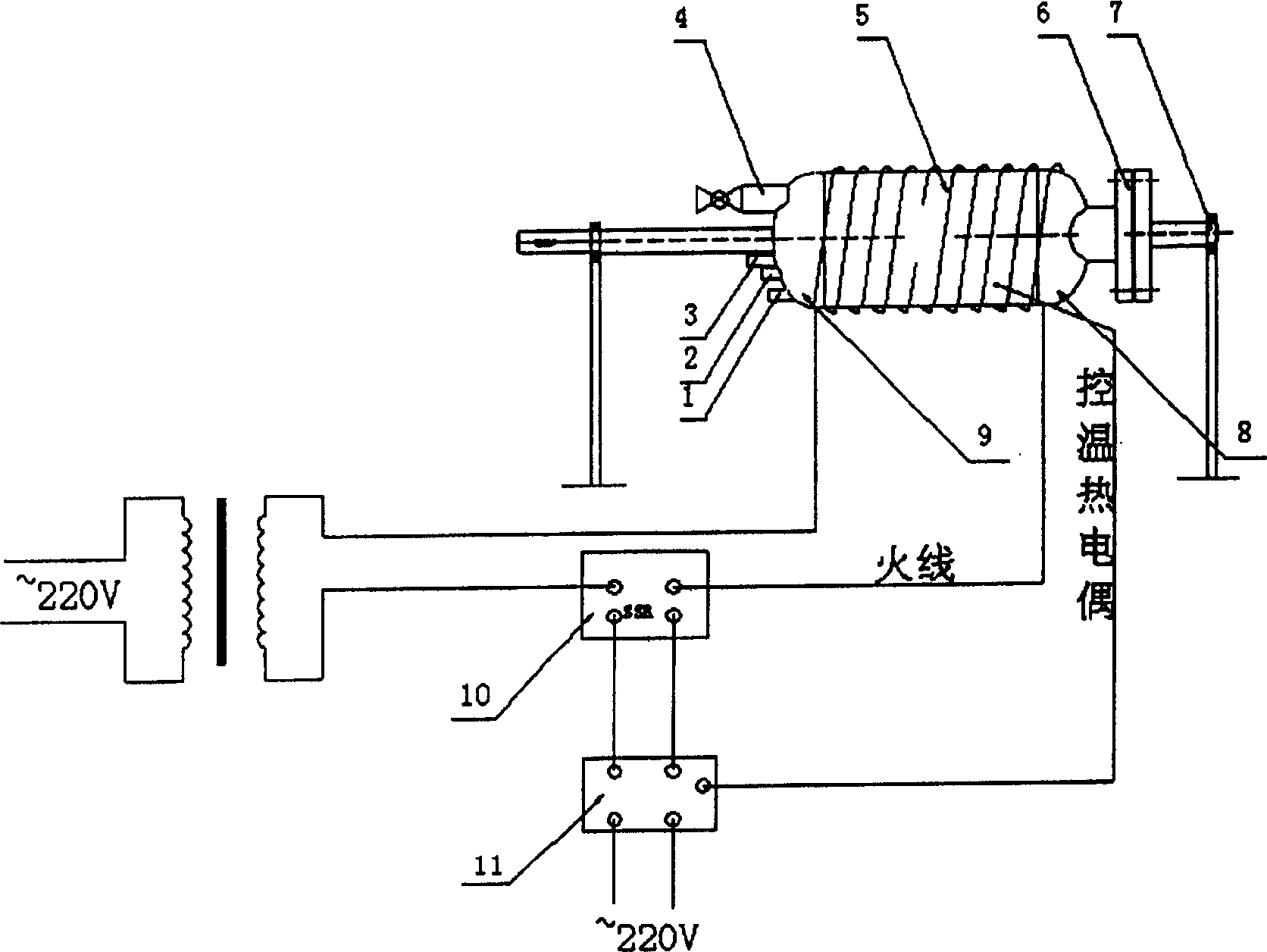

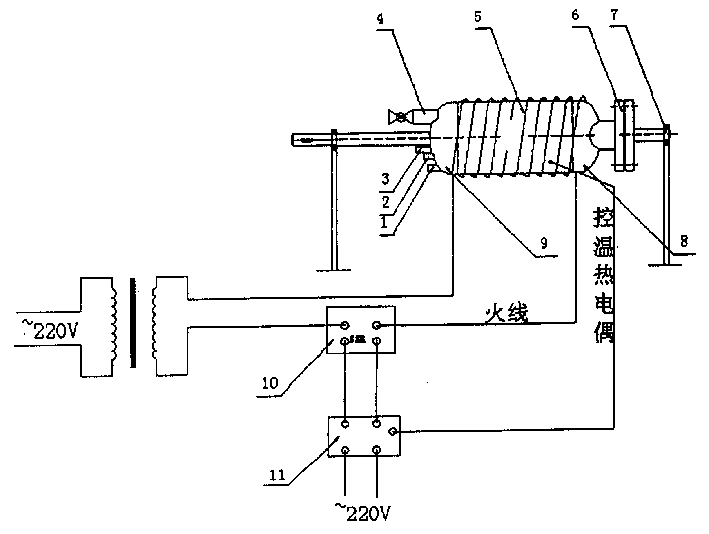

[0019] The object of the present invention is realized on the modifying device independently manufactured by oneself, and the device providing the flash heat source by electric heating is shown in the accompanying drawing. In addition to using electric heating, other high-temperature and high-pressure heat sources (such as boiler sewage) can also be used to achieve the purpose of flash evaporation. At this time, the structure of the flash evaporation device will be simplified; microwave heating methods can also be used. The device of the present invention is composed of a safety valve interface 1, a thermocouple interface 2, a pressure gauge interface 3, a discharge valve 4, a body 8, a heating device 5, and a flange 6. The body 8 is a cylindrical pressure vessel. One end of the body is provided with a flange 6, and the other end is provided with a safety valve interface 1, a thermocouple interface 2, a pressure gauge interface 3, and a discharge valve 4. The heating device 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com