A kind of electrolysis-broaching compound processing method

A technology of composite processing and electrolyte, which is applied in the field of special processing, can solve problems such as the inability to fundamentally improve the performance of broaching processing, achieve clear principles, solve serious tool wear, and improve process performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

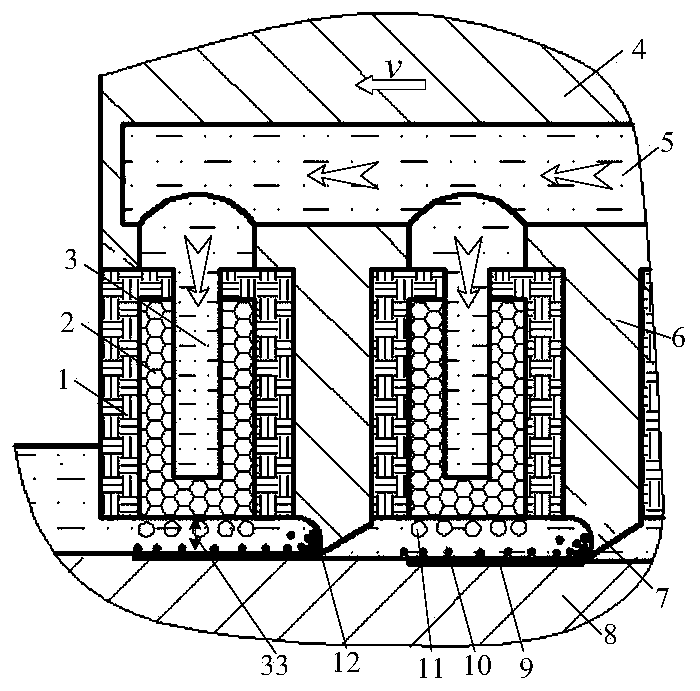

[0026] Such as figure 1 As shown, an electrolysis-broaching composite processing method includes an insulating separator 1, a porous metal plate electrode 2, a porous metal plate electrode inner flow channel 3, a cutter electrode matrix 4, a cutter body inner flow channel 5, and a broaching blade 6. Broaching edge 7, workpiece 8, electrochemical corrosion layer 9, electrochemical corrosion product 10, air bubbles 11, broaching chips 12; broaching blade 6 and porous metal plate electrode 2 are alternately separated by insulating separators 1, between the two No current loop can be formed between them; the distance between the tip of the broaching blade 7 and the electrode 2 of the porous metal plate should not be less than 0.5mm;

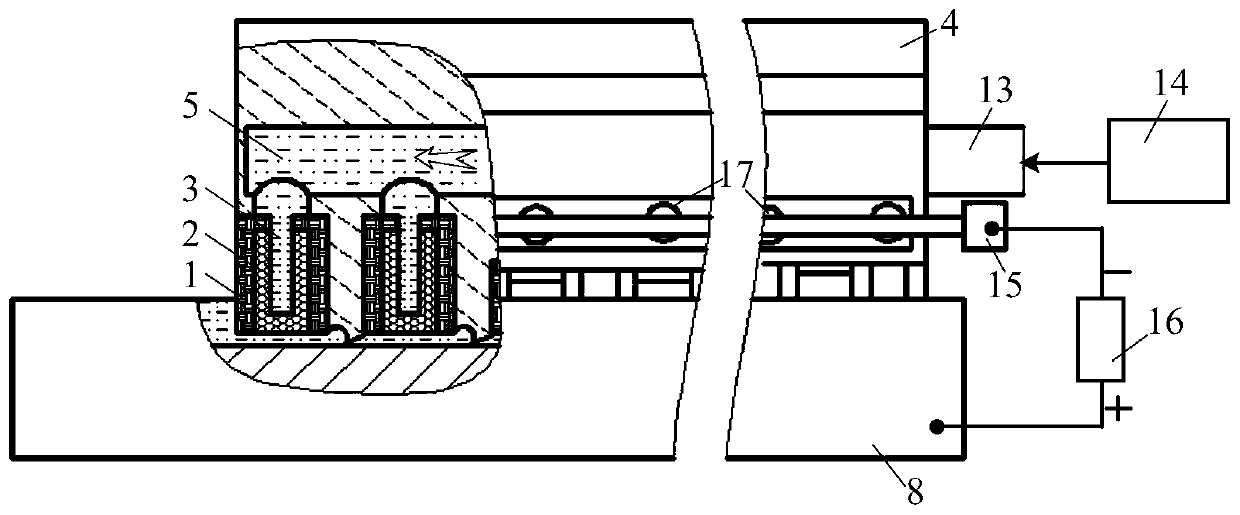

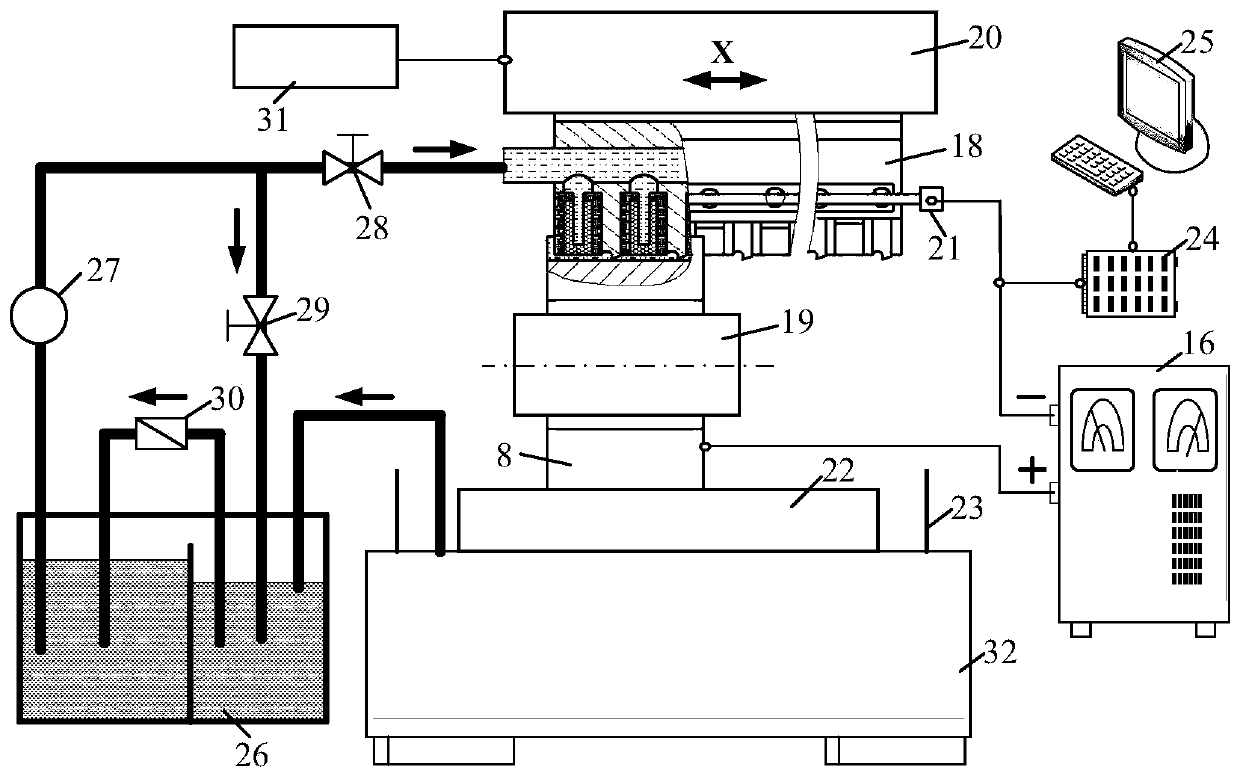

[0027] figure 2 As shown, an electrolysis-broaching composite processing method includes an electrolyte inlet 13, an electrolytic circulating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com