Aqueous composite drier and preparation method thereof

A composite drier, water-based technology, used in driers, chemical instruments and methods, coatings, etc., can solve the problems of impervious drying, great influence of paint, too fast surface drying, etc., to improve leveling, The effect of improving stability and improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

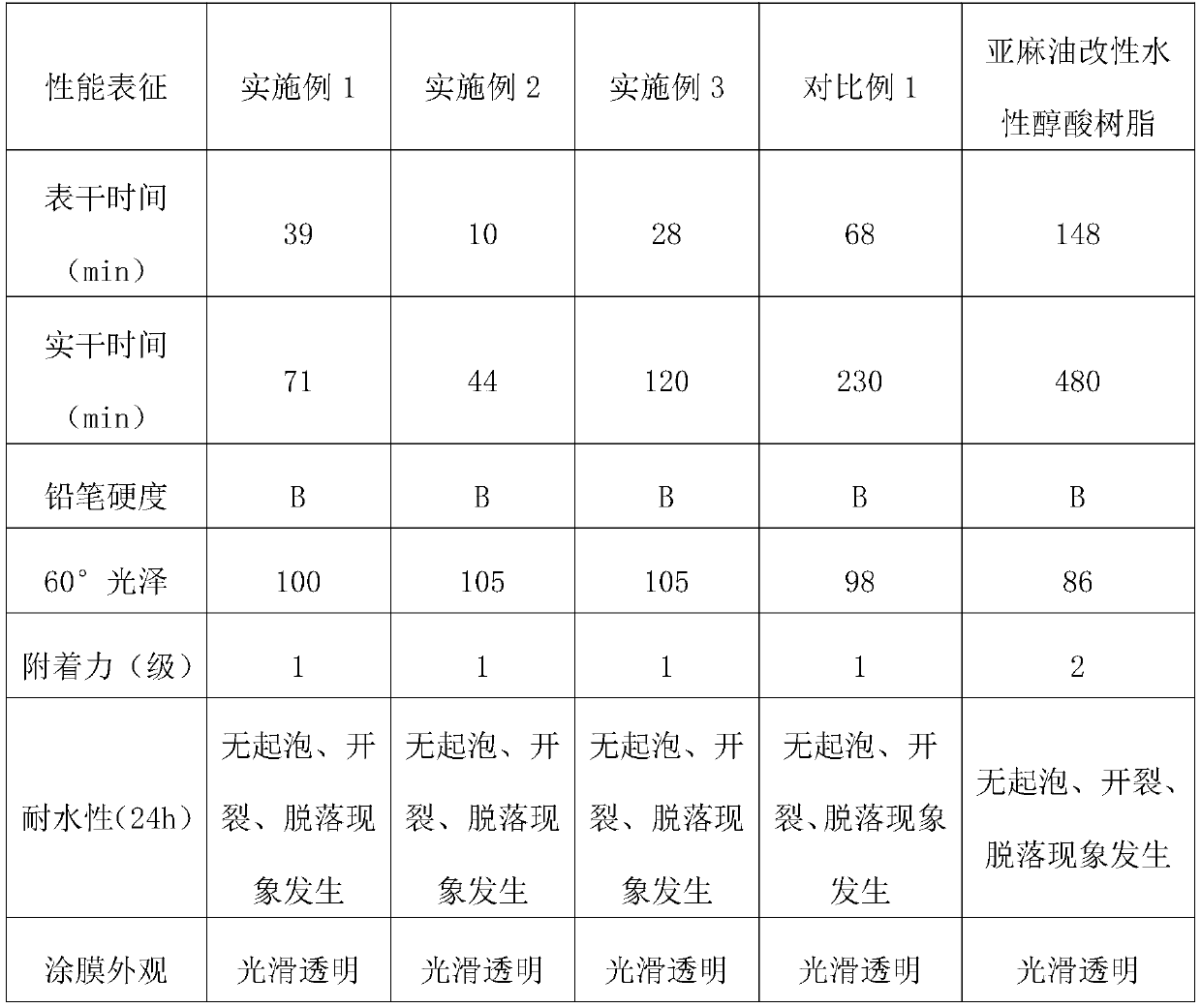

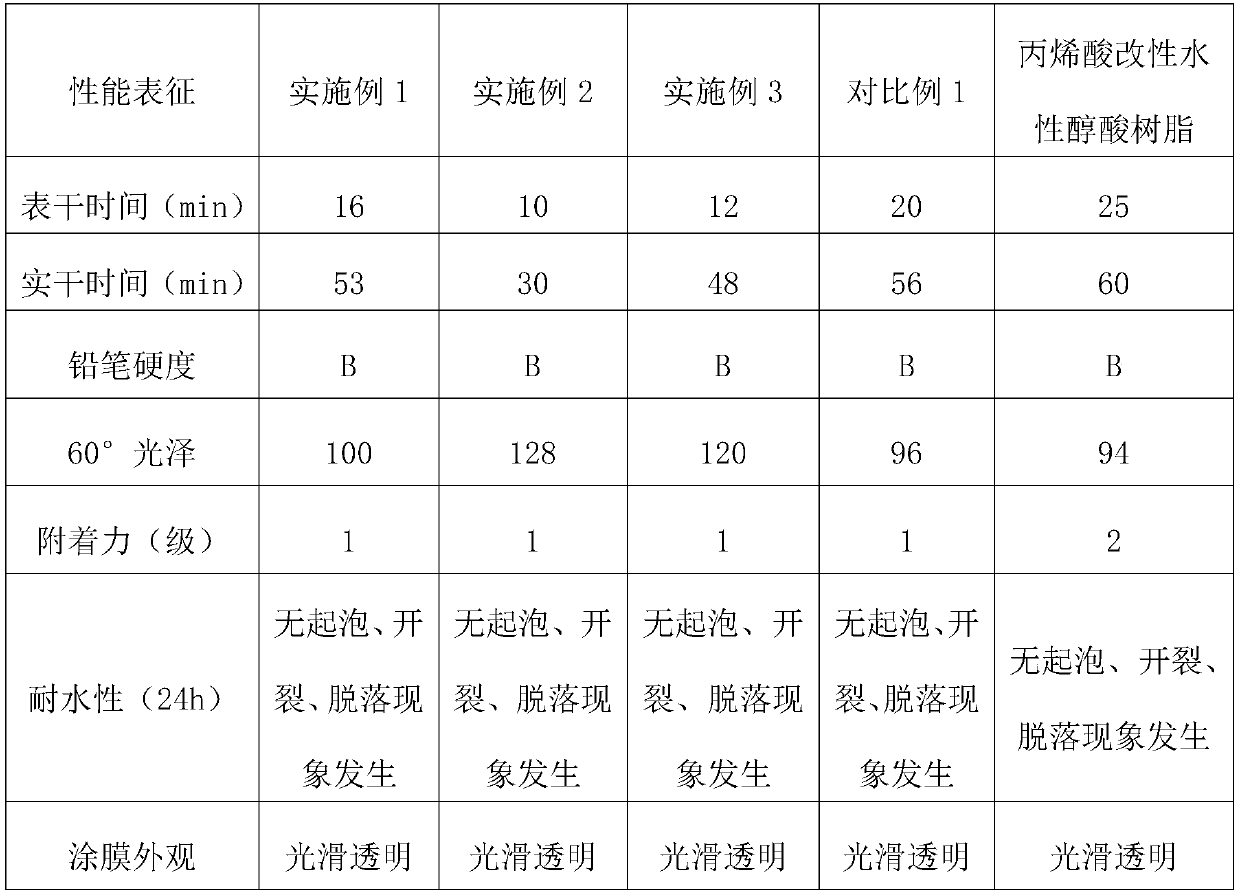

Examples

Embodiment 1

[0017] A water-based composite drier whose components include: 1030kg of zirconium isooctanoate, 1645kg of cobalt isooctanoate, 825kg of calcium isooctanoate, 185kg of 2,2'-bipyridine, 153kg of potassium acetate and 281kg of methanol.

[0018] The preparation method of the above water-based composite drier is to weigh according to the above weight, stir and mix cobalt isooctanoate, zirconium isooctanoate and calcium isooctanoate evenly, then add 2,2'-bipyridine, and stir and react at 80°C for 2 hours , to make it completely dissolved, then add potassium acetate and methanol, and mix thoroughly to obtain a water-based composite drier.

Embodiment 2

[0020] A water-based composite drier whose components include: 1235kg of zirconium isooctanoate, 1853kg of cobalt isooctanoate, 412kg of calcium isooctanoate, 185kg of 2,2'-bipyridine, 153kg of potassium acetate and 281kg of methanol.

[0021] The preparation method of the above water-based composite drier is to weigh according to the above weight, stir and mix cobalt isooctanoate, zirconium isooctanoate and calcium isooctanoate evenly, then add 2,2'-bipyridine, and stir and react at 80°C for 2 hours , to make it completely dissolved, then add potassium acetate and methanol, and mix thoroughly to obtain a water-based composite drier.

Embodiment 3

[0023] A water-based composite drier whose components include: 823kg of zirconium isooctanoate, 2060kg of cobalt isooctanoate, 617kg of calcium isooctanoate, 185kg of 4,4'-bipyridyl, 153kg of potassium acetate and 281kg of methanol.

[0024] The preparation method of the above water-based composite drier is to weigh according to the above weight, stir and mix cobalt isooctanoate, zirconium isooctanoate and calcium isooctanoate evenly, then add 4,4'-bipyridine, and stir and react at 80°C for 2 hours , to make it completely dissolved, then add potassium acetate and methanol, and mix thoroughly to obtain a water-based composite drier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com