Gallic acid chelates composition and uses thereof

A technology of gallic acid and chelate, which is applied in the direction of drug combination, medical preparations containing active ingredients, metabolic diseases, etc., can solve the problems of high toxicity, high price, unsatisfactory absorption rate, etc., and achieve the effect of high absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

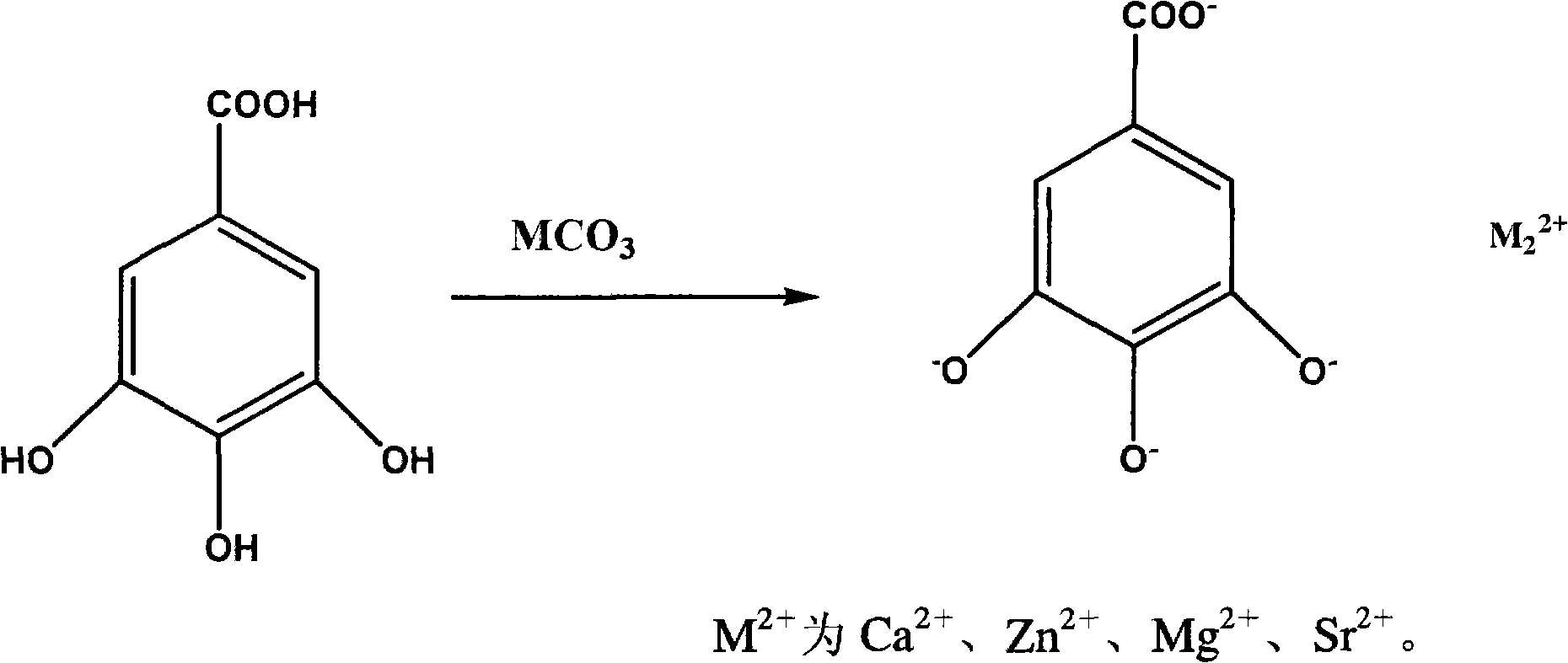

Method used

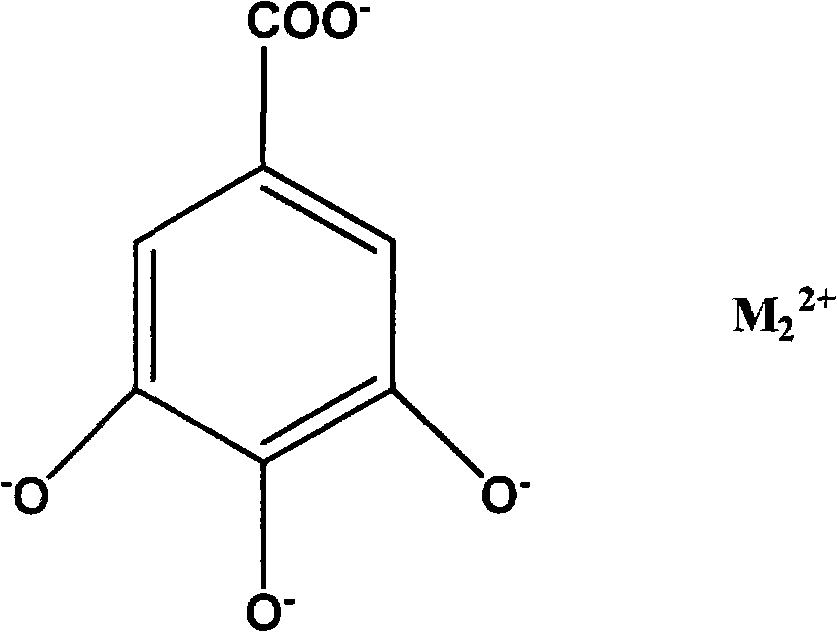

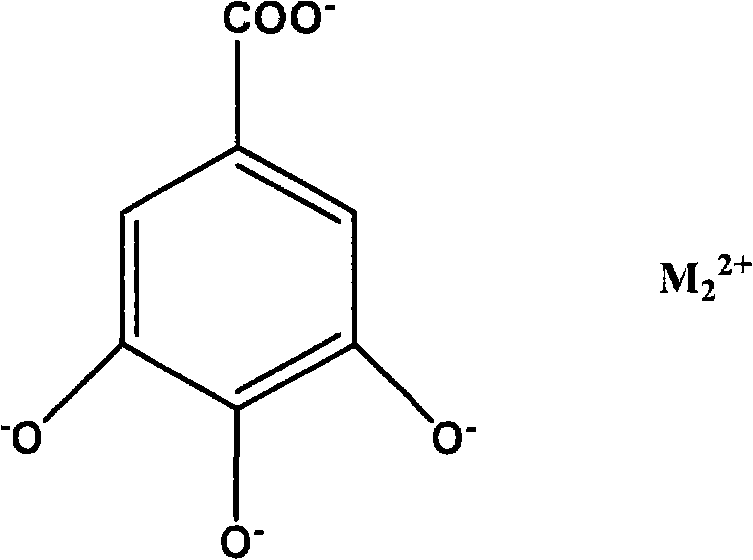

Image

Examples

Embodiment 1

[0016] The preparation of embodiment 1 gallic acid chelated calcium

[0017] Add 8.5 g of gallic acid to 50 ml of 65% aqueous ethanol solution, stir, and heat to 60°C to dissolve the sample completely. Add 10 g of calcium carbonate in batches without stopping the stirring, and continue stirring at a constant temperature until no bubbles are generated. After cooling to room temperature, cool in an ice bath until the calcium gallate chelate precipitates completely. The reactant was suction-filtered, the solid was washed with ethanol, and vacuum-dried at room temperature to obtain 12.3 g of gallic acid chelated calcium (97.5% yield).

Embodiment 2

[0018] The preparation of embodiment 2 gallic acid chelated magnesium

[0019] Add 6.8 g of gallic acid to 50 ml of 65% aqueous ethanol solution, stir, and heat to 50° C. to dissolve the sample completely. Add 6.8 g of magnesium carbonate in batches while stirring, and continue stirring at constant temperature until no bubbles are generated. The reactant was cooled to room temperature, cooled in an ice bath until the precipitation was complete, and filtered with suction. The obtained solid was washed with ethanol, and dried under vacuum at room temperature to obtain 8.0 g of magnesium gallic acid chelate (yield 92%).

Embodiment 3

[0020] The preparation of embodiment 3 gallic acid chelated zinc

[0021] Add 6.8g gallic acid to 50ml 75% ethanol aqueous solution, stir, and heat to 50°C to dissolve the sample completely. While stirring, add zinc carbonate 10g in batches, keep stirring at constant temperature until no bubbles are generated. The reactant was cooled to room temperature, cooled in an ice bath until the precipitation was complete, and filtered with suction. The obtained solid was washed with ethanol, and dried under vacuum at room temperature to obtain 10.2 g of gallic acid chelated zinc (91.2% yield).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com