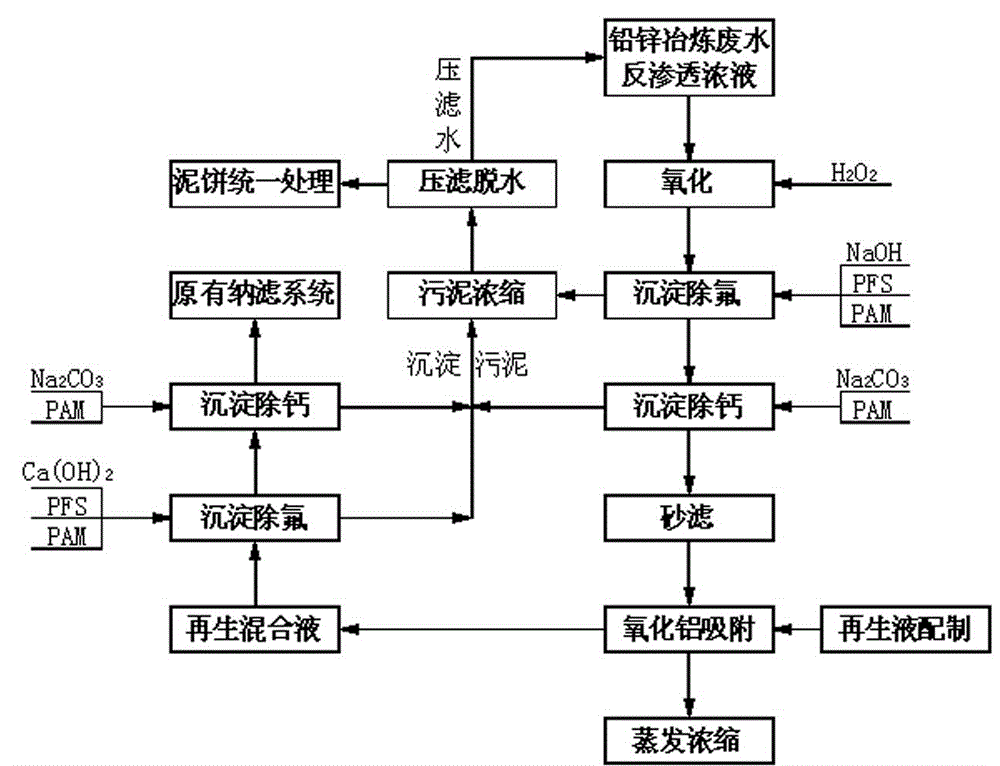

Synchronous fluorine-calcium removal treatment process for reverse osmosis concentrated liquor of waste water from lead-zinc smelting

A technology for reverse osmosis concentrate and calcium treatment, which can be used in metallurgical wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., and can solve problems such as scaling and clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

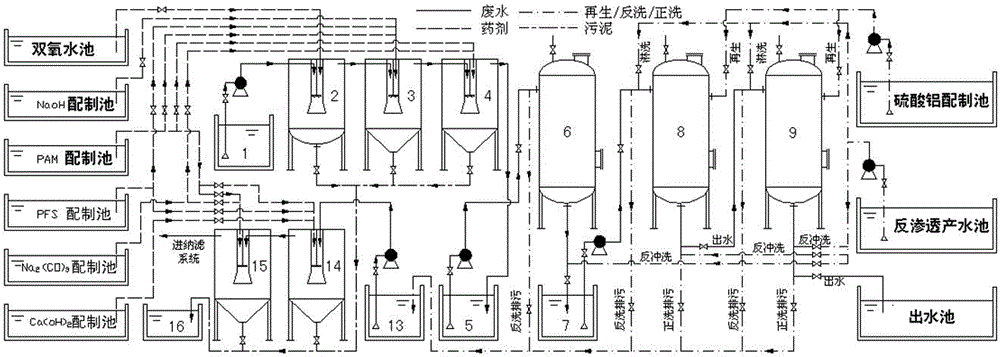

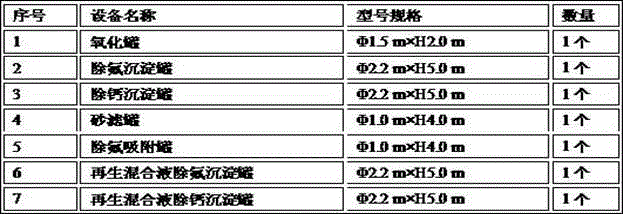

[0030] Embodiment: a smelter The reverse osmosis dope produced during the zero-discharge treatment process of lead-zinc smelting wastewater is the treatment object, which is continuously treated according to the process flow of the present invention, and the treatment scale is 5 m 3 / h, see figure 2 , its working steps are as follows:

[0031] Step 1: From the reverse osmosis concentrated liquid storage tank 1 to 5 m 3 The reverse osmosis concentrated liquid is continuously pumped into the oxidation tank 2 at a flow rate of 10 L / h, and 10% H is continuously added at a flow rate of 10 L / h 2 o 2 To the oxidation tank 2, the effluent of the oxidation tank 2 flows into the fluoride-removing precipitation tank 3 by gravity, and the fluoride-removing precipitation tank is a center tube vertical flow type precipitation tank, and the pH value is adjusted to 8.5-9.0 with a NaOH solution with a mass concentration of 10%, respectively according to Add PFS and PAM at concentrations ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com