Preparation method of roasted calcium-magnesium-aluminum-based LDHs and application of roasted calcium-magnesium-aluminum-based LDHs in phosphorus removal

A calcium-magnesium-aluminum-based, roasting technology, which is applied in chemical instruments and methods, aluminum compounds, and other chemical processes, can solve the problems of slow phosphorus removal process, high sludge treatment cost, and high moisture content, and achieve pollution problems, Significant social value and research value, good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

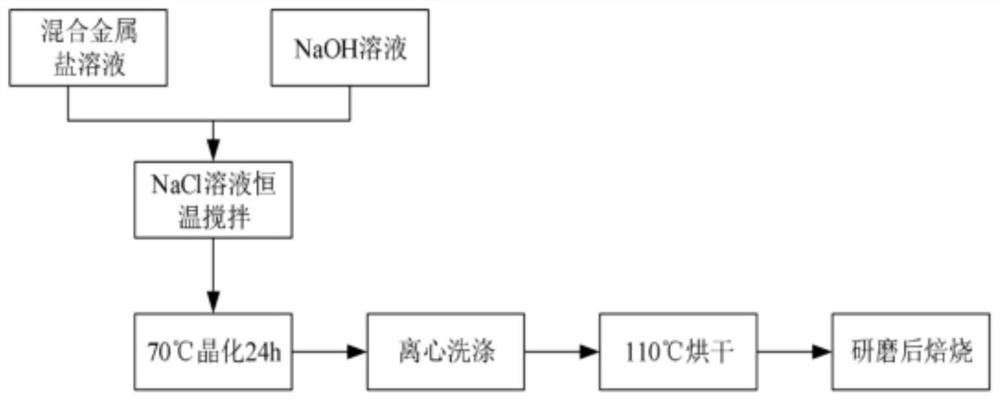

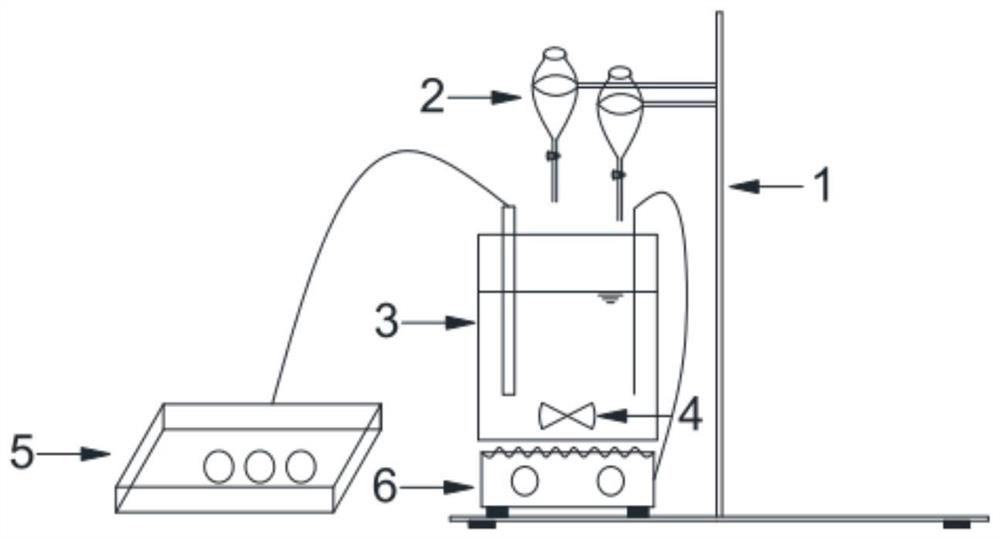

[0028] The method for preparing calcined calcium-magnesium-aluminum-based LDHs provided in the embodiments of the present invention adopts a constant pH double titration co-precipitation method to prepare calcium-magnesium-aluminum-based LDHs. Specific process such as figure 1 , figure 2 shown, including the following steps:

[0029] (a) According to the divalent metal cation (Ca 2+ and Mg 2+ ) and trivalent metal cations (Al 3+ ) Calcium-magnesium-aluminum molar ratio 5:1:2 configuration mixed metal salt solution, wherein the calcium-magnesium-aluminum metal cations are respectively anhydrous CaCl 2 , MgCl 2 ·6H 2 O, Al(NO) 3 9H 2 O configuration, the precipitant uses 1mol / L NaOH solution;

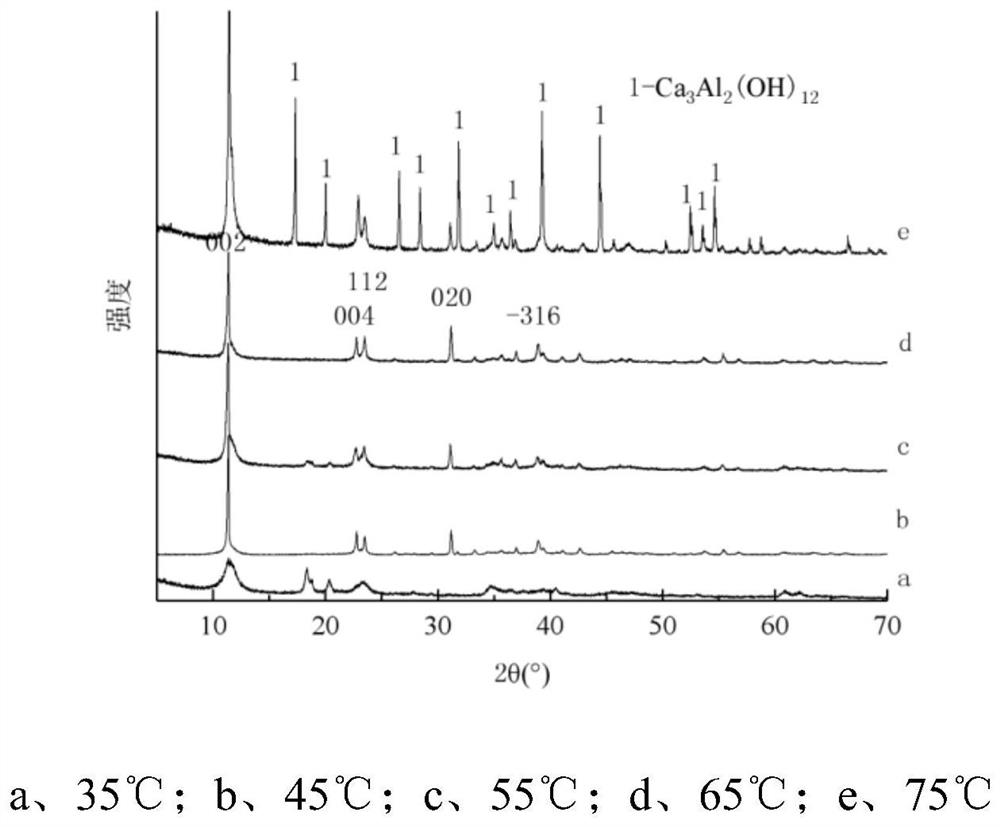

[0030] (b) Add 250mL mixed metal salt solution and NaOH solution dropwise into a beaker filled with 200mL, 0.5mol / L NaCl solution, stir at a constant temperature within the set temperature range of 35°C-75°C, and control the stirring rate (from The initial 700r / min rises to 100...

Embodiment 1

[0033] The calcined calcium-magnesium-aluminum-based LDHs adsorbent is prepared according to the following steps:

[0034] (a) According to the divalent metal cation (Ca 2+and Mg 2+ ) and trivalent metal cations (Al 3+ ) Calcium-magnesium-aluminum molar ratio 5:1:2 configuration mixed metal salt solution, wherein the calcium-magnesium-aluminum metal cations are respectively anhydrous CaCl 2 , MgCl 2 ·6H 2 O, Al(NO) 3 9H 2 O configuration, the precipitant uses 1mol / L NaOH solution;

[0035] (b) Add 250mL mixed metal salt solution and NaOH solution dropwise into a beaker containing 200mL, 0.5mol / L NaCl solution, stir at a constant temperature at a set temperature of 65°C, and control the stirring rate (from the initial 700r / min rises to 1000r / min) to fully mix the solution, the titration rate of the mixed metal salt solution is about 1 drop / second (about 4ml per minute), and the titration rate of the NaOH solution is controlled to maintain the pH of the coprecipitation r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com