Salt-resistant suspending agent as well as preparation method and application thereof

A suspending agent and solvent technology, applied in the field of salt-resistant suspending agent and its preparation, can solve the problems of limited suspension performance, achieve the best suspension effect, good salt resistance, and quick use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

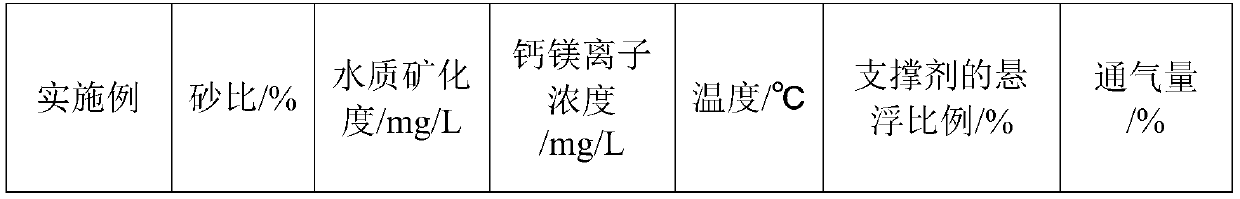

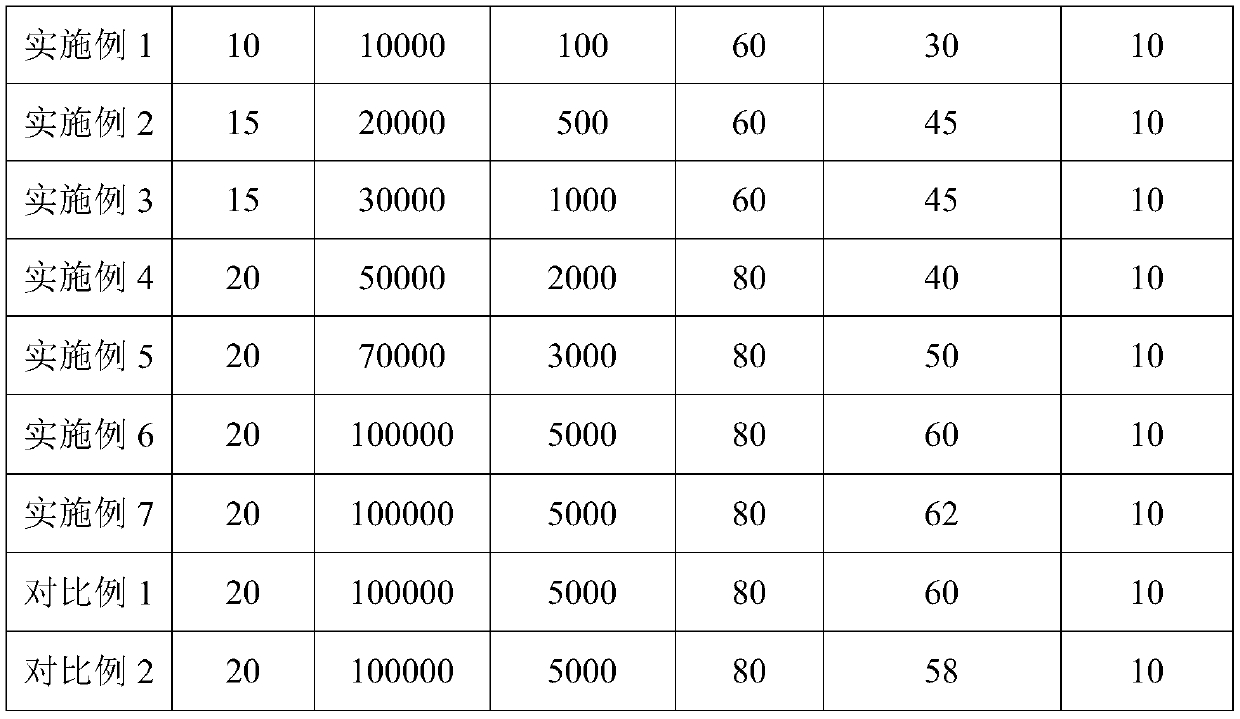

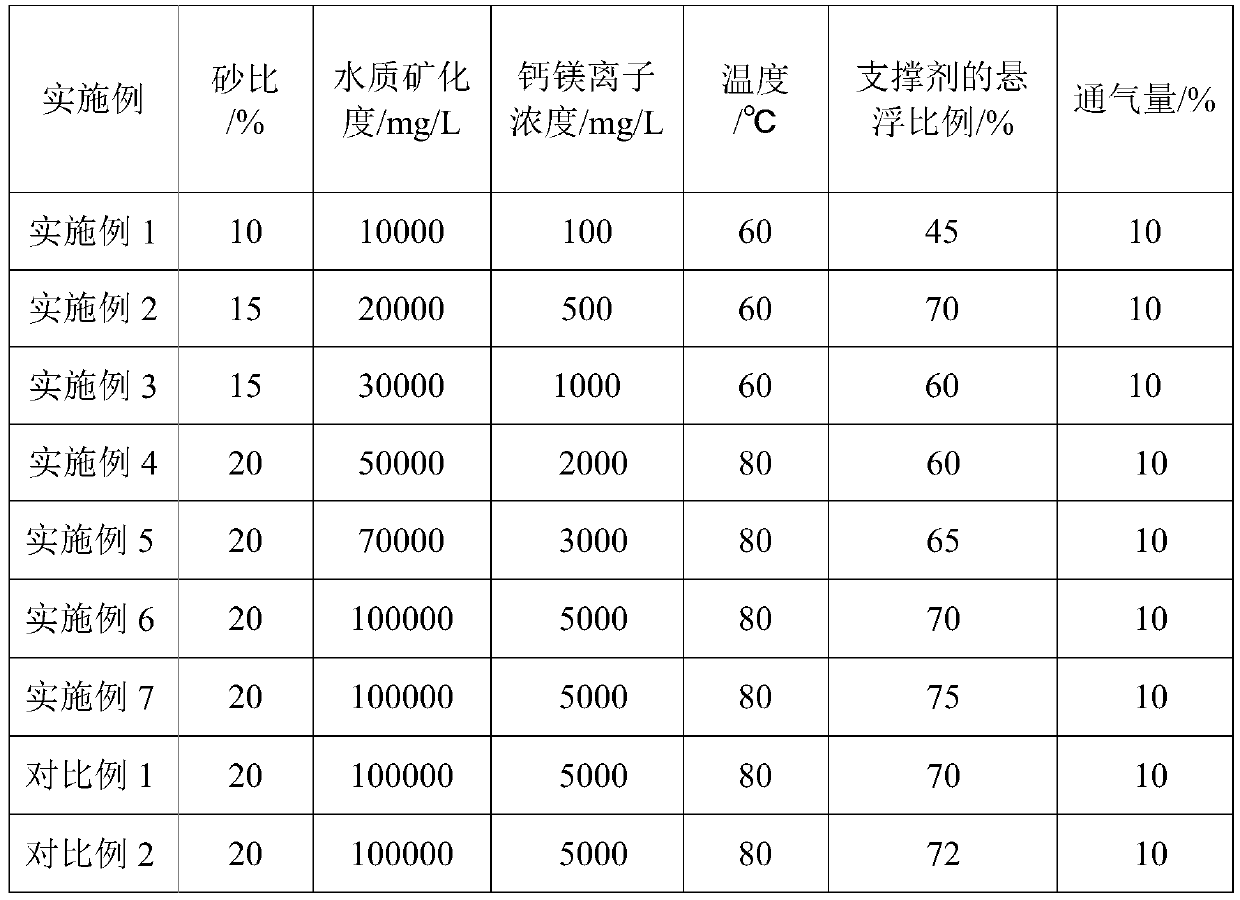

Examples

preparation example Construction

[0060] The preparation method of above-mentioned anti-salt suspending agent, comprises the following steps:

[0061] Weigh each component by weight and stir evenly to obtain the salt-resistant suspending agent; the stirring speed is 150-250rpm / min, and the stirring time is 25-35min; the stirring speed is preferably 200rpm / min, The stirring time is preferably 30 min.

[0062] The using method of above-mentioned anti-salt suspending agent, comprises the following steps:

[0063] The above-mentioned anti-salt suspending agent, solvent and proppant are mixed, stirred evenly, and nitrogen gas is passed; the volume ratio of the anti-salt suspending agent and solvent is 0.2%-0.4%.

[0064] During specific implementation, the using method of above-mentioned anti-salt suspending agent can specifically comprise the following steps:

[0065] Add the above-mentioned anti-salt suspending agent into the solvent, continue to add proppant, stir evenly, and pass nitrogen gas;

[0066] Or ad...

Embodiment 1

[0072] 1. Preparation of salt-resistant suspending agent

[0073] 0.057g surfactant (polyoxyethylene fatty alcohol ether), 0.1g silane coupling agent (0.03g perfluoroheptadecanetrimethyloxysilane, 0.03g N-(β-aminoethyl)-γ-ammonia Propyltrimethyl(ethyl)oxysilane, 0.03g γ-glycidyl etheroxypropyltrimethoxysilane, 0.01g methylphenyldimethoxysilane), 0.1g foaming agent (0.05g terpineol, 0.05g coconut oil fatty acid sodium alanine), 0.12g foam stabilizer (0.1g aminosilanol; 0.02g polyethyleneimine, molecular weight is 20,000), 0.4g dispersant (polyvinyl alcohol, molecular weight is 10-150,000 ), 2.75g hydrophobic agent (4-hydroxyl-7-(trifluoromethyl) quinoline-3-carboxylate ethyl ester), 0.04g pH adjuster (0.04g sodium carbonate) and 20g water mix, stir well, stir The rotation speed is 200rpm / min, and the stirring time is 30min to obtain the salt-resistant suspension concentrate.

[0074] 2. Use of anti-salt suspending agent

[0075] 1) First add to slippery water

[0076] Take ...

Embodiment 2

[0080] 1. Preparation of salt-resistant suspending agent

[0081] 0.605g surfactant (0.5g imidazoline, 0.005g octadecyltrimethylammonium bromide, 0.1g sodium dioctyl succinic acid sulfonate), 0.1g silane coupling agent (0.02g γ-mercaptopropyl Trimethoxysilane + 0.02g tridecafluorooctyltriethoxysilane + 0.06g dodecyltrimethoxysilane), 0.05g foaming agent (0.02g polyethoxy fatty alcohol, 0.02g linoleic acid, 0.01g lauroyl glutamic acid), 0.2g foam stabilizer (0.1g polymeric diamine, 0.1g dimethylformamide), 0.4g dispersant (0.2g polyvinylpyrrolidone, 0.2g polyethylene glycol, molecular weight is 4000), 2g hydrophobic agent (1g perfluorooctyl quaternary ammonium iodine, 1g dioctadecyl dimethyl hydroxypropyl polyammonium chloride), 0.01g pH regulator (0.01g sodium carbonate) and 20g water mixed, Stir evenly, the stirring speed is 200rpm / min, and the stirring time is 30min, and the salt-resistant suspending agent can be obtained.

[0082] 2. Use of anti-salt suspending agent

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com