Amphiphilic block T-shaped copolymer and preparation method thereof

An amphiphilic block and polymer technology, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as low salt resistance and poor oil displacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

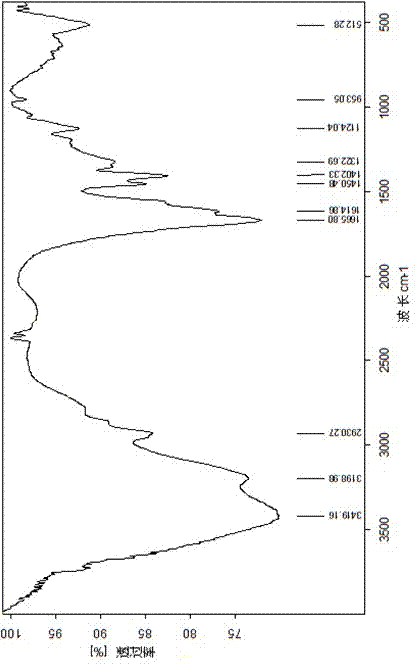

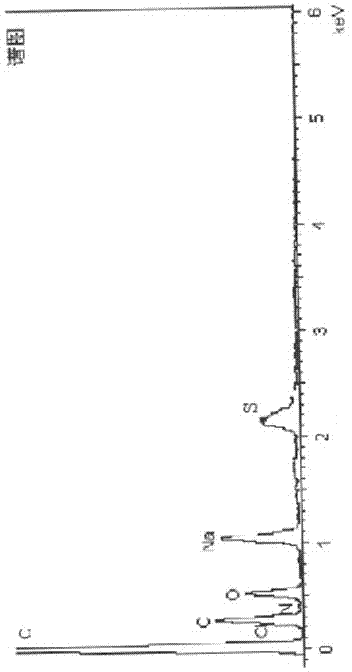

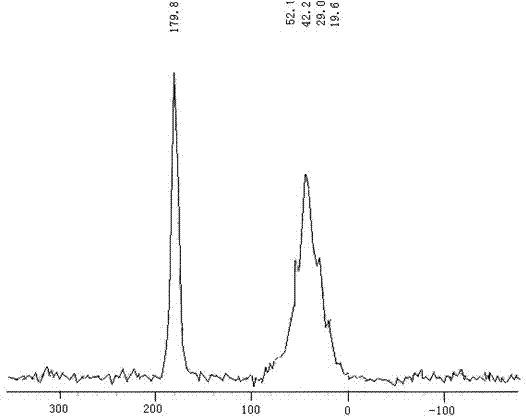

Image

Examples

Embodiment 1

[0038] (1) Dissolve 105.0g of acrylamide and 7.5g of 2-acrylamido-2-methylpropanesulfonic acid in 850g of water, and mix well to obtain a mixed solution;

[0039] (2) Adjust the pH value of the mixed solution in the step (1) to 7, and pass nitrogen protection into the mixed solution;

[0040] (3) Mix 0.2 g of sodium lauryl sulfate and 1.5 g of alkenylphenol polyoxyethylene ether to obtain a mixture solution, wherein m in the alkenylphenol polyoxyethylene ether 2 is 6, n 2 is 14;

[0041] (4) Add 0.08g of K 2 S 2 o 8 -NaHSO 3 The initiator is fully dissolved in water to obtain an aqueous solution of the initiator, wherein the K 2 S 2 o 8 with NaHSO 3 The mass ratio is 3:1;

[0042] (5) At 45°C, slowly add the mixture solution in step (3) and the aqueous initiator solution in step (4) dropwise to the mixed solution treated in step (2), and stir Evenly, continue to pass inert gas until the mixed solution does not contain oxygen;

[0043] (6) React the mixed solution t...

Embodiment 2

[0046] (1) Dissolve 97.8g of acrylamide and 10.0g of 2-acrylamido-2-methylpropanesulfonic acid in 950.0g of water, and mix well to obtain a mixed solution;

[0047] (2) Adjust the pH value of the mixed solution in the step (1) to 8, and pass nitrogen protection into the mixed solution;

[0048] (3) Mix 0.45g of sodium dodecylbenzenesulfonate and 0.5g of alkenylphenol polyoxyethylene ether to obtain a mixture solution, wherein m in the alkenylphenol polyoxyethylene ether 2 is 7, n 2 is 12;

[0049] (4) Add 0.1g of K 2 S 2 o 8 -NaHSO 3 The initiator is fully dissolved in water to obtain an aqueous solution of the initiator, wherein the K 2 S 2 o 8 with NaHSO 3 The mass ratio is 3:1;

[0050] (5) At 45°C, slowly add the mixture solution in step (3) and the aqueous initiator solution in step (4) dropwise to the mixed solution treated in step (2), and stir Evenly, continue to feed nitrogen until the mixed solution does not contain oxygen;

[0051] (6) React the mixed so...

Embodiment 3

[0054] (1) Dissolve 105.0g of acrylamide and 7.5g of 2-acrylamido-2-methylpropanesulfonic acid in 850.0g of water, and mix well to obtain a mixed solution;

[0055] (2) Adjust the pH value of the mixed solution in the step (1) to 7, and pass nitrogen protection into the mixed solution;

[0056] (3) Mix 0.2 g of sodium lauryl sulfate and 1.5 g of alkenylphenol polyoxyethylene ether to obtain a mixture solution, wherein m in the alkenylphenol polyoxyethylene ether 2 is 8, n 2 is 14;

[0057] (4) Add 0.08g of K 2 S 2 o 8 -NaHSO 3 The initiator is fully dissolved in water to obtain an aqueous solution of the initiator, wherein the K 2 S 2 o 8 with NaHSO 3 The mass ratio is 3:1;

[0058] (5) At 45°C, slowly add the mixture solution in step (3) and the aqueous initiator solution in step (4) dropwise to the mixed solution treated in step (2), and stir Evenly, continue to feed nitrogen until the mixed solution does not contain oxygen;

[0059] (6) React the mixed solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com