Hypersalinity solid-free micro-foam drilling fluid or completion fluid

A high-salinity, solid-free technology, applied in the direction of drilling compositions, chemical instruments and methods, can solve the problems of unintroduced drilling fluid system salt resistance, difficult protection and discovery of oil and gas layers, and plugging of gas and gas layers problems such as tunnels, to achieve the effect of simplifying on-site construction technology, convenient and quick preparation, and strong rock-carrying ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

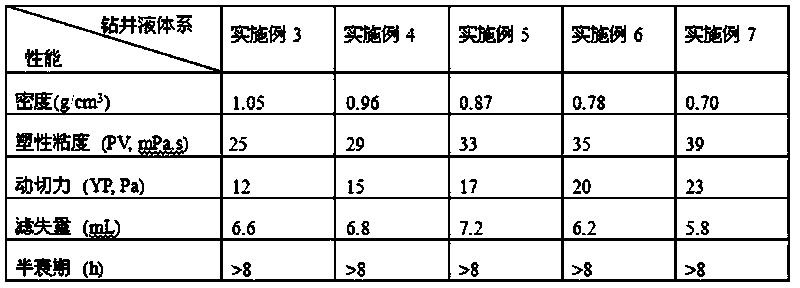

Examples

Embodiment 1

[0057] ⑴ Viscosifier SL-KDT, 0.4 parts, composed of xanthan gum (XC): high viscosity sodium carboxymethylcellulose (HV-CMC) = 1:1 ratio; ⑵ Foam stabilizer SL-KWJ, 0.4 parts , composed of polyanionic cellulose (PAC): polyacrylamide (PAM) = 4: 1.5 ratio combination; (3) Foaming agent SL-KDF, 0.7 parts, composed of salt-resistant modified tea saponin (ZY-WP): α - Sodium alkenyl sulfonate (AOS): dodecyl dimethyl amine oxide (OB-2) = 6:2:1 ratio combination; (4) Fluid loss control agent SL-KJL, 2.5 parts, made of modified starch (DFD-140): lignite resin (SPNH): sulfomethyl phenolic resin (SMP-II) = 4:4:1 ratio combination; (5) flow regulator SL-KDPR, 0.3 parts, organic silicon humic acid Potassium; (6) Soda ash, 0.2 parts, is sodium carbonate; (7) Base liquid, 100 parts, is a saturated solution of sodium chloride.

[0058] Preparation method: the above-mentioned components ⑴-⑹ according to their content, under normal temperature and pressure, under the condition of mechanical stir...

Embodiment 2

[0061] ⑴ Viscosifier SL-KDT, 0.5 parts, composed of xanthan gum (XC): high viscosity sodium carboxymethylcellulose (HV-CMC) = 4:1 ratio; ⑵ Foam stabilizer SL-KWJ, 0.3 parts , composed of polyanionic cellulose (PAC): polyacrylamide (PAM) = 6:1 ratio combination; (3) Foaming agent SL-KDF, 0.8 parts, composed of salt-resistant modified tea saponin (ZY-WP): α - Sodium alkenyl sulfonate (AOS): dodecyl dimethyl amine oxide (OB-2) = 7:3:2 ratio combination; (4) Fluid loss control agent SL-KJL, 2 parts, made of modified starch (DFD-140): lignite resin (SPNH): sulfomethyl phenolic resin (SMP-II) = 5:6:1 ratio combination; (5) Flow pattern regulator SL-KDPR, 0.4 parts, is organosilicon humic acid Potassium; (6) Soda ash, 0.3 parts, is sodium carbonate; (7) Base liquid, 100 parts, is a saturated solution of sodium chloride.

[0062] Preparation method: the above-mentioned components ⑴-⑹ according to their content, under normal temperature and pressure, under the condition of mechanical ...

Embodiment 3

[0065] ⑴ Viscosifier SL-KDT, 0.6 parts, composed of xanthan gum (XC): high viscosity sodium carboxymethyl cellulose (HV-CMC) = 2:3; ⑵ Foam stabilizer SL-KWJ, 0.5 parts , composed of polyanionic cellulose (PAC): polyacrylamide (PAM) = 3:2 ratio combination; (3) Foaming agent SL-KDF, 0.9 parts, composed of salt-resistant modified tea saponin (ZY-WP): α - Sodium alkenyl sulfonate (AOS): dodecyl dimethyl amine oxide (OB-2) = 9:2:2 ratio combination; (4) Fluid loss control agent SL-KJL, 3 parts, made of modified starch (DFD-140): lignite resin (SPNH): sulfomethyl phenolic resin (SMP-II) = 3:5:3 ratio combination; ⑸ flow regulator SL-KDPR, 0.5 parts, organic silicon humic acid Potassium; (6) Soda ash, 0.2 parts, is sodium carbonate; (7) Base liquid, 100 parts, is a saturated solution of sodium chloride.

[0066] Preparation method: the above-mentioned components ⑴-⑹ according to their content, under normal temperature and pressure, under the condition of mechanical stirring (600~10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com