Chemical industry wastewater comprehensive treatment method

A technology for comprehensive treatment of chemical wastewater, applied in the field of wastewater treatment and comprehensive treatment of chemical wastewater, can solve the problems of low efficiency of physical treatment, high biological toxicity, high operating costs, etc., achieve good treatment and purification effect, improve biodegradability, and degrade Effects of Wastewater Toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

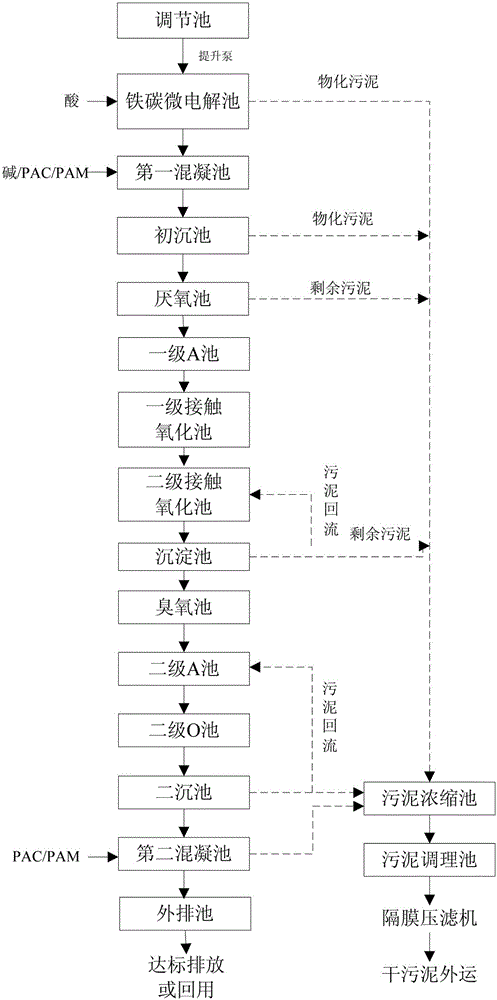

[0049] refer to figure 1 , a method for comprehensive treatment of chemical wastewater, comprising the steps of:

[0050] (1) Pre-treatment system: Wastewater enters the regulating tank, is pumped into the iron-carbon reaction tank by the lift pump, and the pH is controlled to be 3 to 4, and the iron-carbon micro-electrolysis reaction is carried out, and the iron-carbon reaction tank is stirred with compressed air; the reaction takes 2.5 hours Finally, the wastewater flows to the first coagulation tank by itself, and the pH is adjusted to 8-9 by liquid alkali with a mass concentration of 25%, and polyaluminum coagulant (PAC) and polyacrylamide (PAM) precipitant are added, and the precipitated sludge enters The sludge concentration tank is concentrated and then filtered to remove water; among them, the dosage of polyaluminum coagulant is 3‰ of the wastewater volume, the concentration of polyacrylamide is 3.5g / L, and the dosage is 1.5% of the wastewater volume ‰;

[0051] (2) ...

Embodiment 2

[0057] A method for comprehensive treatment of chemical wastewater, comprising the steps of:

[0058] (1) Pre-treatment system: Waste water enters the regulating tank, and is pumped into the iron-carbon reaction tank by the lift pump, and the pH is controlled to be 2 to 3, and the iron-carbon micro-electrolysis reaction is carried out, and the iron-carbon reaction tank is stirred with compressed air; after 1 hour of reaction , the wastewater flows to the first coagulation tank by itself, and the pH is adjusted to 7-8 by the liquid alkali with a mass concentration of 10%, and polyiron coagulant and polyacrylamide precipitant are added, and the precipitated sludge enters the sludge thickening tank to concentrate and then Perform pressure filtration to remove water; wherein, the dosage of polyferric coagulant is 1.5‰ of the wastewater volume, the concentration of polyacrylamide is 1.5g / L, and the dosage is 1.5‰ of the wastewater volume;

[0059] (2) First-level biochemical system...

Embodiment 3

[0065] A method for comprehensive treatment of chemical wastewater, comprising the steps of:

[0066] (1) Pre-treatment system: Wastewater enters the regulating tank, and is pumped into the iron-carbon reaction tank through the lifting pump, and the pH is controlled to be 4-5, and the iron-carbon micro-electrolysis reaction is carried out, and the iron-carbon reaction tank is stirred with compressed air; after 3 hours of reaction , the wastewater flows to the first coagulation tank by itself, the pH is adjusted to 8-9 by the liquid alkali with a mass concentration of 30%, and polyferric coagulant and polyacrylamide precipitant are added, and the precipitated sludge enters the sludge thickening tank to concentrate and then Press filtration to remove water; wherein, the dosage of polyferric coagulant is 5‰ of the wastewater volume, the concentration of polyacrylamide is 5g / L, and the dosage is 2‰ of the wastewater volume;

[0067] (2) First-level biochemical system: after the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com