Unfreezing method of frozen meat

A frozen meat and standing technology, applied in the direction of preservation of meat/fish by freezing/cooling, etc., can solve the problems of loss of protein nutrients in frozen meat, easy biological contamination of meat surface, long thawing time of frozen meat, etc. Fat activity, increase electrolysis efficiency, prevent loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

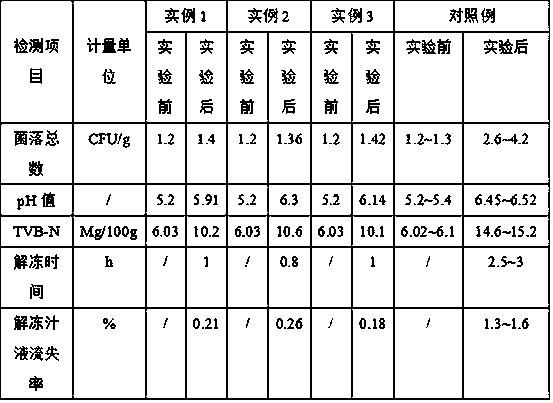

Examples

preparation example Construction

[0019] The preparation method of soaking liquid is:

[0020] A. Put the cactus and ethanol solution into the mill at a mass ratio of 1:3, mill at 800r / min for 30-40min, and collect the milled material;

[0021] B. Put the ground material into a supercritical carbon dioxide extraction device for extraction, collect the extract, filter it, collect the filtrate, distill the filtrate to recover ethanol, and collect the distillation residue to obtain the soaking solution.

[0022] The mass ratio of pre-thawed frozen meat to ammonium nitrate solution is 1:2-4. The thawing method of frozen meat includes the following steps:

[0023] (1) Put the frozen meat in an environment of 0-2°C for 1-2 hours, and use a spray gun to evenly spray calcium oxide on the surface of the frozen meat after standing. 80g, continue to stand still for 30-40min;

[0024] (2) After the above-mentioned standing is over, put the frozen meat after standing in the soaking liquid, make the soaking liquid submerg...

example 1

[0028] The preparation method of soaking liquid is:

[0029] A. Put the cactus and ethanol solution into the mill at a mass ratio of 1:3, mill at 800r / min for 35min, and collect the milled material;

[0030] B. Put the ground material into a supercritical carbon dioxide extraction device for extraction, collect the extract, filter it, collect the filtrate, distill the filtrate to recover ethanol, and collect the distillation residue to obtain the soaking solution.

[0031] The mass ratio of the pre-thawed frozen meat to the ammonium nitrate solution is 1:3. The thawing method of the frozen meat comprises the following steps:

[0032] (1) Put the frozen meat at 1°C for 1.5 hours, use a spray gun to evenly spray calcium oxide on the surface of the frozen meat after standing, the amount of calcium oxide sprayed is 70g per kilogram of frozen meat, and continue to stand 35min;

[0033] (2) After the above-mentioned standing is over, put the frozen meat after standing in the soaki...

example 2

[0037] The preparation method of soaking liquid is:

[0038] A. Put the cactus and ethanol solution into the mill at a mass ratio of 1:3, mill at 800r / min for 40min, and collect the milled material;

[0039] B. Put the ground material into a supercritical carbon dioxide extraction device for extraction, collect the extract, filter it, collect the filtrate, distill the filtrate to recover ethanol, and collect the distillation residue to obtain the soaking solution.

[0040] The mass ratio of the pre-thawed frozen meat to the ammonium nitrate solution is 1:4. The thawing method of the frozen meat comprises the following steps:

[0041] (1) Put the frozen meat at 2°C for 2 hours, use a spray gun to evenly spray calcium oxide on the surface of the frozen meat after standing, the amount of calcium oxide sprayed is 80g per kilogram of frozen meat, and continue to stand for 40 minutes ;

[0042] (2) After the above-mentioned standing is over, put the frozen meat after standing in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com